Is there anything worse than breaking a tap?

Crashing a CNC machine in a way that does costly damage is worse, certainly. But breaking a tap off in an expensive part that's nearly finished has got to come in a close 2nd place.

Every machinist hates breaking taps. It’s a real pain to extract a broken tap without damaging the part. Plus, tapping always seems to be one of the last operations done on a part, which just ensures the highest cost if you need to scrap the part. But, there are 7 things I’m going to show you in this video that will great reduce the number of broken taps you have to deal with.

I just finished the 11th episode of CNC Chef for Cutting Tool Engineering. This video gives you 7 ways to avoid breaking taps:

7 ways to avoid breaking taps from Cutting Tool Engineering on Vimeo.

Watch the video for details, but my 7 ways include:

- Choose the best hole size

- Use Form Taps where possible

- Thread Mill critical and tough jobs

- Use purpose-made Tapping Lubricants

- Use the right tool holder

- Extract chips with a spiral fluted tap

- Mind the depth on blind holes

Taken together they provide a wealth of techniques that will make breaking taps far less likely in your shop.

Let's explore them in more detail.

#1 - Choose the Best Hole Size

The first tip is to choose the best hole size, and it’s also the tip that will make the biggest difference for you.

Look, the recommended hole size found on the tap’s packaging or in your drill index is probably not the best size.

It’s important to realize there is no one drill size for a tap. Different drill sizes result in different thread percentages.

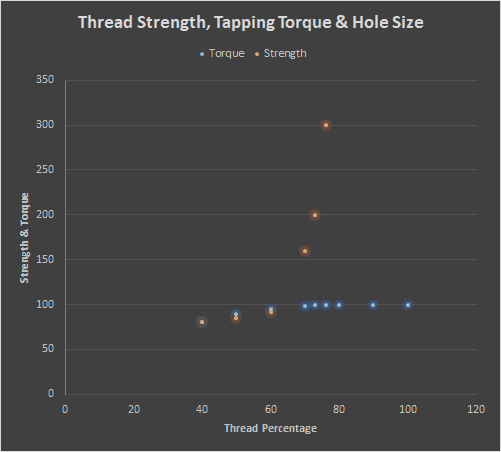

Here’s what’s key—a 100% thread is only 5% stronger than a 75% thread, but it requires 3 times the torque. So, for just a tiny bit stronger thread you wind up with a much greater chance of breaking your tap. The chart on this slide shows the relationship:

The red-orange dots are tapping torque. Look how fast it climbs when thread percentage gets above 60%. The blue dots are thread strength—it flattens out just when the torque starts climbing.

The recommended drill size is almost always a 75% thread. Great strength, but well into that too much torque zone.

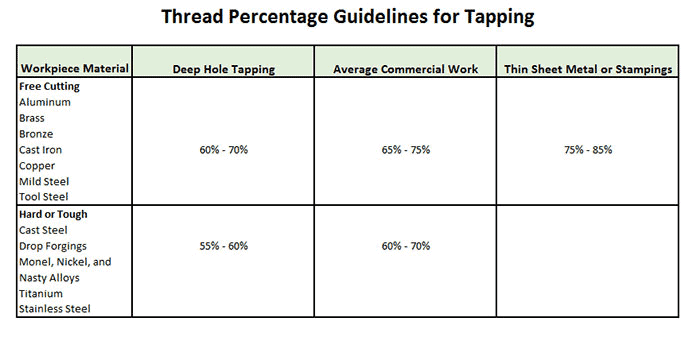

Here are some guidelines for thread percentages based on different conditions:

Dial back to less than 75% when tapping deep holes. Dial back for hard and tough materials too.

Be sure to check the requirements on the job—your customer may require a particular thread percentage. But if they don’t, or if it’s within the ranges in this chart, dial back the thread percentage and your taps will thank you.

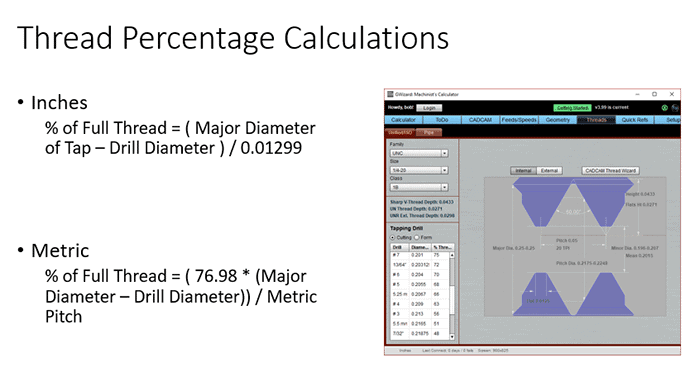

Calculating your thread percentage is easy. The formulas are right here:

Or, you can use a handy chart like the one in CNCCookbook's G-Wizard Machinist’s Calculator (pictured above).

#2 - Form Taps

My second suggestion is to use Form Taps where possible.

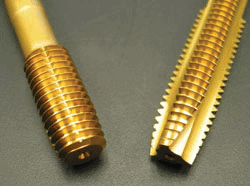

Form Taps don’t generate chips, they push the material into shape, cold-forming the threads.

The most common reason taps break is they get bound up in their own chips, which can’t happen with a form tap.

Form taps also have a greater cross section, so the taps themselves are stronger than cutting taps.

They have two disadvantages.

First, form taps can’t be used on hard materials. You can only form tap up to 36 HRC hardness materials. That’s a lot more materials than you’d think, but there’s definitely materials that can’t be form tapped.

Second, some industries don’t allow form taps because the process can create voids that trap contaminants on the threads. Form Tapping can also create stress risers on the threads.

#3 – Thread Mill

Always consider thread milling instead of tapping on critical or tough jobs.

Thread mills last longer than taps on a job, though they do cut more slowly.

You can thread closer to the bottom of a blind hole, and a single thread mill can cut a variety of thread sizes.

Plus, thread mills can be used in harder materials than taps. They may be your only option on materials over 50 HRC.

Lastly, if you break a thread mill, it’s smaller than the hole, so it won’t get stuck in the part the way a tap does.

#4 - Use Lubricant

My fourth suggestion to minimize tap breakage is to consider a purpose-made tapping lubricant.

Most machine coolants, especially water soluble, are not as good for tapping. If you’re having problems, try using special tapping lubricant. Put it in a spill proof cut that sits on the machine table and program the g-code to dip the tap automatically in the cup.

You can also try coated taps, which add lubricity through their coatings.

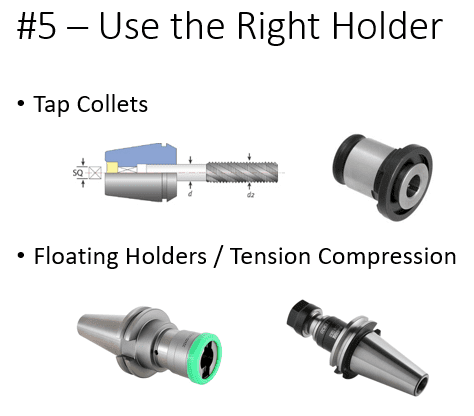

#5 – Use the Right Holder

Let’s talk about tool holders for tapping.

To start, use a holder that locks the square shank on a tap so it can’t twist in the holder. Tapping uses a lot of torque, so having a positive lock on that shank is helpful.

You can do that with chucks made for taps or with special ER tapping collets.

Second, consider a floating holder even if your machine supports rigid tapping.

They’re a must without rigid tapping, but they will increase your tap life even in most rigid tapping situations.

The reason is the machine is limited by acceleration of spindle and axes on how closely it can synchronize the tap to the threads it’s making. There’s always some axial force pushing or pulling. A floating holder will relieve stress from lack of perfect synchronization.

#6 - Spiral Fluted Tap

If you’re tapping a blind hole, failure to extract the chips is the most common reason taps are broken.

That’s why they have spiral fluted taps—they eject the chips up and out of the hole.

Note that spiral fluted taps are not as strong as the more common spiral point taps, which is why they’re not used all the time. Just use them on blind holes.

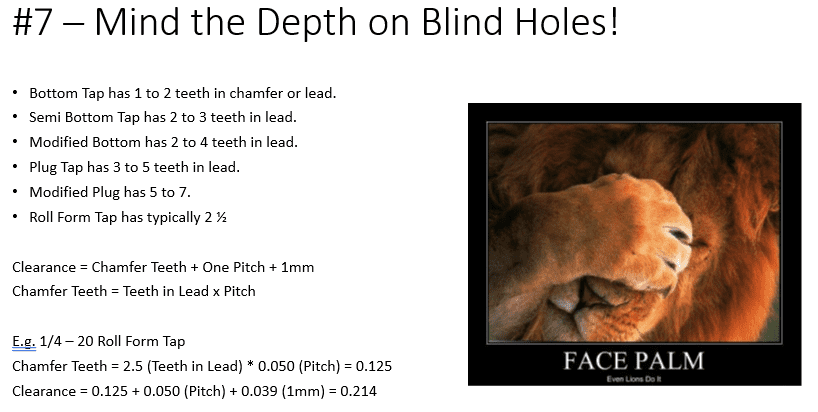

#7 - Mind the Depth

Speaking of blind holes, my 7th and last tip is to mind the depth on blind holes. Crashing the tap into the bottom of the hole will almost certainly break it.

Many are not aware, but you can calculate how much clearance to leave at the bottom and it’s probably more than you’d think.

I walk you through the math below and you can see that for the example ¼-20 roll form tap we needed not quite a ¼ inch of clearance from where the tap stopped to the hole bottom.

You can also see that based on the type of tap you’ll need to leave slightly different allowances.

Conclusion

Here are 7 ways to dramatically reduce your risk of breaking a tap:

- Choose the best hole size

- Use Form Taps where possible

- Thread Mill critical and tough jobs

- Use purpose-made Tapping Lubricants

- Use the right tool holder

- Extract chips with a spiral fluted tap

- Mind the depth on blind holes

Taken together they provide a wealth of techniques that will make breaking taps far less likely in your shop.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.