![Lean Manufacturing Tools [Easy Tutorial and Guide]](https://www.cnccookbook.com/wp-content/uploads/2016/09/LeanManufacturingWordCloud.jpg)

TOOLS AND TECHNIQUES

Get the latest Tools and Techniques to up your CNC Machining game. Free CNC Training Courses. Free CNC Calculators. CNC Dictionary.

![Lean Manufacturing Tools [Easy Tutorial and Guide]](https://www.cnccookbook.com/wp-content/uploads/2016/09/LeanManufacturingWordCloud.jpg)

Mastering CNC 3D Carving: A Complete Guide

What does it take to transform a concept into a stunning CNC 3D carving? With the right tools and knowledge, you can engrave intricate designs and elevate your craftsmanship to new heights. Our guide cuts to the chase, providing you with insights on selecting...![Tormach’s New Machine [ 1500MX ]](https://www.cnccookbook.com/wp-content/uploads/2024/04/1500MX-Base-Machine_Windows_1500px-300px.webp)

Tormach’s New Machine [ 1500MX ]

Tormach has just released a new machine, and it is a potent new offering in their lineup. The new Tormach 1500MX has almost everything anyone could wish for in terms of upgrades to the company’s 1100MX machines. For starters, the machine is largely made in...

Master STL to Gcode Conversion: Step-by-Step Guide for Success

Struggling with stl to gcode conversion for 3D printing or CNC Machining? Look no further. In this article, you’ll quickly grasp how to transform STL files into G-code, the language your 3D printer or CNC Machine understands. We’ll guide you through the selection of...![Thermal Expansion Equations [Easy Calculation Formulas]](https://www.cnccookbook.com/wp-content/uploads/2024/04/img_6612ef2961223.png)

Thermal Expansion Equations [Easy Calculation Formulas]

Thermal Expansion Equation G-Wizard’s thermal expansion calculator uses a simple formula for thermal expansion of any object. The equations for linear and volumetric expansion are very similar. Linear expansion formula: ΔL = aL₁(T₂ – T₁) Volumetric expansion...

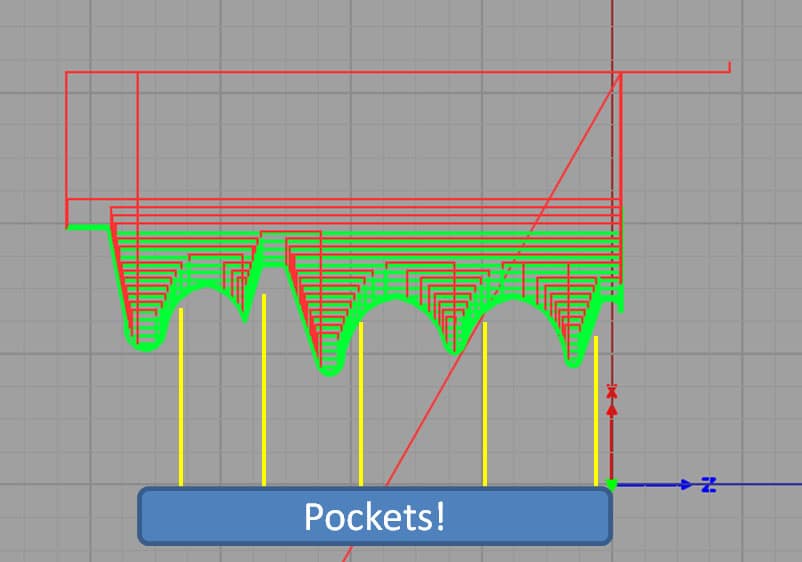

G71 Type 2: Rough Turning With “Pockets”

G71 Type 2: Rough Turning With “Pockets” This article is part of CNCCookbook’s G-Code Tutorial. What is a “Type II” G71 Cycle? The piece on G71 Type I mentioned that the Type II cycle is appropriate for profiles with pockets. You might...![Tap Speed and Feed Calculator [Free + Pro Calculator]](https://www.cnccookbook.com/wp-content/uploads/2016/07/TappingDrillChart.jpg)

Tap Speed and Feed Calculator [Free + Pro Calculator]

Free Tap Speed and Feed Calculator Free Tap Speed and Feed Calculator Threads per inch TPI Spindle Speed:RPM Feed Rate (Feed Calculator):IPM Tap Feeds and Speeds Basics Tapping Feeds and Speeds are pretty easy to calculate because they’re constrained by the...![Lights Out Manufacturing [ Definitive Guide + 21 Tips ]](https://www.cnccookbook.com/wp-content/uploads/2018/04/img_5ae4b4b1dca2e.png)

Lights Out Manufacturing [ Definitive Guide + 21 Tips ]

Lights Out Manufacturing: Definitive Guide + 21 Tips Lights Out Manufacturing: let the machines keep working after you go home. It’s the next step for greater productivity and profitability in manufacturing. This Guide shows you how to start doing Lights Out...![Tool Setter: Measuring Tools for Length [Easy Guide]](https://www.cnccookbook.com/wp-content/uploads/2017/11/TouchSetter.jpg)

Tool Setter: Measuring Tools for Length [Easy Guide]

Tool Setter: Measuring Tools for Length [Tool Data Management] CNC depends a lot on accurately measuring tools for length. CNC machines require tool data, by which I mean length and diameter information, so they understand exactly where the cutting is happening. The...

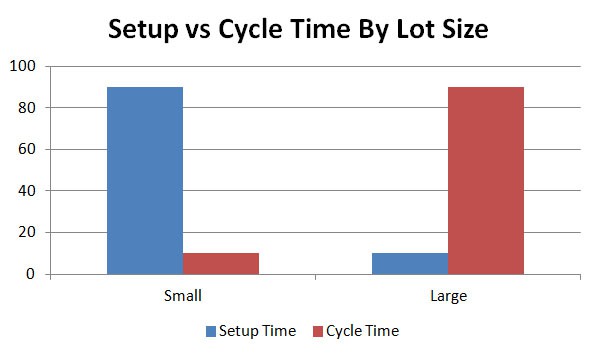

CNC Setup Time and Cycle Time Savings

CNC Setup Time and Cycle Time Savings This piece belongs to our CNC Machining and Manufacturing Cookbook series. It contemplates on which should be prioritized to enhance Shop Productivity – reducing Machine Cycle Time or Machine Setup Time. Presumably...Mini Lathe Mods Catalog

Mini Lathe Mods Catalog Mini Lathe Mods to make it better, stronger, faster: the $6 million lathe! This page is my catalog of all the lathe modifications I’ve stumbled across in my web travels. I couldn’t begin to tell you how good they are, but they sure...![Eccentric Turning and Offset Turning [ Lathe Tips ]](https://www.cnccookbook.com/wp-content/uploads/2021/06/eccentricsplitfinished.jpg)