Chamfer Mills or Chamfer Tools are an essential part of any CNC'ers tooling. They make it easy to put that nice chamfered edge on parts that is such a signature for CNC machined work. This Easy Guide tells you every thing you'll need to choose and use Chamfer Mills and Chamfer Tools.

What is a Fillet and a Chamfer? What about a Bevel?

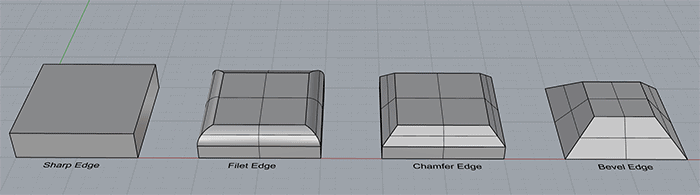

The easiest way to see the difference is with a picture of the different edge treatments:

What's the difference between a Fillet Edge, Chamfer Edge, and Bevelled Edge?

Here are the different types of edge treatments:

- A fillet is a radiused edge on the work piece. The profile is an arc.

- A chamfer edge applies a flat at an angle to the edge on the work piece. The angle is usually a 45 degree chamfer.

- A bevel occurs when the flat is the whole edge and there is no vertical wall.

Easy stuff, right? But terminology matters so it's important to lay it out.

What is the Purpose of Chamfering?

The most common reason to create a Chamfered Edge is to make sure they're not sharp. Machining operations can leave razor-sharp edges that can cut fingers and flesh.

Even if the edge is not too sharp, there may be burrs left behind by the machining process. Chamfering removes the burrs and saves on other methods of Deburring.

Sharp Edges and Burrs are often unacceptable for finished parts. Chamfer Mills can be an important part of deburring operations. If a print specifies "break all edges", chamfer the edges with a chamfer mill.

Another use for chamfers is to cause the head of a bolt to recess and be flat on a surface.

Chamfers are also more pleasing to the eye. They make the edge less delicate and harder to damage. If two pieces are to be welded together, put a chamfer along the welded joint for both pieces to support the welding process.

Chamfer vs Bevel

In comparing the two (i.e. Chamfer vs Bevel), recall that a Bevel occupies the whole edge, while a chamfer is just the top of the edge.

Bevel cuts can be decorative. They can also be used for safety, wear resistance, or to facilitate joining one piece to another.

Bevel cuts are necessary to fit moldings at angles and are a common joinery technique.

Chamfer cuts are used to ease an otherwise sharp edge for safety or to prevent damage. It is a very common edge design in the machining world.

Chamfers are always 45 degrees.

When Should You Choose a Fillet Instead of a Chamfer?

Fillets can be more expensive to cut. They involve more material removal and the corner rounding bits used to cut fillets are more subject to chatter, so Feeds and Speed must be less.

So why would you ever choose to machine a Fillet over a Chamfer?

The biggest reason is stress distribution. Chamfers do little to distribute stress whereas an arc for a Fillet is the ideal profile for stress distribution. Also, if a protective coating such as paint will be applied, the thickness will be more uniform over a fillet than a chamfer.

One last tip-chamfers are more forgiving if parts must be fit together than are fillets.

Chamfering Tools, Chamfer Mills, Cutters, and Router Bits

The tools, bits or cutters used to Chamfer Edges go by the names "Chamfering Tools", "Chamfer Tools", "Chamfer Mills", "Chamfer End Mills", "Chamfer Cutters", "Chamfer Bits", or "Chamfer Router Bits" if you're searching for them online. We'll just refer to them as "Chamfer Mills" from here on as they are a type of End Mill.

Typically, they look like this:

Chamfer Mill...

Chamfer Mills Can Have Multiple Uses

In addition to creating chamfers, a chamfer mill can be used for multiple machining operations including beveling, deburring, countersinking, engraving, and spotting.

Taking advantage of the multiple uses can reduce tool changes and save time on your job.

Chamfered Holes and Spot Drills for Chamfering

Most holes and especially tapped holes benefit from a chamfer to clean up an burrs and ensure a clean start for threads. Rather than using a conventional chamfer mill, holes are usually chamfered using a spot drill so the same tool can be used to spot the hole as well as to chamfer it.

Tip: When using the same tool to spot and chamfer a hole, make sure the angle of the chamfer bit is larger than the angle of the drill that will follow it.

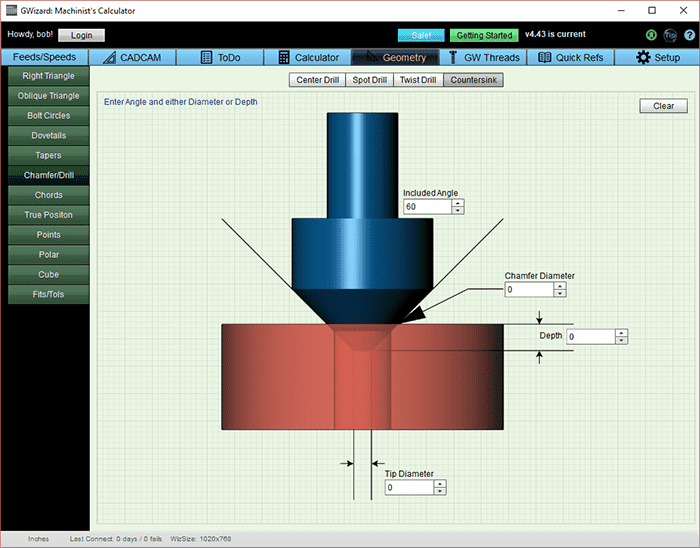

A calculator helps to determine the depth to spot given a desired chamfer and hole diameter:

Chamfer Mill Calculator

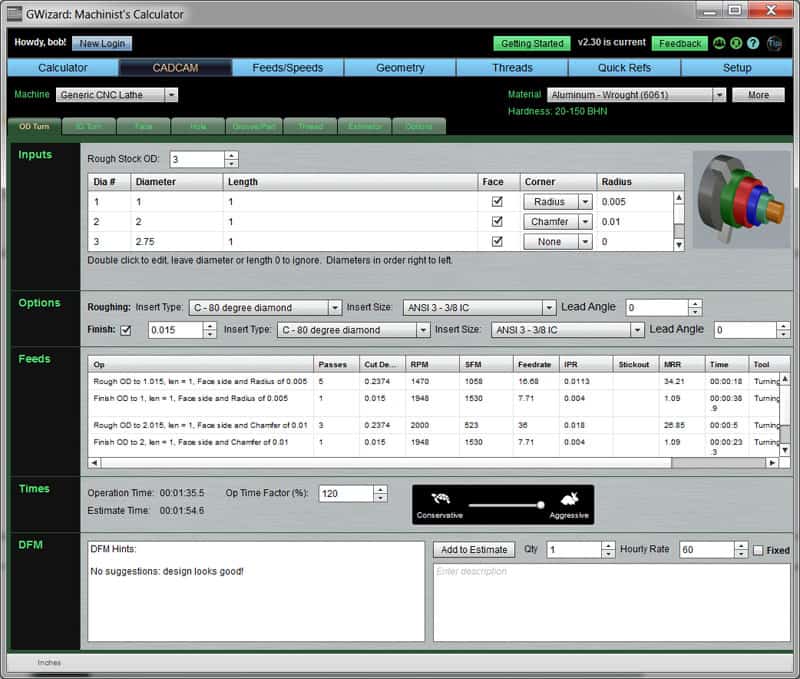

Our G-Wizard Feeds and Speeds Calculator includes a special geometry calculator that makes determining chamfer depth easy:

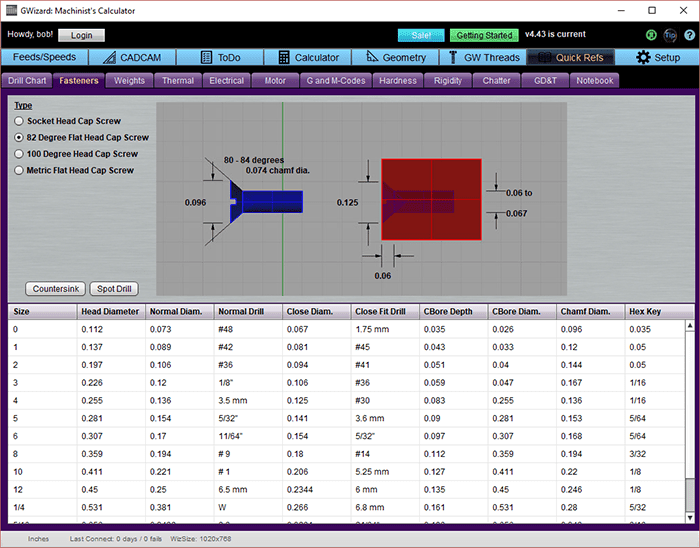

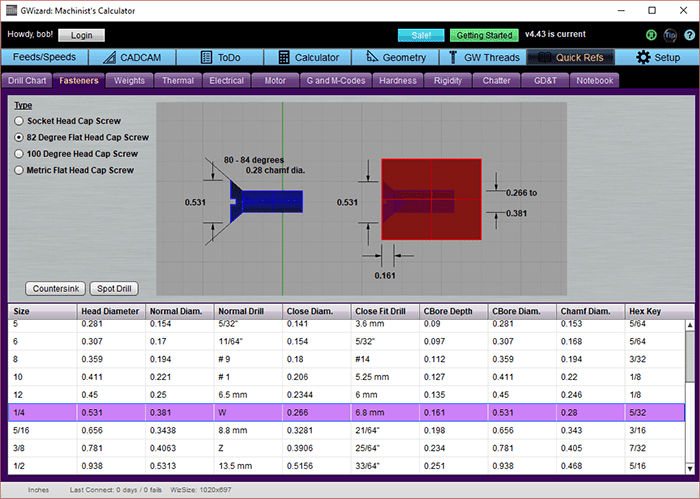

There's even a handy database to tell you how deep to counterbore for fasteners:

Try a Free 30-Day Trial of G-Wizard today. Even if you don't choose to purchase at the end of the trial, the chamfer mill calculator and fastener database will continue to work free of charge.

Chamfering Tool for Deburring

A chamfer mill is also a great deburring tool. There are a lot of ways to deburr, but using a chamfer mill as a deburring tool is one of the most efficient because the process can be completely automated. Manual deburring can be such a time consuming process, that it's no wonder using a deburring tool in a CNC machine is so popular.

The whole edge of the chamfering tool is available when used as a deburring tool. Only a very light depth of cut is needed, so higher feeds and speeds with long tool life are possible with deburring tools.

Combination Tools for Drilling and Chamfering

Combination tools save time by putting more than one function on the same tool. This avoids a tool change to access two tools. Whether you plan to interpolate a hole or drill it, you can get combination tools that have a countersink for chamfering on the same tool:

Combination single flute end mill and countersink...

Combination twist drill and countersink...

Of course it's important that the hole depth requirements be compatible with the tool. For example, a blind hole may not be deep enough to allow the combination countersink and twist drill to work.

Indexable Chamfer Mills

Like most other tooling categories, you can get indexable chamfer mills that use inserts that are cheaper to replace than buying an entire new solid chamfer mill.

Here's a typical Indexable Chamfer Tool:

It's a combination spot drill, chamfer mill, and engraving tool. Talk about saving some tool changes!

Chamfers for Lathes

With Lathes, putting a chamfer on an edge is simple and doesn't require special tooling. It's just part of the profile that needs to be cut.

Since the operation is so common, many CNC Lathes have a built-in capability to do chamfering and corner rounding (filleting) of edges. It's associated with the G01 command, and we discuss how to do that sort of programming in our Free Online CNC G-Code Programming Course.

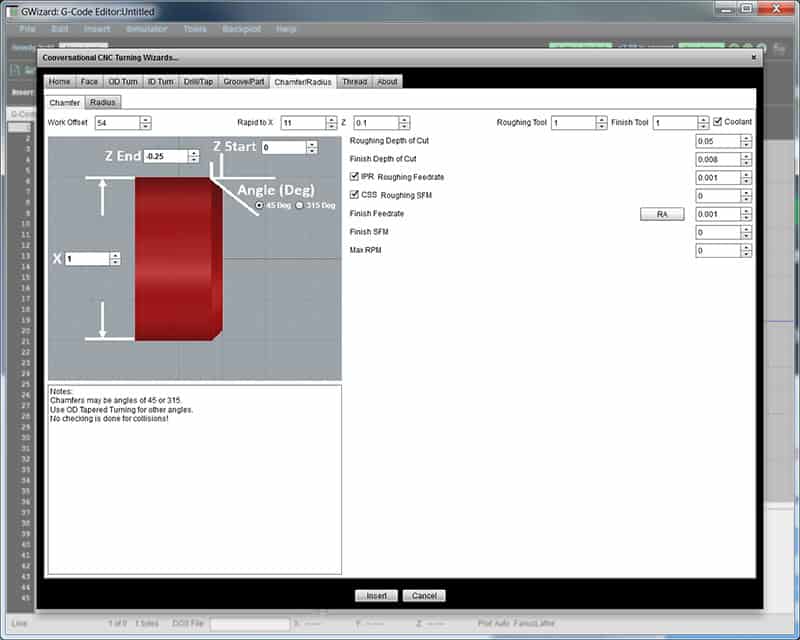

Conversational Chamfering for Lathes with G-Wizard Editor

Our G-Wizard Editor software includes Conversational Programming, which makes it easy to chamfer the edges when a series of OD's (Outer Diameters) are being cut:

Note how the "Corner" column near the graphic has options to treat the corner with a Radius (Fillet), Chamfer, or leave it alone.

If you need even greater control, try the Conversational Chamfer Wizard:

Here’s a video demonstrating the Chamfer Wizard in action:

Chamfer Feeds and Speeds

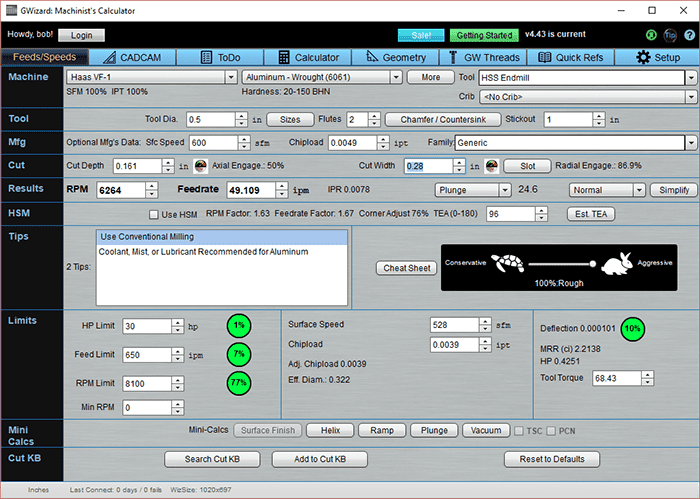

It's easy to figure Chamfer Mill Feeds and Speeds with G-Wizard Calculator:

Step 1: Choose Machine and Material

As you would for any Feeds and Speeds calculation, setup your machine and material first.

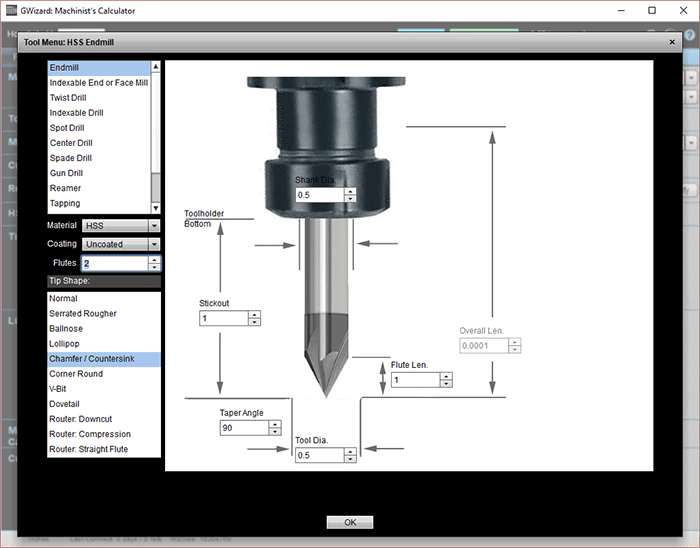

Step 2: Choose the Right Tool

Chamfer Mills are a sub-type of Endmills. So, click the tool selector, choose "Endmill" at top, set the material, coatings, and flutes, the choose "Chamfer/Countersink" from the Tip Shape menu.

Step 3: Use the Chamfer Depth Calculator or Fastener Database to find your Cut Depth and Cut Width

Suppose I'm cutting the chamfer on a 1/4" Flat Head Cap Screw. The Fastener Database says I need a counterbore depth of 0.161", Chamfer Diameter of 0.280" and an 82 degree angle counterbore:

Step 4: Read Off Your Feeds and Speeds

From that information, G-Wizard gives me the Feeds and Speeds to use:

Pretty easy stuff, right?

Frequently Asked Questions (FAQs)

When would you use a chamfer?

Chamfers are often used to create clearance for mating or connecting parts. They can also simplify the task of manually positioning parts during assembly. Finally, they prevent injury by eliminating sharp edges.

What is the most common angle for a chamfer?

Chamfers are almost always machined at a 45 degree angle.

What is the difference between a chamfer bit and bevel bit?

The bevel bit may be at an angle other than 45 degrees. If it has a 45 degree angle, it may be used interchangeably with a chamfer bit.

What are the advantages of chamfered edges?

Primarily improved safety. Chamfered edges eliminate sharp corners, burrs, and sharp edges that may cut careless fingers.

How deep should a chamfer be?

For milled chamfers, the default Chamfer depth is 0.1 inches of 3 mm.

How do you call out a chamfer?

Chamfers may be dimensioned in either of two ways:

- Calling out the length by angle. Here both the length (given by depth) and angle are called out.

- Calling out the length by length. Here it is called out by giving the actual depth of the chamfer. The angle is assumed to be 45 degrees.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.