What is cutting force?

Cutting force is the resistance of the material being cut against the intrusion of the cutting tool. The force directions and strengths can vary based on the different machining process such as turning, milling, drilling and so on. Cutting Force is a combination of a Friction Force generated as the chip slides over the tool and a Shear Force generated by the tool slicing off the chip. The strongest cutting forces are encountered in metal cutting machining operations.

What is the unit of cutting force?

Cutting forces are measured in Newtons for the metric system and either pounds-feet or ounce-inches in Imperial.

Why should we care about Cutting Forces?

The analysis of Cutting Forces is important when researching or trying to solve the following:

- Improving cutting processes,

- Improving the cutting tool (geometry, coating)

- Improving auxiliary equipment (such as coolants)

- Dimension machine structures and components to ensure they have enough rigidity

- Comparing and optimizing machining strategies

- Verifying process models and simulations

- Performing intelligent programming by means of integrating the measured force into the machine control system

For day-to-day machining, the most important reason to analyze Cutting Forces is Tool Deflection.

Because it can cause Tool Deflection, which is bad for Tool Wear

Tool Deflection is the tendency for a cutting tool to deflect when force is applied to the tip. Such deflection can cause abnormal tool wear. The greater the Cutting Force, the greater the Tool Deflection and associated Cutting Tool Wear.

Cutting Force is a Bad Way to Size CNC Machine Axis Motors

Sometimes, people contact me wanting to know how to use Cutting Force to size their axis stepper or servo motors. They're thinking that overcoming the cutting force in the machining process is all these motors have to do, and they will have a good performing machine.

It turns out not to be case. In fact, if you size your motors this way you will you have a machine that is woefully underpowered. The reason is that most of the motor's power is used to accelerate the machine's axes. You can calculate how much power is needed with Newton's famous equation:

F = ma

Where F is the force, m is the mass being accelerated, and a is the acceleration in the appropriate units.

How do we Calculate Cutting Force using G-Wizard?

If you have our G-Wizard Feeds and Speeds Calculator, it's relatively easy to calculate the tangential cutting force. That's because G-Wizard will tell you how much torque is being used in the cut, or at least how much power is being put out by the spindle for most milling operations. From there, it's a short step to calculate the tangential cutting force using this formula:

F = T/L

Where F is the force, T is the Torque, and L is the lever arm that the torque applies against. In most cases, that would be the radius of the cutting tool, assuming it is a rotating tool.

Example: How do you calculate cutting force for drilling?

Let's say we have a 3/4" twist drill. G-Wizard gives us feeds and speeds of 6 IPM and 458 RPM. It says the cut will take 2.5484 Horsepower.

We can convert that to torque using the time honored equation:

H = T x rpm/5252 or T = H / (rpm/5252)

So, Torque in this case is 2.5484 / (458/5252) which is 29.3 ft-lb of torque.

Lastly, we use F=T/L to calculate the force:

F = 29.3/(0.375/12) = 0.016 lbs of Cutting Force.

How can we Reduce Cutting Forces?

A reduction in cutting speed or spindle speed will reduce cutting forces. Basically, any factor that reduces Material Removal Rate will reduce cutting forces. There are also toolpath considerations such as Climb Milling that can reduce cutting forces.

How to Measure Cutting Forces Directly

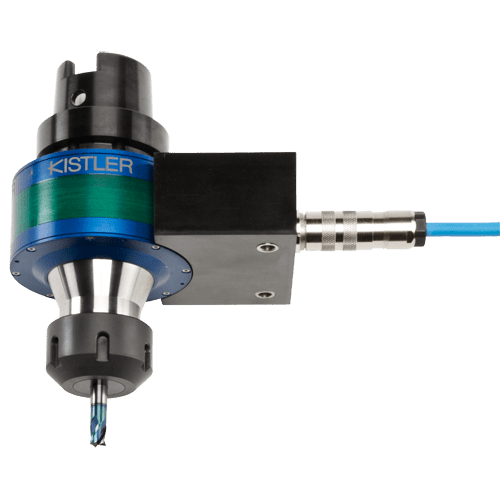

Measuring Cutting forces is done with a cutting force dynamometer.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.