Let's shift our focus from Feeds and Speeds for a moment and discuss CNC Coolant. Regrettably, such liquid is referred to as "coolant" when the truth remains, cooling is its least significant function in machining.

Note: This is Lesson 10 of our Free Email Feeds & Speeds Master Class. Click here to learn more about the Master Class.

Here's a quick video intro I did for Cutting Tool Engineering Magazine on the role of coolants:

We use coolant for three distinct reasons:

The Role of CNC Coolant in Machining

Coolant performs 3 roles in machining[1](javascript:void(0))C S Reddy, Araveeti & D V, Paleshwar & Murthy, Kln & Sandeep, B.. (2020). A Review on Coolant Feeding System of CNC Machining Process. 10.1007/978-981-15-7827-4_44. :1. Chip Clearing: Spraying a cutting fluid at the cut helps move the chips out of the way of the cutter. Clearing chips minimizes recutting the chips. The chips already cut aren't getting sloshed around and slammed aginst the walls of the cut.

Recutting chips destroys surface finish and dulls tools much faster. In the worst case, a cutter down in a slot or hole can get clogged with chips and get much hotter or even break.

2. Lubrication: Some materials, like aluminum or some steels, are sticky. They have a chemical affinity for the cutter and will try to weld themselves to the cutter. Lubrication makes things slippery so the chips are less likely to adhere and weld on. Clearing chips makes adherence less likely too.

3. Cooling: Liquids are capable of carrying much more heat away from the cut than air. Plain water conducts heat 25 times more efficiently than air, for example. So water-soluble coolants are better at cooling than oil-based.

I put cooling dead last for a reason: cooling is the least important role of cnc coolant in CNC machining!

In fact, I was very pleased when Haas released a video called, "Haas Chip Clearing and Tool Lubrication." The video puts the emphasis where it should be and not on the cooling aspects of machine coolant. Finally, the word is getting out about what cnc coolant is all about!

Some machining operations, such as gun drilling, emphasize cooling even less. They are recommending a coolant (oil) that conducts half as well as water.

Chip Clearing: CNC Coolant #1 Priority

Chip clearing is by far the most important function. I cringe every time I see a cut where the chips pile up.

Sure, it's easier to photograph the action. But those piling chips are very hard on your cutter's life and can even lead to breakage.

If the cutter must recut the same chips over and over again, you’re much more likely to experience built-up edge (BUE). BUE is where chips weld onto the cutter. It's possible to use up all the chip clearance your cutter has available. The older chips have to compete with freshly cut chips, which can lead to cutter breakage.

At the very least, it means you can't cut as fast.

If your machine has no flood coolant, rig up an air blast or mist to get the chips out of there. Get paranoid about having too many chips around.

Most tooling manufacturers recommend you turn off the flood coolant when surface speed goes above a certain point[2](javascript:void(0))Application of coolants during tool-based machining – A review Khor Zheng Yang a, A. Pramanik a, A.K. Basak b, Y. Dong a, Chander Prakash c, S. Shankar d, Saurav Dixit e f, Kaushal Kumar g, Nikolai Ivanovich Vatin e. They say this will increase the life of your tooling. If it was all about heat, that shouldn’t be the case as more surface speed means more heat.

Lubrication: CNC Coolant #2 Priority

Lubrication helps the tool to cut more easily so it generates less heat. As the face of the tool slides across the workpiece, it rubs while cutting. As the chip curls up, it also rubs on the tool, generating more heat. All that rubbing will produce less heat with a little lube, as any sliding fit would.

Reducing heat is an important role for lubrication, but it’s not the most important one.

A much bigger role for lubrication is reducing the likelihood of Built Up Edge (BUE). This is a big deal as anyone who has seen a big wad of aluminum get welded to their cutter will attest to. Things stop working quickly when that happens!

Chips welded to the cutter...

Fortunately, BUE is material-specific. It applies mostly to Aluminum and low-carbon or unalloyed Steel. Titanium is another material that has a reputation for being sticky.

Use of sharp cutters with very high rake angles (positive rake is your friend!) can help reduce adhesion, but it’s not enough.

Many coatings used on tools can also provide lubrication. But coatings are fragile. They wear off or chip and shouldn’t be the primary answer to BUE. In the end, a little bit of mist can deal with this problem as well as flood coolant, so it isn’t the end of the world.

By now, you should realize you need to do something about lubrication before that wad of aluminum welds itself in all the wrong places.

I’ve heard many professional machinsts flat out declare you can’t machine aluminum without some form of lubrication. Even a little spritz of WD-40 makes a big difference with aluminum.

Cooling: CNC Coolant #3 Priority

Which brings us to our next issue, Cooling (and its Evil Twin Shock Cooling). The temperature of the tool is the biggest factor affecting tool life.

A little heat is good, as it softens the work material, making it easier to cut. A lot of heat is bad. It softens the tool, which means it wears, becomes dull, and cutting forces skyrocket. That makes it get hotter, and soon you have a vicious cycle.

Note that the amount of heat allowed is dependent on the tool material and coating. Carbide takes a lot higher temperatures than HSS. Some coatings, such as TiAlN, need the higher temperatures to do their job properly.

Different tool coatings can help tools resist higher temperatures and they can also reduce friction by acting as lubricants...

The benefits of TiAlN aren’t even present until there is enough heat to “activate” it. So TiAlN is often used without cnc coolant. In fact, turning your cnc coolant off can often increase tool life under the right conditions because it avoids Shock Cooling.

What is Shock Cooling?

Carbide develops micro-cracks under the thermal shocks of uneven heating and cooling. Imagine submerging glass heated by boiling water into ice water. It’s going to crack.

This “Shock Cooling” can impact tool life in higher performance applications.

Sandvik, in their cutting tool study course, recommend either no flood coolant or copious amounts of flood coolant to avoid this problem.

Too much heat causes thermal expansion. This is not helpful to accuracy, as it makes your workpiece change size.

How to avoid flood coolant with mist

If you don’t have a full machine enclosure, flood coolant is messy and almost unusable. Fortunately, cooling is the least important thing about cnc coolant. We still must manage chip clearing and lubrication, but cooling is less important. So, we can dispense with flood coolant for many applications. A strong compressed air blast will handle chip clearing. Adding a lubricant to the air blast to make a mist takes care of lubrication.

Here's a Fogbuster Mist Cooler mounted on a small Tormach CNC Machine:

There are some materials where flood coolant still reins supreme. Stainless Steel and Titanium are two examples. It's hard to do a good job on these with mist.

Let's take a deeper look at each of these three critical machining coolant functions.

Types of CNC Coolant

While it may seem tempting, never use water alone as it encourages rust and corrosion. Instead, choose one of the 4 coolants types listed below.

Synthetic Fluids

These coolants are the friendliest non-polluters because they contain no petroleum or mineral oil. They comprise rust inhibitors and lubricants that break down in water. They’re typically mixed with water to a certain concentration to produce a metalworking fluid.

Synthetic FLuids possess high cooling capacity, corrosion prevention, easy maintenance, and lubricity.

They are primarily employed in high-heat processes such as surface grinding because of their excellent cooling capacity.

Synthetic Fluids come in two types: simple and complex or emulsifiable. Simple Sythetics are commonly used for light-duty grinding. Complex synthetics contain fluids suitable for moderate to heavy-duty machining procedures.

Pros

- Synthetic Fluids possess high microbial control and excellent resistance to rancidity.

- They have excellent resistance to corrosion and have high cooling capacity

- They have greater stability after mixing with water.

- Synthetics allow easy maintenance.

Cons

- Other machining fluids, such as lubricating oils, can contaminate synthetic fluids quite easily. You must manage and maintain these fluids effectively.

- Synthetics often generate fine mists or foam due to moderate to high agitation conditions.

Semi-Synthetic Fluids

Semi-synthetics are a hybrid of synthetics (polymer) and soluble oils. They contain 2-30% mineral or petroleum oil. The remaining percentage of semi-synthetic components consists of water and emulsifiers. Other elements may include biocides, wetting agents, and corrosion inhibitors.

Semi-synthetics are usually translucent. Many have good heat sensitivity.

Pros

- Semi-Synthetics are excellent lubricants for moderate to heavy-duty applications.

- Semi-Synthetics can allow cutting at faster feed rates and higher speeds due to their remarkable wetting and cooling characteristics.

- These coolants possess low viscosity, allowing better settling and cleaning properties.

Cons

- Water hardness can impair the stability of semi-synthetics causing hard water scum deposits.

- These fluids foam easily because their cleaning additives provide less lubrication than soluble oils.

Straight Oil

These oils consist of petroleum, mineral oil, animal, and other elements derived from vegetables or fats. They may also contain other ingredients, such as phosphorous, sulfur, and chlorine additives. Straight Oils are usually insoluble in water and often provide the best lubrication, rust prevention, longer sump life, and easier maintenance.

Bacteria only thrive in fluids with water content, so straight oils don’t sour.

Pros

- Straight oil offers good lubricity which reduces friction in machining operations.

- They ensure excellent finishes and minimize tool wear and tear.

- They’re often affordable and have high compatibility with bronze, steel, and iron.

Cons

- Straight Oils have poor cooling performance (see below).

- They can require higher maintenance and oil changes because they degrade quickly with use.

- These oils are not ideal for specific high-performance applications.

- Straight Oils exhibit adverse environmental impact if not properly disposed of.

Soluble Oils

Soluble Oils, also known as water-soluble oils, are excellent for general machining applications. They perform well in diluted form and provide excellent lubricity and heat transfer performance.

They are cheap and are therefore in common use. They comprise 60-90% petroleum, emulsifiers, or mineral oil and adhere to the workpiece during machining. They’re ideal for lubrication and offer excellent rust resistance with the right additives.

Pros

- Soluble Oils can provide better cooling and lubrication because of the water and oil blend.

- They are multipurpose and ideal for light to medium-duty applications.

- You may accompany operations such as tapping and broaching with straight oils.

Cons

- The coolant tank encourages microbial growth of bacteria when improperly maintained.

- Oil in the mixture can result in rust control problems, evaporation losses, and tramp oil contamination.

CNC Machine Coolant Concentration

When using coolants that incorporate water, it is important to understand the appropriate coolant concentration to achieve the best results. This concentration is measured with a refractometer[3](javascript:void(0))Fukuta, Mitsuhiro; Yanagisawa, Tadashi; Miyamura, Satoshi; Ogi, Yasuhiro (2004). "Concentration measurement of refrigerant/refrigeration oil mixture by refractive index". International Journal of Refrigeration. 27 (4): 346–352. doi:10.1016/j.ijrefrig.2003.12.007 and must be monitored regularly to offset the effects of evaporation.

Measuring coolant concentration with a refractometer...

If the coolant concentration is lower than the minimum requirements it can result in:

- Microbial Growth

- Faster tool wear on cutting tools

- Corrosion of parts and machinery

On the other hand, excessive coolant concentration can result in:

- Foaming

- Toxicity

- Concentrated Wastage

- Reduced heat conduction

- Poor lubrication

- Discoloration of machinery or machined parts

- Degradation of tools due to residue build-up

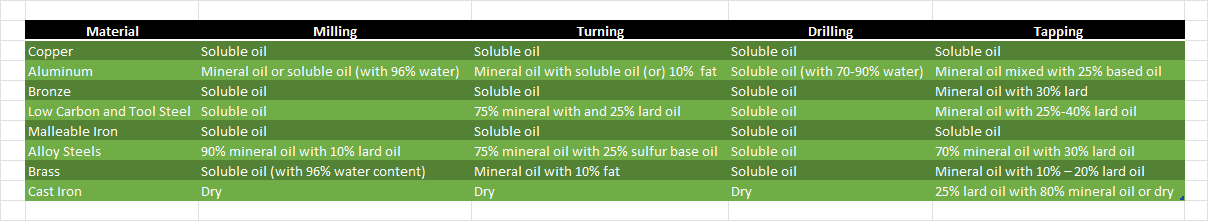

CNC Coolant Concentration vs Materials

Material

Milling

Turning

Drilling

Tapping

Copper

Soluble oil

Soluble oil

Soluble oil

Soluble oil

Aluminum

Mineral oil or soluble oil (with 96% water)

Mineral oil with soluble oil (or) 10% fat

Soluble oil (with 70-90% water)

Mineral oil mixed with 25% based oil

Bronze

Soluble oil

Soluble oil

Soluble oil

Mineral oil with 30% lard

Low Carbon and Tool Steel

Soluble oil

75% mineral with and 25% lard oil

Soluble oil

Mineral oil with 25%-40% lard oil

Malleable Iron

Soluble oil

Soluble oil

Soluble oil

Soluble oil

Alloy Steels

90% mineral oil with 10% lard oil

75% mineral oil with 25% sulfur base oil

Soluble oil

70% mineral oil with 30% lard oil

Brass

Soluble oil (with 96% water content)

Mineral oil with 10% fat

Soluble oil

Mineral oil with 10% – 20% lard oil

Cast Iron

Dry

Dry

Dry

25% lard oil with 80% mineral oil or dry

Oil vs Water Soluble Cutting Fluids: Which Cools Better?

Let’s also talk about coolant type. There are water soluble cnc coolants (cutting fluids), and there are oil-based coolants (cutting oils). From a cooling standpoint, the water soluble coolants win. How much? Consider this data:

CNC Coolant

Specific Heat of Coolant

Steel A (tempered)

Temp Decrease %

Steel B (annealed)

Temp Decrease %

Air

0.25

Compound oil, high viscosity

0.489

3.9

4.7

Compound oil, low viscosity

0.556

6

6

Aqueous solution of wetting agent

0.872

14.8

8.4

Aqueous “soda product” solution, 4%

0.923

–

13

Water

1.00

19

15

The efficiency of the various cnc coolants at removing heat corresponds to the specific heat of the coolant.

The second thing to notice is that air is pretty lousy, about 1/4 as good as water. That’s not as bad as predicted, since water carries 25x more heat than air.

The reason for the difference is the coolant doesn’t make efficient contact everywhere. Also, if you’re using the right cutting parameters (e.g. feeds and speeds), most of the heat is carried away in the chips, not the coolant.

Oil-based cnc coolants are about half as effective as water-based at cooling the tool and workpiece. Between that and the health considerations, its no wonder a lot of shops have gone to water-soluble coolants–they cool better.

On the flip side, the oil lubricates better (natch), and there are still some applications where machinists may prefer oil (usually turning) to the water soluble coolants.

One last thing about flood coolants. Above a certain critical surface speed, they all start to work about the same. The faster you go the less cooling effect they have.

At higher speeds, there isn’t time for a big gout of coolant to make it’s way into all the nooks and crannies. Cooling becomes less and less consistent. This also contributes to the shock cooling effects that make cnc coolant hard on carbide life above certain speeds.

BTW, people are constantly asking on the forums which flood coolant people like and use. We did a major survey that has resulted in our Buyer’s Guide to CNC Coolants.

Material Considerations for Machining Coolant

There are two material-specific considerations for coolant. The first is the tendency for BUE. Preventing chips welding onto the cutter through lubrication is important.

The second is the ability of the workpiece material to absorb and transfer heat. Some materials do not transfer heat very well–titanium is a good example.

Those materials are often more dependent on the coolant for cooling to offset the inability of the material to carry heat. That inability makes it harder for the chips to carry away heat. And also harder for the workpiece to stay cool without changing size due to excess heat. Titanium further compounds the problem by producing relatively small chips.

If the material you’re cutting transfers heat poorly relative to aluminum (which is an excellent conductor of heat), steel (a decent conductor), or other common materials, make sure you’ve got a good flood coolant setup and are using it well.

Work hardening materials also benefit because cnc coolant can reduce work hardening. Stainless Steel is a good example.

Feeds and Speeds with Different CNC Coolant Options

It may surprise you to learn that very few recommend different feeds and speeds for mist versus flood coolant. The reason is that there is a baseline expectation that no matter what you do for coolant, you will make sure that chips are adequately cleared.

Baseline Coolant: Clear the Chips!

The baseline role for any would-be CNC Coolant system is to clear the chips. Recutting chips is bad for the cutter, bad for your part’s surface finish, and is to be avoided. Therefore, let’s start with the assumption that whatever you’re doing about CNC Coolant it is clearing the chips. For example, manual machinists often make use of chip brushes to periodically sweep chips away. This is way too cumbersome and ineffective for CNC, but in that sense, the chip brush is a form of “Coolant”.

A step up would be spritzing the area with an air gun. Perhaps you will even have rigged a continous air flow from a nozzle of some kind. Or, maybe you’re on a CNC Router and you’ve got a vacuum system sucking up all the chips as fast as they are made. Now we’re getting into the realm of the real baseline for CNC Coolant. A baseline provides no advantage, rather, it is the minimum acceptable level of Coolant to be usable and reliable for CNC work.

There’s one more thing called for from a baseline CNC Coolant system and that’s the ability to lubricate the cutter and material if needed. Certain materials, such as aluminum, require lubrication or they will tend to weld onto the cutter and disaster follows not long after–broken cutters, globby taffy-like aluminum clinging to cutter, and ruined part. Clearly avoiding this has to be a part of our baseline.

Folks can stand by giving an spritz now and then from a can of WD-40, but like the chip brush, that’s really not adequate if you plan to cut much of whatever material demands the lubrication. There are some cutter coatings that eliminate the need for lubrication, but be aware the coatings wear and the failure will be sudden when there’s no long enough coating to keep going. You can sometimes make due if your chip clearing is prodigious enough and you keep your cuts extremely shallow, but you’re probably living on borrowed time for your cutter the deeper you go and the more chips escape extraction and wind up being recut.

Flood versus Mist: Which CNC Coolant Option is Better?

This may come as a surprise to many, but the difference is almost entirely a function of which one will clear the chips better. Let’s do a simple thought experiment. Suppose you have a simple low-performance Flood Coolant system. It’s putting out a slow trickle of CNC Coolant. Maybe you’ve even turned it down so you don’t have to wear a pancho when running the machine because you have no enclosure. Imagine your machine cutting a deep pocket or slot with your trickle of Coolant. The pocket is full of cutting fluid. There’s no question the cutter is immersed in it. But are the chips being cleared? In a word, “No!” They’re sitting under that pool, and the pool is almost protecting them from removal because the force of the Flood is not strong enough to blast them out of there.

Now consider a good Misting system. There’s no pool to hide under. You can easily see whether the chips are being cleared and crank up the air pressure if not. You’re less worried about the mess because Mists are much less messy. It should now be more obvious that Mist is going to be a better CNC Coolant option than a mediocre Flood Coolant!

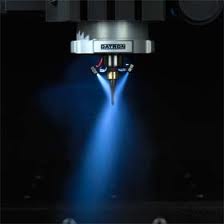

While we’re on the subject of Misting, there are basically two kinds of Mister–plain old Mist systems which produce a coolant aerosol:

Misters produce a coolant aerosol…

Plain old Misters work great for machining, but they use more coolant than they need to and they fill the shop air with the mist–not the world’s best thing to be breathing all day. There is an alternative called the Fog Buster that focuses on propelling larger droplets without creating an aerosol mist:

Fewer larger droplets from the Fog Buster…

By launching fewer larger droplets, the Fogbuster makes sure they don’t travel all over your shop–they mostly land on the workpiece where the thing is pointed. Better for you and just as good for the machining work. They cost a little more, but for a premium Mist system they sure are worth it.

How do we make sure our Flood Coolant system isn’t mediocre (else we may as well use Mist)?

There are a couple of parts to the answer. First, we need to make sure we can generate sufficient pressure on the Flood system to make sure the chips are cleared out. When it’s cranked up good, you almost can’t see what’s going on there’s so much CNC Coolant flying around. Second, we need to make sure the Coolant is properly aimed to clear the chips. That can be a little harder. Different tools are different lengths. Things move around as the work progresses. Typically, we want to either aim for the bottom of the cut or the top of material if the nozzle can’t “see” the bottom of cut.

By now you're probably realizing there's another reason not to give Feeds & Speeds bonuses for flood coolant: it's hard to properly identify whether a flood system is really clearing the chips. Operators assume they are, but most are not paying close enough attention to it. How the coolant is aimed matters tremendously.

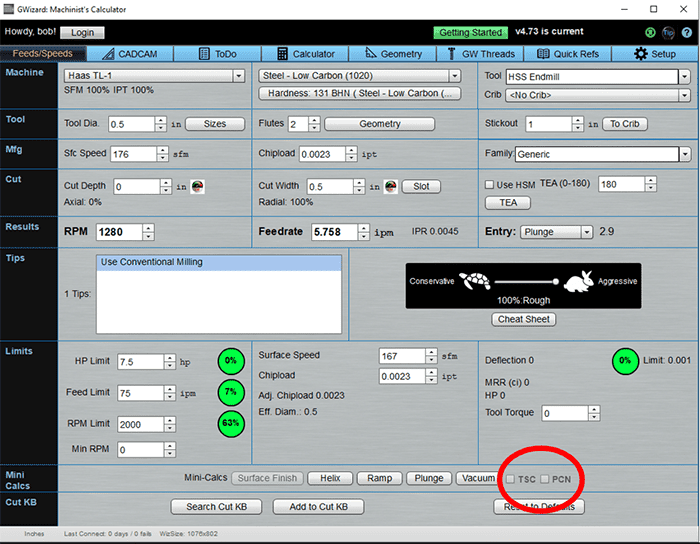

Good chip clearing and lubrication where needed are the baseline assumptions that our G-Wizard Calculator makes about your CNC Coolant. However, while we don't recommend slower feeds and speeds as the answer to poor coolant, G-Wizard does know how to take advantage of premium coolant options such as programmable nozzles, through spindle coolant, and high pressure coolant.

To calculate proper feeds and speeds with premium cnc coolant options, just click the boxes in the machine profile that tell G-Wizard your machine has these capabilities. Then, you can operate the check boxes on the Feeds and Speeds Calculator to take advantage:

Performance Recipe: Aiming CNC Coolant for 5% Higher MRR

Where you aim the coolant matters, whether for chip clearance, cooling, or lubrication. But how many machinists take time to aim the coolant after each tool change? Different tools have different lengths. Different machining operations may also change the best aim of the coolant.

Adjusting the coolant nozzle is a productivity burden. Avoid it by using multiple nozzles preset to a range of heights. With three nozzles, you can cover a pretty decent range.

The problem with this approach is you now only have 1/3 of your coolant available at the ideal spot. With enough volume and pressure there is a wall of coolant. That's why the high pressure and volume option available for most machines is worthwhile.

Lastly, you can retrofit your machine with an automated nozzle that allows you to pinpoint your coolant by twisting a knob on the control panel. These programmable coolant nozzles can track your tool changes and change the aim automatically, something that will improve the efficiency of any milling process.

Spidercool programmable coolant nozzles...

What’s good aim worth? Spider Cool says its good for 5% better MRR, and they have a free trial to prove it. Might be worth checking into your coolant aim.

Our G-Wizard Feeds and Speeds Calculator will make the allowance for a Programmable Coolant Nozzle in its Feeds and Speeds Calculations.

BTW, if you’re very conscientious about coolant and take time to make sure your nozzles are properly aimed, you can go ahead and tick the box for PCN and get the bonus. You’re doing the same thing the automation does.

One thing you’ll quickly discover about these bonuses is they can be a very cost effective way to improve your shop’s productivity. Investments in better coolant technology are often not that expensive relative to the benefits you get on nearly every job.

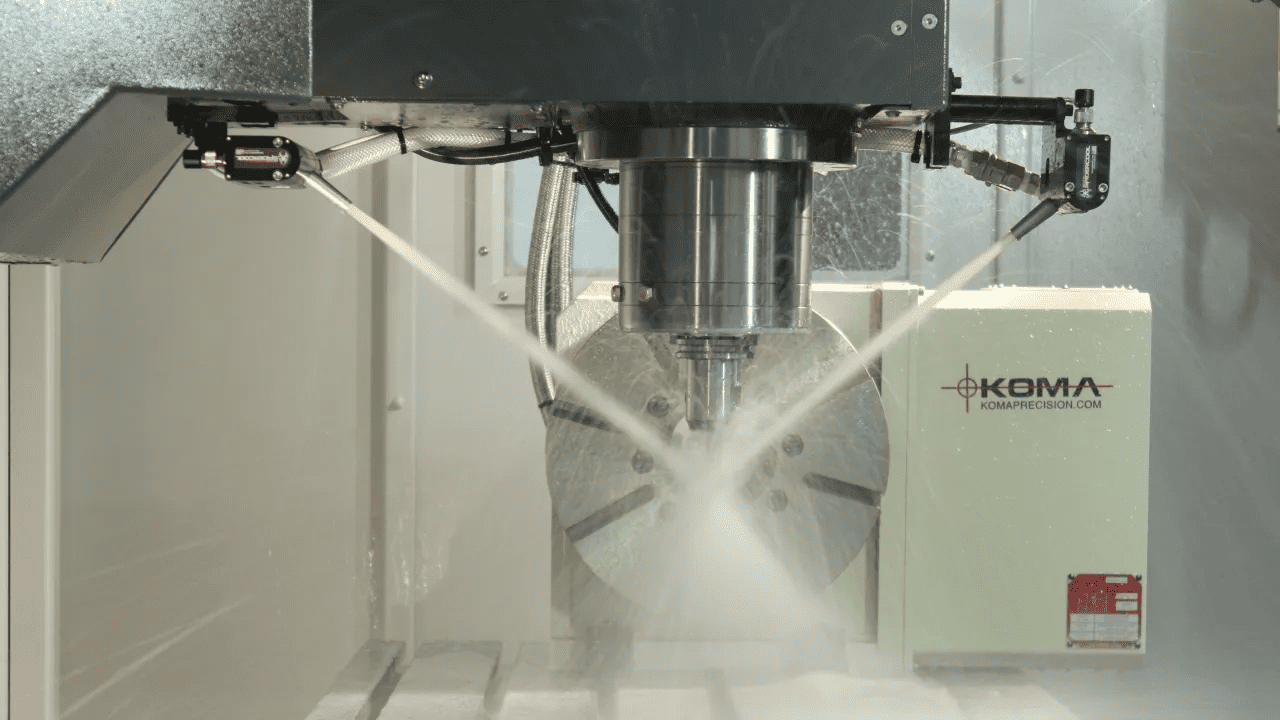

Performance Recipe: Through Spindle Coolant & High Pressure Coolant

Programmable Coolant Nozzles are great, but they can’t guarantee the coolant goes to the optimal place every time. Some places are just not accessible, for one thing. Consider the bottom of a deep hole you’re trying to drill. No way to aim the nozzle there–it’s below the surface of the material and there is no access. Or is there?

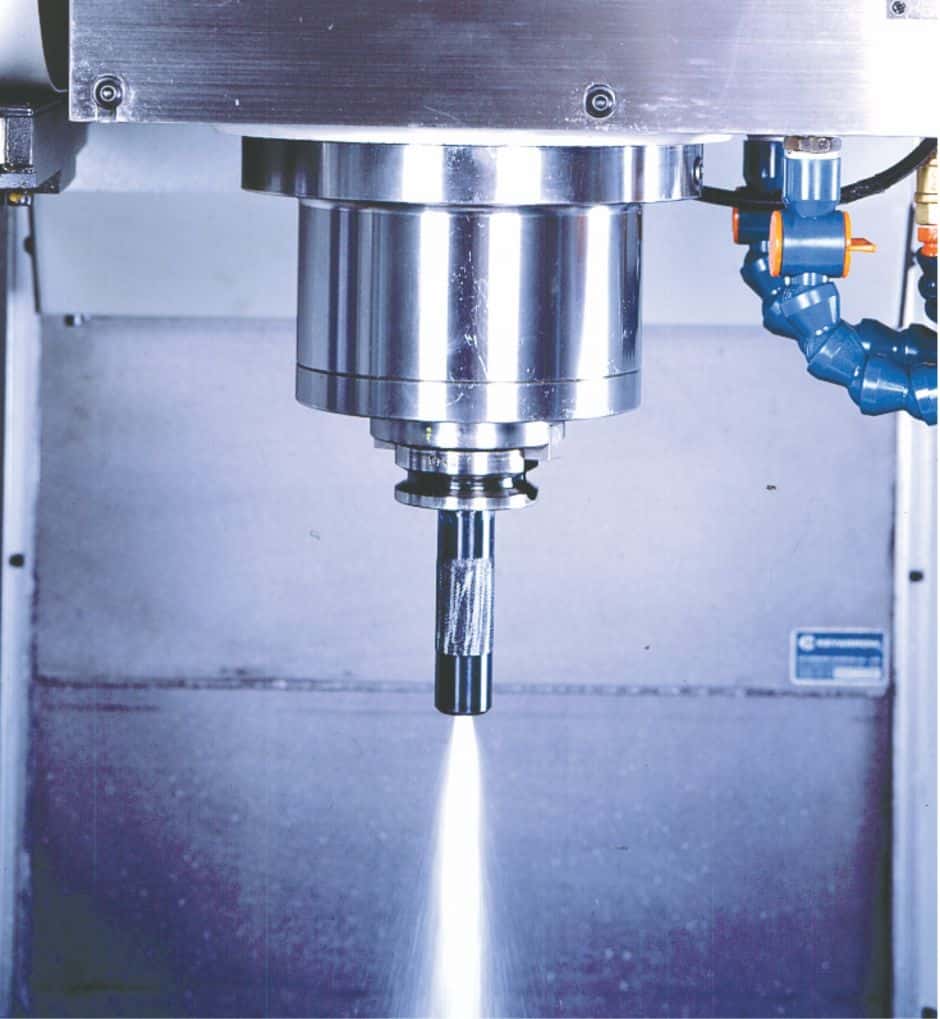

Through Spindle Coolant (abbreviated TSC) gains access by feeding coolant through your spindle like the name says, and from there it can exit via passages inside the tool. You really can have a nozzle built into the bottom of your drill bit, for example:

Through Spindle Coolant: Like a Nozzle in your tool’s tip. (Image courtesy of MC Machinery Systems)

TSC ensures the cnc coolant is going to exactly the right spot to make the most difference. BTW, there are lathe equivalents that go through the tool rather than the spindle, but the principle is exactly the same.

With Through Spindle Coolant, performance can be greatly increased. It is nearly the perfect delivery system for coolants. Even higher chip loads can be tolerated, holes can be deeper, and peck drilling can be eliminated due to the improved evacuation of chips. Of course, G-Wizard Calculator has an option for TSC too.

Another advantage for TSC machines: you can often run more flutes, particularly when profiling.

Once you have Through Spindle Coolant, you’re still not at the pinnacle. To go further, you’ll need a High Pressure Coolant system.

High Pressure Coolant

With Through Spindle Coolant, you’ve made sure the cnc coolant is being delivered to exactly the right location where it will do the most good. The next level of benefit comes from dramatically increasing the pressure and volume of coolant delivered to that sweet spot in the cutting zone. Of course this improves chip evacuation, hence the reduction in the need for peck drilling, but High Pressure Coolant (abbreviated HPC) is where there’s a chance for the cooling ability of “Coolant” to really shine.

The trouble with Coolant’s cooling is that it can be spotty. A droplet hits the tool here, another hits the workpiece there, a third bounces off a chip, and there’s just not enough consistency. Mist and air blasts do almost as good a job cooling as a result. The exception is on materials like Titanium that don’t conduct heat very well. For those types of work, flood coolant is essential. But aluminum, for example, conducts heat extremely well. It’s hard to tell a difference between flood and mist unless you’ve really got a great flood system going.

There’s another problem with liquid coolants too. It’s called “shock cooling.” Unless there is enough coolant to keep carbide from really heating up, what happens is those random droplets cool the carbide randomly. One moment it’s very very hot, the next a big droplet lands (splat, sizzle!) and it is shock cooled back down to low temperature. This leads to micro-cracking of the carbide which can severely reduce tool life. Always check with your tooling manufacturer, especially on high performance insertable tooling, whether there is a point where the coolant needs to be turned off and a pure air blast used to prolong your carbide’s life.

High pressure coolant system...

High Pressure Coolant can provide an alternative. By using very high pressures, 1000 psi or more, as well as high volumes, it’s intent is to deliver so much coolant that nearly all of the heat will be carried away before it can ever build up. Practically speaking, what this means is higher surface speeds, more rpms at the spindle, higher material removal rates, and longer tool life. You can trade some of that off as well. For example, let’s suppose you’ve got a job drilling thousands of holes in some material that requires carbide drill bits. You might very well sacrifice a little of the ultimate rpm potential in exchange for longer life so you don’t break a bit and have to scrap a part.

Performance with a High Pressure Coolant system can be amazing compared to running without one. G-Wizard is set up to give appropriate SFM bonuses when you have HPC, so go ahead and check it out. You can use G-Wizard to figure out the ROI (return on investment) for an HPC system by calculating what sort of increase in feeds and speeds the HPC will enable for you.

You Paid to Have Premium Coolant Options on Your CNC Machine.

They Make a Big Difference.

**Why Not Use a Feeds and Speeds Calculator that

Takes Advantage of Them?**

Try G-Wizard Calculator. Free!

Horizontal Mills and Lathes Have Gravity Helping Clear Chips

Don't overlook the benefits of gravity for machining. On vertical mills, gravity makes it harder to pull chips out of deep holes. On lathes and horizontal mills, gravity makes it easier. Kinda makes you wonder why nobody has a machine that cuts from underneath. You'd need a pretty crazy palette loader so you could drop the workpiece onto the table and then flip it for cutting. Too far out, I thought, but then I discovered such machines actually exist. They're called "Inverted Spindle Lathes" and are a potent alternative to bar fed lathes.

Here is a link to an MMSOnline article about them.

Exotic Recipe: Alcohol as Coolant

Datron uses an ethanol alcohol mist as coolant for its HSM machines. They make a good case for it:

It is ideal for high-speed, micro-tooling of non-ferrous metals and some plastics due to a thinner-than-water viscosity that allows the ethanol to quickly cover and cool more of the surface area on fast-moving parts. The low evaporation point of ethanol makes it an

efficient cooling and lubricating solution. Since the ethanol simply evaporates, disposal, recycling and their associated costs are a thing of the past. Plus, ethanol coolants leave no residue on machined parts, which makes costly secondary operations, like de-greasing, obsolete — maximizing throughput, increasing efficiency and ultimately improving a manufacturer’s bottom-line.

Mist in the Air and In Your Lungs

A big downside of liquid and mist coolants is that inevitably they will create a mist in the shop air. Left to its own devices, this mist will wind up in your lungs and it's definitely not good for you. The answer to this problem is to employ a Mist Collector to extract the mist before it can go very far.

CNC Machine Coolant FAQs

When is the right time to change a CNC machine coolant?

Most CNC machine makers recommend changing coolant every 6-12 months as a general rule of thumb. The exact time to change coolant will be based on the machined material, coolant type, amount of machining use, and operating condition of the CNC machine.

How do I kill bacteria in CNC Machining Coolant?

There are several ways to kill bacteria in CNC Machining Coolant. They range from anti-bacterial additives that can be put into the coolant to ozone treatments to preventing oil films from blocking oxygen exchange with the coolant.

What causes foaming in a CNC coolant?

Lack of minerals in the water supply is a primary cause of foaming in coolants. Check the water's hardness using Hardness Testing Kits is advisable.

What is CNC coolant made of?

CNC coolant may be made of oil, oil-water emulsion, aerosols (mists), air, or other materials. They may be made from petroleum, plant oils, water, or compressed air.

What is the best coolant for CNC machines?

Never use water by itself, as it can lead to rust and corrosion. Instead, use one of the following types of coolant:

Soluble Oils

Soluble Oils are inexpensive and are the most common in machining operations. They're created by adding mineral oil to water in specific percentages. Emulsifiers are also added to keep the solution mixed. Other additives add additional useful properties such as corrosion resistance, bacteria prevention, and lubrication. Soluble Oils work best in light-cutting operations.

Synthetic Fluids

Synthetic Fluids combine water with additional chemical compounds but no mineral oil. Other additives can include lubricants, rust inhibitors, and corrosion inhibitors.

A primary benefit of Synthetic fluids is no foaming. Foaming is more common in mineral oil-based coolants.

Synthetic Fluids are more durable than other metalworking fluids.

Semi-Synthetic Fluids

Semi-Synthetic Fluids are a blend of mineral oil, corrosion inhibitors, and additives for clean operation in high-speed and high-pressure CNC machines.

Straight Oils

Straight Oils are not mixed with water and have a mineral or petroleum oil base. The include additives that are biodegradable and environmentally friendly.

Straight Oils provide the best lubrication but have the poorest cooling characteristics.

Conclusion

For many high performance applications, machinists can focus on chip clearance and lubrication and ignore the cooling issues. Above a certain surface speed, many tooling manufacturers recommend turning off the flood coolant and using an air blast (perhaps with mist for lubrication) to clear chips. Materials that don't transfer heat well like titanium will require flood coolant regardless.

One last tip. Coolant and chips are messy. Most machinists like to use an air gun to spray them off the part before removing it from machine. You can automate that task with a chip fan.

Choosing the right coolant strategy is important for most machining operations. Coolant delivery can be the key to superior performance of your machining process.

Additional Information

CNC Coolant Nozzles: Coolant rings, coolant collars, and more types of coolant nozzles.

Coolant Buyer's Guide: See the relative market shares and customer satisfaction of various machining coolants.

CNCCookbook Cutting Fluid Survey: See what our readers think about machine coolant.

Coolant Mister: Try a mister if flood coolant is just too messy.

Chip Fans: Automate removal of chips and machine coolant from your parts.

DIY Flood Coolant: Need to put together your own flood coolant system? Check this article out.

CNC Coolant Filter: Find out how to filter fine particles from your CNC Coolant.

Tramp Oil Skimmer: Easy to build but powerful tramp oil skimmer.

CNC Enclosure: Easy to build enclosure so you can run flood coolant.

Turning Down the Heat in a Cut

References

-

1

C S Reddy, Araveeti & D V, Paleshwar & Murthy, Kln & Sandeep, B.. (2020). A Review on Coolant Feeding System of CNC Machining Process. 10.1007/978-981-15-7827-4_44.

-

2

Application of coolants during tool-based machining – A review Khor Zheng Yang a, A. Pramanik a, A.K. Basak b, Y. Dong a, Chander Prakash c, S. Shankar d, Saurav Dixit e f, Kaushal Kumar g, Nikolai Ivanovich Vatin e

-

3

Fukuta, Mitsuhiro; Yanagisawa, Tadashi; Miyamura, Satoshi; Ogi, Yasuhiro (2004). "Concentration measurement of refrigerant/refrigeration oil mixture by refractive index". International Journal of Refrigeration. 27 (4): 346–352. doi:10.1016/j.ijrefrig.2003.12.007

Want to Learn More Deep CNC Knowledge?

If you liked this article, you should try our Free Feeds and Speeds Master Class.

Take our Feeds and Speeds Master Class. Free!

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.