Table of Contents

Drilling Feeds and Speeds Calculator

Introduction

Sharpening

Pre-Drilling & Pilot Holes

Annular Cutters

Through Spindle Coolant

Entry Conditions

Point Angles & Types

Spot Drilling

Deep Holes

Note: This article is Lesson 9 from our Free Feeds and Speeds Master Class. It contains information applicable to all twist drills. For specific information on Carbide Drill Feeds and Speeds see the linked article.

Introduction to Twist Drills and Chip Formation

The lowly twist drill is one of the most commonly used tools in the machinist's arsenal. By all accounts, it also has some of the highest material removal rates of any of the tooling available. As such, it's worth getting to know them a little better.

For general information about twist drills, check out our Guide to CNC Twist Drills and Holemaking. If you want the scoop on how to maximize twist drill performance, you're in the right place.

The number one factor affecting twist drill performance is chip formation and evacuation. The deeper the hole, the more likely chips can jam. The ideal chips are short curled chips because they evacuate the most easily. Listen to your twist drill for a steady sound. If the sound starts and stops, you're getting some chip jamming. Also, take a look at whether nice curled chips are coming out or there are bent chips. The latter is an indication of jamming.

Entry Conditions

Depending on the condition of the surface, feedrate should be varied to accomodate the surface. Examples:

- Irregular or Rough Surface: Cut the feed (chip load) back to as low as 1/4 the normal feedrate to avoid chipping the twist drill.

- Convex: Convex surfaces are hard to do unless the radius of the convex surface is greater than 4 times the drill diameter and you're entering perpendicular to the convex radius. If this is not the case, mill a flat spot for the drill to get started on before attempting to drill.

- Concave: Don't attempt a concave surface unless the radius is more than 15x the drill diameter and the drill is centered on the concavity and not the wall. You can drill the wall of a concave surface. Reduce feed (chip load) to 1/3 when entering. If the surface doesn't meet these requirements, mill a flat before attempting to drill.

- Angled: Treat entry and exit of angled surfaces the same. If entering or exiting an angle surface of 2 to 5 degrees angle to the tip or less, reduce feed (chip load) to 1/3 of normal to accomdate this interrupted cutting condition. For surfaces angled 5 - 10 degrees, ideally use a drill whose point angle matches the angle of the surface. If the angle is more than 10 degrees, you'll need to mill a flat before drilling.

Note: You can save a step on angled surfaces by using a Flat Bottom Drill Bit. They don't need you to mill a flat before drilling.

Keep ‘Em Sharp!

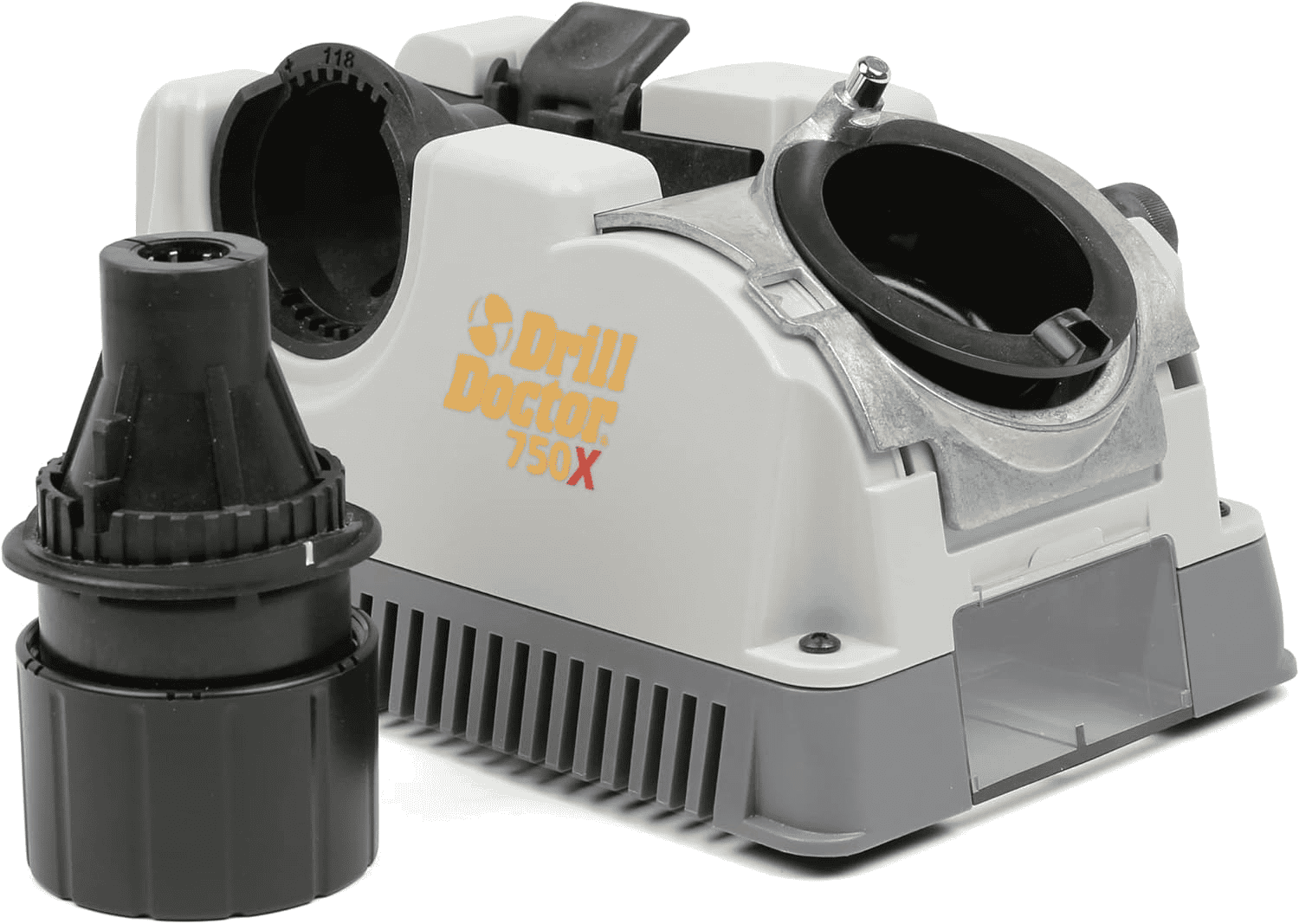

One of the easiest ways to improve twist drill performance is to make sure their cutting edge stays sharp. You'll be using the heck out of your Twist Drills and nothing is more annoying than a dull bit. There's a lot of life left in the twist drill if you can sharpen them. Drill bit sharpeners are available at every price range or you can sharpen by hand at the grinder. I use a Drill Doctor which is cheap and cheerful, has all the right adjustments, and makes it super easy to have sharp twist drills on hand at all times.

You'll be amazed at how much your actual results improve with sharp tools!

Use the Right Point Angles and Point Types

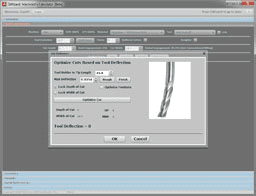

Each different workpiece material will benefit from being sharpened with different drill bit point angles. Being able to deal with the different cutting edge angles is one reason to have a sharpening machine on hand, or to have good facility with hand sharpening the drills. You can look up the best point angle for the cutting edge in references like the Machinery's Handbook, or you can use our G-Wizard Calculator to tell you the right point angle for any given workpiece material you've chosen:

G-Wizard recommends either a split or notched point with a 135 degree angle for 300 series stainless steel...

In addition to the angle, the point type is also useful in maximizing twist drill performance.

Regular point on the left, split point on the right...

The more exotic points require a little more effort, but they are an aid in self-centering the bit, they reduce cutting forces, and they break chips better.

Pre-Drilling, Pilot Holes, or Step Drilling Holes

There's a lot of controversy around this practice. Should you pre-drill a pilot hole or not? What about step drilling?

The value of the pilot hole is to reduce drilling forces around the center of the hole and hopefully, to more accurately position the drill. The effectiveness of a pilot hole is dependant on the size of the pilot relative to the larger twist drill that will follow. In general, pilots are discouraged for holes smaller than 1" (25-30mm). If you're drilling such a smaller hole, just go for it without a pilot. That's not to say you might not benefit from spot drilling (see below), but that's different than a full depth pilot hole.

Why discourage pilots? Because chip breaking doesn't proceed correctly if the pilot hole is too large relative to the overall hole and because it's faster to go without the pilot for holes smaller than 1" or so. If you're seeing the issue with chip breaking, you can readily understand that step drilling, where you make multiple passes in the hole with increasingly large bits is also discouraged.

There is a case where a pilot hole can be helpful for all hole sizes. When you're drilling more than 7 x Drill Diameter in depth it can be helpful to do a small pilot hole to a depth of 2 x Drill Diameter. G-Wizard will automatically offer this tip when appropriate.

When drilling a pilot hole, make the diameter a little larger than the web thickness of the big twist drill you're clearing the way for.

Spot Drilling and Other Techniques to Accurately Position Twist Drill Holes

Use Screw Machine-Length Twist Drills

The simplest way to improve the accuracy of your drilling is to use screw machine-length twist drills instead of jobber length. The shorter bits will flex less and are therefore more accurate. The full length of a jobber-length twist drill is seldom used anyway when metalworking as the jobs gets more challenging in a hurry the deeper the hole.

Spot Drill the Hole

If you use a carbide drill or a screw machine length drill, spotting is typically not needed. As a matter of fact, most manufacturers will recommend against spot drilling a carbide drill or an insertable drill because the spot-drilled hole is more susceptible to chipping the carbide. You can save a lot of time by avoiding spot drilling.

If you must, use a spot drill to locate the hole. While many manual machinists use center drills for this purpose, a true spot drill with no small-diameter pilot is a better bet. The center drill is a specialized tool for producing holes for lathe centers. Its small diameter pilot is delicate and center drills are unnecessarily more expensive than spot drills.

You want to use a spot drill whose angle is the same as or greater than the twist drill's point angle. The reason is that you want the twist drill to make contact with the spot drill's hole at the tip, not the edges, for best centering.

You should consider avoiding a spot drill when using a solid carbide drill or when drilling workpiece materials that work harden easily.

For more, we have a special Spot Drilling page too.

Tip: Annular Cutters or Interpolation for Large Through Holes

Cutting forces go up in a hurry with larger hole sizes. Not much will tax the machine's horsepower limits more than loading up a great big twist drill, or worse a big spade drill to make a large hole. Cranking a 2" indexable drill through 300-series stainless steel takes 8HP, for example.

There are two good alternatives, depending on whether you need a through hole or a blind hole. For through holes, the best bet may be an annular cutter:

The annular cutter removes a slug by creating a ring-shaped hole and leaving the center intact...

Because they don't have to turn the whole hole into chips, just the circumference, annular cutters can move a lot faster and with a lot less power than an equivalent sized twist drill. Unfortunately, if they don't go all the way through, there's no way to extract the slug that's left, so they're only good for through holes.

The alternative for blind holes (which also works on through holes, just not as fast) is to use an endmill and interpolate the hole.

Through Spindle Coolant

Whether you're trying to drill a deeper hole or just drill faster, Through Spindle Coolant can make a huge difference in your speeds and feeds results. G-Wizard Calculator is the only Speeds and Feeds Calculator that is set up from the start to handle Through Spindle Coolant.

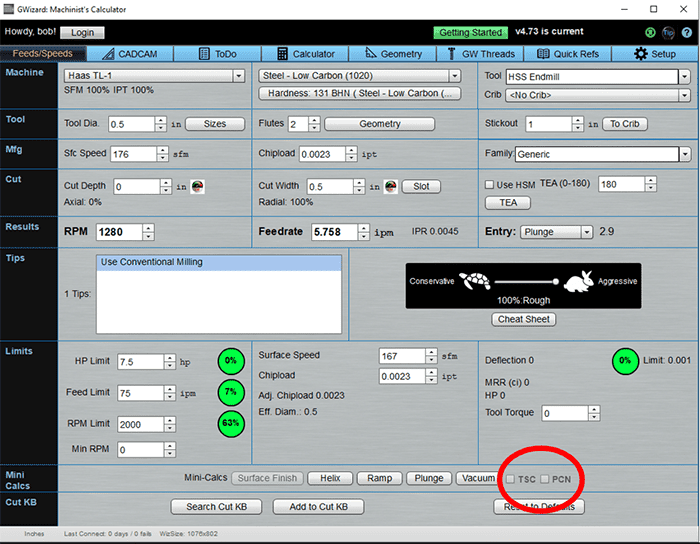

The red circle shows G-Wizards Through Spindle Coolant (TSC) option...

Switching on the TSC option for a basic cut in a workpiece material of 6061 aluminum took spindle speed from 9980 rpm to 11277 rpm and feed rates from 71.854 to 93.375. That combination took the Material Removal Rate from about 18 cu in/min to 23.3 cu in/min. That's almost a 30% increase without changing the cutting tool-nothing to be sneezed at for productivity!

For more on Through Spindle Coolant see our article on CNC Coolant.

Techniques for Deeper Holes

What is a Deep Hole?

A deep hole is any hole that is more than 5 diameters deep. The deeper the hole, the more difficult chip extracton becomes. Because of this, you should be reducing your speeds and feeds the deeper the hole gets.

Here is a handy table summarizing techniques for drilling deep holes:

For full details, check out our Deep Hole Drilling Guide or our Peck Drilling guide.

Drilling Speeds Feeds Calculator

You've found our simple free online Drilling Speeds and Feeds Calculator that uses the classic cutting speed formulas taught in shop class for things like surface speed to rpm. With a calculator, you don't need to worry about how to calculate spindle speed or feed rate. Just key in the parameters and our calculator will give you the feeds and speeds.

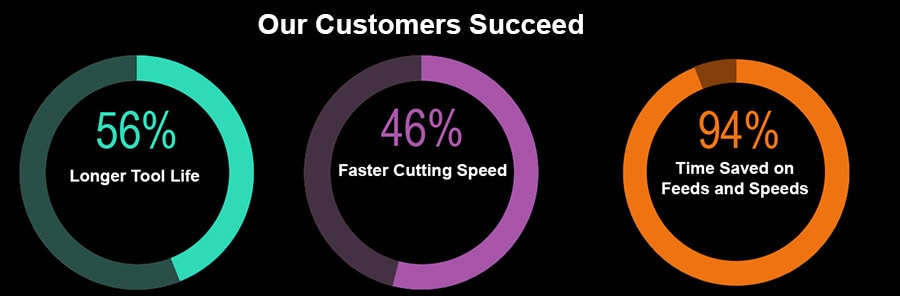

We offer both that free online drill feeds and speeds calculator using simple shop formulas, and also a free (for a limited time) full-featured calculator that is the industry leading speeds and feeds calculator. It’s used daily by thousands of the world’s best manufacturers.

They know what they’re doing and wouldn’t waste time or money if the software didn’t work.

The thing is, why use that simple free calculator when you could grab our full-featured G-Wizard Feeds and Speeds Calculator completely free for 30-days? It will give you the best results possible for your specific material in imperial units or metric units. While the simple free calculator can only do high speed steel as a tool material, G-Wizard handles all the others such as Cobalt and Carbide. For almost any specific application, it beats the simple calculator hands down.

How do you lose with that deal?

It takes just 37 seconds to download and start using G-Wizard. It costs you nothing and you can get great feeds and speeds from it for the next 30 days. If you want to go back to our free online calculator after that, no worries.

But you may as well drive the high performance model as long as it’s free, right?

G-Wizard Has Features for Each Machine Type

Still not convinced? Consider that G-Wizard has specific features for each machine type. In effect, you get 3 Calculators in one:

-

Turning Speed and Feed Calculator

-

CNC Router Feeds and Speeds Calculator

-

CNC Mill Feeds and Speeds Calculator

Click through each of those to see features tailored by machine type.

Or, just use our simple online drill speeds and feeds calculator below:

Drill Speeds and Feeds Calculator [HSS Feeds and Speeds]

Drilling Feeds and Speeds

Spindle Speed Calculator

Drill Diameter>inches**Surface Speed:SFM (see table below for workpiece material SFM values)Spindle Speed / Drilling Speed:>RPMSpindle RPM Formula = (12 * SurfacceSpeed) / (PI * CutterDiameter)**Tip: On a turning operation using constant surface speed set a maximum speed on smaller holes so things don't get too crazy.

Feed Rate Calculator

Spindle Speed:>RPMFeed/Tooth (Chipload) from workpiece material table below:>IPT (inches / tooth)Number of Flutes (Teeth):>**Feed Rate / Drill Feeds:**IPM (inches / minute)Feed Rate Formula = Chipload * NumberFlutes * RPM

Drilling Surface Speeds for HSS Twist Drills

Workpiece Material

Surface Speed (SFM)

Aluminum - Wrought (6061)

250

Brass

200

Cast Iron - Ductile

80

Cast Iron - Gray

120

Copper Alloy - Wrought

70

Magnesium Alloy

250

Stainless Steel

30

Steel - Mild

110

Steel - Hard Alloy

60

Steel - Tool

60

Need a Material Not Listed? We Can Help!

Drilling Chip Load for HSS End Mills

Workpiece Material

Chip Load (IPT)

Aluminum - Wrought (6061)

0.005 - 0.010

Brass

0.005 - 0.010

Cast Iron - Ductile

0.004 - 0.008

Cast Iron - Gray

0.002 - 0.006

Copper Alloy - Wrought

0.004 - 0.008

Magnesium Alloy

0.005 - 0.010

Stainless Steel

0.002 - 0.006

Steel - Mild

0.002 - 0.010

Steel - Hard Alloy

0.002 - 0.006

Steel - Tool

0.002 - 0.006

Note: Chipload should be adjusted for hole depth. Deeper holes tolerate much lower chip loads! You can look this up in the manufacturer's catalog, or we can help. CNC Feeds and Speeds Chart Wood Not Sure the Correct Value for Your Cutter? We Can Help!

Hang on: You Deserve Better!

Show Me How to Improve Speeds and Feeds for:

How to Calculate Feed Rate for Drilling?

Wondering how to calculate feed rate for drilling? Perhaps so you can create your own spreadsheet?

The basic feed rate formulas for drilling are simple, but getting real-world feeds and speeds are quite a bit harder. We give you all the basic formulas in our free online Feeds and Speeds Course.

Want all the best tips and techniques for Twist Drills? Read our Twist Drill and Hole Making Guide here.

More Feeds and Speeds Calculators

-

G-Wizard Feeds and Speeds Calculator

-

Milling Speeds and Feeds Calculator

-

Chip Load Calculator

-

Simple Feeds and Speeds Calculator

-

Lathe Feeds and Speeds Calculator

-

Drill Feeds and Speeds Calculator

-

Tapping Feeds and Speeds Calculator

-

Master Feeds and Speeds Calculator List

Drilling Feeds and Speeds FAQ

How deep can a twist drill go?

Twist Drills can go down 5 diameters deep without issue. From 5 to 7 diameters, you should use Peck Drilling. From 7 to 10 diameters, use a parabolic flute drill with peck drilling. Any deeper will require a Deep Hole Drilling Technique.

How can I avoid work hardening when drilling?

Never stop feeding while the drill is in the hole. If you pause or dwell, the action of the drill tip rubbing without cutting will work harden the workpiece material making further drilling much harder.

How can I increase my drilling feeds and speeds?

To increase feeds and speeds, use drill bits made of Cobalt or even better Carbide. These tool material are much harder than high speed steel. Coatings can also increase the performance of the drill bit.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.