1 month by cncdivi

Here are the results from our 2019 CNCCookbook Cutting Fluid Survey. Benchmark data like this survey can be extremely helpful. It tells you the best practices of your peers and competitors so you can see how your own practices measure up. If you plan to buy CNC Coolant or Cutting Fluids, you need this info!

Type of Coolant Delivery Used

There are a lot of different ways to deliver Cutting Fluid to the workpiece and cutting tool. This question tells us which are the most popular:

There’s no text provided to rephrase. Kindly input the text you would like me to help you paraphrase.

Basic flood coolant wins by a wide margin. It’s more sophisticated (and higher performance) cousins, Through Spindle (19%) and High Pressure (15%) come in next. Mist is the most common alternative to flood, with 12% popularity. It is followed by Minimum Quantity Lubrication (5%), a simple Air Blast (1%), No Coolant used (1%) and Hand Spraying Cutting Fluid on.

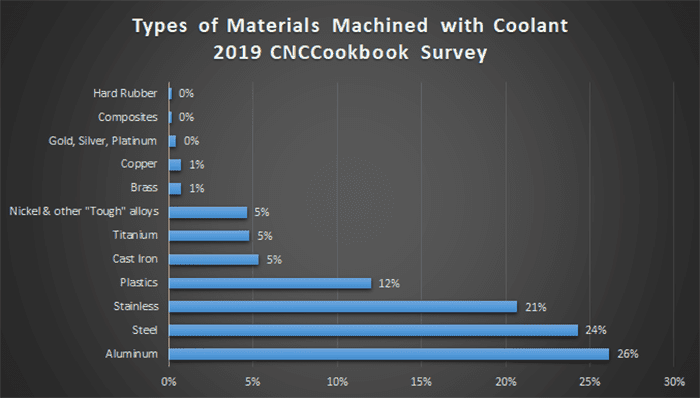

Types of Materials Machined with Cutting Fluid

These are the types of materials our respondents most commonly use Cutting Fluid to machine:

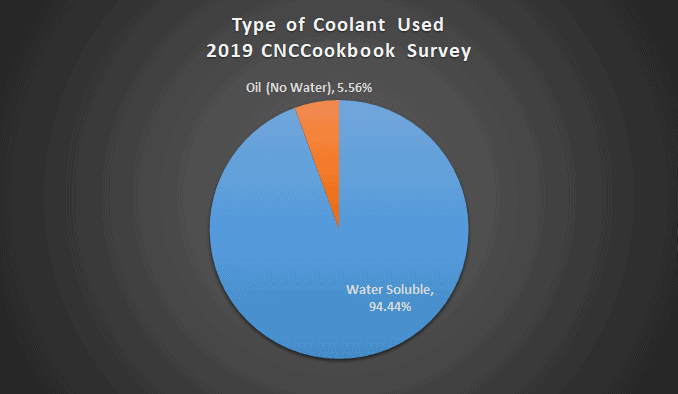

Cutting Fluid Type

The vast majority of folks with coolant use one of the Water Soluble varieties rather than Cutting Oil.

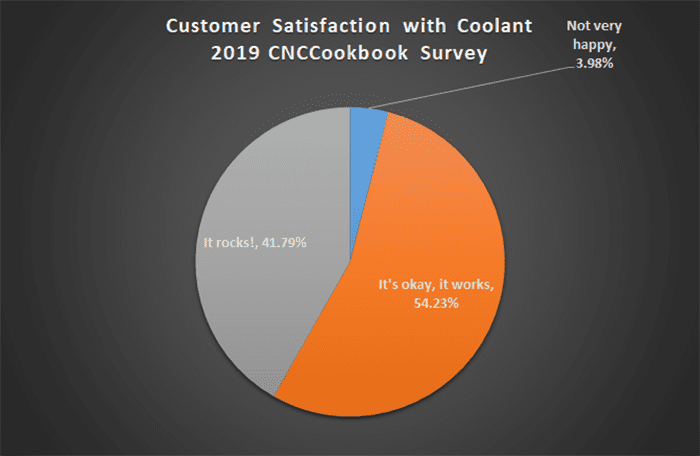

Overall Satisfaction with Cutting Fluid

Overall, people seem pretty satisfied with the Cutting Fluid they use. Only a little under 4% report they’re Not Very Happy, while 54% say, “It’s okay, it works,” and about 42% say, “It rocks!”

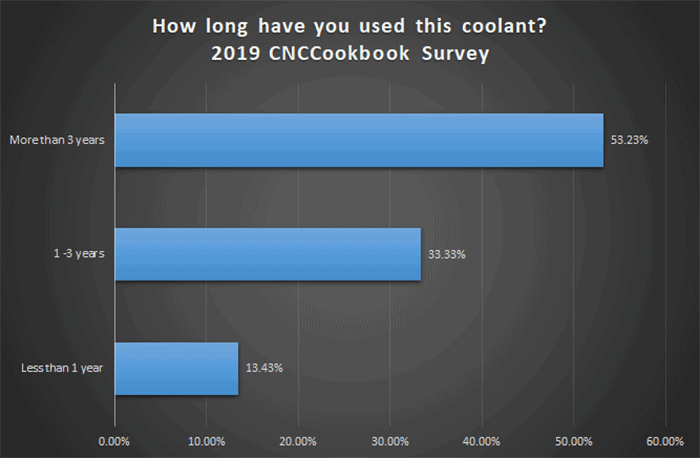

How Long Have You Used this Cutting Fluid?

From these results, it seems safe to say that once a Cutting Fluid is chosen, shops tend to stick with it. No wonder vendors are so eager to give free samples!

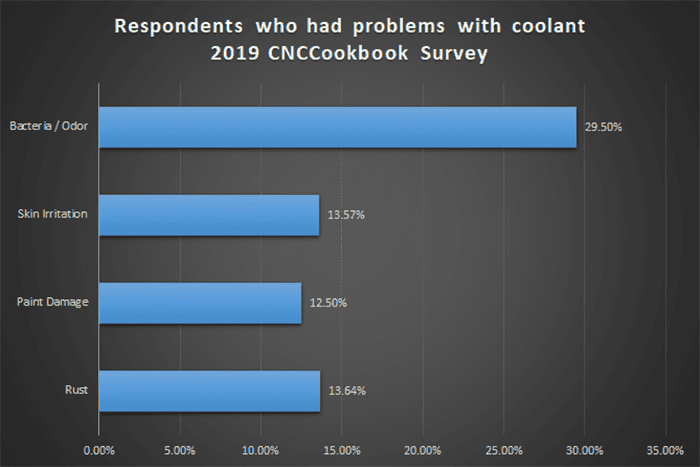

Cutting Fluid Problems

CNC Cutting Fluids are not without their problems, however. Some 30% report bacteria and odor problems. Almost 14% have experienced rust problems with a similar number reporting skin irritation such as rash. And a little over 12% report that their coolant attacks the paint on their CNC machines.

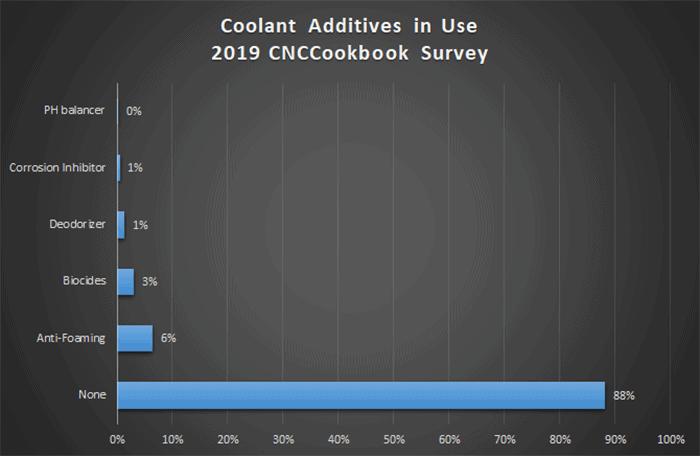

Cutting Fluid Additives

Most folks don’t use any coolant additives. As several noted in comments, they expect the coolant to be complete and shouldn’t require additives.

OTOH, 22% do use some additives, and the most common are anti-foaming agents and biocides to kill bacteria.

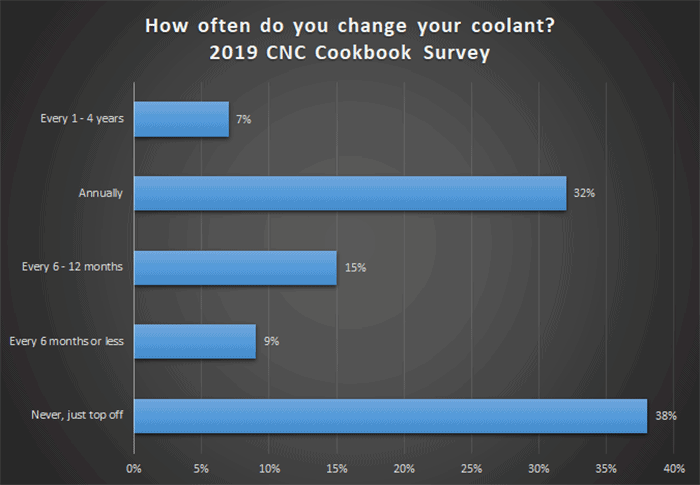

How Often Do You Change Your Cutting Fluid?

When asked how often they change their coolant, respondents tied between never changing it (they just top off until it tests correctly) and changing it annually. The next most common response was changing it every 6 months.

While it should make sense to simply top off the Cutting Fluid, it also makes sense that coolant can wear out, and topping it off may not adequately refresh it.

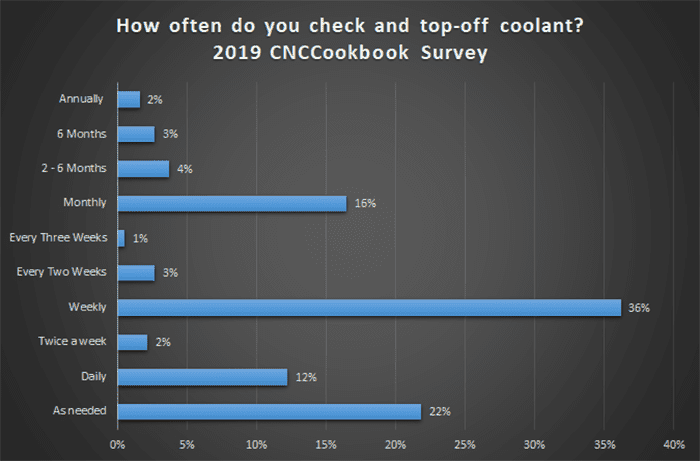

How Often Do You Check or Test Your Cutting Fluid?

Answers here were interesting. While we might assume some number of folks answering “as needed” just don’t know, I choose to think of “as needed” as meaning they have no established preventative maintenance procedure for CNC Coolant.

Most shops, 78%, do have a fixed interval at which they check and top off Cutting Fluid.

The most common interval is weekly, followed by monthly, and then daily. Somehow, daily seems a bit much to me, but perhaps not if machining operations are heavy and perhaps run across multiple shifts.

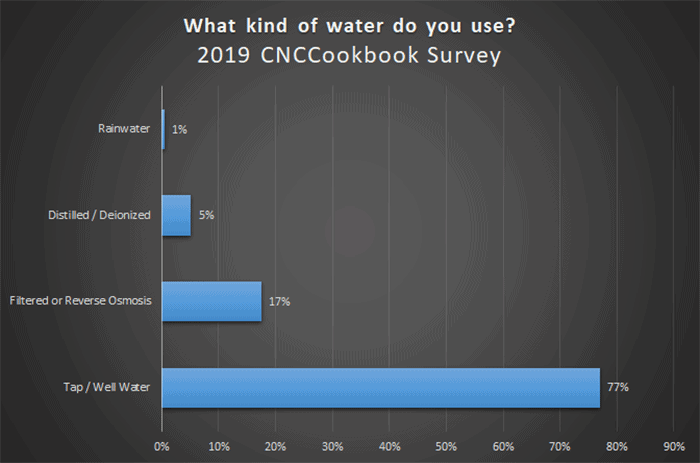

What kind of Water do you use?

The majority use tap or well water to mix up their water soluble Cutting Fluid, and that’s exactly what many manufacturers recommend and have formulated their coolant for. The next most common option is filtered or reverse osmosis water, followed by distilled or de-ionized water.

I read with interest the use of well water and even rainwater to help defray costs.

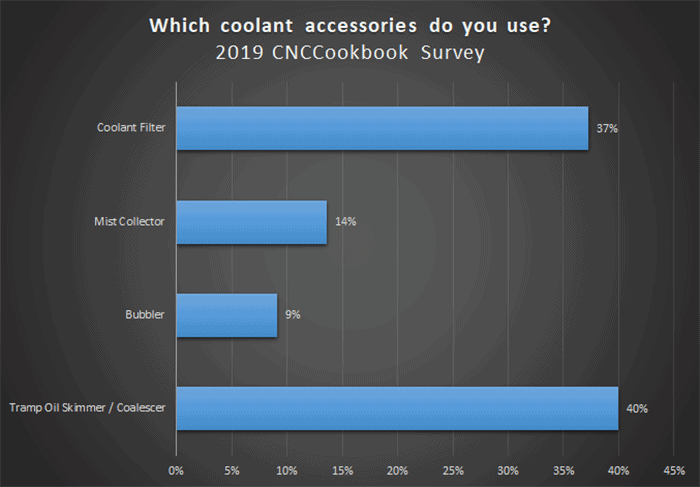

Which Coolant Accessories do you use?

A huge variety of coolant accessories are available. They fall into some major categories:

- 40% of respondents use a Tramp Oil Skimmer, Coalescer, or Tramp Oil Pillows (floating absorbers) to control tramp oil.

- 37% use a coolant filter, which can keep fine chips from clogging or damaging the coolant system.

- 14% use a mist collector to keep mist out of the air and out of the lungs of folks near the CNC machines.

- 9% use a bubbler in the coolant tank, which is another way to control anaerobic bacteria like the Tramp Oil Skimmers.

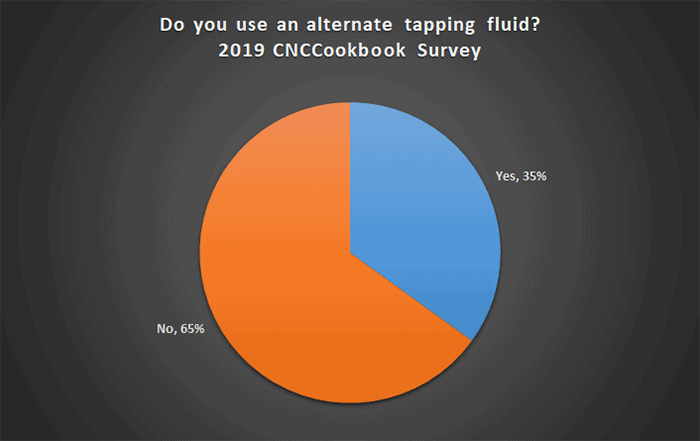

Do you use an Alternate Tap Oil?

Modern CNC Cutting Fluids are designed to work with a variety of operations, but one operation in particular can benefit from use of a specialized fluid–tapping. While most just use their general purpose cutting fluid, 35% switch to a special tap oil for tough tapping operations.

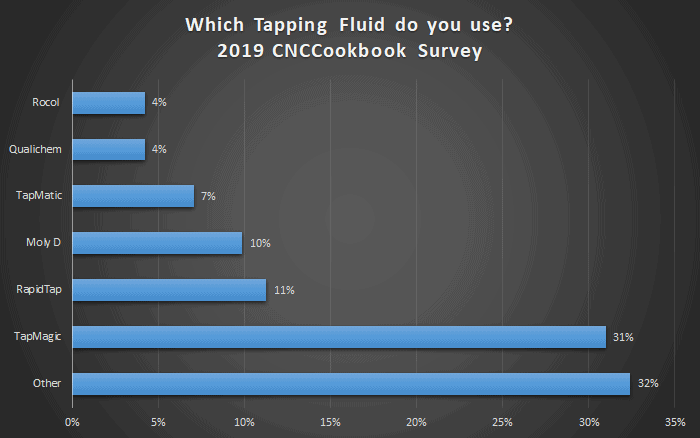

Which Alternate Tap Oil? (Hint: Tap Magic has the biggest share)

We asked which tapping fluid and these were the most common answers:

Tap Magic has the biggest share among Tap Oils, followed by RapidTap and Moly D.

Buyer’s Guide

We offer an exclusive CNC Coolant and Cutting Fluid Buyer’s Guide for our newsletter subscribers. It includes market share, customer satisfaction, and any reported problems with specific CNC Cutting Fluids. If you’re thinking of buying CNC Coolant any time soon, you need our Buyer’s Guide.

Just one thing though–I will only be making it available to folks registered for our mailing list. So, if you’re interested and you’re not on our mailing list, be sure to sign up. Just scroll down to the form below to get our newsletter together with choice premium content such as our CNC Coolant Buyer’s Guide and much more!

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

![CNCCookbook 2019 CNC Cutting Fluid Survey [+Buyer’s Guide]](https://www.cnccookbook.com/wp-content/uploads/2019/06/img_5d164e8e73379-768x675.png)

![CNCCookbook 2023 CAD Survey [ Market Share, Customer Satisfaction ] Bar chart displaying top CAD package market share from CNCCookbook's 2023 CAD Survey, with SolidWorks leading followed by Fusion360 and AutoCAD.](https://www.cnccookbook.com/wp-content/uploads/2023/04/img_643ebcf902e51-150x150.png)

![CNCCookbook 2020 CAM Survey [ What’s the most popular CAM? ] A collection of popular camera brands and logos displayed on a white background.](https://www.cnccookbook.com/wp-content/uploads/2020/01/img_5e13a1665ad11.png)

CIMCOOL is the coolant we have used on/off for many years

We use a water soluble coolant on steel and stainless steels called Ecocool SEP. It’s from a smaller company called Baccara Lubricants Ltd in England, UK. It works well as had no dusting of components or foaming issues. It does lose its colour a little but I guess that’s to be expected.

p.s Thought the survey asked all the right questions, good work!

Just one personal observation, most of the shops I know use oil in their Swiss style lathes and use coolant in their lathes, mills and grinders. This may not be apparent in the above stats.