I just uploaded a new G-Wizard Calculator release, version 4.16. Click the link to download it.

The new release has 2 main changes:

- Added Tapping and Thread Milling to CADCAM Hole Wizard.

- Enabled ISO Trapezoidal Threads. They were disabled in the prior release by mistake.

Let's go over the new hole wizard feature for Tapping and Thread Milling.

Tapping and Threading in G-Wizard's CADCAM Hole Wizard

First, if you've never tried the CADCAM Wizards, you should check them out. Just click the CADCAM Tab in G-Wizard Calculator.

The point of CADCAM Wizards is to get a complete recipe for a typical CAM operation with as few steps as possible. In addition, the CADCAM Wizards optimize the variables such as Cut Depth and Cut Width to give you the best possible performance.

CADCAM Wizards are unique to G-Wizard Calculator, and there's nothing else with similar power available. I always start my own work with CADCAM Wizards, and drop into the traditional Feeds/Speeds tab for more fine tuning if needed. Most of the time I just go with the straight recipe given.

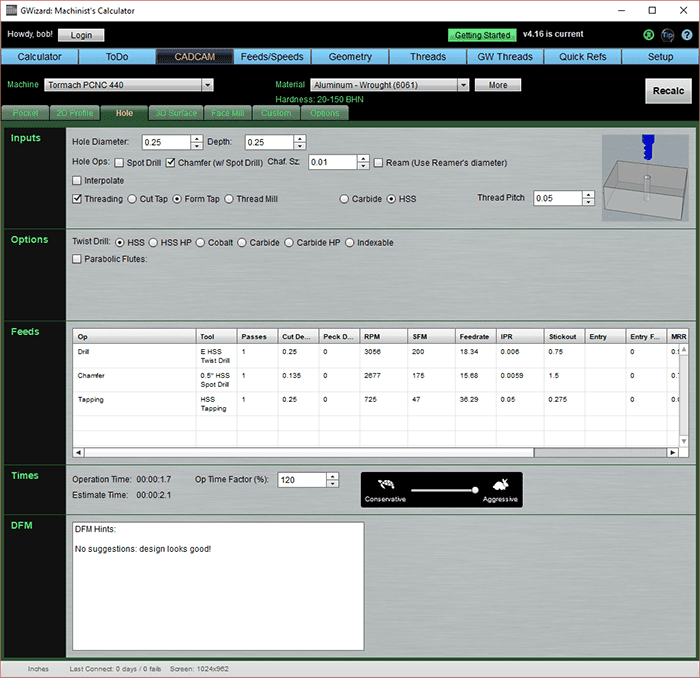

Here's the CADCAM Hole Wizard:

You forgot to provide the text. Please provide the text you want to be rephrased.

For most things, you need only tell it the values in the "Inputs" row and the Wizard will do the rest.

Holes are some of the most complex single features we create with CNC. Note all the options for what you can do to holes:

- Diameter and Depth: Of course, these are the most basic things.

- Hope Ops: There's a whole raft of addition ops you can add to a basic hole.

- Spot Drill: Spot Drill the hole before drilling

- chamfer: Use the Spot Drill to chamfer the hole at the end

- Ream: Ream after drilling. The CADCAM Wizard assumes the hole diameter is the reamer diameter and tells you what size Twist Drill to start with in the recipe.

- Interpolate: If you wish to interpolate the hole with an endmill, check this option.

- Threading: To thread the hole, turn this option on and then choose whether you want to use a cut tap, form tap, or thread mill.

With that information, the CADCAM Wizard will give you a complete recipe in the Feeds box. Here's a typical example of a hole for a 1/4-20 fastener that we wanted to spot and chamfer and then tap in aluminum with a form tap:

I just entered the inputs and clicked "Recalc" to get this result. I'm now ready to pass the information along to my CAM software and move on to the next feature.

If you've never tried G-Wizard Calculator, be sure to check it out with our free 30-day trial.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.