Have you had a chance to try our new Tool Tracker and Tool Management software? It’s free during Beta Test, you just need a working trial or subscription copy of our G-Wizard Calculator.

What is G-Wizard Tool Crib?

It's a Tool Tracker and Tool Management software.

A Tool Crib is a place to efficiently store, and control specialty tooling like cutters, toolholders, gages, and fixtures. G-Wizard Tool Crib is designed to help you efficiently manage and control your tool and equipment inventories.

In its finished form, G-Wizard Tool Crib will help you to efficiently solve the following kinds of problems:

- Tool Tracking Software: Where is my XYZ tool? Who had it last? Where is it being stored?

- Tool Management / Tool Inventory: Do I have enough of the right kinds of cutters to do the jobs I have coming up? When should I reorder, what should I reorder, and how many should I reorder?

- Tool Cost Analysis: How can I assign tool costs to the proper jobs?

- Tool Life: How long are these tools lasting? Which tools are giving me the best value based on MRR vs Tool Life vs cost of the tool?

- Tool Setup: What's the minimum number of tools I need to change on that machine to be able to run this job? How do I make sure the right tools are in the machine to run a particular job?

- Tool Selection: How can I be sure the tools selected by our CNC Programmers are the ones we want them to use?

- Tool Maintenance: How can I be sure tools get resharpened, repaired, or have the correct inserts installed?

While individual tooling may be inexpensive, the total investment in consumables, fixturing, dies, molds, gages, and so on can represent up to one third of your manufacturing investment. Having a tracking tool for these assets can make you hugely more productive and profitable if you're running a business.

A Quick Tour of G-Wizard Tool Crib

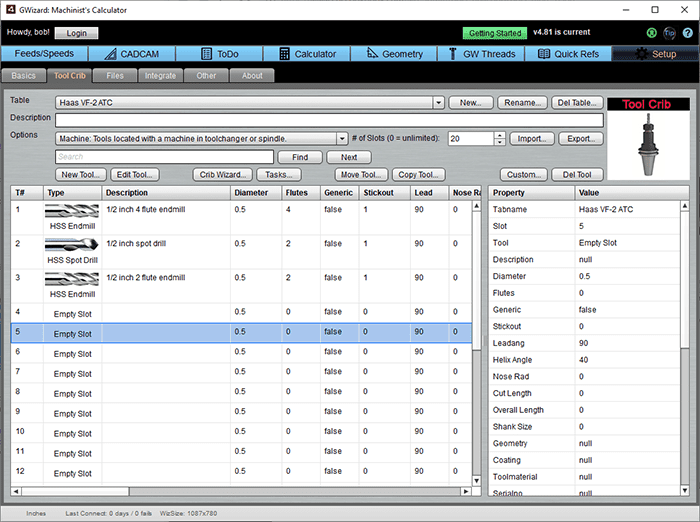

G-Wizard Calculator has always had a Tool Crib feature that lets you create tables that hold tool definitions. What GW Tool Crib adds is more features to these basics.

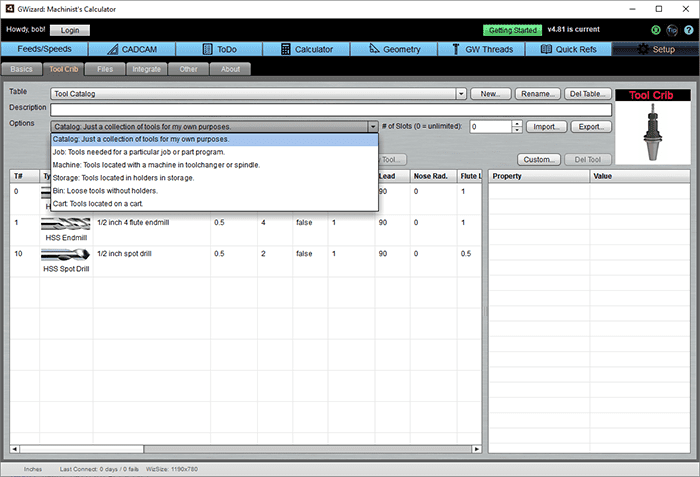

Tool Crib Types: Modeling Physical Tool Storage

The original Tool Cribs are pretty abstract. They have no real connection to physical tooling and storage. GW Tool Crib adds the ability to define Tool Crib Types:

- Catalog: Just a collection of tools for my own purposes.

- Job: Tools needed for a particular job or part program.

- Machine: Tools located with a machine in toolchanger or spindle.

- Storage: Tools located in holders in storage.

- Bin: Loose tools without holders.

- Cart: Tools located on a cart.

Note how these tool crib types correspond to pretty obvious physical tool storage. The key to tool tracking is knowing where every given tool is physically located at all times.

For example, a tool could be located in a bin such as this Huot Twist Drill Dispenser:

Twist Drills in a dispenser like that are not in tool holders, but this is a pretty common way to store them until they're needed for a job.

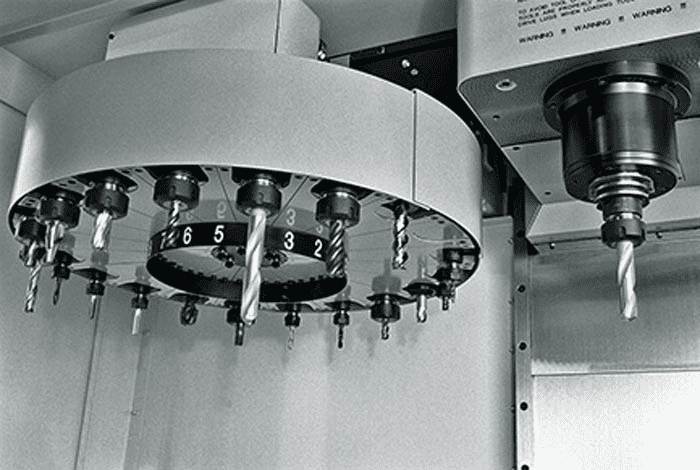

Or, a tool could be located in a particular machine's automatic tool changer:

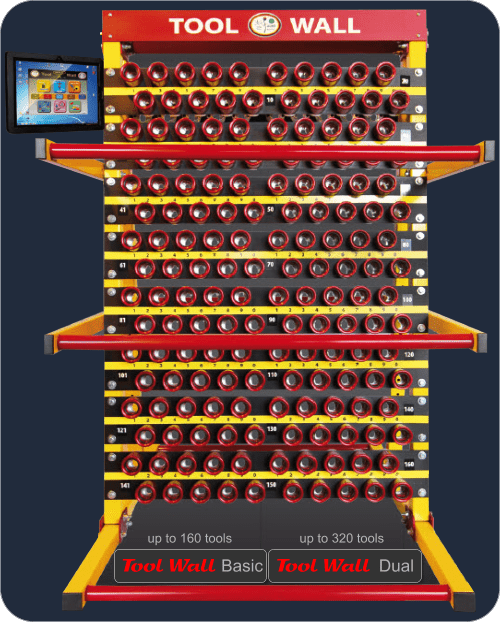

A tool could be located in a toolholder that resides in a storage rack like this Tool Wall:

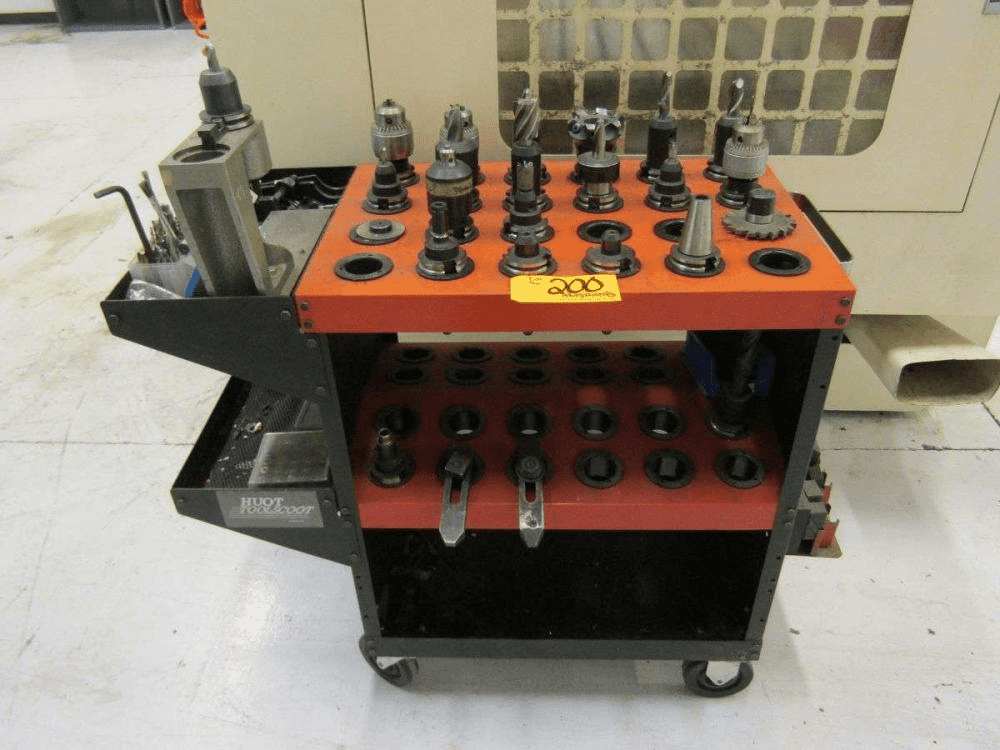

Lastly, it could be on a Tool Cart so it can be transported between Tool Storage and the CNC machine it'll be used on:

Using these different Tool Crib types make it possible to model the physical tool storage of your shop, which is exactly what Tool Tracking is all about. By logging all of your tooling into the software, and then moving tools from one location to the next to mirror physical movement, you can get full tool tracking and the ability to manage tools and monitor all of your tool inventory.

There are still a couple of abstract Tool Crib types-Catalogs and Jobs.

You'd use a Catalog to track things like the approved tooling in use by your shop. Or, use a Job to show the tooling required by a particular Job.

This provides the Tool Tracking capability that is the heart of G-Wizard Tool Crib.

GW Tool Crib includes commands to Copy or Move tools from one Tool Crib to the next. So, for example, you might move tools from Storage to Carts and then to a Machine to reflect a tool that is checked out of your tool crib for a particular job (and a Job Crib might be used to show which tools to check out) and then installed on a machine to make parts for that job.

Tool Description and T#

You use the Tool's T# to say where within the Crib the tool is located. You might also make a notation in the Tool's Description if that helps.

To maximize productivity, you may wish to label your storage racks, bins, and carts with T#'s that will correspond to what's in G-Wizard's Tool Crib Database. Your CNC Machines toolchanger (or turret) probably already has numbers.

Tool Crib Types: Max Slots

Whenever we model physical tool storage, there is a notion of Max Slots. You only have so many positions in a machines tool changer, so many positions in a toolholder rack, or so many bins in a raw tool dispenser. G-Wizard will enforce and track those limits with its Max Slots setting.

Example: Set Up an Automatic Tool Changer

Suppose you have an ATC on your Haas VF-2 that holds 20 tools. You might set it up to track tools in G-Wizard like this:

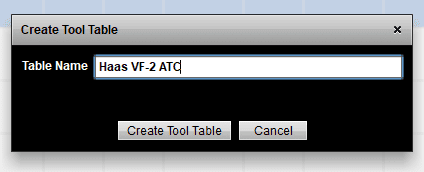

- Click the "New" button just to the right of the Tool Crib dropdown to create a new tool table.

- Enter a name for the table in the popup.

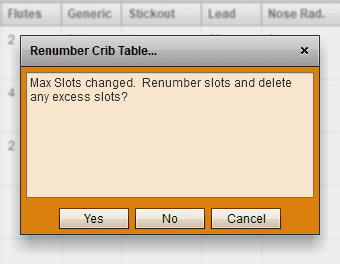

3. Enter Max Slots value of 20 and set the Table Type (under Options) to Machine. If any changes or renumbering is required, G-Wizard will ask you to confirm.

Now you've got a Tool Crib corresponding to your machine's ATC that has the correct number of slots and is ready to go.

You can move tools to this table (or copy, or just create them in place) to manage what's installed on your Haas.

Modelling Your Shop With G-Wizard Tool Crib

Your first step to get the maximum benefit from GW Tool Crib is to model your shop in GWTC. That is, you want to create cribs that correspond to all the physical locations tools could be found in your shop.

For example, you could start with a setup like this:

- Tool Catalog: This crib captures all the tools you've ever used or considered. These tools don't exist physically, this is just a place to get their data prior to deciding whether to acquire them.

- Tool Crib: Let's say you track all tool stored in your Tool Crib area by putting them into the Tool Crib table.

- Machine ATC's: Create a crib corresponding to the tool change or turret on each of your CNC machines.

A setup like that would suffice for a lot of smaller shops.

What Can You Do With This Information?

Tool Management Software can enable a number of different useful functions involving tracking maintenance schedules.

The ability to schedule maintenance and track maintenance schedules can help with everything from preventative maintenance to calibration alerts to tool sharpening, damage tracking, and similar work. Maintenance Tracking is an important part of any tool tracking system.

Implementing inventory control can help reduce shrinkage and other kinds of waste that impacts your costs.

Contract Management is another important component of tool tracking. You need to be able to assign tooling to particular contracts and jobs and thereby assign the expenses of those tools (or fixtures, gages, tooling or other asset tracking) to those jobs.

What Else?

Obviously this is just the start of functionality needed to fully solve the range of problems G-Wizard Tool Crib is aimed at. We'll be steadily adding more software solutions over time. Stay tuned!

Latest News

New Beta of G-Wizard Tool Crib just uploaded!

The latest Beta release is contained in G-Wizard Calculator.

[ Download G-WIzard with G-Wizard Tool Crib ]

Like each of our packages before, you’ll be able to use it free of charge during the Beta Test.

There’s just one proviso–you must have an active G-Wizard Calculator Trial or Subscription, because G-Wizard Thread Calculator is an add-on module for G-Wizard Calculator. BTW, we also have G-Wizard Estimator in development, which is the same deal–you can use it free as long as you have an active G-Wizard Calculator Trial or Subscription.

Remember: This is Beta Software and you will almost certainly encounter bugs. Just report them to me via email to [email protected].

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.