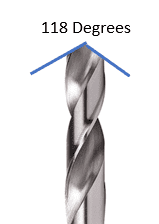

An important factor when choosing the best drill bits for your project is Drill Bit Angle. The two most common Drill Bit Angles, or to be precise, Drill Bit Point Angles, are 118 degrees and 135 degrees. The point angle is measured like this:

The choice of which angle to use is largely based on the material being drilled. The 118 degree point angle is more aggressive and is preferred for soft materials like wood on up to aluminum. However, the 135 degree angle will give a gentler cut which is better suited to harder materials. Using a 118 degree point angle in a hard material will result in excessive tool wear of your drill bits.

The gentler cut of the 135 degree point is because the flatter angle means the cutting edges come into contact with the hold more evenly and gradually than a 118 degree point.

The disadvantage of a 135 degree point angle is that the bit is more prone to walking around. This is the flip side of more gradual even contact of the cutting edge. You're more likely to need a spot drill or at least to center punch the hole. Grinding a split point can help to minimize this walking behavior. Using a more rigid setup such as a drill press can also help.

A split point drill bit has two additional edges ground into the chisel edge, which make the entire point of the drill one long cutting edge. This reduces the amount of pressure needed to make the drill cut. This style is also self centering which means the drill starts cutting without the need of a pilot hole.

So which twist drill bits are best?

According to Drill Doctor, some years ago most twist drill bits were 118 degree but now the 135 degree split point drill bits are the most commonly used angle. They say this was mostly a marketing ploy.

One more geometry-related tip for drill bits:

If you are drilling deep holes, you will find parabolic flutes are extremely helpful. See our article on deep hole drilling for many more tips.

If you have a choice of which style to use, you should take advantage of that choice. Our G-Wizard Calculator tells you the best drill point angle to use based on the material to be drilled.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.