![]()

G-Wizard Calculator

Fast, Easy, Reliable Feeds and Speeds

Light Years Ahead.

Traditional Feeds and Speeds involve too much guesswork

Trying to gauge by "feel"

Dealing constantly with new materials

So many different kinds of tooling

Micro-milling is a whole new ballgame

HSM is a game changer, with another new learning curve

Having to be right the first time on small runs and expensive parts

Is everyone in the shop doing feeds and speeds differently?

Calculating Feeds and Speeds is time consuming

Calculations are complex: G-Wizard considers over 60 variables each time

Going through your Machinist's Handbook is no picnic

Every part needs feeds and speeds

Job Quotes need feeds and speeds

Phew!

You Need Good Feeds and Speeds Quickly and Easily

With G-Wizard Here's How:

Start Simple

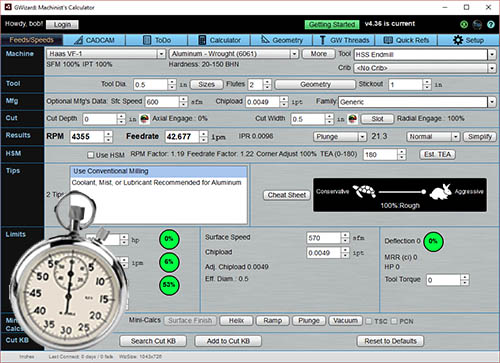

Fill in the fields, left to right, top to bottom to get your feeds and speeds.

G-Wizard will consider 60 variables to come up with its answer. It knows the capabilities of your machine, right down to the spindle power curve. It can adjust for the lack of rigidity on smaller machines. It's Material Database covers thousands of combinations across many families. It has a huge library of different tooling types that you can choose from.

G-Wizard gives you reliable Feeds and Speeds tuned for your machine, material, tooling and cut conditions.

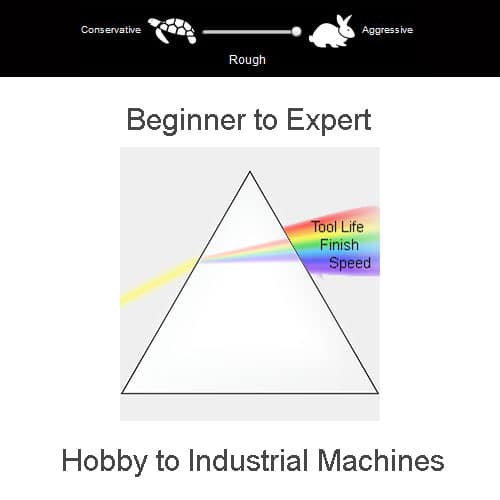

Check the Tips

Remember thumbing through tooling catalogs and seeing all those little notes giving you nuggets of wisdom about what to do in various situations? Do you remember and use all that? Me neither, until G-Wizard!

We put a whole bunch of those tips and rules into G-Wizard. It knows the darnedest things, and it's always on the lookout for a chance to share them with you in the "Tips" section. For example, as CNC'ers we're used to pretty much always Climb Milling, but it isn't always the best thing to do. As your width of cut approaches the full diameter of the cutter, it turns out that Climb Milling forces the cutting geometry to turn more negative, which increases cutting forces and has various other effects that aren't helpful. So G-Wizard gives you a tip. For this cut you ought to use Conventional Milling.

Why remember all that when G-Wizard will do it for you?

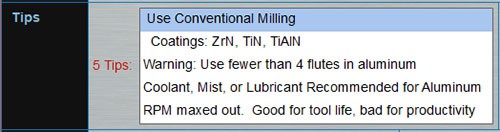

Rouging or Finishing, Tortoise or Hare?

Not all cuts are equal. Sometimes we want the ultimate Material Removal Rate to rough our way through buckets and buckets of chips. Sometimes we want the finest finishing pass we can get without making the tool rub, which shortens its tool life. What if we need something in between? Maybe we've got a new tool and we're not totally sure about it yet. Or, perhaps we're nearly done with a job that has a lot of hours invested in it. Making a mistake now would be very costly. Let's take it easy and be a little more conservative.

G-Wizard has got you covered for these situations with our exclusive Tortoise and Hare Slider. Dial in whatever level of Conservatism and Fine Finish you need versus Roughing and all out Hare-y (sorry!) chip throwing action.

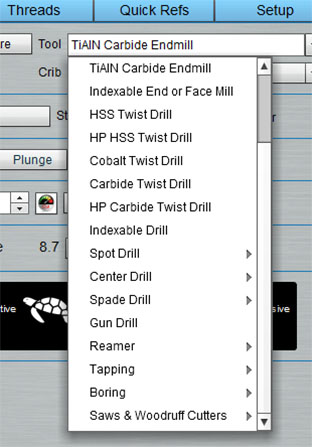

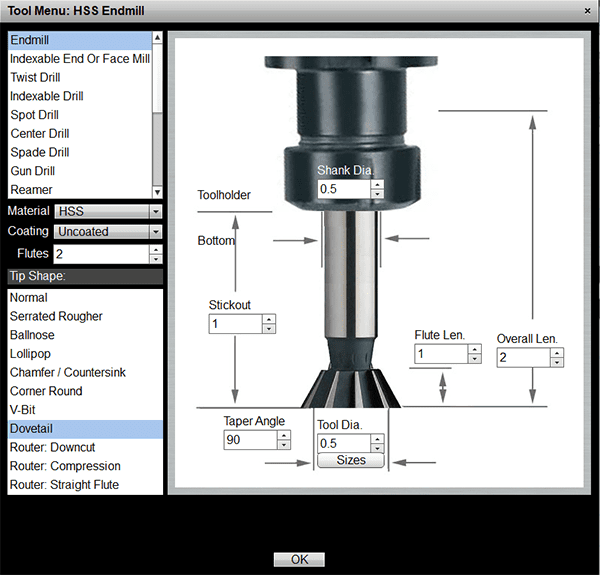

So Many Tools to Choose From

Computer people like to say, "There's an app for that." Seems like CNC people ought to be saying, "There's a Tool for that," because we sure do use a lot of different tools. And every single one of them needs it's very own Feeds and Speeds. G-Wizard Calculator covers a great many tools and we're constantly adding new ones. Our tool menu is large enough you can't really take it in with a single screen shot:

And like that old TV ad used to say, "But wait, there's more!" Because using the Geometry menu you can access even more tool types:

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.