For the most recent changes, visits the Change Log first page.

12/20/18: Release 4.55 (PC Only Optional Release)

- GWLite now has a minimum of 2 HP instead of 1.

12/13/18: Release 4.54 (PC Only Optional Release)

- Added Stellite 6 and Stellite 25 to Material DB.

- Add CADCAM Wizard Setup options for power users: Use Premium Coolant Options and Default Roughing Strategy. These will allow higher MRR's.

12/7/18: Release 4.53 (PC Only Optional Release)

- Created new video walkthrough of First Time Setup: /g-wizard-calculator-video-university/

- Give better feedback on why logins fail-ID not recognized, trial expired, etc..

12/6/18: Release 4.52 (PC Only Optional Release)

- Simplified UI for CADCAM Wizards. Removed all the time-related features-they're for GW Estimator anyway. Options are hidden until you press the new "Options" button.

- Added new machine profiles for Tormach 1100M and 770M.

- Added some additional usability logging to help improve onboarding.

12/4/18: Release 4.51 (PC Only Optional Release)

- New Gage Block & Sine Bar Calculator under Geometry tab.

11/30/18: Release 4.50 (PC Only Silent Release)

- New Setup Wizard at startup for new users.

11/28/18: Release 4.49 (PC Only Silent Release)

- Improve on-boarding for new trials. When they logout they're taken to the upgrade page.

10/30/18: Release 4.47 (PC & Mac Feathered Release.)

- No new functionality. Signed with latest digital certificates that won't expire until 2021.

9/13/18: Release 4.45 (PC & MacFeathered Release.)

- Add a Chamfer option to Pocket and 2D Profile CADCAM Wizards.

- Improved Tool Crib Wizard with more Twist Drill options. You can now select Imperial, Metric, Wire Gage, and Letter Sizes.

- Improved Login Wizard to try to make it more clear why a Login isn't being accepted, and to reduce the number of EULA popups.

- Added new materials: Dibond ACM and Sintra PVC Foam Board.

- Added an option on Setup Basics to keep the GW Calculator window on top.

- Added a "To Crib" button to make it easy to add a tool setup in Feeds/Speeds to the Crib.

- Added a Getting Started Tour for Tool Cribs.

- Fixed a bug on GD&T Quick Ref-clickthroughs to web site weren't going to correct page.

- Fixed a couple areas that would only show Imperial units so they now can show Metric as well.

7/26/18: Release 4.44 (PC and Mac Feathered Release. Mandatory update.)

- Add the Interpolation "Helix" Mini-Calc to Thread Mill Feeds/Speeds page.

- Got rid of the 4 flutes in aluminum warning for Thread Mills.

- Made EULA acceptance more forgiving. It would fail to login if the user accepted before the message was fully loaded.

7/16/18: Release 4.43 (Feathered PC Only)

- Improved the CADCAM Wizards for Lathes so they can get around machine horsepower limitations by reducing depth of cut.

- Fixed a bug where the percentage dial gauge for deflection was being erroneously shown without the rest of the deflection information.

- Fixed a bug in the Thread Calculator that caused the Manual Lathe threading passes to show to large an infeed.

7/13/18: Release 4.42 (Silent PC Only)

- Fixed some bugs when certain tool types were set as being "Cobalt" material (e.g. Reamers).

- Fixed a bug where Cut Width label remained visible when the Cut Width field was not.

7/11/18: Release 4.41 (Feathered PC & Mac)

- De-dupes machines list.

- Fixed a couple bugs in the new deflection calculations.

7/2/18: Release 4.39 (Silent PC only)

- Made a number of improvements to streamline onboarding and setup for new users.

- Fixed a deflection bug where a weird combinations of flute length, stickout, and cut depth could led to excessive calculated deflection.

- Redoing Examples to use latest screen shots.

6/27/18: Release 4.37 (Feathered PC+Mac)

Made a number of improvements to Tool Deflection & Cut Optimization calculations:

- Works much better close to spindle power limits.

- Deflection now takes flute length vs overall tool length into account. Shorter flute length = less deflection.

- Deflection now has a more sophisticated model of Shank Diameter vs Tool Diameter. This gives a better result for small endmills, which frequently use a tapered shank.

Taken together, these changes all allow a little more breathing room before encountering deflection limits.

6/24/18: Release 4.36 (Silent PC Only)

- Testing in-app registration improvements.

6/18/18: Release 4.34 (Feathered, PC & Mac)

- Fixed a bug that prevented the deflection warning from being triggered properly.

6/18/18: Release 4.33 (Feathered, PC & Mac)

- Moved deflection to top of its column and added a color changing percentage indicator to it.

- Fixed problem where text inside the Tortoise Hare slider was invisible in some themes.

6/17/18: Release 4.31 (Silent, PC Only)

- Added more entries to hardness conversion database so it can convert a wider range of hardnesses.

- Fixed a bug where choosing soft alloys didn't show the hardness in the "More" button of Feeds/Speeds

- Fixed a bug that could hang at startup sometimes if the last tool used was deleted from the Tool Crib in the prior session.

- Added Stepcraft to machine profile database

- Machine profiles are now downloaded from the web so they can be updated without installing a new version of G-Wizard.

- Improved screen real estate before for screens with less than 768 pixels height.

- "Original Flava" theme now does a much better job restoring itself if you switch to it at run time.

- Eliminated the simple tool menu on Feeds/Speeds. There's now just the one popup.

- Fixed a problem with the Tap Drill table and metric use on the Threads applet.

6/14/18: Release 4.30 (Silent, PC Only)

5/29/18: Release 4.20 (Feathered, PC & Mac)

- Fixed a bug in which options showed with interpolated holes in the CADCAM Wizard.

- CADCAM Wizard now adds tool change times to time estimates.

- Fixed a bug on More Material selector where it wasn't showing the wood species after selection.

- Fixed a bug with Tool Crib Tools. After selecting one in Feeds/Speeds that had Mfg info, there was no way to get rid of the Mfg info when a Tool without Mfg info was selected.

5/29/18: Release 4.20 (Feathered, PC & Mac)

- Fixed a bug in the new "More" button Material Selector.

5/28/18: Release 4.19 (Optional, PC & Mac)

- G-Wizard will now remember your last tool and crib chosen across sessions.

- Fixed a bug in the new "More" button Material Selector

5/25/18: Release 4.18 (Optional, PC only)

- Updated the UI of the "More" button Material Selector to be more friendly.

- Fixed a bug that could delete Tool Crib entries if you cancel out of creating a new tool.

5/24/18: Release 4.17 (Optional, PC only)

- Added Hardness Conversion Calculator and unit-independent Hardness widget to Material browser (More button) in GW Calculator.

4/23/18: Release 4.16 (Optional, PC only)

- Added Tapping and Thread Milling to CADCAM Hole Wizard.

- Added ISO Metric Trapezoidal threads to Thread Calculator. It was disabled in 4.15.

- Minor bug fixes

4/15/18: Release 4.15 (Optional, PC & Mac)

- New Lollipop tip type for end mills.

- Added ISO Metric Trapezoidal threads to Thread Calculator.

- Added Manual Lathe instructions to Thread Calculator.

4/2/18: Release 4.11 (Silent, PC Only)

- New Setup Wizard to make onboarding easier.

- New Manual Lathe tab in Thread Calculator.

3/27/18: Release 4.1 (Optional, PC Only)

- Beta Release of the new Thread Calculator.

- Adds BSPP and ACME threads.

- Fixes bugs in metric unit conversion for the Vacuum Mini-Calc

3/18/18: Release 4.04 (Optional, PC Only)

- Beta Release of the new Thread Calculator.

- New Thread Family Metric MJ Aerospace Threads

- New Thread Family Whitworth BSW Threads

- New Thread Family British Association (BA) Threads

3/9/18: Release 4.01 (Optional, PC Only)

- First Beta Release of the new Thread Calculator.

- New Thread Family Added: UNM

- New Thread Family Added: UN STI

- New Thread Family Added: ISO STI

- New Thread Family Added: Pg

- New Thread Family Added: UNJ

- Implemented multiple thread starts in Thread Calculator

3/3/18: Release 4.01 (Optional)

- First Beta Release of the new Thread Calculator.

- Fixed some bugs in CADCAM Hole Wizard that gave erroneous "No viable feeds and speeds" message.

- Added D2, F51 (UNS S31803) Duplex, and CPM 10V steels to Materials DB.

1/4/18: Release 4.00 (Feathered)

- Added Blind Hole Clearance Calculator for tapping blind holes. It can be found on the Threads tab.

12/5/17: Release 3.99 (Silent)

- Added tool images to tool selector for Spot Drill, Reamer, Spade Drill, Boring Head, Taps, and Thread Mills.

- Added a % indicator to the Deflection field so you can tell how close to the limit you are.

- Tool Crib csv file format now has a "units" column that tells whether the units for all values in the row are inches or mm.

8/6/17: Release 3.97 (Silent)

- New Feature: CADCAM Wizards added a column for cut entry type (Plunge, Ramp, or Helix) and Feedrate when pocketing or 2D profiling.

- Fixed a bug where every other new tool created in the crib could sometimes overwrite an existing tool.

8/6/17: Release 3.95

- Double click on a row in results of CADCAM Wizard will transfer the result to Feeds/Speeds for further refinement.

- Added Kovar F-15, Plexiglass, and Lexan to Material DB.

- Added support for Countersinks under geometry for endmills.

- Added a new Center Drill image to the Geometry menu instead of showing a generic endmill.

- Fixed a bug in the Simple Machine Setup that sometimes prevented it from saving.

7/9/17: Release 3.91

- Added new simplified machine setup. Use the Simple tab unless you need max performance and then fill in the Advanced tab. Setup is much faster-60 seconds or so.

6/14/17: Release 3.90 (Mandatory release)

- Added material AL6XN, a type of stainless steel.

- Fixed a bug that made it hard to access lathe tooling when creating new tools in Tool Crib.

- Fixed a problem on really tight screens or when resizing the window small where the IPR and Plunge feedrates could be cut off or hidden.

- Added unit indicator for feedrates on Machine Profile.

5/2/17: Release 3.89

Release 3.89 adds a Polar to Rectangular Coordinate Calculator to the Geometry applets in G-WIzard.

3/16/17: Release 3.87

Release 3.87 is the latest (and hopefully last) in a bevy of silent fix releases that dealt with various issues reported in the field about Tool Families and that dealt with various other minor features including:

- Added 5051 aluminum

- Set up Tool Selection from cribs to order the menu in whatever order the user has the Tool Crib sorted in.

- Alphabetized Tool Crib names.

2/25/17: Release 3.81

Release 3.81 adds:

- Tool Families can now be Shared Preferences.

- Added Tool Family support to Tool Crib. Your Tool Crib tools can now be set up with a Tool Family.

- Added new material PVDF to Plastics: Soft.

- Added the ability to import Tool Families via CSV file.

- Fixed some bugs on the Material selection "More" button that made it refuse to select specific alloys and conditions when selected via History List or Keyboard.

- Fixed a couple of minor bugs on the Weights and Volumes applet.

2/7/17: Release 3.80

Release 3.80 adds:

- Tool Families

- Option to set Inches per Second on feedrates for Shopbot users. The option appears on the Machine Profile.

- Added new Machine Profiles for Shopbot Desktop, Desktop Max, and PRSalpha CNC Routers. To add them to your list, click the "Reset" button on the Machine Profile page. It adds back any default profiles that aren't there but won't change profiles that exist already.

1/31/17: Release 3.72

Release 3.72 adds:

- The "Plunge" label on Feeds/Speeds is now a dropdown so you can see feedrates to enter cuts using Plunge, Helix, or Ramp styles.

- Renamed "Interpolate" mini-calc "Helix" for compatibility with the Plunge style.

- Tool crib now stores coating and tool material.

- Changed Tool Crib so that when you create a new tool, it uses the same generic parameters every time instead of the parameters of the currently selected tool. While the latter can be a handy shortcut, it was confusing way too many people.

- Fixed a number of minor bugs in the tool crib reported by customers.

1/24/17: Release 3.70

Release 3.70 adds:

- Unit labels on fields of Feeds/Speeds to make it more obvious.

- GD&T applet now handles all GD&T symbols.

- New Getting Started Tour shows how to use the Cheat Sheet.

- Built with AIR 23 for compatibility with GWE.

1/4/17: Release 3.69

Release 3.69 adds:

- Cheat Sheet: Press this button below the Tips to pop up the Ultimate Feeds and Speeds Cheat Sheet

- CNC Router vs VMC Rigidity Options: When using rigidity adjusted power curves, there is a new option to aim for either CNC Router or VMC level rigidity. CNC Routers are typically less rigid because they're doing lower tolerance work.

12/8/16: Release 3.66

Release 3.66 adds:

- Added support for ZrN coating.

- Changed text color on Threads applet to improve readability.

- Added a short cut to copy RPM and Feedrate to clipboard if you click their labels. This just reduces the number of steps required to copy them over to your CAM software.

- Fixed bugs in calculating pipe weights and a bug that sometimes caused CADCAM Wizards to select a Cut Width wider than the cutter.

10/26/16: Release 3.65

Release 3.65 adds:

- New GD&T App under QuickRef tab gives a summary of GD&T Symbol Meanings with links to our GD&T Tutorial.

- New Machine Selector popup allows machine list to be filtered by Make.

- Added Fadal VM 15, VMC 15XT, VMC 4020, and VMC 4525 machine profiles.

- Added Hurco VM20i and VMX24i machine profiles.

- Fixed a unit conversion bug in the Ramping Mini Calc. It was always showing Imperial.

- Improved the usability of the limits. Limits now turn red when within 0.5% of their redline. There are tips that explain what the limits mean. Plus other detail changes.

9/24/16: Release 3.61 (Minor Release)

Release 3.61 adds new Social Login and Getting Started Tours per the article linked.

9/17/16: Release 3.59 (Minor Release)

Release 3.59 adds:

- Lots of updates to streamline and improve the usability of Login process. Added Social Logins, for example.

- Fixed a bug where pressing "New Tool" with no Tool Crib selected was causing problems.

8/29/16: Release 3.49 (Minor Release)

Release 3.49 adds:

- Fixed Bug: Tabbing through a field shouldn't turn on the padlock.

- Added G10 Material under Composites.

8/15/16: Release 3.45 (Minor Release)

Release 3.45 adds:

- Corner Rounding Endmill: New geometry type for Endmills.

- When importing toolcrib.csv, if there is no key or tabname, these fields will be automatically created.

- Made Cut Optimizer 3-5x faster

- Retuned feeds and speeds a bit for composites and chamfer bits.

- Reclassified ABS from hard to soft plastic per Onsrud's practice.

- Fixed a bug where cancelling from the Tool Crib popup menu meant it would take 2 clicks to bring the menu back.

7/31/16: Release 3.38 (Minor Release)

Release 3.38 adds:

- The old version would overwrite toolcrib.csv if there was an error loading it. New version renames it toolcrib.csverror rather than overwriting it.

- Add new materials by user request: N08031, Copper C110 H02.

- Tool crib would develop errors if "<" or ">" was used in any of the text fields. Fixed this problem.

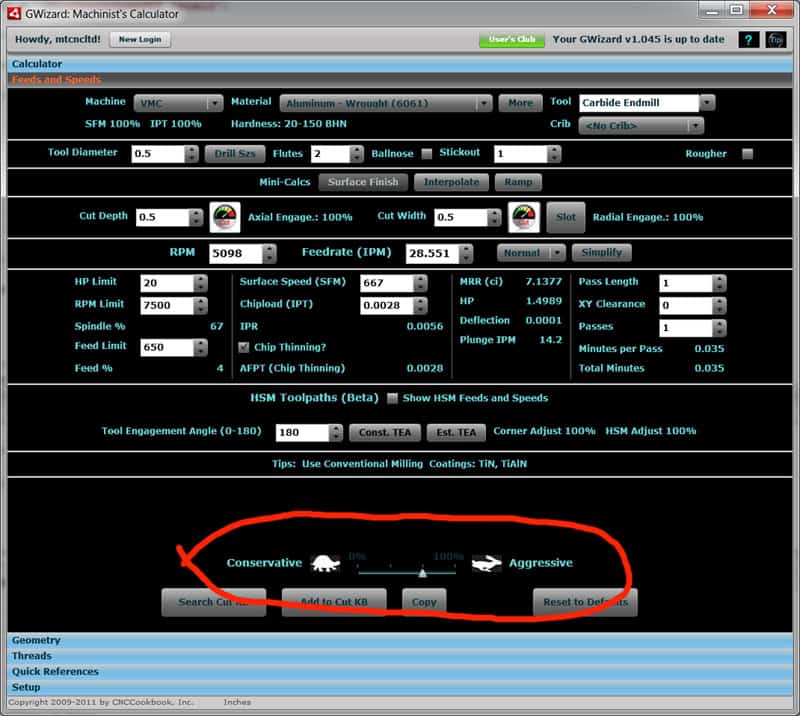

- Modified Tortoise-Hare slider to allow percentage settings so it now has 100 settings instead of the original 4. Also made it produce a smoother curve of results than the old slider.

- Expired trial users now get lifetime access to Calculator, ToDo, Threads, and QuickRefs.

- Added a bolt circle save function to save to a csv file.

- Re-formatted the Hardness conversion page and added some new scales.

- Moved the IPR display down next to the IPM feedrate for Lathe Feeds and Speeds.

- Added a new graphical tool selector page for Indexable Face and End Mills.

7/8/16: Release 3.34 (Minor Release)

Release 3.34 adds:

- Lumber Size Calculator

- Hawaiian Koa Wood added to Material DB

6/27/16: Release 3.33 (Minor Release)

Release 3.33 adds:

- Giant new databases for Softwood and Hardwood.

- Feedrate adjustment based on Janga hardness for Softwoods and Hardwoods.

- Added a Beginner's Glossary accessible from the First Login Menu.

- Updates to Machine Setup Guided Tour.

- Wrote a new Material DB Guided Tour.

- New Maraging Steel 300 and 250 Materials.

- New Duplex 2205 Material.

- Fixed some Tool Crib issues around Lead Angles and corruption of that field in CSVs.

- Moved Plunge label closer to Plunge Feedrate value.

6/12/16: Release 3.31 (Minor Release)

- Vacuum Table Mini-Calc

5/10/16: Release 3.30 (Minor Release - Mandatory)

Release 3.30 introduces the ToDo Wizard. A Pomodoro-style time management aid for CNC'ers.

5/5/16: Release 3.26 (Minor Release)

Release 3.26 includes:

- Added a Real Time Cut Optimizer feature. Just click the label of Cut Width or Cut Depth to see the values immediately update to the maximum they can be within deflection limits.

- Support for PCD endmills.

- Fixed a bug that made it impossible to change the angle on a V-Bit.

- Fixed a problem with editing Cut Width.

- Fixed an error in calculating the effective chipload when rpm is overidden and HSM is checked.

4/10/16: Release 3.21 (Minor Release)

Release 3.21 is a minor release that includes:

- Improvements and bug fixes to the new pictorial popup tool menu.

- Fixed a few Cut Optimizer issues.

4/2/16: Release 3.19 & 3.20 (Minor Release)

Release 3.19 & 3.20 are minor releases that include:

- Feeds and Speeds now recalculates on every keystroke. v3.20 fixes bugs in keystroke editing brought on by this new recalculation scheme.

- Fixed bugs preventing the editing of Tool Crib geometry.

3/12/16: Release 3.18 (Minor Release)

Release 3.18 is a minor release that includes:

- Redid the layout of the New Tool popup in the Tool Crib for increased readability and consistency with the Feeds and Speeds app.

- New graphical tool menu comes up when the Geometry button is pressed.

- Increased the wait time on logins for slow Internet connections to succeed.

3/2/16: Release 3.15 (Minor Release)

Release 3.15 is a minor release that includes:

- Tool Menu Popup (access via "..." button just right of tool menu) is now operational. We'll continue to label it Beta for a release or two, but I've been using it successfully for my own work. There's quite a lot of new functionality there, and still more to come in future near-term releases.

- Fixed a bug where making the shared folder a removable drive and then unmounting the drive could sometimes hang the software.

- Alphabetize machine list for better usability.

- Improved behavior of CADCAM Hole Wizard so it can get around Tool Deflection challenges a little better.

- Fixed material menus to stay synchronized between Feeds and Speeds and CADCAM Wizard tab.

2/12/16: Release 3.10 (Minor Release)

Release 3.10 is a minor release that includes:

- Added a bunch of user requested Aluminum alloys including: 6026, 33103 H14, 4015 H14, 5251 in O, H22, H24, and H26 conditions, and 6106 T6.

- Fixed some problems when trying to use CADCAM Wizards with Routers.

- Updated CADCAM Wizards so it uses the current unit system (metric or Imperial) for tool diameters.

- CADCAM Wizards now get the hints in the results table for each cut stage.

- Added a Shapeoko 3 Machine Profile with two variations-one for DeWalt and one for Porter Cable spindle.

- Changed the label on the Mfg's Data to make it clear this data is optional and not required for a Feeds and Speeds calculation.

2/2/16: Release 3.09 (Minor Release)

Release 3.09 is a minor release that includes:

- Fixed some Tool Crib issues.

- Updated Tool Selection UI Mockup so it does a more complete job bringing in the current tool's parameters and so it works better with the Tool Crib. There were also a lot of behind the scenes changes to support the new Tool Selection UI.

1/26/16: Release 3.06 (Minor Release)

Release 3.06 is a minor release focused fixing some bugs that prevented proper saving of the spindle power curve for some users. Also fixed conversion back and forth to metric vs imperial units on the spindle power curve.

1/20/16: Release 3.04 (Minor Release)

Release 3.04 is a minor release focused on presenting a new UI design for the Tool Selection menu for comment. The UI design is a mockup that is not functional and is intended for comment only.

1/14/16: Release 3.03 (Minor Release)

Release 3.03 is focused on usability improvements:

- HSM now recalculates automatically when you change Cut Width. The UI is changed slightly to reflect this. You can override the Tool Engagement Angle if you want to enter one manually rather than use Cut Width to calculate it.

- Changed the Tips message so it is a drop down to make it easier to see multiple Tips.

- Added new tips for Aluminum that warn to use Coolant/Mist/Lubricant and to use less than 4 flutes with endmills.

1/6/16: Release 3.02 (Minor Release)

Release 3.02 fixed a bug that prevented the Crib Wizard from working.

1/4/16: Release 3.01 (Minor Release)

Release 3.01 fixes a bug in Cut Optimizer that comes up with very tiny endmills (e.g. 0.005" diameter).

1/2/16: Release 3.00 (Minor Release)

Release 3.00 is a minor release that includes:

- Tool Cribs can now be shared.

- Added a Tormach PCNC 440 machine profile. Just click "Reset" to add back any new machine profiles to your list. Existing profiles will not be overridden.

- Added CPM S35VN steel to the Material DB. This is a popular high performance stainless for knife makers.

- Made some cosmetic improvements to the Feeds and Speeds page.

1/1/16: Release 2.99 (Minor Release)

Release 2.99 is a minor release that includes:

- Tool Crib bug fixes.

- Added 8640 Steel to Material DB

12/16/15: Release 2.98 (Minor Release)

Release 2.98 is a minor release that includes:

- Shared Machine Profiles

- Added Melamine to materials under MDF, and SAE 660 Bearing Bronze to Materials DB.

- Converted the file format of machine profiles to CSV. You can load it into Excel to look at it or modify it if that's convenient. Be careful not to delete any columns or change the first row.

- Made the Plunge Feedrate accessible for Copy.

- Fixed some bugs in the Hardness conversion utility

- The Machine Hourly Rate Calculator button is back to tell you that it is available in G-Wizard Estimator, which is free during Beta Test to G-Wizard Calculator users.

10/20/15: Release 2.95 (Minor Release)

Release 2.95 is a minor release that includes:

- New 3D Surfacing CADCAM Wizard.

10/12/15: Release 2.94 (Minor Release)

Release 2.94 is a minor release that includes:

- Startup of CADCAM Wizards is considerably faster than it was.

10/6/15: Release 2.92 (Minor Release)

Release 2.92 is a minor release that includes:

- Update on slitting saw support. Now gives a warning when the depth of cut is too large for a pass.

- Added Materials: ATS-34, ATS-35, 3CR12, 13-8PH @ H1000, 4047 aluminum.

- Fixed a bug where settting full Tortoise with an 80% derate on chipload could force the rubbing warning to be on all the time.

- Made a number of improvements in numeric field behavior for localized regions that use "," instead of "." for decimal point.

9/7/15: Release 2.87 (Mandatory Minor Release)

Release 2.87 is a minor release:

- Added Login Helper to make it easy to troubleshoot the login process.

- Fixed a couple localization problems in Machine Setup.

- Made Feeds and Speeds a bit more graceful dealing with Horsepower Limits.

9/2/15: Release 2.86 (Minor Release)

Release 2.82 is a minor release:

- Added Login Wizard to simplify the login process.

- Added in-app offer notification so you don't miss out on our sales.

8/9/15: Release 2.82 (Minor Release)

Release 2.82 is a minor release:

- Machine Hourly Cost Calculator has been moved to G-Wizard Estimator.

- Fixed a variety of customer reported bugs in CADCAM Wizards. In particular, the CADCAM Hole Wizard for Lathes had a lot of work done on it.

- Added a DFM warning when parting more than 10x the parting blade width per Sandvik recommendations.

7/3/15: Release 2.81 (Minor Release)

Release 2.81 is a minor release:

- Added Thread Mill Feeds and Speeds.

- Added ER Collets to the list of standard tapers.

- Added PTFT to Plastics - Soft

- Added a machine profile for the Tormach 16 PRO Slant Bed Lathe

- Added an option that is on by default to constrain stepdown to equal steps for CADCAM Wizards

- Fixed a few minor bugs reported by customers.

5/13/15: Release 2.80 (Minor Release)

Release 2.80 is a minor release:

- Add support for High Pressure Coolant with TSC. Improved TSC coolant support as well.

- Added a machine profile for Carbide 3D Nomad 883.

- Fixed a few minor bugs reported by customers.

3/19/15: Release 2.79 (Minor Release)

Release 2.79 is a minor release:

- Tune up the Fits and Tolerances applet.

- Changed Home and End key behavior on numeric fields so it moves cursor to first and last position.

- Fixed a bug in ID Turning CADCAM Wizard that caused it to miscalculate the number of passes.

- Added boring bar sizing DFM messages to ID Turning CADCAM Wizard.

3/19/15: Release 2.78 (Mandatory Release)

Release 2.78 is a minor release:

- HP calculations were tweaked to make them better for marginal horsepower situations on small machines. They also figure in the HP reductions due to High Lubricity Coatings and Serrated Corncob Roughers.

- Fixed a bug where you couldn't sort the columns of data grids.

3/15/15: Release 2.76 (Minor Release)

Release 2.76 is a minor release that adds A513 Low Carbon Steel material for Feeds and Speeds.

3/2/15: Release 2.75 (Minor Release)

Release 2.75 is a minor release that adds a new Cobalt Chrome (CoCr) material family for Feeds and Speeds.

2/16/15: Release 2.74 (Minor Release)

Release 2.74 is a minor bug fix release that fixes a problem where the "Sizes" button was disabled.

2/12/15: Release 2.73 (Feathered Release)

Release 2.73 is a minor bug fix release:

- Fixed a problem with feedrate being way too large when a Ballnose is selected in Metric.

- Add C69300 Silicon Brass to Material DB.

1/28/15: Release 2.72 (Minor Release)

Release 2.70 is a minor feature release:

- More tuning up on the new Data Grid personalization features.

- Tormach users get 3 HP on Lathes in GWLite mode to support the Tormach lathe.

- Added Haynes 188 / Inconel 188 to the Materials DB

- Changed icon on login bar from accessing the User Club Forums to accessing the Question Exchange.

1/15/15: Release 2.70 (Minor Release)

Release 2.70 is a minor feature release:

- Many of the Data Grids now have enhanced functionality so you can change the order of columns, hide columns, change column width, and change sort order and the system will remember these choices from one session to the next. This helps greatly with tables that have a lot of columns, such as the tool table. To invoke the feature, just click the mouse in the column header and popup to edit the columns will appear.

- Updated the spindle power curve so it can have as many points as you wish and it shows a snazzy graph of the curve as well.

- Flute Length in the Geometry table is now working and will be saved in Tool Tables.

- Fixed a slew of Localization problems when the decimal is something other than "."

- Fixed a few other user-reported problems and usability glitches in various places that aren't encountered very often.

12/27/14: Release 2.64 (Minor Release)

Release 2.64 is a minor feature release focused on these areas:

- Audited and revamped MRR and spindle power calculations. Incorporated refinements from Kennametal on how to modify HP based on W/D ratios as well as how to modify HP based on whether it's turning, drilling, or milling. Most others just use the same machinability factor for all these cases and that's not quite right.

- Fixed some user-reported issues with CADCAM Wizards.

12/6/14: Release 2.59 (Minor Release)

Release 2.59 is a minor feature release focused on these areas:

- Material History List (under "More" button) now updates whenever Materials are selected instead of just when they're selected via "More".

- Turning Feeds and Speeds now warn when RPM limit is reached by turning it red.

- Added a "No Plunge" warning for Compression and Downcut bits on CNC Routers.

- Fixed problem where graphics would disappear on QuickRefs, Fasteners.

- Fixed a bug on CADCAM Wizards so you don't have to hit "Recalc" to change between extents modes.

- Made the data grid horizontally scrollable on CADCAM Wizard results for better usability on smaller screens.

- Modified the Tortoise Hare slider to make sure the feedrates are always in order. Sometimes a faster feedrate could appear in the middle of the range before this update.

- Added #12 flat head screw size to QuickRef fasteners.

- Added new materials: 5115 / 16MnCr5 / 1.7131 Steel, ASTM A743 CA6NM, C65500 High Silicon Bronze, Din No. 1.4305 Stainless steel, ST37- Din No. 1.0037 Steel, F91, F22, and F11.

10/15/14: Release 2.58 (Minor Release)

Release 2.58 is a minor feature release focused on these areas:

- Added features aimed at supporting large Tool Tables better. These include ability to search for tools in tables, the ability to filter tools by type in the Feeds and Speeds popup, and performance enhancements aimed at making very large tables perform better.

- Fixed a problem whereby some of the graphics were missing in v2.56 from the Thread Reference, Countersink/Chamfer Geometery, and a couple other places.

10/9/14: Release 2.56 (Mandatory Minor Release)

Release 2.56 is a minor feature release focused on these areas:

- Changed CADCAM Wizards to use a recalc button at the top right. It turns red when recalculation is needed. We had a lot of users who felt like the automatic recalculation was too slow when they wanted to change multiple input parameters, so this should make them much happier.

- Added Mach3 tool table formats to the Tool Crib Import/Export. We will start adding CAM tool table formats soon too, but this one gets us started down the path of supporting multiple formats.

- Our code signing certificate is expiring, so this release has a migrational certificate plus a newly renewed certificate.

9/9/14: Release 2.54 (Minor Release)

Release 2.54:

- Adds new silent download upgrades

- Fixes a problem where Tabbing between fields in FeedsSpeeds had quit working

- Corrects error in minor diameter data for 6-32 threads.

- Corrects a problem that would sometimes hang the Face Milling CADCAM Wizards during recalc.

8/25/14: Release 2.52 (Minor Release + Mandatory Release)

Release 2.52 fixes a problem with Field Operators that had made them hard to use.

7/17/14: Release 2.51 (Minor Release)

Release 2.51 fixes a problem that prevented CADCAM Wizards from recalculating if accessed before the Feeds/Speeds page. Also improved the accuracy of CADCAM Wizard time estimates.

7/2/14: Release 2.50 (Minor Release)

Release 2.50 fixes a problem that was inhibiting recalc of the CADCAM Wizards on some machines.

6/27/14: Release 2.49 (Minor Release)

Release 2.49 fixes a problem that would times trigger recalc over and over in CADCAM Wizards. It also adds new materials: AR400, AR500, 4145, and Hastelloy X. Lastly, it disables the 3D Surfacing CADCAM Wizard so the fact that it is still just a mockup is less confusing.

6/12/14: Release 2.48 (Minor Release)

Release 2.48 fixes problem problems with the Threads app that were introduced in 2.47.

5/26/14: Release 2.47 (Minor Release)

Release 2.47 fixes a problem with indexable tooling when lead angle is other than 90 degrees. It also reduces the startup time.

5/9/14: Release 2.45 (Minor Feature Release)

Release 2.45 fixes a couple of bugs to do with error messages and adds the new Crib Wizard to the Tool Crib page. The Crib Wizard is capable of automatically generating Tool Crib entries for endmills or twist drills in standard sizes. In addition, Tool Cribs now have a "Description" field that can be used to describe the purpose and contents. Also added a unit indicator for drill peck depth.

4/29/14: Release 2.42 (Minor Release)

Release 2.42 fixes a couple of minor problems with the Tool Crib tool editor (pops up with double click).

4/24/14: Release 2.41 (Minor Release)

Release 2.41 fixes a problem with Center Drill Feeds/Speeds.

4/21/14: Release 2.40 (Feature Release)

Release 2.40 is a feature release that adds:

- Added Lathe Threading as a new Tool Type in Feeds/Speeds.

- Added a Threading CADCAM Wizard.

- Added the ability to transfer thread specs from the Thread Database to the Threading CADCAM Wizard.

- Added a Center Drill Tool Type in Feeds/Speeds.

- Added CADCAM Custom Wizard for CADCAM Estimator and other Cycle Time calculations.

- Updated the csv file format to include an "opTime" column that is the time in minutes for the operation. This makes it easier to do further calculations on the operation.

- Fixed a bug in calculating the number of passes for the CADCAM OD Turn wizard.

4/7/14: Release 2.38 (Minor Release)

Release 2.38 is a minor feature release that adds:

- Peck Depth is now displayed in the Tips on Feeds/Speeds

- Did a mini-upgrade on Peck Depths. Added through spindle coolant and HP (high helix) support.

- For Mill-Turn users, you can now select Milling tools through the "Milling" sub-menu at the bottom of the Lathe Tool Menu.

3/28/14: Release 2.37 (Feathered Release)

Release 2.37 is a minor feature release that adds:

- Improved UI of Groove/Part in Feeds/Speeds to be clearer.

- Added Groove/Part CADCAM Wizard.

- Custom CADCAM Wizards to calculate cycle times on arbitrary Feeds/Speeds setups and add them to CADCAM Estimator.

- Reduced the slowdown penalty for deep cuts that have very shallow stepover. These cuts will now run faster.

- Fixed some bugs to do with not triggering recalc every time it was needed in CADCAM Wizards.

- Improved the automatic balancing of real estate among the different controls on a CADCAM Wizard so that it optimizes better and you can see more without scrolling.

3/21/14: Release 2.36 (Feathered Release)

Release 2.36 is a minor feature release that adds Facing and ID Turning (Boring) CADCAM Wizards.

3/19/14: Release 2.35 (Mandatory Release 3/28/14)

Release 2.35 is a minor bug fix release:

- Made the message about incompatible machines only appear when the Tool Crib is open because that is what it refers to.

- Fixed a bug that grayed out the Surface Finish calculator for ballnosed endmills.

- Changed precision on "Leadscrew" on the Motor tab in QuickRefs to 4 digits.

- Fixed a rounding problem on some numbers in the Calculator. It was showing tiny errors 16 digits out.

- Fixed a problem setting the corner style on the OD Turning CADCAM Wizard.

- Fixed a couple of metric bugs on the OD Turning CADCAM Wizard.

- Increased the Surface Speed when machining brass with TiAlN coated endmills. It still can't go as fast as aluminum (as recommended by most tooling manufacturers) but it is closer.

- Fixed some cases in CADCAM Wizards where SFM or IPR might show "NaN".

3/13/14: Release 2.34

Release 2.34 is a minor bug fix release:

- Fixed some OD Turn Wizard problems with metric.

- Fixed a problem where the Cut Depth Mini-Calc wouldn't paste back to Feeds and Speeds.

- Fixed a problem that would sometimes cause the Spindle Power Curve code to make feeds and speeds oscillate between best for HP and best for Feedrate.

- Changed the popup Feeds and Speeds from CADCAM Wizards so they won't allow Tool Crib picks until CADCAM Wizards can handle them.

- Fixed a problem that made it hard to change the machine associated with a Tool Crib.

3/10/14: Release 2.33

Release 2.33 is a minor bug fix release:

- Added Titanium alloys TA14, 15, 16, and 17 to the Materials DB.

- Fixed a bug calculating ballnose endmills when cut depth was greater than tool radius. Bug was introduced in 2.30.

- Fixed a problem where the CADCAM Hole Wizard could quit recalculating if non-standard hole diameters were used.

- Fixed a problem where TiAlN and HP endmills would come up without those prefixes when editing an entry in the Tool Crib.

3/9/14: Release 2.32

Release 2.32 is a minor bug fix release. Tool Cribs that had double quotes for inches in the string fields were losing those tools.

3/4/14: Release 2.30 + 2.31

Release 2.30 is a minor release focused on:

- New OD Turn CADCAM Wizard for lathes.

- Added Chamfer Mill geometry.

- Lots of clean up work on Tool Crib and Tool Geometry.

- Release 2.31 fixed a bug introduced in 2.30 that was ignoring a chipload value and generating NaNs in the feeds and speeds results.

2/28/14: Release 2.29

Release 2.29 is a minor release focused on usability and bug fixing for the Tool Crib and Tool Geometries. It's clearing the way to make it easier to add more geometries going forward.

2/17/14: Release 2.28

Release 2.28 is a minor release that focuses on:

- UI for OD Turning CADCAM Wizard is mocked up along with CADCAM Wizard options for lathes.

- Added History and Search to Material DB "More" button popup.

- Added Phenolic and Tufnol to Material DB.

- Added an explanatory label to Feeds and Speeds Tortoise-Hare slider that explains what each setting is for. Spread out the stops so they're more evenly spaced. There used to be a big gap from Full Tortoise to the next step up.

- Fixed a bug in loading CADCAM Estimator files.

2/11/14: Release 2.27

Release 2.27 is a minor usability release that focuses on:

- Got rid of commas in numeric fields.

- Did an overhaul of Gun Drill Feeds and Speeds. Reviewed a bunch of new data and fine tuned it. Simplified the UI to quit showing fields that don't affect Gun Drill such as Cut Depth and Stickout.

- Added MIC-6 and K-100 cast aluminum tooling plate to the material DB.

- Fixed some seldom seen Cut Optimizer bugs associated with the interaction between CADCAM Wizard and Feeds and Speeds.

1/25/14: Release 2.26

Release 2.26 is a minor bug fix release that focuses on:

- CADCAM Wizard bugs reported by users.

- Changed the rubbing warning to be less sensitive for soft materials like Plastic and Wood.

1/8/14: Release 2.25

Release 2.25 is a minor feature release that includes:

- New popup Feeds and Speeds popup for CADCAM Wizards. Just double click the row on the operations list, edit in the Feeds and Speeds popup, then click the Save button. This makes it easier to fine tune and optimize the CADCAM Wizard results.

- New ability to import Estimate files (csv files).

- New file format for the Estimate files with more record types and more columns to capture more information. Note: there are more file format changes coming and the current format is primarily for testing and casual use. Once we have a complete file format, we'll publish a spec for it and make future versions upward compatible.

- Added Waspalloy to the Materials DB.

- Fixed a number of problems with CADCAM Wizard time estimating.

12/12/13: Release 2.20

This release is focused on bug fixes and user feedback:

- Spindle min and max rpm can now be set to 10 rpm increments on Machine Profile page. Had been 100 rpm.

- Tool Crib folder is remembered when import/export dialog pops up.

- Material selection including the "More" info is now remembered across sessions.

- Fixed an error in the angle for the BT, CAT, and R8 tapers.

12/7/13: Release 2.12 through 2.18

These releases are focused on bug fixes and user feedback plus:

- CADCAM Wizard is a lot smarter about tool selection for machines with lower horsepower limits.

11/23/13: Release 2.11

Release 2.11 is a minor bug fix release. It has CADCAM Wizard bug fixes, plus it will convert a "," entered into a number field to a "." so International users can type the decimal point they're used to.

11/20/13: Release 2.09

Release 2.09 is a CADCAM Wizard algorithm and performance update. If you need to change a parameter during recalc, you can do so and recalc will pause and then restart again in a few seconds. The algorithms have been retuned to be more robust at finding the best possible combination of Cut Depth and Cut Width as well. Lastly, v2.09 is the first v2 release available as a .dmg file for Mac users.

11/19/13: Release 2.08

Release 2.08 is a feature release:

- Added the ability to increase the deflection allowance. There's a new Setup Other tab that has a percentage to multiply the deflection allowance. It is only triggered if the Tortoise-Hare slider is on "full Hare." Suggest values are 200-300%.

- Added the option to interpolate holes to the CADCAM Hole Wizard. It'll give a DFM warning if you try to interpolate more than 2x Tool Diameter deep.

- Improved the CADCAM Wizard algorithm to find better solutions. It'll run more slowly as a result because its trying more possibilities.

- Put back the missing CADCAM 2D Profile Wizard.

11/17/13: Release 2.07

Release 2.07 is a bug fix release.

11/15/13: Release 2.05

Release 2.05 is a Beta release focused on bug fixes and minor improvements:

- Improved the Tortoise-Hare "super finish" setting so it uses a reduced deflection allowance more suited to finishing.

- Improved the weight-adjusted power curve option to ignore weight adjustment for drilling. Drilling needs to use a lot of power and its forces are concentrated along the hole axis where deflection does less harm.

- Fixed an error where CADCAM Wizards was reporting tool sizes in Imperial when Metric was the selected unit system.

- Fixed an error where the override padlocks wouldn't recalculate once turned off.

- Fixed a crash bug involving Tool Cribs.

11/13/13: Release 2.04

Release 2.04 is a Beta release focused on bug fixes and minor improvements to make it work better on smaller screens. All open Beta bugs (but not enhancement feedback) have been fixed for this release.

11/6/13: Release 2.02

Release 2.02 is a Beta release w/ some new features:

- Applet UI navigation changed from the accordion style to tab bar at the top to reduce screen real estate.

- Added a "Reamer" option to CADCAM Hole Wizard.

- Full "Tortoise" on the Tortoise-Hare slider is now a "Super Finish" cycle. It goes about 10% faster than would trigger the rubbing warning.

- Fixed a bug where lathes were showing the mill Surface Finish Mini-Calc popup.

- Fixed a bug that prevented double clicking from CADCAM Wizards to Feeds and Speeds for drilldown.

- Fixed several bugs on the Feedback popup.

11/5/13: Release 2.01

Release 2.001 is a Beta release:

- Major UI facelift.

- 2.01 fixes a bug where text was invisible on Surface Finish Mini-Calc.

10/28/13: Release 1.997

Release 1.997 is a CADCAM Estimator release:

- Added a scrap allowance to CADCAM Estimator, 5% default - Added Addl Cost and Addl Time fields to recalculation in CADCAM Estimator - Added a new operations to CADCAM Estimator: Components Op, Deburr Op, Finish Op, Coating Op, and Programming Op. - ButtonBar implementation of Add Op selector for better real estate management. - Added different tabbed sections for per part and one time costs.

10/24/13: Release 1.996

Release 1.996 is minor feature release:

- Added new material "Graphite" for the EDM crowd.

- Added spot drilling option to CADCAM Hole Wizard.

- Added chamfer with spot drill option to CADCAM Hole Wizard.

- Fixed a bug that caused Feeds and Speeds to go haywire if you switch from Normal to V-Bit or Ballnose and then back to Normal geometry.

- Fixed a bug in CADCAM Pocket Wizard that cause it not to leave a finish allowance for finishing the floor of the pocket when it calculated cut depth.

10/21/13: Release 1.995

Release 1.995 is largely a CADCAM Estimator release:

- Each Machine Profile now carries a billing rate field that is automatically selected based on machine used for the Estimator.

- There is a new Machine Billing Rate Calculator that may be used to calculate your machine billing rates.

- Estimator ops now have a "Qty" field so that quantities can be specified for the op, for example, when drilling many identical holes.

- Machine and Hour Rate are now exported with the Estimator spreadsheet.

- CADCAM Wizard should no longer wipe out your Feeds and Speeds values with its own unless you double click the CADCAM results to see them in Feeds and Speeds.

- Fixed some bugs associated with Tool Cribs.

10/18/13: Release 1.994

Release 1.994 is bug fix release:

- Fixed problem where GWC had stopped saving the machine and material between sessions.

- Fixed problem where CADCAM Wizard wasn't saving the options for Imperial or Metric endmill sizes.

- Increased the resolution of the CADCAM Wizards so they're less likely to produce slightly different results on successive runs.

10/5/13: Release 1.992

Release 1.992 is bug fix release:

- Fixed a problem in Estimator where Add Op always added a row even if you cancel out of it.

- Fixed a bug where you couldn't add the same CADCAM Wizard op twice to an Estimate.

- Fixed a bug that sometimes caused the Feeds and Speeds to show lathe tooling with a Mill.

- Fix a bug where if you start up in the Setup app and switch to CADCAM Wizard it would just show a blank screen.

9/30/13: Release 1.991

Release 1.991 is a major feature release:

- Added CADCAM Facemill Wizard.

- Added Job Cost Estimator to CADCAM Wizard.

- It's now possible to enter Taps in a Tool Crib, although you'll have to set the pitch manually.

- Fixed several bugs in CADCAM Wizard found by customers. It now works a lot better on really difficult combinations.

- Fixed a bug in the Weights applet where it was miscalculating hex stock.

9/19/13: Release 1.98

Release 1.98 is a feature release:

- Added the new Hole Wizard to the CADCAM Wizards.

- Added access to the Tortoise-Hare slider on every CADCAM Wizard so it is more obvious it is there and more convenient to access.

- Added a "Part Cutout" option to the 2D Profile CADCAM Wizard that sets the cut width to full slot when cutting parts out by milling their profile.

- Fixed the button label on the popup "More" material selector so it is no longer cut off.

- Fixed a bug where the feedrate in CADCAM Wizard wasn't properly converting to metric.

- Fixed a couple of other cosmetic bugs and one hang bug on really small corner radii for the Pocket CADCAM Wizard.

9/12/13: Release 1.971 Mandatory

Release 1.971 is a bug fix release. In addition to fixing several minor issues reported by customers, a major issue causing the CADCAM Wizard to be too aggressive with long tool stickouts was fixed. This is a mandatory upgrade to get everyone on the same version of CADCAM Wizard since a lot of issues have been taken care of in recent releases.

9/10/13: Release 1.97

Release 1.96 is a minor release focused on:

- Increased Internet disconnect time from 2 weeks to 4 weeks.

- Normalize the time format in CADCAM Wizard to use 00:00:00 to help the user recognize time values quickly.

- Added In-App Registration so you don't have to go to the web page to register.

- Fixed a CADCAM Wizard bug that prevented it from properly accessing machine parameters until the Feeds and Speeds page was brought up.

- Fixed a bug that prevented the unit conversion menus working when the Calculator was undocked from G-Wizard.

- Fixed a bug introduced in 1.96 that prevented accessing some of the apps when disconnected from the Internet.

9/2/13: Release 1.96

Release 1.96 is a feature release focused on CADCAM Wizard:

- Opened access to CADCAM Wizard. Prior release only allowed paying customers to access it. Now current trials and GWLite customers can access it.

- Added 2D Profiling Wizard.

- Added an option to restrict tool sizes in CADCAM Wizard to Imperial, Metric, or Both.

- Fixed all reported CADCAM Wizard bugs.

- Fixed a unit conversion problem in the Feeds and Speeds calculator that was giving incorrect torque values in metric.

- Fixed a problem where Tool Crib imports via spreadsheet that contained incorrect tool types could prevent use of the crib.

8/29/13: Release 1.95

Release 1.95 is a fairly major release:

- Adds the new CADCAM Wizard, which is in Alpha test. It is only accessible to paying customers at this stage. Keep an eye on the results as this is brand new code and no doubt has some bugs. In this first release of the CADCAM Wizard, only pocketing is available.

- Recalibrated the Tortoise-Hare Slide on Feeds and Speeds to match the slider on CADCAM Wizard. Read the CADCAM Wizard article for details.

8/7/13: Release 1.85

Release 1.85 is a minor release:

- Adds a new Setup Lock function so you can lock out changes to Setup. You'll need the lock code which is unique to every account. Contact us to get a code.

- Added mouse zoom wheel functionality to all the numbers. You can hold down Shift to accelerate the spinning with the mouse wheel.

- Fixed a bug where under certain conditions cut width would appear to be larger than tool diameter. Internally, it used the right numbers, so this is a cosmetic fix.

- Souped up SFM on deep cuts where tool engagement is low. GW was overly conservative in those cases on really deep cuts.

- There's quite a bit of behind the scenes work to prepare for our upcoming CAD/CAM Wizard feature. More about that next release.

4/7/13: Release 1.8

Release 1.8 has quite a lot of new functionality around Tool Geometry, hence we skipped ahead to 1.8 instead of 1.727 or some such. Specifically:

- Corner Radius is now enabled on the Tool Geometry popup. This lets things like bullnose endmills, button, and toroidal cutters be specified.

- All appropriate chip thinning and effective diameter calculations are handled for corner radius. You can also combine corner radius and lead angle for even more exotic indexable tooling geometries where the round inserts are laid back at an angle.

- Taper angle is also now enabled for appropriate Geometry types. So, if you have an endmill that has a built-in draft angle, you can enter that angle and the effective diameter will be calculated based on depth of cut and the "Cut Length" parameter. If you do not specify "Cut Length" on the Geometry popup, G-Wizard will assume the taper continues for the entire stickout.

- Note: Neither the Corner Radius nor Taper Angle are being saved in the Tool Crib or Cut KB yet-that'll be the subject of a future release.

- The Plunge feedrate was moved up on the same line as the RPM, and Feedrate to make it more obvious.

- In place of Plunge is a new cutting force indicator. Cutting force is expressed as spindle torque in Oz-In or N-m depending on whether you've set G-Wizard to Imperial or Metric.

- Effective diameter may now be found down in the HSM area.

3/8/13: Release 1.726

Release 1.726 is a minor release that:

- Fixed a few inaccuracies in the Fasteners Database.

- Improved flexibility of Feeds and Speeds to trade off in over-constrained problems, particularly when horsepower limited.

- Added HSS and Cobalt to the Materials DB under Tool Steels.

- Added C70600 90/10 Nickel Copper allow to the material DB.

- 6063 T52 Extruded Aluminum added to Material DB.

- Fixed a problem with custom tool data where the very smallest endmills where being set to 0 chipload sometimes.

1/31/13: Release 1.725

Release 1.725 is a minor release that fixed a few bugs, added C86300 Manganese Bronze to the Materials DB, and ensured compatibility with GW Editor.

12/17/12: Release 1.720

Release 1.720 is a minor feature release where we completely revamped the geometry menus for endmills. We'll do an update shortly for twist drills.

12/6/12: Release 1.714

Release 1.714 is a bug fix release:

- The ballnose surface finish calculator had quit transferring the effective diameter so was broken. Fixed that bug and added a button to transfer the stepover back.

- Fixed a bug in the taper calculator.

11/28/12: Release 1.711

Release 1.711 is a minor release:

- Added new material UHMW under Plastics, Hard.

- Reduced the SFM penalty for large radial engagements based on my annual review of the latest tooling manufacturer recommendations. This will result in some higher rpms for many cuts and greater productivity.

- When you redock calculator, it stays on the application you had been using. Redocking is a signal you are done with the calculator, so why switch to it?

- Made a number of changes to speed up the Cut Optimizer by about 4x. Thanks Tom for keeping after me to do this!

- Fixed cut and paste from calculator.

- Fixed a bug where if you switched from a hard material like stainless to a soft material like plastic and then right back it gave overly optimistic feeds and speeds. Thanks for finding that one, William!

- Fixed a bug when importing a custom tool data spreadsheet. If there was a -1 in the SFM column, it would enter 0 for SFM. Now it enters the G-Wizard default SFM for that material and tool type.

11/16/12: Release 1.710

Release 1.710 is a minor feature release:

- If GWC is exited running at a higher resolution and reopened with a screen to small for that resolution, the window opens maximized.

- Fixed the problem where saving a machine profile would reset to the first machine. This was causing a lot of confusing.

- Redesigned the ballnose surface finish calculator. Instead of appearing at the bottom near the HSM area, it is now a pop-up Mini-Calc accessed via the Surface Finish button. This was done to reduce the screen real estate requirements as part of our preparations to develop a mobile version for tablets. Also added the ability to calculate stepover given scallop height and scallop height given stepover.

- Added a bunch of new materials based on user requests: P20 steel, polyurethane foam tooling board such as RenShape in several grades (hard plastics menu choice), Torlon both as a resin and carbon composite (former is on hard plastics, latter is on composites material family), and added Aluminum Composite Materials such as Reynobond (composites material choice).

- Minor cosmetic tweaks and bug fixes here and there.

10/24/12: Release 1.7000

Release 1.700 is a major feature release:

- The Calculator tab has gotten a nice UI facelift and can now be undocked so it is always available for use with the other tabs. Just click the little undock button in the top right to undock or redock. This work represents the beginnings of work to reduce the screen real estate requirements on each of the GW Calculator applications so they can happily run on a tablets like the iPad or Android equivalents. Expect more to come.

- Printing. At last you can print any tab. Just right click and select "Print" from the menu that comes up.

10/15/12: Release 1.680

Release 1.680 is a major release focused on:

- Added a Fits and Tolerances Calculator for ISO 256 to the Geometry Tab. If you need a Press Fit Calculator, this is the one. The Calculator is considered experimental for the time being as it needs more testing and user feedback. If you have questions or comments, email to Bob.

- Whenever there is a limit hit in the Feeds and Speeds calculator and the numbers turn orange, the calculator will make sure the display is in "Advanced" mode so all the values are visible to make it easier to see where the orange is coming from.

- Several minor user-reported bugs were fixed.

10/09/12: Release 1.671

Release 1.671 is a minor release focused on:

- Fixed a bug where GWE users with the latest release would see a Post error on loading.

- Added the buttons for "Getting Started" and "Support" just like we added to GWE in its last release.

- Added QC-10 Aluminum and Machinable Wax ("Wax" on the materials list) materials.

10/01/12: Release 1.670

Release 1.670 is a bug fix release focused on:

- Added Instant Registration for GW Calculator trials.

- Fixed a few more Geometry tab bugs.

- Fine tuned micro-mill support further with better calculation of deflection forces and the rubbing threshold for chipload.

- Added Duplex and Super Duplex Stainless Steels to the 300 Series Stainless Materials DB

9/20/12: Release 1.667

Release 1.667 is a bug fix release focused on fixing some problems in the Geometry tab. This was a signalled upgrade.

9/5/12: Release 1.660

Release 1.660 is a minor feature and bug fixing release. Changes include:

- Added a "Generic CNC Router" machine type for new users. It's only accessible for a new install. Should help new CNC Router users to come up to speed faster.

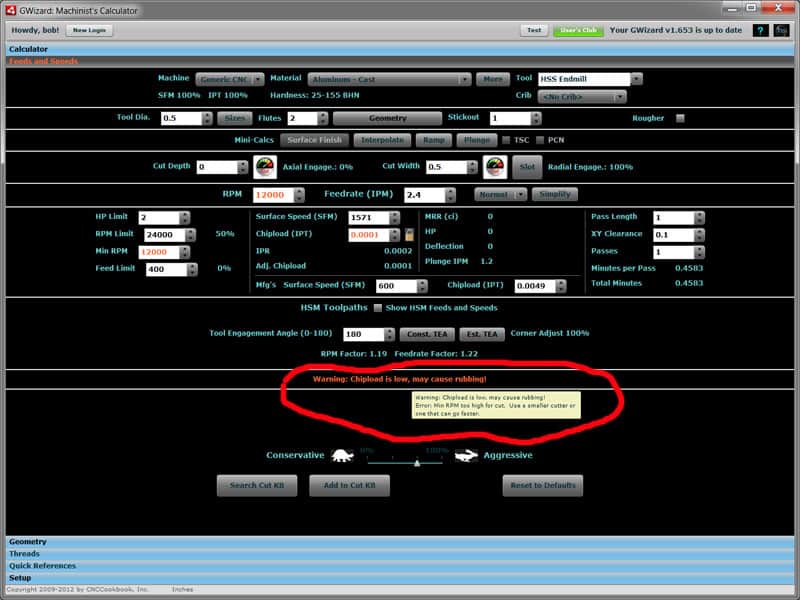

- Added a new Hint that warns when chipload falls to less than 20% of Mfg's Recommended (or G-Wizard's Recommended) chipload. Chiploads this low can lead to rubbing.

- The Tool Tip for Hints (popup when you hover mouse over it) now shows all the Hints messages. It's possible for there to be too many to display in the 1 line Hint area and we've gotten to a point where GW has a lot of Hints to offer.

- Version checking machinery was changed to work using version numbers instead of dates. The latter are prone to error when the date on the machine is not set correctly.

- Tweaked Thermal Expansion Calculator and a variety of other areas to work better for metric users.

- Reset box used to specify tap type when switching from end mills to taps. The same box denotes a rougher for end mills and it was confusing not to reset it.

- Tweaked a variety of Tool Crib issues based on user feedback. Also fixed import/export of the user defined fields.

- Improved Ramp Mini-Calculator to allow longer ramp lengths.

8/6/12: Release 1.651

Release 1.651 is a bug fixing release with a minor feature:

- Rewrote the Geometry applets so you don't have to clear every entry each time to try a new value. Instead, whenever a value is changed, the override padlock comes on like in Feeds and Speeds. You can change to your hearts content. To clear the override, just click the padlock.

- Fixed several user reported bugs including one where the geometry menu wouldn't clear when tool type was changed.

7/5/12: Release 1.645

Release 1.645 is a bug fixing release with a few minor features:

- Changed the Geometry pulldown (used to access alternate cutter geometries like ballnose or V-bits) to be a button with a popup. Added the ability to specify a custom shank size to be used when the shank is smaller than the tool diameter for deflection calculations.

- Added some new materials to the Materials Database: D2 Steel - Annealed (Tool Steel category), Custom 465 Stainless (under the 17-4 PH category), Caldie (Tool Steel category).

- Added pre-defined machine profiles for several Haas CNC machines, Tormach PCNC 770, Taig Mill, and RF-45 mills.

- Fixed some bugs associated with the warning that rpms are too slow for spindle.

5/21/12: Release 1.641

Release 1.641 is a feature release:

- Added the ability to enter Manufacturer's recommended chipload and surface speed right on the front page of G-Wizard. I'll be doing a revised video and updating the docs shortly to describe how to use this feature. For now, if you want to use the feature, enter chipload and surface speed from manufacturer's catalog without any adjustments for a normal (non-slotting) cut. G-Wizard will make the adjustments needed for the particular cut conditions (depth and width of cut) you describe. The Manufacturer's numbers will show unadjusted while G-Wizard's surface speed and chipload will show the adjusted values. Manufacturer's numbers are saved in the Tool Crib, so you only have to enter them once.

- Revisited tapping and bumped up the speeds in a number of cases, particularly where carbide taps are in use. GW was being too conservative there.

- Added support for Ctrl-X, C, V (Cut, Copy, Paste) to various fields that were missing it.

- Fixed a couple of cases that weren't switching between metric and Imperial properly.

- Added a simple servo and stepper motor sizing calculator under Quick Reference. Check out the new Motor calculator tab. I'll add more there over time.

4/11/12: Release 1.635

Release 1.635 is a feature release aimed at CNC Router users:

- Added downcut, compression, and straight flute router cutters to the endmill geometry selector.

- Added the ability to specify a minimum spindle rpm.

- Increased limits on max feedrates and rapids for metric users.

- Removed the chip thinning checkbox. You should always compensate for chip thinning, so it is always on.

- Fixed some bugs on the cut time estimator having to do with improper rounding.

- Added Rene 41 (High Temp Nickel Alloy) to Materials DB.

2/20/12: Release 1.630

Release 1.630 is a minor feature release:

- We've added buttons so you can go to the correct web page to Purchase G-Wizard as your trial is running out or to renew your subscription if it is running out. It's also easy to see how many days are left on your trial or subscription as they draw to a close.

- Added a button to the "Search KB" popup to show all entries.

- Re-evaluated the Rougher Endmill performance and upped the feedrates for it.

- Added 4 user-defineable fields to the Tool Crib so you can track extra information of your own choosing. One customer wanted this to be able to track the quantity of particular cutters he had on hand. To use it, click the "Optimize" button and you can name the fields. All cribs use the same field names. The 4 fields are scrolled all the way to the right.

- Cleaned up some rounding issues for the Bolt Circle calculator.

- Fixed a bug in tool deflection calculations where we had assumed the body of indexable tooling was made of carbide instead of steel.

- Fixed a problem with CSV exports of Tool Cribs and CutKB.

1/1/12: Release 1.621

Release 1.621 is a bug fix release:

- Fixed a bug where the install link sometimes wouldn't appear on mandatory releases.

- Fixed some bugs associated with saving or accessing ballnose and other non-standard geometries in the Cut KB.

- G-Wizard now rechecks the server whenever you change your login. Older versions sometimes required you to exit and restart to force it to check with the server.

In addition, two minor things were added:

- The smallest Surface finish on the scallop height ballnose calculator was reduced from 0.0001" to 0.00001".

- We added EN45 and 9260 spring steels to the Materials DB by request.

1/1/12: Release 1.620

Release 1.620 is a minor feature and bug fix release:

- Renamed "Cap Screw" tab to be "Fasteners" under "Quick Reference".

- Added 2 new columns to "Fasteners" database that lists the drill size for normal fit and close fit.

- Added buttons that appear for the flat head cap screws that will take you to the chamfer calculator with parameters already filled out for depth and angle.

- Fixed a bug where the Geometry menu did not display the correct choices in the Cut KB and Tool Crib.

- Fixed a bug where exporting the Cut KB to a .csv file sometimes gave errors.

- Fixed a bug where going from "Normal" to "Rigid" actually was slowing down feeds and speeds for ballnose and other geometries.

12/18/11: Release 1.611

Release 1.611 is a bug fix release.

12/4/11: Release 1.610

Release 1.61 fixes some bugs in the V-Bit support and adds Dovetail cutter Feeds and Speeds.

11/23/11: Release 1.603

Release 1.603 is a bug fix and fit and finish release:

- Updated some areas on the Cut Optimizer and Setup to be in metric.

- Eliminated the optimization button from Cut Optimizer. It will automatically recalc if you change any parameter on the popup.

- You can now see how many HP your G-Wizard Lite subscription will be able to handle in the Setup About box. If you subscribe to G-Wizard, you automatically get an additional GW Lite HP for each year of subscription you purchase in G-Wizard. If you let the GW subscription lapse, the product will still operate as GW Lite, but it will be restricted in the amount of HP it can calculate for a cut.

- Extended the timeout on the calls back to our Cloud so that it is less likely GW will complain of needing a connection in cases where the connection is just slow.

11/5/11: Release 1.601

Release 1.601 is a bug fix release. The spindle power interpolation wasn't quite right.

I also added a direct EXE download for Windows users to bypass the installer for those whose popup blocker interferes.

10/30/11: Release 1.600

Release 1.600 is a feature release:

- Added a new tool type for lathes: Parting/Grooving. Nothing too special here, just support for a very common operation on lathes. The hints will remind you that you can run OD grooving (not parting) a little bit faster than ID grooving.

- Reworked the adjustments to spindle HP and added a new type. You now have 3 choices:

- No Adjustment: Use the peak power at all times.

- Weight Adjusted: Look at the machine's envelope and weight and de-rate lighter weight machines. Folks with small machines like Taigs, Sherlines, and the smallest Siegs report this helps a lot.

- Power Curve Adjusted. You may model a power curve with one peak. Set Low RPM to the lowest rpm your spindle can do, Low HP to the HP (or KW for metric users) at that RPM, Peak RPM to the rpm of your machine's peak power, Peak HP to the amount of power available at the peak, High RPM to the spindle's fastest rpm, and High HP to the HP at the High RPM. G-Wizard will then interpolate the available HP Limit based on the rpm selected in feeds and speeds. This is helpful on single speed machines with very peaky power curves. If you have more than one speed, you could try a different machine profile for each speed.

- Added Aluminum 6082 in O, T4, T451, T6, and T651 conditions to the Materials DB. Also added FX-XTRA from A Finkl to the Materials DB.

- Fixed a bug in the ballnose scallop calculator where it was being way to conservative on calculated stepover. Thanks Kvom!

9/18/11: Release 1.550

Release 1.550 is a feature release:

- The major new feature is the "Notebook" tab under QuickRef. Notebooks let you bring in your own reference information to G-Wizard so it'll be handy. By default, every notebooks has a link to CNCCookbook's home page, the Doc Page for the software, and the Release Notes for the software. You add your own files or download data from our list. Initially, Notebooks support web pages, CSV files, and .txt (Notepad) files.

- Initial data available for download to your notebook includes: Imperial and Metric O-Rings, Shaft and Keyway Standards, and Split Lockwashers in Inch Sizes. If you have some worthwhile data to share, please forward it via email and we'll add it to the database.

- New tooling data was added for Titan Excelerator 601 endmills, Melin MVH Series 4 Flute endmills, and Imco M525's.

- Fixed some unit conversion bugs.

- Drill chart now shows a maximum of 3 (instead of 4) decimal places on metric measurements.

- Fixed a bug that caused paste to paste twice into fields.

- Added taper information for BT 30/35/40/45/50, CAT 30/40/45/50/60, and NMTB 30/40/50 tapers to the Taper Calculator under Geometry.

- Added support for V-Bits used by engravers. This has been a frequently requested feature. They're accessed by selecting an endmill, and then using the geometry pulldown to specify a V-Bit of appropriate tip angle. 30, 45, 60, and 90 degrees are supported. This is the same pulldown used to select a ballnose. Internally, G-Wizard will compute the effective diameter based on the cutting depth, angle, and overall tool diameter. Recommended depths for engraving are 0.005 to 0.010". Feedrates are adjusted down in light of the geometry of a V-Bit (it's crude compared to a helical endmill). If you have a particularly delicate tip or difficult workpiece, try setting the Gas Pedal slider all the way left. If you are running a spring-loaded engraving holder, you can as much as double the feedrate.

9/10/11: Release 1.545

Release 1.545 is a usability fit and finish release. It's been a while since we had a GWC release, and I have a pretty big feature in the works (Notebooks), but I didn't want to hold up these user-suggested revisions for that:

- Stickout is no longer locked when selecting a Tool Crib tool. It takes its default value from the Crib, but you can change it if you need to. Thanks Joe!

- The slot number (T# for a g-code program) appears on the item name for Tool Crib tools so you can easily see which one you're using when programming or working with your CAM package. Another one from Joe!

- Added a dedicated button to set up all the particulars for the MeshCAM integration. For MeshCAM users, this lets you set up clipboard copies from Feeds and Speeds in a format that MeshCAM understands. Got another CAM integration waiting in the wings for an announcement from the CAM manufacturer too!

- Fixed a nasty bug that made all the cap screw data disappear in metric mode. Sorry George!

- GW will now remember if it was maximized when closed and will restore that status the next time it is opened. Thanks Grant!

Expect another release of GWC fairly soon with Notebooks and perhaps a little more.

7/27/11: Release 1.540

Release 1.540 has several nifty new things:

- There's a new Cut Depth Mini-Calculator for turning.

- The HSM calculator is slightly changed. It no longer messes with SFM or Chipload-these are left as they were without HSM compensation. Instead, correction factors are applied to RPM and Feedrate. The amount of the multiplier for each is also now displayed in the calculator. This makes it easier to enter custom SFM and Chipload based on manufacturer's tooling recommendations and then apply the HSM multiplier downstream. Thanks to William for the suggestion!

- If you select a particular Alloy and Condition from the Materials DB, your selection will now be displayed below the Materials drop down.

- You can run G-Wizard for up to 2 weeks without an Internet connection. What's new in 1.540 is it will start to warn you 3 days in advance of when the 2 weeks runs out. This was based on feedback from customers who didn't want last minute hiccups with G-Wizard not running when they got in on a Monday. 3 days will let you know Friday to take care of it over the weekend if need be.

- Your Cut Depth is now limited to be less than Stickout.

- The number of decimal places on feedrate is reduced when in metric-there were too many and it made it hard to read sometimes.

- We added a "Made by CNCCookbook in America" notice because we're proud of our roots.

7/11/11: Release 1.53

Release 1.53 has a number of customer-suggested changes as well as some work under the covers to prepare for bigger features that are coming.

- Made a change so that manufacturer's data needs to be brought in via csv spreadsheet import. Manual editing within G-Wizard has been disabled. Over time, we've found it's just a lot easier and less error prone to edit the CSV sheets, so we're discontinuing support going forward for manual edits.

- Fixed a bug that could cause the default taper list to pop up empty sometimes for metric users.

- Add unit conversion for the remaining fields on interpolation so they all show in metric.

- The drill chart now has options to select inch or metric endmill sizes. This makes it easy to use the drill chart for setting endmill size. Since it handles more than just twist drills, the button is now called "Sizes".

- The old "ballnose" and "parabolic" check boxes have been changed to a single combo box that will be used to capture geometry options for tooling. At the moment, it only handles the ballnose on endmills and parabolic on twist drills, but this is how we'll handle a much larger variety of geometries in future releases.

- CSV import files used to only accept Imperial units. You now have the option to use metric on any column. For columns normally in inches, just add "-mm" to the column name and it will be in millimeters. For surface speed (e.g. SFM), you can use "-mpm" for "meters per minute." This should make dealing with manufacturer's tool data easier for metric users.

- Made a number of changes to make the tool information import more robust with better error checking.

- Made a usability improvement to Cut Optimizer so it has 3 radio buttons for the different options instead of 2 radio buttons and a checkbox-makes a lot more sense when you read it. Thanks Travis!

- It was possible when calculating tapping feeds and speeds for the feedrate to get out of sync with the rpms, which is a sure way to break a tap. I've now disabled overrides when tapping, and if the required feedrate is unavailable due to a limit, it will set the feedrate to "0" to signal there is a problem.

6/13/11: Release 1.52

Some really good stuff in 1.52:

- We've added a Plunge Roughing mini-calculator. Plunge Roughing is a very efficient roughing strategy for machines and setups where rigidity is a problem. This calculator will be in Beta for a while so folks can validate the results. I checked it against a number of online sources, and it seems conservative, if anything.

- We've taken the HSM constant tool engagement calculator out of beta-it's finalized now. The last step was to validate it not only with our own users, but with online data sources such as this database on the eMastercam group.

- We now suggest a twist drill size to use with reamers in the hint area at the bottom of feeds and speeds. This was a customer-suggested feature (thanks, John!).

- Another customer-suggested feature is the ability to select sheet metal gauges in the Weights and Volumes calculator. You select a gauge from the popup list and this sets the material thickness for further calculations. This also provides a handy reference for sheet metal thickness.

- Added units to the hardware profile page to make it more obvious what to enter.

- We now have support for Through Spindle Coolant (TSC) and Programmable Coolant Nozzles (PCN) like SpiderCool or Haas P-Cool. These can add a lot of productivity to a machining center, especially drilling holes. To use the features, you must indicate they're enable for you machine on the machine profile (Setup tab). You then access them with checkboxes just to the right of the mini-calcs.

- Fixed a number of customer reported bugs and made other minor tweaks for usability and appearance.

5/19/11: Release 1.51

This is a minor release that includes:

- Several bug fixes including improvements to the metric units handling around machine weights and rigidity adjustment.

- Correction to data for M16 threads.

- Added SA516 Group 70 to Low Carbon Steel. This is a pressure vessel alloy.

- Minor usability improvement: remember thread size when switching between internal and external threads.

5/10/11: Release 1.5

Version 1.5 of G-Wizard Calculator was just uploaded. I'm going to wait a few days before I activate the upgrade notices to make sure there are no issues.

There's several new things in this release, but the main reason I'm being cautious is there are code changes to the login to support our upcoming new login server which should register new users and new subscribers faster. We don't have the faster part working yet, but getting this out there is an essential part of the process.

Aside from the new login code, which ought not to be noticeable unless you look really closely (it should be a little faster as it transfers a lot less data to do its thing), we've added:

- A point angle tip based on materials that appears in feeds and speeds for Twist Drills. This tip also suggests split points or cobalt (HP HSS) for tough materials.

- The Geometry calculator was updated to make it easy to select standard twist drill point angles from a menu.

- Several fixes to bugs reported by customers.