Struggling with stl to gcode conversion for 3D printing or CNC Machining? Look no further.

In this article, you’ll quickly grasp how to transform STL files into G-code, the language your 3D printer or CNC Machine understands. We’ll guide you through the selection of slicing and CAM software, the setup of your model, and getting the precise G-code output for optimal results. Let’s dive into the process that takes you from digital model to tangible object.

Key Takeaways

- For 3D Printers, STL files are converted into G-code using slicing software, which allows for precise adjustments to print parameters like filament extrusion, improving print quality and compatibility across different 3D printers.

- For other CNC Machines, STL files are converted into G-Code using CAM Software.

- The STL to G-code conversion process involves choosing appropriate slicing software, adjusting model resolution and settings, and generating G-code with optimized support structures and machine-specific commands for high-quality 3D prints.

- When using CAM Software for CNC Machining G-Code, there are several parameters to adjust for high-quality parts.

- Post-conversion quality assurance through G-code review is essential to avoid print failures, and continuous optimization of print settings and printer maintenance can significantly enhance the final print results.

Understanding STL and G-Code in 3D Printing

Imagine a digital potter’s wheel, where the artist’s hands are replaced by a series of tiny triangles. That’s an STL file, the most common 3D printing file format, which describes a model’s geometry through a mesh of interconnected triangles. But how does this virtual sculpture become a physical object?

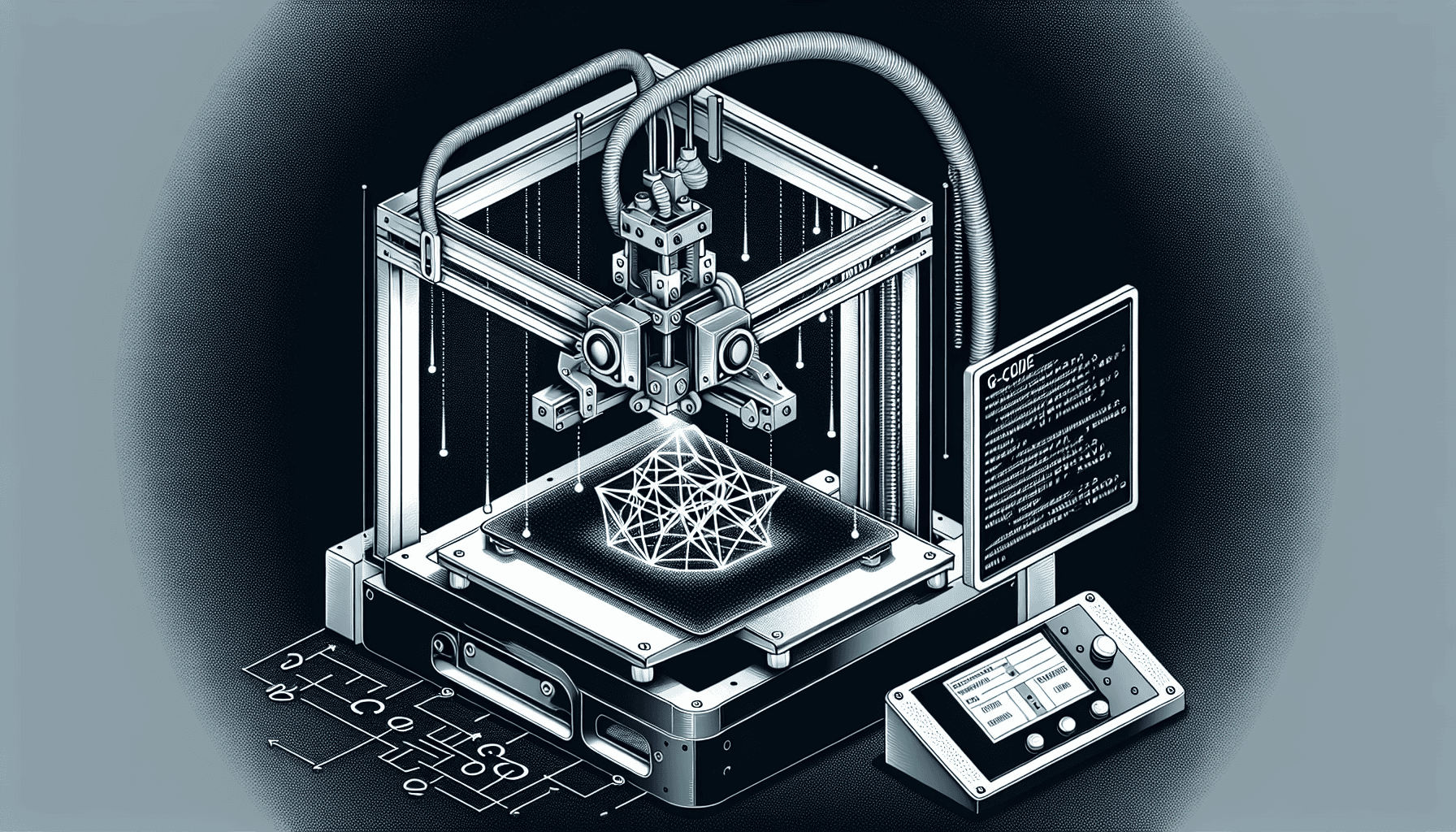

Enter G-code, the programming language that gives 3D printers and CNC machines their marching orders. If the STL file is the blueprint, G-code is the contractor interpreting that blueprint, guiding the actual movements of the cnc machine to create the physical object. This conversion from STL to G-code is achieved through slicing software, which translates the 3D model’s geometry into executable printer instructions, or g code files. To generate g code, it’s like giving directions to a robot to build your design. With the generated g code, your CNC machine can now follow those directions and bring your design to life.

Understanding this conversion process is the key to mastering 3D printing. By learning how to convert STL files to G-code, you’ll gain greater control over the printing process, enabling you to produce high-quality prints reliably and consistently.

Key Advantages of Converting STL Files to G-Code

So, why convert STL files to G-code? One of the biggest advantages is the ability to make precise adjustments to print parameters. Converting STL to G-code allows you to fine-tune settings such as filament extrusion, which can improve print accuracy and quality, and prevent issues like oozing. This level of control can lead to maximized print quality and optimized material use.

Moreover, G-code instructions transform 3D designs into actionable instructions for a 3D printer, ensuring the efficient construction of the object layer by layer. It’s like having a detailed recipe for your 3D printer to follow, ensuring the final product comes out just right.

One of the most compelling benefits of converting STL files to G-code is the universality of G-code. Once your designs are converted, they can be printed on a wide range of 3D printers. This universality provides greater control over the printing process and makes your designs widely compatible.

The Conversion Journey: STL to G-Code

The journey from STL to G-code can be broken down into manageable steps:

- Choose the right slicing software, considering your printer model and project requirements.

- Import your STL file into the slicing software.

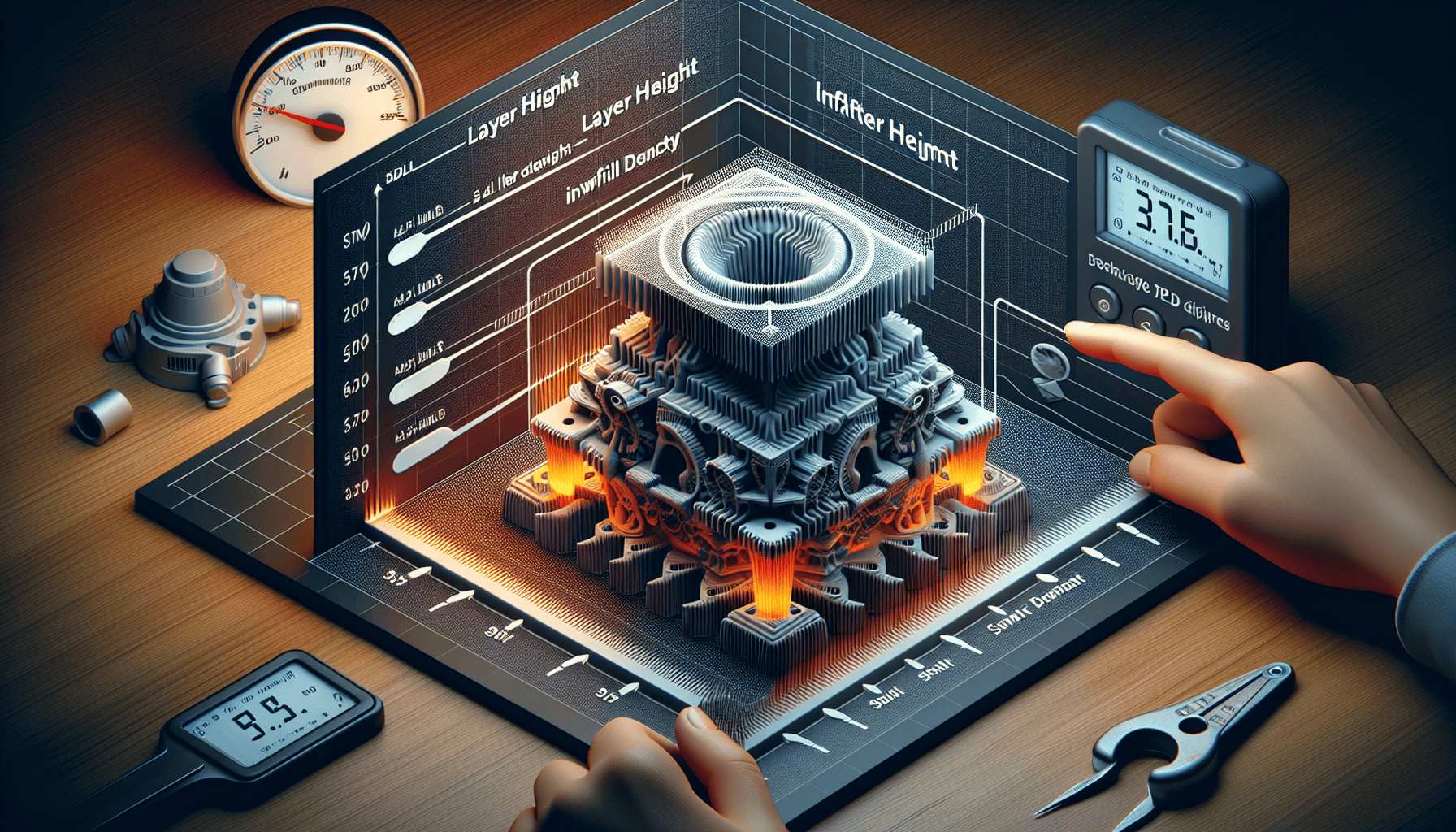

- Configure your settings, such as layer height, print speed, and infill density.

- Slice your model to generate the G-code, which contains instructions for your 3D printer on how to print the object.

By following these steps, you can easily convert your STL file into G-code for 3D printing.

Throughout the conversion journey, you’ll make important decisions that can affect the quality of your final print. For instance, you’ll adjust your model’s resolution settings based on its complexity and the capabilities of your printer. This process gives you the opportunity to customize your print to your specific needs, ensuring you get the best possible result.

Choosing Your Slicing Software

Your choice of slicing software is a key factor in successful STL to G-code conversion. We recommend Cura, an open-source slicer created by Ultimaker. Cura is free, user-friendly, and produces high-quality results, making it an excellent choice for both beginners and seasoned 3D printing enthusiasts.

Preparing Your STL File

Preparing your STL file for slicing is a crucial step in the conversion process. You’ll need to adjust the model’s:

- resolution

- layer height

- infill density

- wall thickness

to match your desired print quality and strength. These adjustments are akin to a chef fine-tuning a recipe, modifying ingredients and cooking times to achieve the perfect dish.

However, it’s important to strike a balance. Over-refining your mesh by using too many tiny triangles can increase your file size unnecessarily, potentially exceeding the printing capabilities of most systems. Before slicing, it’s essential to optimize settings like resolution and mesh complexity to ensure a balance between high-quality prints and manageable file sizes.

Generating Your G-Code

Now that your STL file is prepped and ready, it’s time to generate your G-code. Your slicing software plays a crucial role in this process, determining factors such as support structures and layer heights. It’s like a translator, interpreting the language of your STL file and communicating it to your 3D printer in a language it understands.

Slicing software offers several features for 3D printing, including:

- Generating support structures for complex 3D objects

- Modifying machine-specific commands for optimal printing results

- Automating the generation of G-code commands

- Providing features to preview and edit toolpaths for 3D printing

In other words, with slicing software, you can craft a customized set of instructions tailored to your specific project and printer.

Post-Conversion Checks for Quality Assurance

Congratulations! You’ve made it past the conversion process, but the journey isn’t over yet. It’s time for some post-conversion checks to ensure the quality of your G-code file. The quality of the G-code determines the precision and accuracy of the movement of the print head and the extrusion of the filament, which directly affects the quality of the 3D printed part.

Reviewing the G-code is crucial to spotting potential issues, ensuring a successful print process, and preventing waste of materials and time. It’s like proofreading a draft before submitting the final version, catching any errors before they can cause problems.

Slicing software provides preview and simulation features to visualize the printing process, allowing for the identification and correction of errors post-conversion. This gives you a chance to correct any potential errors before they become physical misprints, saving you time, materials, and frustration.

Printing with G-Code: From File to Reality

Now that you’ve generated and checked your G-code, it’s time to bring your 3D model to life. This stage involves more than just hitting ‘print’; there are several practical aspects to consider to ensure a successful print. One of these is setting up the print bed by adjusting the screws to alter the gap between the nozzle and the build plate.

Temperature control is another important factor. To ensure a successful print, follow these temperature guidelines:

- Set the nozzle temperature appropriately to prevent stringing.

- Set the build plate temperature appropriately to prevent warping.

- Getting the temperature right is vital for the appearance and integrity of the print, just like baking a cake.

Before you start the print, execute the homing process to align the printhead with the bed’s origin point, and run a first-layer test to verify an even print surface. Once everything is set up, turn on the printer and watch your design come to life, as the prepared, level, and temperature-controlled bed brings the G-code file into reality.

Optimizing Print Settings for Best Results

Even after mastering the conversion process and successfully printing your design, there’s always room for improvement. Optimizing your print settings involves:

- Fine-tuning aspects like the flow rate

- Calibrating E-steps to address print gaps caused by over- or under-extrusion

- Balancing print speed to avoid quality issues like ringing or overheating.

Maintaining your printer is also a key part of optimizing print quality. Regular tasks such as cleaning the print bed, lubricating the printer rails, and keeping firmware up to date can make a significant difference in the quality of your prints. It’s like maintaining a car; regular checks and minor adjustments can keep it running smoothly and prevent bigger problems down the line.

Don’t be afraid to experiment. Try different build plates and adhesives to see how they affect adhesion and the final surface finish. And remember, achieving the best results often requires a delicate balance of settings and techniques, so keep iterating and refining your process.

Troubleshooting Common Conversion and Printing Issues

Even with careful planning and preparation, you may encounter some common issues with your prints. One such issue is a warped print bed, which can result in uneven first layers and affect overall print adhesion. To address this, ensure proper leveling of the print bed using a piece of paper to check the nozzle height at various points.

Temperature fluctuations can also affect print quality. For instance, a drop in room temperature can cause PLA to not adhere well, resulting in stringy and messy prints.

To tackle these issues and consistently produce high-quality prints, follow these steps:

- Maintain a stable printing environment by keeping the room temperature consistent.

- Adjust your printer settings as needed to compensate for temperature changes.

- Monitor the temperature during the printing process and make adjustments if necessary.

By following these steps, you can ensure that temperature fluctuations don’t compromise the quality of your prints.

Understanding STL and G-Code in CNC Machining

Imagine a digital potter’s wheel, where the artist’s hands are replaced by a series of tiny triangles. That’s an STL file, which describes a model’s geometry through a mesh of interconnected triangles. But how does this virtual sculpture become a physical object?

Enter G-code, the programming language that gives 3D printers and CNC machines their marching orders. If the STL file is the blueprint, G-code is the contractor interpreting that blueprint, guiding the actual movements of the cnc machine to create the physical object.

This conversion from STL to G-code is achieved through CAM software, which translates the 3D model’s geometry into executable printer instructions, or g code files. To generate g code, it’s like giving directions to a robot to build your design. With the generated g code, your CNC machine can now follow those directions and bring your design to life.

Understanding this conversion process is the key to mastering CNC Machining. By learning how to convert STL files to G-code, you’ll gain greater control over the machining process, enabling you to produce high-quality parts reliably and consistently.

The Conversion Journey: STL to G-Code

The journey from STL to G-code can be broken down into manageable steps:

- Choose the right CAM software, considering your printer model and project requirements.

- Import your STL file into the CAM software.

- Configure each feature on the STL file. Features are the visible features you need to machine away to create your part. They include pockets, 2D profiles, 3D profiles, holes, and much more.

- Use your CAM Software to generate the G-code, which contains instructions for your CNC Machine on how to carve the object out of solid material.

By following these steps, you can easily convert your STL file into G-code for CNC Machining.

Throughout the conversion journey, you’ll make important decisions that can affect the quality of your final print. For instance, you’ll adjust your machine's cut depth, choice of cutting tool, and feeds and speeds. This process gives you the opportunity to customize the process to your specific needs, ensuring you get the best possible result.

Choosing Your CAM Software

Your choice of CAM software is a key factor in successful STL to G-code conversion. Fortunately, we can offer a couple of resources to help:

- We have a detailed article to help you choose the best CAM Software for your needs.

- We have a comprehensive survey that shows you which CAM Software is the most popular as well as what the Customer Satisfaction is for each package.

Preparing Your STL File

Other than possibly providing some dimensioning information to your CAM Software, no prep is needed on your STL File.

Generating Your G-Code

Now that your STL file is prepped and ready, it’s time to generate your G-code. Your CAM software plays a crucial role in this process. You'll go through your 3D model feature-by-feature. For each feature, you tell it all the parameters it needs to cut out that feature. It’s like a translator, interpreting the language of your STL file and communicating it to your CNC Machine in a language it understands.

CAM software offers several features that are used to cut out the 3D Model's features. They're called "toolpaths" and include:

- Surfacing of flat areas to keep them perfectly flat and correctly dimensioned.

- Pockets are depressions in the surfaces.

- 2D Profiles are walls around raised areas.

- 3D Profiles are the most complex features as they can be any arbitrary shape.

- Holes are the most common feature found in CNC Machining.

Post-Conversion Checks for Quality Assurance

Congratulations! You’ve made it past the conversion process, but the journey isn’t over yet. It’s time for some post-conversion checks to ensure the quality of your G-code file. The quality of the G-code determines the precision and accuracy of the movement of the machine's spindle and associated cutter, which directly affects the quality of the machined part.

Reviewing the G-code is crucial to spotting potential issues, ensuring a successful process, and preventing waste of materials and time. It’s like proofreading a draft before submitting the final version, catching any errors before they can cause problems.

Most CAM software offers rudimentary simulation functions that have a lot of shortcomings. Better to use a purpose-made g-code simulator such as our own G-Wizard Software.

Machining with G-Code: From File to Reality

Now that you’ve generated and checked your G-code, it’s time to bring your 3D model to life. This stage involves more than just hitting ‘Go’; there are several practical aspects to consider to ensure a successful part.

One of these is setting up the machine with appropriate work holding to hold onto your part while it is being machined.

Another important factor is providing your CNC Machine with information about the cutters to be used in the job.

Lastly, we need to tell the machine where part zero is so it knows the origin of the coordinates being used.

Once everything is set up, turn on the printer and watch your design come to life!

Summary

Throughout this blog post, we have journeyed from the digital realm of STL files to the tangible reality of 3D printed and CNC Machinedobjects. We’ve explored the roles of STL and G-code, the benefits of converting STL to G-code, and the process of conversion using software. We’ve also discussed post-conversion checks, practical aspects of using G-code, optimizing settings, and troubleshooting common issues.

As we conclude, remember that mastering STL to G-code conversion is not just about understanding the technical process. It’s about unlocking the full potential of your machine, gaining greater control over your parts, and turning your digital designs into tangible reality. Keep exploring, keep learning, and keep making parts!

Frequently Asked Questions

What apps convert STL to G-code?

You can use slicing software like Cura, PrusaSlicer, or Simplify3D to convert STL files into G-code for 3D printing. These programs generate the G-code instructions from the STL model, allowing precise control over the printer's movements layer by layer.

What is the role of STL and G-code in 3D printing?

STL files describe a 3D model's geometry, while G-code provides detailed instructions for 3D printers and CNC machines to create physical objects from the model. These two components are essential for 3D printing.

Why should I convert STL files to G-code?

Converting STL files to G-code allows for precise adjustments of print parameters and improves print quality while making designs compatible with different 3D printers.

What is slicing software, and why is it important?

Slicing software is important because it translates the geometry of an STL file into executable printer instructions, or G-code, which is crucial for the STL to G-code conversion process.

What are some ways to optimize print settings for best results?

To optimize print settings for best results, balance print speed, maintain the printer, and experiment with build plates and adhesives. These factors can contribute to improved print quality.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.