Have you ever struggled with a drilling task, wondering why your standard drill bit just isn’t cutting it? Enter the split point drill bit - an innovative solution designed to overcome common drilling challenges while offering improved accuracy and stability.

Short Summary

- Split point drill bits are designed for precision drilling into hard materials, offering increased accuracy and stability.

- They feature a flatter point angle than standard drill bits and are used in industries such as aerospace, automotive, and electronics.

- When selecting split points it is important to consider material compatibility & size. Proper maintenance & sharpening will ensure optimal performance.

- Given their higher performance, split point drill bits are more costly than standard points and require sharpening more often.

Quick Video Summary

Understanding Split Point Drill Bits

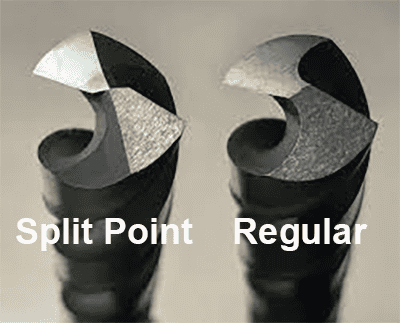

Split point vs regular drill tip types...

Split point drill bits are a game-changer in the realm of drilling. Unlike standard drill bits, which are more suitable for soft materials like wood, split point drill bits are specifically designed for drilling into hard materials such as metal and high alloy steels.

This is achieved through their unique design, featuring a flatter point angle and a rounder tip, providing increased accuracy and stability during drilling. Moreover, the two curving grooves on the shaft of a split point drill bit facilitate the removal of debris, leading to faster and smoother drilling.

But what exactly sets split point drill bits apart from their standard counterparts? Let’s delve deeper into the design features and benefits that make split point drill bits the go-to choice for many drilling applications.

Design Features

The design of split point drill bits centers around precision. They feature a flatter point angle of approximately 135 degrees, which is distinctly different from the standard 118-degree point angle found in standard drill bits. This flatter angle, often called spurs, helps reduce walking and enhances accuracy when drilling into various materials, ensuring a smooth surface.

In addition to the unique point angle, split point drill bits also have a tighter fit when drilling, making them perfect for high-precision applications. The split point design of the drill bit allows for easy and precise starting, which is essential for precision drilling. The combination of these design features makes split point drill bits the ideal choice for many drilling tasks.

Benefits

The benefits of using split point drill bits are numerous. First and foremost, their unique tip design facilitates easy and accurate initiation, making them suitable for a variety of drilling tasks on different surfaces. This means no more struggling with walking or slipping when starting your drilling project.

Moreover, split point drill bits, available at your local hardware store, offer reduced walking, quicker drilling, and enhanced anchoring in hard materials compared to standard drills. This is particularly beneficial when working with tough materials like metal, as it allows for faster and more efficient drilling of holes with less effort.

Ultimately, split point drill bits provide answers to an upgraded drilling experience that outperforms their standard counterparts.

Common Applications of Split Point Drill Bits

Split point drill bits have become increasingly popular across a range of industries due to their versatility and effectiveness. They are often used for drilling into harder materials such as:

- metal

- high alloy steels

- stainless steel

- aluminum

Their unique design makes them a preferred choice in precision manufacturing industries, where accuracy and stability are of utmost importance.

Whether you’re working on a construction project or a delicate piece of jewelry, split point drill bits can be the essential tool to ensure both accuracy and efficiency.

Drilling Hard Materials

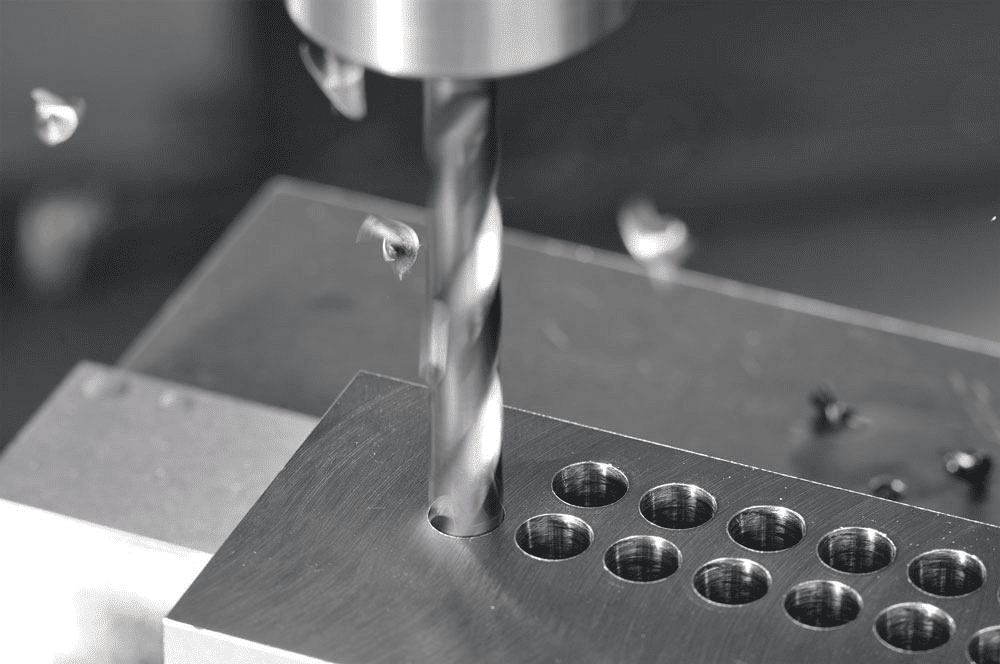

Split point drill bits are designed to handle the challenges of drilling through hard materials like cobalt steel and carbide. Their unique design features, such as the split point tip, aid in reducing walking and skidding when drilling, as well as reducing the amount of pressure needed to drill through hard materials.

This means that using split point drill bits for drilling hard materials not only provides increased efficiency but also reduces the risk of walking and skidding during the drilling process. In comparison to standard drill bits, split point drill bits clearly outperform when it comes to drilling through tough materials.

Precision Drilling

Precision drilling is another key application of split point drill bits. The tighter fit and reduced walking provided by the split point design ensure a more exact hole. This makes them an ideal choice for tasks that require a high degree of accuracy and control, such as in the aerospace, automotive, or electronics industries.

The split point tip features two additional edges ground into the chisel edge, creating a single long cutting edge that reduces the pressure required to make the drill cut. This self-centering feature ensures that your drilling project remains on point and precise, giving you confidence to tackle even the most complex tasks.

Tips for Choosing the Right Split Point Drill Bit

When selecting the right split point drill bit for your project, there are a few key factors to consider. Material compatibility and size are two essential aspects to take into account in order to ensure the best possible drilling outcome.

Understanding the design and benefits of split point drill bits is important, but it’s also crucial to choose the right bit for the job in order to achieve optimal results.

Material Compatibility

Material compatibility is a critical factor when selecting a split point drill bit since they are engineered for specific materials, such as metal or wood. A split point drill bit is suitable for a variety of materials, including stainless steel, cast iron, titanium, and even some soft materials, which are known for their tough nature.

To ensure the best outcome, it’s important to choose a drill bit that is compatible with the material you’re working with. This will help you achieve the desired results while minimizing the risk of damaging your drill bit or the material itself.

Size Considerations

Another important aspect to consider when choosing a split point drill bit is size. The size of the drill bit required will depend on the diameter of the hole that needs to be drilled. Common sizes include 3/16 inch and 3/32 inch.

When selecting the appropriate size, it’s essential to consider the specific drilling application and the material being drilled. By choosing the right size for your project, you’ll ensure optimal performance and accuracy in your drilling tasks.

How to Maintain and Sharpen Split Point Drill Bits

Inexpensive Drill Doctor can sharpen split point drill bits. About $149 on Amazon...

Proper maintenance and sharpening of split point drill bits are crucial for ensuring their longevity and optimal performance. This includes cleaning and storing the drill bits correctly and using appropriate sharpening techniques.

By taking care of your split point drill bits, you’ll ensure they remain a reliable and efficient tool for your drilling needs.

Cleaning and Storage

Cleaning and storage play a significant role in maintaining the performance of your split point drill bits. It’s recommended to clean your drill bits regularly to ensure their effectiveness. Removing any debris and organizing them in a dry environment helps avoid potential damage.

In addition to cleaning, proper storage is essential to maximize the lifespan of your drill bits. Split point drill bits should be kept in a dry environment, free from moisture and dust. By following these guidelines, you’ll ensure your drill bits remain in top condition for all your drilling projects.

Sharpening Techniques

Sharpening your split point drill bits is an important aspect of maintaining their performance. A variety of techniques can be used, such as using a grinder, drill bit sharpener, or oilstone.

When using a grinder to sharpen your drill bits, it’s essential to follow specific steps and use a wheel with a sharp enough corner. The recommended setting for sharpening the edges of the point angle of a split point drill bit is 155 degrees.

By employing proper sharpening techniques, you’ll ensure the longevity and optimal performance of your split point drill bits.

Summary

In conclusion, split point drill bits are an invaluable tool for drilling tasks that require precision, stability, and efficiency. With their unique design, they outperform standard drill bits when it comes to drilling hard materials and precision tasks. By choosing the right split point drill bit for your project and ensuring proper maintenance and sharpening, you’ll be well-equipped to tackle even the most challenging drilling tasks. So why not give split point drill bits a try and experience the difference for yourself?

Frequently Asked Questions

What is a split point on a drill bit?

Split point drill bits have two extra edges on their chisel edge, creating a longer cutting edge that requires less pressure to cut. This makes them ideal for drilling through hard materials such as steel, aluminum, and other metals. They are also great for drilling through wood, plastic, and other software materials. The extra edges also help to reduce the amount of time.

What is the advantage of a split point drill bit?

The advantage of a split point drill bit is its self-centering capability, which eliminates the need for predrilling in most applications, as well as its superior chip removal and lower cutting force compared to other drill points.

THis makes it an ideal choice for drilling into hard materials as it requires less effort and produces a cleaner hole.

What is the hardest drill bit set?

Carbide is the hardest drill bit material, designed to drill into the toughest metals. It is mostly used for production drilling in high quality toolholders and equipment.

Can split point drill bits be used for drilling wood?

Yes, split point drill bits can be used for drilling wood, although they are primarily designed for harder materials.

How do I sharpen a split point drill bit?

To sharpen a split point drill bit, use a grinder or drill bit sharpener.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.