Thread mills, the cutting tools used in CNC milling machines, employ a machining method known as "thread milling" to create both internal and external threading.

The other threading process for CNC Mills is Tapping. On lathes, single point threading (turned threads) and taps are used.

The popularity of these machining solutions is Tapping, Single Point Threading, and Thread Milling in that order.

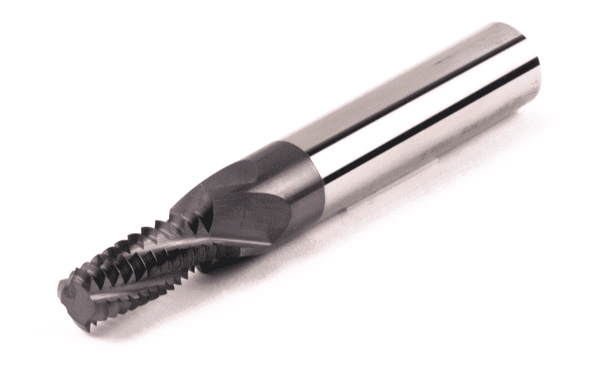

A selection of thread mills. Image courtesy of Harvey Tool.

CNC Thread Milling vs Tapping

Let's get one thing out of the way up front-Tapping is faster than CNC Thread Milling. However, thread milling is a more accurate, controllable, and safer machining solutions. If you need a perfect thread, you probably want thread mills.

That being the case, you might wonder why anyone ever uses Thread Mills? There are a number of advantages it has over Tapping that often make it the preferred choice of machining solutions include the following technical tips:

- If you break a Thread Mill, it won't get stuck in the part. Removing broken taps is painful, especially if the tap is embedded in a part that's already been machined at considerable expense. Thread milling is often preferred for expensive components and late stage machining for this reason.

- The teeth of thread mills are larger and stronger than taps because of the reduced need for chip clearance. This makes them less likely to break.

- Thread Milling is better for hardened materials because you can cut the material in smaller steps, and speeds and feeds can span a wider range than a tap, which is limited by the pitch of the thread being tapped. Their use as machining solutions for hardened materials is another reason they're almost always carbide.

- Chip clearance is easier because thread mills generate short, comma-shaped chips whereas taps can create long stringy chips that "bird nest".

- Thread Milling requires less horsepower than tapping, which may be an advantage for lighter-weight CNC machines.

- The lower cutting forces exerted by a thread mill can be advantageous in long reach and thin wall applications where tool deflection and chatter are problems.

- A single thread mill of the right type can be used to cut many thread sizes. A separate tap will be needed for each thread size. On parts with multiple threads, there can be considerable toolchange savings with thread milling. There is also savings in reducing the amount of tooling inventory that must be kept on hand for standard thread sizes.

- You can thread mill odd-sized threads for proprietary applications.

- Thread mills can be used to back chamfer the hole.

- Thread mills have no need for special tension compression holders or tapping heads. This is an advantage on CNC Machines that lack rigid tapping capability.

- Taps get increasingly expensive as size increases. At some point, thread mill cutters are cheaper than very large taps.

- While coolant can be used, most manufacturers suggest dry machining is the first choice for thread mills. Exceptions would be stainless steel (reduces work hardening), aluminum (reduces chip welding), and cast iron (to keep the dust down). Otherwise, a good compressed air blast will be fine.

- The same thread mill can cut both internal and external threads.

- Threads will have the best form, finish, and dimensional accuracy. Positional accuracy is also the best. If you want a perfect thread, try thread milling.

- Full-bottom threading and precise thread depth control are possible.

That's quite a long list of advantages for carbide thread mills that may make them perfect for your application instead of tapping.

Thread Mill Cutters

For starters, most thread mill cutters are made of carbide. They need the extra rigidity and strength to do their job versus HSS.

Technical Tips: Spiral Flute Thread Mill (also called "Multi-Point" or "Multi-Form" Thread mills)

A Spiral Flute Thread Mill can cut faster than Single Profile (or Single Point) Thread Mills because more than one thread can be cut by the multiple rows of teeth. The same Spiral Flute Thread Mill can cut lefthand or right hand threads and it can vary the diameter of the threads, but they are limited to a single thread pitch governed by the spacing of their teeth.

They're called "Multi-Form" because they form many threads per pass. You may only need a single pass for all threads in the hole if the thread length is the same or less than on the thread mill. A Multi-form thread mill thus cuts faster than the Single Profile or Single Point thread mills we will look at next.

Technical Tips: Single Profile Thread Mill (also called Single Point Thread Mills)

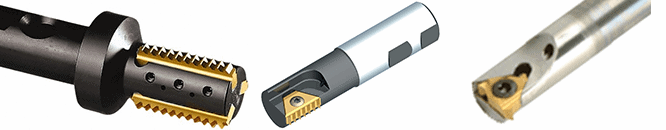

A single profile thread mill. Image courtesy of Lakeshore Carbide.

A Single profile thread mill only has teeth to do one thread at a time. Therefore, they can be used for a wide variety of threads by varying the depth of cut and the pitch of the thread helix. But a Spiral Flute Thread Mill can only do one helix pitch because the distance between teeth is fixed.

Integrated Countersink

Many thread mill manufacturers offer versions with integrated countersinks at the top of the thread mill to eliminate the need for a tool change where countersinking or chamfering is desired (almost always!).

Solid Carbide vs Indexable Thread Mills: Technical Tips

As with most any other tool type, Thread mills are available as indexable tooling with replaceable inserts. A variety of types are available including Single Profile, Single Insert Spiral Flute, and Multiple Insert Spiral Flute.

The usual motivation for indexable tooling is cost-you can replace an insert rather than the entire tool. However, as is the case with most indexable tooling types, the geometry and therefore the performance of equivalent solid carbide tooling is superior. Therefore, an indexable thread mill is only preferred when doing large volumes of threading in relatively larger holes.

Choosing a Thread Mill

Use the following Technical Tips to help choose a thread mill:

Profile Distortion: Diameter

If the diameter of the thread mill is more than 70% of the diameter of the thread, the thread profile can be distorted, so be sure the thread mill is no larger.

Single Profile or Spiral Flute?

This choice will be based on whether you want to maximize flexibility for multiple thread sizes or reduce cutting forces as much as possible. In either case, a Single Profile Thread Mill is preferable. But, if those are not at issue, a Spiral Flute Thread Mill will generally cut faster as well as spreading wear over multiple flutes so the tool lasts longer.

Coatings

When thread milling hardened materials, your thread mill will wear much faster. Coatings can reduce that wear and are worth investigating on those materials.

Through Coolant?

Through Coolant is most important for evacuating chips in blind holes.

Use the Manufacturer's Help

All tooling catalogs for Thread mills are full of suggestions and guides to help you choose the right thread mill for your job. They've also got support lines where you can call up and get a consultation. Be sure to take advantage of these resources to help you choose the best cutter for your job.

Technical Tips: Toolholders for Thread Milling

Most (but not all!) Thread mill manufacturers recommend set-screw type toolholders over ER Collet Chucks for Thread Milling. If you plan to use a set-screw holder, make sure your Thread mills have the Weldon Shanks that maximize the effectiveness of the holder.

= How to Thread Mill =

Feeds and Speeds + Thread Milling Calculator

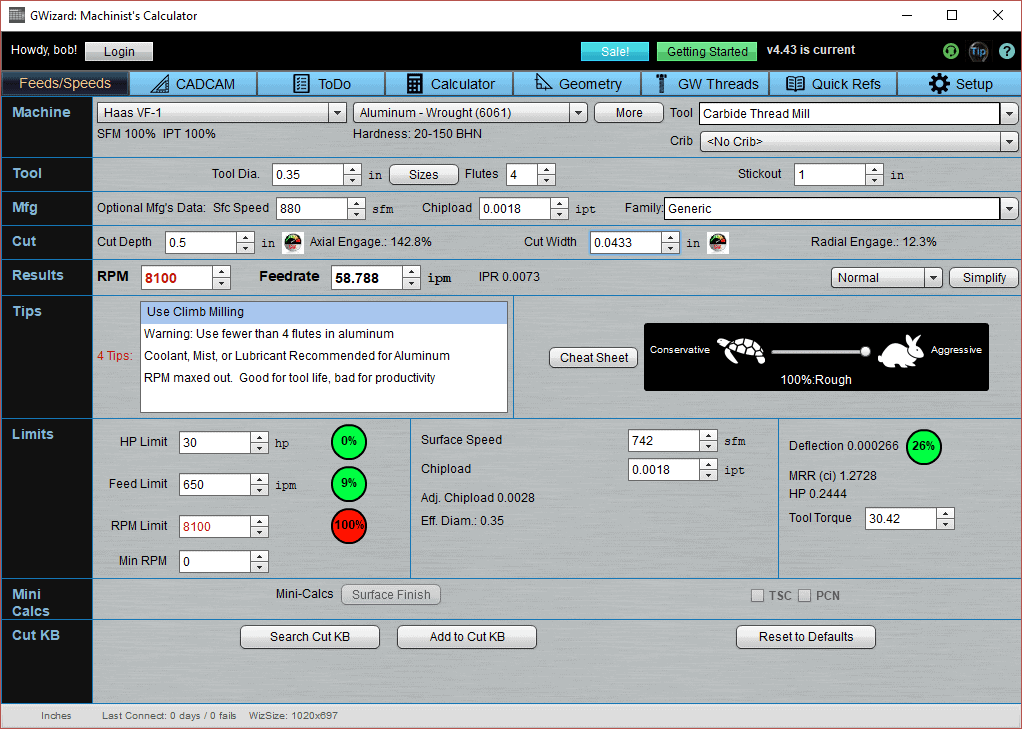

Like anything else having the right Feeds and Speeds is very important for Thread Milling. A Thread mill can be small, delicate, and expensive, so it's no fun to break one. The good news is our G-Wizard Feeds and Speeds Calculator does Thread mill Feeds and Speeds!

Here's how it works:

Step 1: Choose machine and material

Step 2: Choose a thread mill for tool type

Step 3: Enter Tool Diameter and Flutes

Let's say we're going to cut a 1/2-20 internal thread. Our rules for selecting a thread mill require no more than 70% of hole diameter for thread mill diameter. So we want a thread mill that is no more than 0.350" in diameter. I like Lakeshore Carbide's tooling (Carl is great to deal with), so I will go choose a thread mill from his online catalog.

I picked an uncoated thread mill and the specs say 0.350" diameter, 4 flutes.

Step 4: Enter Cut Depth and Cut Width

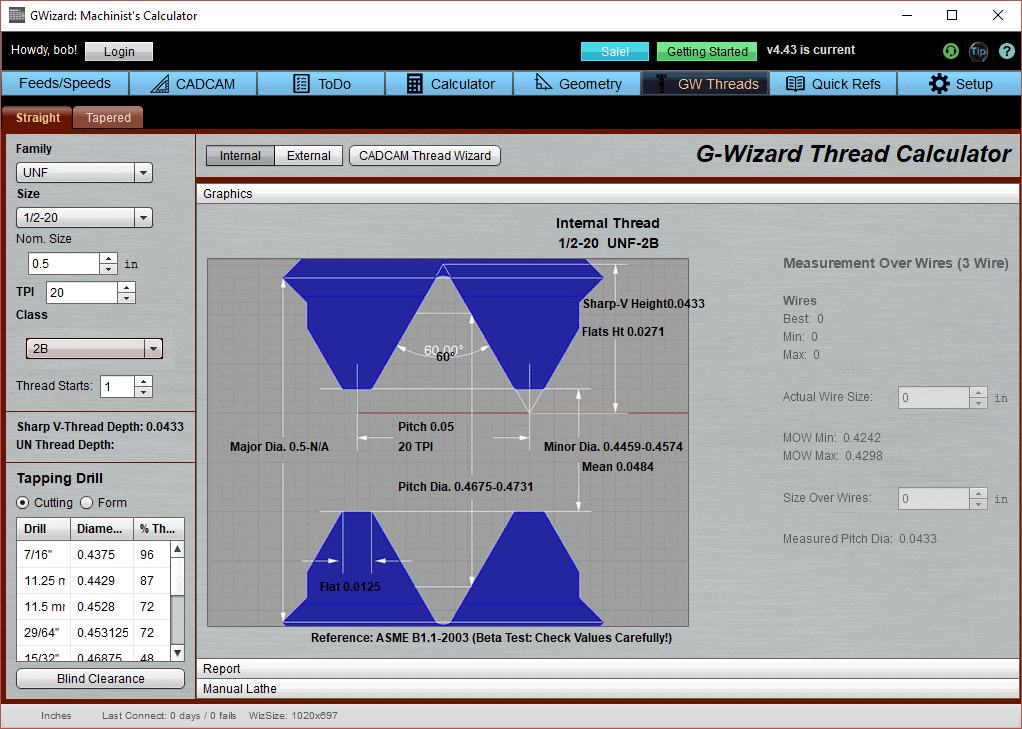

I'm going to cut threads a 1/2" deep in one pass, so I will set my Cut Depth to 0.500". Cut Width is the difference between major and minor diameter of a 1/2-20 thread. We can look that up on G-Wizard's Thread Tab:

I'll just use the Sharp-V height (0.0433") because its easy. In practice, our cut depth is a little less to allow for the flats.

That's about all it takes to get some Feeds and Speeds back from G-Wizard:

Note that as the tips say, we could be going a lot faster rpm-wise, but it's okay to go slower. We'll get better tool life too, especially in hardened materials.

If we wanted to take it a little easier, we can dial back the Tortoise-Hare slider more to the Tortoise side-whatever feels right for the situation.

That's all it takes. If you've never tried G-Wizard, get on board with our free trial:

Writing Thread Milling G-Code and Thread Mill Program Generators

Helical Interpolation

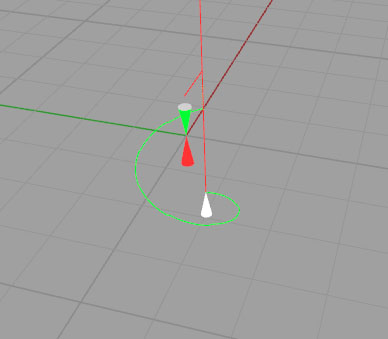

CNC Thread Milling is possible because CNC Machines allow us to program Helical Interpolation. This allows the cutter to follow a helical path that corresponds to the thread's helix:

A Helix programmed in G-Code…

Here's a chapter to show you how to write helical interpolation in g-code that's part of our Free GCode Programming Course.

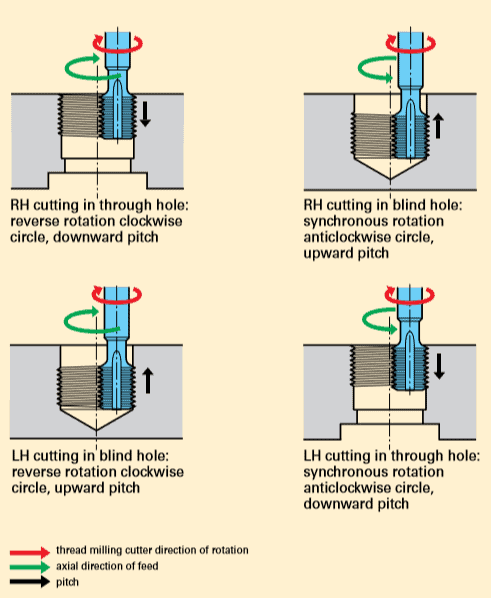

Reverse Rotation vs Synchronous Milling

Assume clockwise spindle rotation. The difference between reverse rotation and synchronous milling is a function of whether the thread mill's helical motion is clockwise or counter-clockwise. If the helix is clockwise like the spindle rotation, it is called "reverse rotation milling". Why that makes sense to call it reversed when the direction is the same, I don't know! But remember it that way.

Alternatively, we can think of synchronous rotation as down milling and reverse rotation as up milling. As always, we prefer down-milling (aka Climb Milling) where the tool is fed in the direction of tool rotation. It provides the lowest cutting forces and the best surface finish. Lower cutting forces are particularly helpful when cutting hardened materials.

If the direction of the helix (viewed from above) is counter-clockwise, it's called synchronous milling.

Synchronous Milling is usually preferred because it achieves lower cutting forces, improved chip formation, better tool life, and better surface finish. But, there are specific conditions to consider when choosing which direction to cut:

Reverse Rotation vs Synchronous Milling. Image courtesy of Guhring.

Note the black arrows that show the direction the helix unfolds based on whether we're cutting RH or LH threads and the direction of the helix. When the arrow points up (blind holes in other words), we start at the bottom of the hole and thread to the top.

Cylindrical vs Conical (Tapered or Pipe) Threads

Having established all of our directions of motion, the next consideration is whether we're cutting a cylindrical or conical helix. Tapered (Pipe) threads require a conical helix. This is accomplished during programming by correcting the helix every 90 degrees. Each 90 degree segment corrects its endpoint to account for the tapered thread helix. For even greater accuracy machining solutions, divide the arcs into 8 sections or 45 degrees each.

Thread Milling Entry Methods

We now understand the shape of the helix and the directions of motion. How do we get the Thread mill Cutter into the thread so it can start cutting?

There are several methods described by these Technical Tips:

- Linear Plunge: The Threadmill moves from center of hole to cutting with a straight linear plunge. This method is simple to program but has mutliple drawbacks. It creates the biggest loading on the tool and long chips. Plus, there will be a small delay mark in the threads as the tool transitions from plunge to helical motion. Therefore, this method is not recommended where accuracy is required or the threads are small.

- Quarter Circle Entry: We can program the Threadmill to ramp in via a quarter circle that gradually meshes into the thread helix over 90 degrees. In this method, we make a linear motion to get the Threadmill close to engaging and then finish ramping in with the quarter circle arc move. It's advantage is simplicity plus improved performance over a simple linear plunge. However, it is still only recommended when the Threadmill is quite a bit smaller than the hole.

- 180 Degree Semicircle Entry: Here the tool starts in the center of the hole and performs a semi-circular arc of 180 degrees to enter the cut. This takes the most programming effort but produces the best results across the widest range of parameters.

Troubleshooting

Problem

Potential Cause and Solutions

Too much insert flank wear

Cutting speed too high: Reduce speed or use a coated insert that can handle the speed.

Chips are too thin: Increase feedrate.

Insufficient coolant: Increase coolant flow or aim the coolant better.

Cutting edge chipped

Chips are too thick: Reduce the feedrate or increase rpms at same feedrate.

Vibration: Check and improve workpiece and tool stability.

Material build up on cutting edge

Incorrect cutting speed: Use proper speeds and feeds.

Unsuitable carbide grade; Use a coating appropriate for the material.

Inadequate coolant: Use a coolant that promotes lubrication with the material being cut and make sure there is adequate flow to the right spot.

Chatter or Vibration

Feed rate is too high: Reduce the feedrate.

Profile is two deep: Perform the cut in two passes.

Thread length is two long: Make multiple shorter passes to cover the full length.

Insufficient thread accuracy

Tool deflection: Reduce stickout and feedrate.

Chipping of non-cutting edges

Vibration: Check cutter and part stability.

Threadmill and Thread Milling FAQ

What is Thread Milling?

Thread milling is an alternative machining solution to tapping on CNC machines for cutting threads. It works by moving a cutter along a helical path that corresponds to the thread's helix.

Why threadmill instead of tapping?

There are a number of reasons to thread mill instead of tapping. Let's get one thing out of the way up front-Tapping is faster than CNC Thread Milling.

However, thread milling is a more accurate, controllable, and safer machining solution. If you need a perfect thread, you probably want to thread mill. If you are working in a hardened material, you're less likely to break a treadmill than a tap. If a thread mill breaks, it won't get stuck in the part the way a tap does.

A single treadmill can cut multiple different thread sizes, saving toolchanger positions and tool changes.

A thread mill requires less machine horsepower, so is better suited to small machines when tapping large threads.

Check our thread mill article above for still more advantages of these unique machining solutions.

What types of Thread Milling Cutters are available?

There are single-row and multi-row thread mills. A single row has one row of teeth. It's virtues are lower cutting forces (beneficial on large threads) and the flexibility to do many thread sizes.

A multi-row has multiple teeth. They can thread faster because they cut multiple grooves in one pass. However, they only cut a single pitch thread size as the distance between thread grooves is fixed.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.