1 month by cncdivi

Fixture Design: What’s the very first thing to do when designing a fixture?

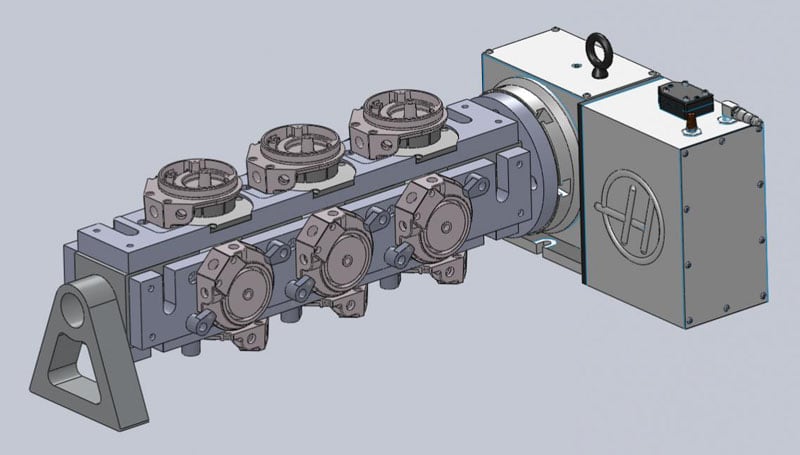

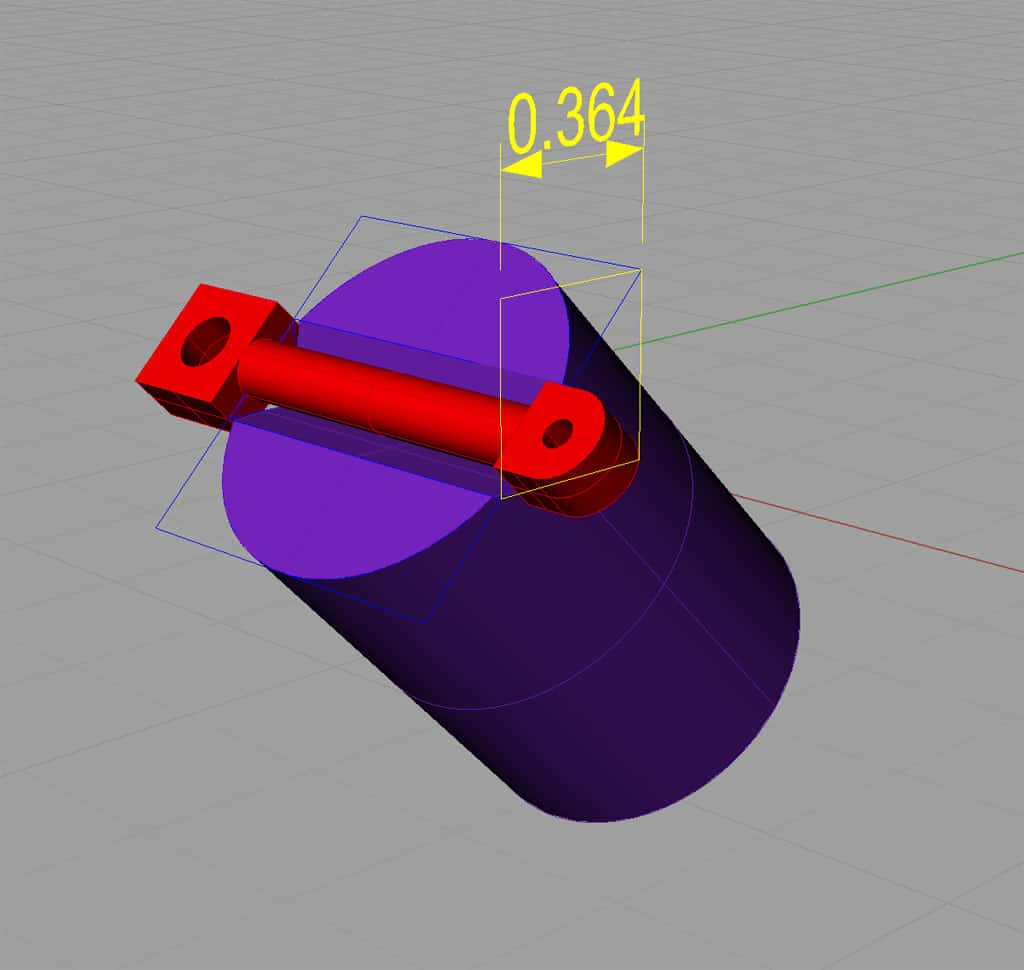

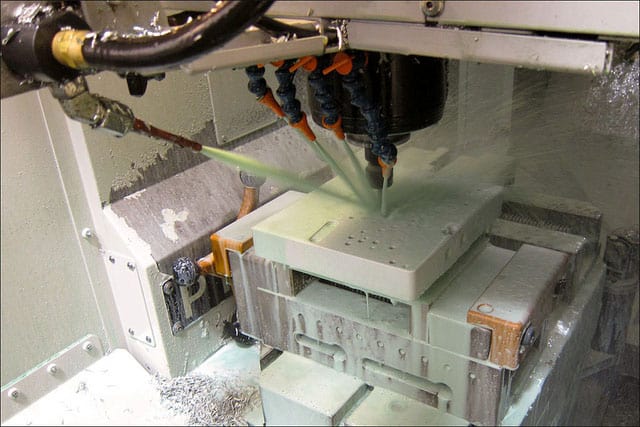

Designing fixtures can be so complex and specialized, that there are many CNC firms totally dedicated to the job of offering Fixture Design Services. These days, many firms are using 3D Printing to create sophisticated fixtures.

If you’re like me, you’re something of a fixture junkie. Smart fixturing really can save a lot of time, and it’s hard to learn to be good at fixture design. So, as a fixture junkie, I am always on the lookout for new fixturing ideas.

But here’s an important fixturing tip, perhaps the most important one you will ever see:

The first step in fixture design is to decide whether you even need a fixture at all!

It’s been said more than once that great fixtures are the secret to profitability for machine shops. But that’s not always true.

There’s the shops that leave a couple of vises permanently mounted to the table, set their work offsets to the corner of a fixed jaw, and swear by that. Not much of a fixture in that, yet many of these shops seem to do just fine.

Sometimes a fixture pays handsomely, while other times it is an additional expense that won’t pay for itself. How do you tell whether a fixture makes good economic sense or not?

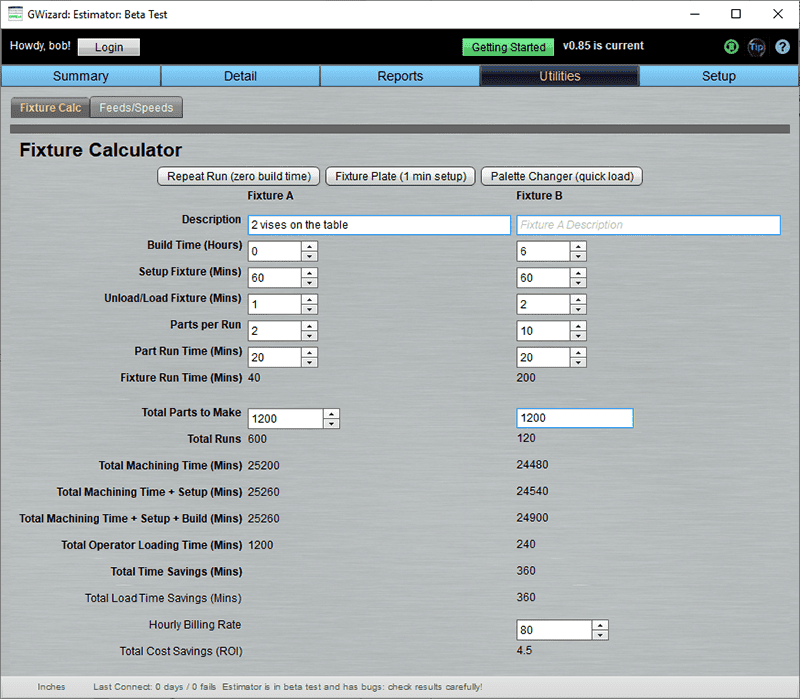

It turns out that it is tragically knowable whether spending time to create a fixture makes sense or not. Our G-Wizard Estimator software includes a calculator that’s designed to help you decide whether a particular fixture makes sense or not. All you have to do is answer a few question and it cranks out the answer for you.

Here’s what the Fixture Calculator looks like:

The Fixture Calculator from G-Wizard Estimator…

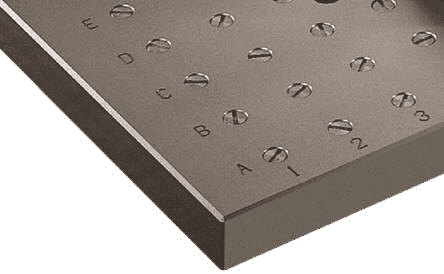

The idea is to fill out some basic information on two fixturing alternatives. In this case, we’re comparing a couple of vises to a custom fixture plate with toe clamps that will hold 10 parts. So, the vises can do 2 parts per lot and the fixture plate does 10. Here’s the basic information that has to be filled in to evaluate the fixture design:

– Description: Just so we can keep the two options straight.

– Build Time: How long to build the fixture? In this case, we already had the two vises so there is no build time.

– Setup Fixture: How long will it take to setup the fixture on the machine?

– Unload/Load: Time to unload the parts in the fixture and load new material for the next run.

– Parts per Run: How many parts will the setup take per run?

– Part Run Time: How long to run a single part?

Lastly, we need to know how many total parts are to be made. In this case, I picked 1200 because it was the number where the two came out equal in terms of total time.

Of course there are some things to think about:

– The fixture saves quite a lot of Operator load time–360 minutes for this example. Can you do something valuable with that time? You may prefer a fixture that doesn’t yield a Total Time Savings just because it frees up an Operator to do something else valuable enough to offset the Total Time Cost.

– The fixture saves Operator time, but it burns more skilled machinist time because the fixture has to be made. We’ve budgeted 6 hours for that in the example. You’ll have to decide whether the Operator Load Time Savings is worth spending some of the more skilled machinist’s time. In this case, we spend 6 hours of machinist time to save 6 hours of operator time. That might not be the best trade off.

– Is the fixture an investment in the future? Will the customer reorder more of the same parts? Can the fixture be re-purposed easily for similar parts? Perhaps a nice vacuum fixture that will see a lot of use is worth investing in even if it doesn’t make sense for the particular job it’ll be used on first.

By playing with some different scenarios, you can get an idea pretty quickly of whether it will make sense on a particular job to take time out and build a fixture.

Having a good fixture calculator sets you up to start your Fixture Design efforts right. You’ll know whether investing in building and designing a custom fixture makes sense for your job.

If you’d like to try the Fixture Calculator, you’ll need to get G-Wizard Estimator. While Estimator is in Beta, it’s free for anyone who can access G-Wizard Calculator either via Trial or Subscription. If you haven’t tried our G-Wizard Calculator Software, by all means give it a test drive. You’re in for a real treat as our many customers will tell you.

Video: What’s a Good Fixture Worth?

Hey, don’t want to mess with G-Wizard Calculator or Estimator?

No worries!

The fellow that runs Mitee-Bite saw the Fixture Calculator in G-Wizard Estimator and asked if I would make it available for their web site. Not a problem. Plus, I include the web version below.

You really do need to figure out whether a fixture makes before launching into fixture design. So I wanted to make sure you’ve got exactly the resources you need to answer that question. I do recommend you try G-Wizard Estimator though at some point. There’s even more power there for your planning and estimating needs.

CNCCookbook Fixture Calculator

Use this fixture calculator to determine if you'll save with a custom workholding fixture. Compare two scenarios on the left and right.

Fixture A |

Fixture B |

|

Description |

||

Build Time (Hours) |

||

Setup Fixture (Mins) |

||

Unload/Load Fixture (Mins) |

||

Parts Per Run |

||

Part Run Time (Mins) |

||

Fixture Run Time (Mins) |

||

Total Parts to Make |

||

Total Runs |

||

Total Machining Time (Mins) |

||

Total Machining Time + Setup (Mins) |

||

Total Machining Time + Setup + Build (Mins) |

||

Total Operator Loading Time (Mins) |

||

Total Time Savings (Mins) |

||

Total Load Time Savings (Mins) |

||

Hourly Billing Rate |

||

Total Cost Savings (ROI) |

||

Definitions

| Repeat Run | Click to set Build Time to zero. On repeat runs, the fixture already exists. |

| Fixture Plate | Click to reduce Setup Time to 1 minute. With a fixture plate, we're dropping onto pins. |

| Palette Changer | Click to reduce Unload/Load time on Fixture B to 30 seconds. |

| Build Time | The length of time it will take to build the fixture |

| Setup Fixture | The time needed to setup the fixture on the machine so it's ready to use |

| Unload/Load Fixture | The time needed to load material into the fixture and remove parts for the next run |

| Parts per Run | Number of parts the fixture produces per run |

| Part Run Time | Length of time to finish a single part on a run |

| Fixture Run Time | Time to finish all the parts in the fixture on a single run |

| Total Parts to Make | Total parts that will be made before the fixture is removed |

| Total Runs | Number of runs required to make all the parts |

| Total Machining Time | Total time to machine all runs |

| Total Machining Time + Setup + Build | Overall time for the job |

| Total Operator Loading Time | Time the operator will spend loading and unloading |

| Total Time Savings | Total savings of Fixture versus the other fixture |

| Total Load Time Savings | Total load time savings of Fixture versus the other fixture |

| Hourly Billing Rate | The hourly rate you charge for the job. Need to calculate your Machine Hourly Rate? Try this CNC Machine Hourly Cost Calculator. |

| Total Cost Savings (ROI) | Based on the time savings and hourly rate, this is your total cost savings. It's basically the ROI of Fixture B over Fixture A. |

Fixture Productivity Tips

- Reduce labor costs through longer cycle times with high-density fixtures. Longer cycles allows operators to run additional machines or perform other tasks. Longer cycles with a high-density fixture also opens the possibility for profitable lights out machining.

- Using this calculator will identify how much more quickly you can move jobs through your machines. Moving jobs quickly means increased capacity without increasing machinery or employees.

- Tool changes are reduced with more parts on the table as each tool goes through every part before changing to the next tool. This saves additional time and reduces wear and tear on your machinery.

- Creative fixture designs and methods can also reduce the number of operations needed to make a part.

- Machine idle time can be drastically reduced by loading and unloading fixtures offline while the machine makes chips.

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

![Fixture Design Fundamental [ Do You Need a Fixture? ]](https://www.cnccookbook.com/wp-content/uploads/2020/04/VMC4thTombstone.jpg)

Bob,

If parts are simple enough that maybe only one tool change is required, if it is a close to net size sawed barstock job, it can be running in 2 or 3 minutes, no fixture or soft jaws required. With a complex / odd shaped part with 3 or more tools, the time savings in doing multi parts per tool change can be the deciding factor. On a machine with a large Z, the chip to chip time can really add up.

Pt

Although fixtures can be a very profitable venture, i find that with my work (Custom Guns) a fixture is as yet not in my future. When the work comes in and there are several of the same projects coming in at the same time i can see the need to build a fixture, but until it does I’m stuck with 1 off’s.

This works assuming 0 tool changes, but what about if you have 10 tool changes and it takes 10 seconds chip to chip? That’s 100 seconds of tool changes per run, so over 600 runs that’s 1000 minutes of tool changing, and over 120 runs that’s 200 minutes of tool changing for the same number of parts. (not certain my math is correct, but I think so)

Don’t get me wrong, I like this idea, and I guess I could just add it in when I fill this out, but that could get tedious. I think if you added a tool change time and number of changes or something on the next version, that would make this even better.

Kevo, the part time is expected to include tool changes. I don’t really want to break it out because there are any number of things we might then want to break out. Better to just figure it into your part time.

BTW, even if it was broken out, tool changes will vary depending on whether your CAM software can do Tool Sorting for multiple parts. In other words, it does every feature with the tool on every part before changing to the next tool. Some CAM does that, some does not. Makes a big difference as you point out.

Hi Bob,

Why do you not include the cost of the fixture, other than build time? While in most cases the fixture materials cost may be minimal when compared to build hours, some fixtures may need a number of pricey bought-in parts which need to be considered as part of the cost comparison.