Free Tap Speed and Feed Calculator

TPI (Threads per inch)

Spindle Speed:

RPM

Feed Rate (Feed Calculator):

IPM

Tap Feeds and Speeds Basics

Tapping Feeds and Speeds are pretty easy to calculate because they're constrained by the thread that is being tapped. Everything starts from Tapping Speeds

What Tapping RPM or Tapping Speed Should I Use?

The spindle speed depends upon the material you're trying to tap and the diameter of the tap. For a more sophisticated calculator that will figure that out for you as well as help you find the right TPI value and work in Metric, keep reading!

Recommended Surface Speeds (SFM) by Material

We can find the recommended surface speed to tap many workpiece materials in this table:

Aluminum - Cast Alloys 60

Aluminum - Diecast Alloys 70

Aluminum - Wrought Alloys 80

Brass 60-100

Bronze 30-40

Copper 60-80

Gun Metal 50-60

Cast Iron - Grey 30-60

Cast Iron - Ductile 50

Cast Iron - Alloys 15-30

Malleable Alloy 20-40

Magnesium Alloys 50-70

Nickel Alloys 10

Nimonic Alloys 10-12

Mild Steel 30-50

Steel - Medium Carbon 35

Tool Steel 15-25

Cast Steel 25

Titanium Alloys 10

Stainless Steel - 300 Series 10-20

Stainless Steel - 400 Series 15

Plastic 50-70

Zinc - Diecasting 80

Given SFM from the table, plus the tap's diameter, we can calculate rpm with this formula:

Spindle RPM = SFM / circumference of tap

circumference of tap = PI * tap diameter

BTW, that's from our article on RPM from Surface Speed if you want the details.

Tapping Feed Rate & Tapping Feed Rate Formula

Given the spindle rpm's the Tapping Feed Rate is just how fast we have to feed to move one full thread per spindle revolution. It's our spindle rpm divided by our threads per inch (TPI).

So if we're going 1000 rpm and cutting a 20 TPI thread, we need to advance 1000/20 = 50 IPM. That's our Tapping Feed Rate, and you couldn't hope for an easier feed calculator.

[ More Cutting Speed Formulas ]

Pro Power Tap Feeds and Speeds Calculator

Quick and dirty calculators like the one above are what you see most often on the web, but most machinists and CNC'ers need more than they can offer. That's why we make the G-Wizard Calculator, a serious power tool for folks like you.

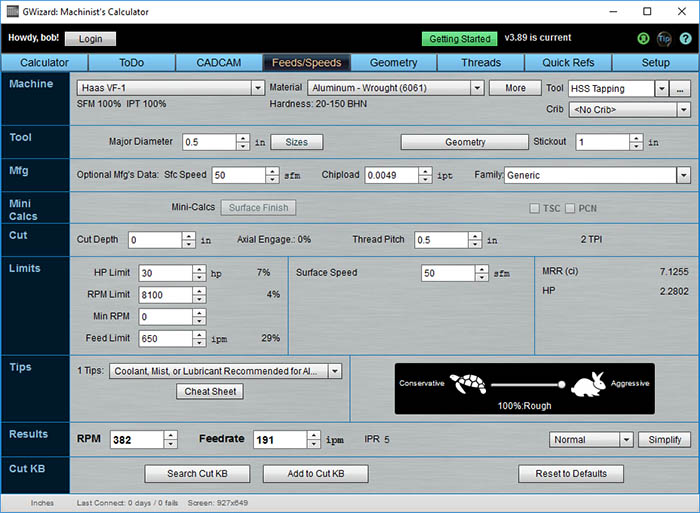

Here's what G-Wizard's Tap Speeds and Feeds Calculator looks like:

G-Wizard Tapping Speeds Calculator...

Capabilities:

- Handles both Form and Cut Tap as cutting tool

- Large Material Database

- Tortoise-Hare slider for pinpoint control in difficult materials

- Metric and Imperial units

- Gives Tapping Speeds and Feed Rate

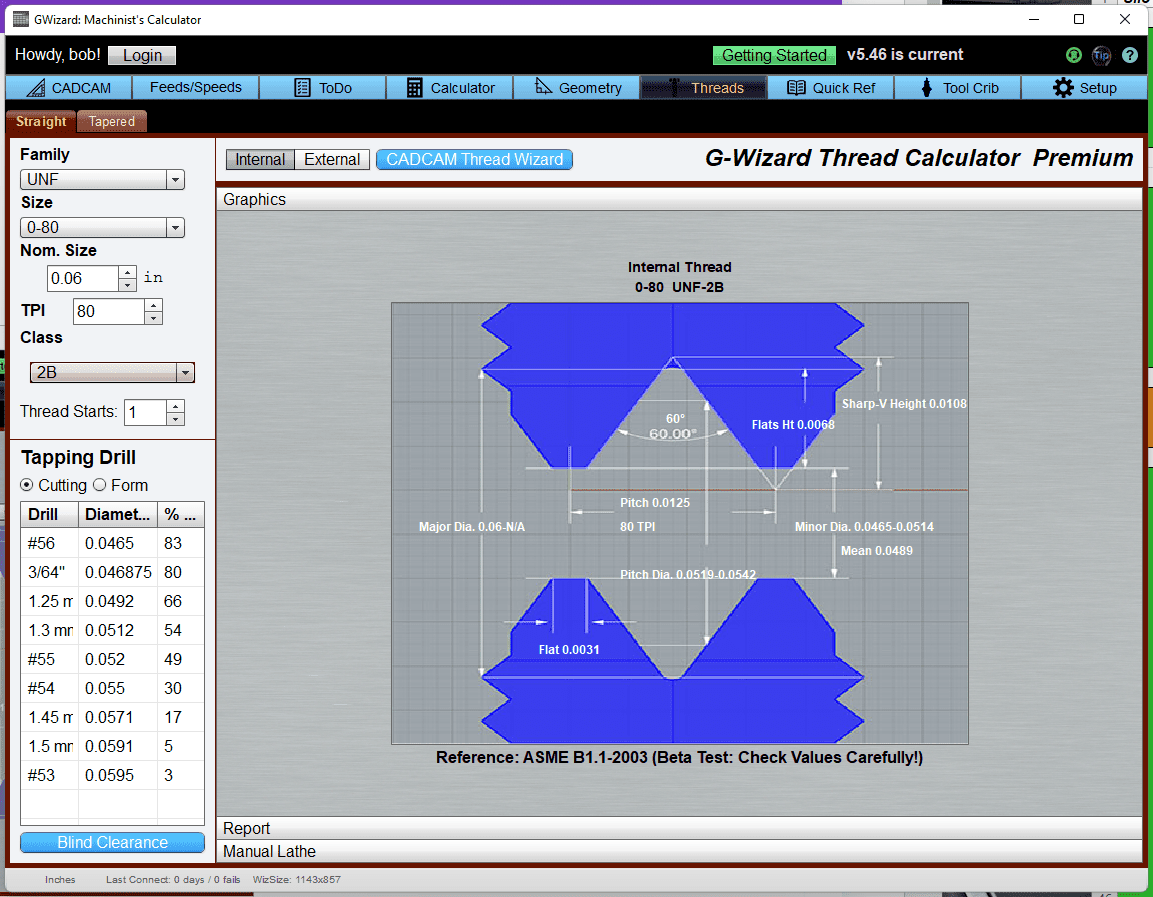

- Extensive Thread Calculator:

Extensive Thread Calculator...

The thread calculator includes tapping drill size recommendations with thread percentages for both cutting and form taps. Right now we're offering a very special deal on our Thread Calculator, so be sure and check it out:

Want to Avoid Breaking Taps?

Of course you want to avoid breaking taps. A broken tap can ruin your whole day. I hate it, but I have largely quit breaking them by using G-Wizard.

How?

It's because of that thread database with the % Thread info. Here's the dirty little secret of tapping:

The recommended hole size for tapping is usually not the best. There is no one perfect size, but you can often do a lot better by considering the thread percentage.

The deal with thread percentage is the recommended tap drill sizes you find in most online charts and on the tap packaging are for 75% threads. That's conservative from a strength standpoint, but aggressive from the standpoint of over-stressing your tap. Premium tap makers like Guhring actually recommend 60% to 70% percentage of thread for most applications because it significantly lowers the torque force required to tap without giving up much thread strength. That means you're way less likely to break the tap and you're sacrificing very little holding strength. You get much better tool life by slightly lower percentage of thread.

You can learn a bunch more from our article on tap drill sizes, but now you know enough to greatly reduce your chances of breaking a tap. It's impossible to optimize tool life without considering the thread percentage and by using proper tapping speeds. Your cutting tool will thank you if you do both.

Our G-Wizard Calculator includes this powerful Tap Speeds and Feeds Calculator and a whole lot more. Try this more powerful calculator (and much more) just by signing up for our 30-day trial. That's right-most of the calculators can still be used after the trial expires. For example, you can still access the Thread Database with it's percentage of thread table.

To sign up, simply visit the G-Wizard page.

Need to Program Tapping on a CNC?

We've got you covered with this great article on tapping g-code. It even includes information on our easy Conversational CNC Wizard for tapping.

More Feeds and Speeds Calculators

-

G-Wizard Feeds and Speeds Calculator

-

Milling Speeds and Feeds Calculator

-

CNC Feed Rate Calculator

-

Chip Load Calculator

-

Simple Feeds and Speeds Calculator

-

Lathe Feeds and Speeds Calculator

-

Drill Feeds and Speeds Calculator

-

Tapping Feeds and Speeds Calculator

-

Master Feeds and Speeds Calculator List

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.