CAD CAM Software-what's that?

Let’s face it–there’s a lot to learn as you’re starting out in CNC. CNC is all about computer-controlled machine tools, so a lot of that learning has to do with software. CNC newcomers need to understand the software suite that underpins all CNC work. And both CAD and CAM Software are very important to that Beginner's Software Suite.

There's a lot to learn for CNC. What are the shortcuts?

There are a lot of different kinds of CNC Software which I like to call “Digital Tooling.” You don’t need to know about all the software, but if you’re curious, learn more from our Complete Guide to CNC Software. It breaks down exactly what each type of CNC Software does.

In this article you will learn:

- The simplest beginner's CNC Software Suite.

- How to choose each component in the Beginner's CNC Suite to make sure you get the best option for you.

- Some special offers that will save you money on some combinations.

Note that this is an in-depth guide. If you just want a quick intro, you might try our CNC Router Software article.

The Beginner's CAD CAM Software Suite

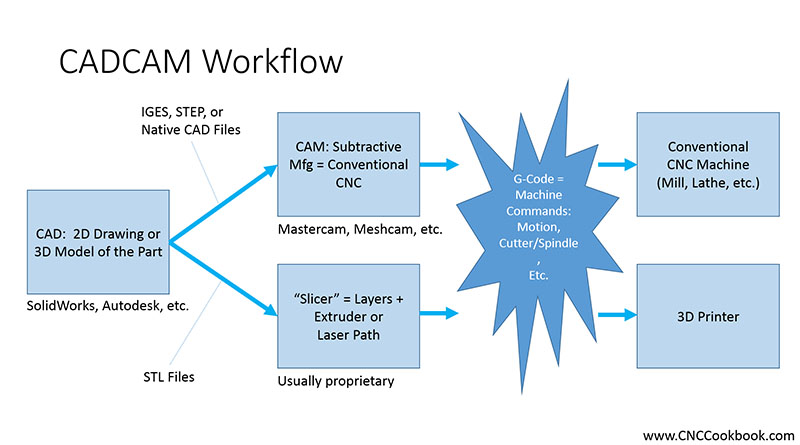

What you're looking for is the simplest set of software to support the basic CAD/CAM Workflow:

The process from CAD CAM software to CNC devices...

To do that, you'll want the following types of software:

-

CAD Software: CAD stands for Computer Aided Design. CAD Software is for drawing on the computer, but with measurements applied to the drawings. Use it to create and revise your designs. CAD Software is how you create “blueprints” for parts in the CNC world.

-

CAM Software: CAM stands for Computer Aided Manufacturing. It takes a CAD drawing file in and with a lot of hints from you, uses the information to create g-code. G-Code tells your CNC machine exactly how to cut.

-

Feeds and Speeds Calculator: Some CAM packages have limited Feeds and Speeds that are terrible. Poor Feeds and Speeds was one of the top complaints about CAM Software in our annual surveys. Beginners need all the help they can get to avoid breaking tools. A good Feeds and Speeds Calculator will make that easy for you.

-

Control Software: This is usually built into your CNC Machine, so I only give a basic overview about it here.

We'll go over each category to help you make the best choices to buy. Before we do that, I want to touch on a couple of more general topics. First, I want to go over whether Free Software is right for you. Second, I want to talk about how Pros and Beginner/Hobbyists approach their CNC software. Each has different needs that affect how you’re choosing your software. Lastly, I want to get you to hit the software BEFORE you buy the CNC Machine.

Free CAD CAM Software: Is it Right for You?

Everyone loves FREE, right? We offer a comprehensive guide to Free CNC Software. But before you go scurrying off in that direction, stop and ask yourself:

Is Free Software right for me?

The answer is not obvious, despite what your wallet may be telling you. The problem is that free software is seldom the best in anything but price.

As I already mentioned, there’s a lot to learn before you can make parts with your CNC machine. You don't want to fight an uphill battle against buggy or non-intuitive software to save a couple of bucks.

Most of the free software that’s available (but not all!) is inferior to the paid, and there are many paid packages that are not all that expensive anyway.

CAD CAM software will be the most complex software you'll use for your cnc programming. And it will be the software you spend the most time learning and using. It's worth taking time and potentially money to get the right solution for you.

You only need to come up with three software packages-CAD software, CAM software, and Feeds/Speeds Calculator. There are even offers available that bundle a couple of these together. Read on to check them out. They'll save you loads of time and frustration in exchange for a few dollars. Getting off to a great start in CNC is worth it!

Pro vs Beginner/Hobbyist CAD CAM Software

In many pursuits, it's tempting to want to start with the best. Get the same software Pro's use, how can you regret it?

The reason why that may not work is that Pros and Beginners need to solve different problems.

Consider these differences:

- Many pro shops run the market-leading software packages because they need to exchange files with Customers.

- Shops need to be able to hire Talent that's familiar with the software without requiring a lot of expensive training to come up to speed.

- Pro shops can afford to use software that's much more difficult in exchange for more power.

In either case, choosing the market leader or industry standard software for their market may make sense. It ensures they're more likely to have the same software as Customers so they can share files. And, it ensures new hires are more likely to know the popular software they've chosen so less training.

Beginners and Hobbyists shouldn't care about either one of those issues.

BTW, the leading CAD software for Pros is SolidWorks, and the leading CAM software is Fusion 360.

Pros need the software that performs best for someone who is an expert in using the software. They want CAD that lets experts create precision drawings faster. They want CAM software that generates g-code that executes as fast as possible on their CNC machine, even if that means only experts can make the software do anything at all. That's because they're manufacturing potentially thousands of parts from one g-code program. They want software that supports the myriad manufacturing processes a pro shop must be involved with.

While faster drawing and faster g-code may sound great, Beginners and Hobbyists often just want to get to making their parts as soon as possible. Who wants to invest hundreds of hours before you can do even something simple?

I've got a lot more to say in my article on how Pros vs Beginners choose software, but let's keep it simple here:

You want software that's easy to learn and affordable, even if it isn't the ultimate in powerful.

Hobbyists and Beginners have different needs than industry. If you can accept that and stick to it, you'll be up and running your own CNC parts a lot faster.

Buy Your CAD CAM Software BEFORE Your CNC Machine

Big Tip: Get your CNC Software BEFORE your CNC Machine!

Look, it's going to take weeks to get at all proficient with your CNC Software. Plan to spend 4-6 weeks on it. Let's say you purchase the software at the same time as your CNC Machine. I mean, that shiny machine is so exciting, you MUST get your hands on it right now!

But, once you get it and set it up, you can't run it. Not without understanding the CNC Software. And you're going to need 4-6 weeks to do that. What a bummer!

Get the software first. It's cheaper than the machine anyway. Learn the software. Have a little fun with it. When you feel you are close to having the software figured out order your CNC machine. That's the smart way to do things, and it will get you into CNC machining the fastest.

A Word About Software Platforms

If you're a Pro, your choice of software platform should be clear. You'll be running all of your software on Pc's running Windows Operating Systems. The Windows Operating Systems have commanding market share in the CNC world. The CNCCookbook blog sees 93% of its traffic running on Windows machines. Mac OS is a little under 4% and Linux is less than that.

Frankly, if you're a beginner, I would certainly consider running your software on a Windows PC. You'll just have a much larger choice of software if you do.

CAD Software for Beginners and Hobbyists

Step one is to find CAD software you can learn to love. This is the software you'll be using more than any other of the 3 basic packages, and it will take the most time to master as well. The very first thing you need to know is that there is no one single best CAD package for everyone. There's not even a best for Beginners.

That's because different individuals will find different packages to be more or less intuitive (i.e. in tune with the way they think about drawing on computers) and therefore easier to learn. Also, different packages have different design capabilities. If you want to design precision machine parts, that's one set of capabilities. If you want to design artistic products, such as signs to be made on CNC Routers, that's a different set of capabilities.

You're going to need to invest 2 weeks or so trying out each package you put on your shortlist, and I advise you to try to put 3 packages on the list. If you're building a CNC Machine, or waiting for one to arrive, spend that time wisely trying out CAD packages to find the right one for you.

I'll tell you more about how to try them out once you've got your shortlist, but first, here are a few things to think about when putting together your short list of CAD packages to consider.

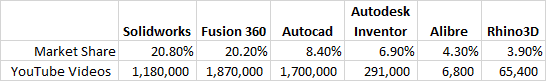

Market Share

As a Beginner/Hobbyist, you don't want an obscure package that very few people are using. You want something that many are using so it'll be around for a long time and so you can find people to help you with it. Good news: we have extensively surveyed CNC'ers about CAD and CAM and can tell you what the market shares are.

Integrated CAD/CAM Packages

Here's another tempting possibility. Integration always sounds good, right? And most CAM packages have built-in CAD. So maybe we don't need to worry about CAD. Maybe we just choose the right CAM and it will take care of the problem with its integrated CAD.

There are two things that I want you to take away about prospects for integration. First, it is far more important that you have a great CAD package than that you have an integrated CADCAM package. Most of the all-in-one packages with two exceptions (Fusion360 and Aspire) are riddled with compromise when we talk about CAM software that has built-in CAD software functions. For that reason, I highly recommend that if you want integration, you look for CAM that integrates with a successful CAD vendor's package. It so happens that Fusion 360 is such a package, which is probably why it is the one exception.

Second, Integration is far more important to Professionals than Hobbyists and Beginners. Basically, take it if the CAD and CAM you choose are compatible and the right choices on their own, but don't worry about integration otherwise.

Community

I'm a big believer that Community should absolutely be your first consideration when selecting your CAD software. As a Beginner or Hobbyist, you will need help learning the software. You'll have questions. And, you don't know what you don't know. A thriving online community can help with all that. They'll be discussing CNC machining in terms familiar to the particular cad cam software you've chosen.

Take your list of potential CAD software, and go looking for great online communities that support that software. I can tell you right now that all things Autodesk, including Fusion 360 have great online communities. Solidworks has a great online community. Rhino3D, which would otherwise be one of my favorites, uses a very old-fashioned (dating back almost pre-PC) approach to online community that's not very user friendly. I'm not sure I can recommend it for that reason.

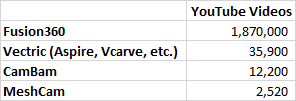

Be sure to visit YouTube as well, as having access to learning videos is extremely helpful. Here's some data on Market Share and YouTube videos for various CAD packages to help you out:

Any package with hundreds of thousands to over a million available YouTube videos is going to be easy to find free online training for. And BTW, those are the top 6 packages by market share from our survey too.

Affordability

Most Beginners and Hobbyists can't spend $4000 on a CAD software package any more than they can buy a brand new state-of-the-art VMC. They need something affordable, and that means hundreds of dollars, not thousands of dollars.

The good news is that the markets recognize this to a greater or lesser extent. In fact, you can get every one of the packages above in a price range that's affordable for Beginners and Hobbyists. I don't want to publish the scoop on all of it here because I'm afraid that would make the special offers go away, but if you want to sign up for the Freebie below, I can email the details to you:

2D vs 3D/Solid Modeling

In this day and age, why consider a pure 2D CAD system? All the reputable 3D systems can read and write DXF (the most popular 2D file format) and can create 2D models as well.

How to Evaluate and Choose Your CAD Software

OK, we've gotten this far and we have a few rules of thumb to use in getting to our shortlist. Now that you're down to just 2 or 3 choices, it's time to evaluate those choices. You need to invest some serious time in doing that. I recommend you spend 2 weeks on each package. That's because it'll take that long to get past the initial frustration and learning curve so you can begin to discover whether the package suits you or not.

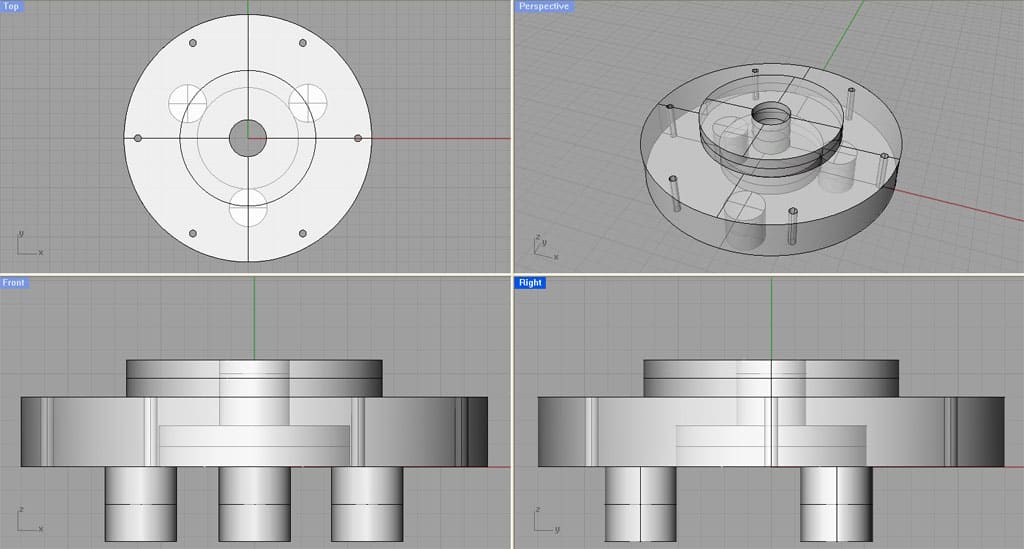

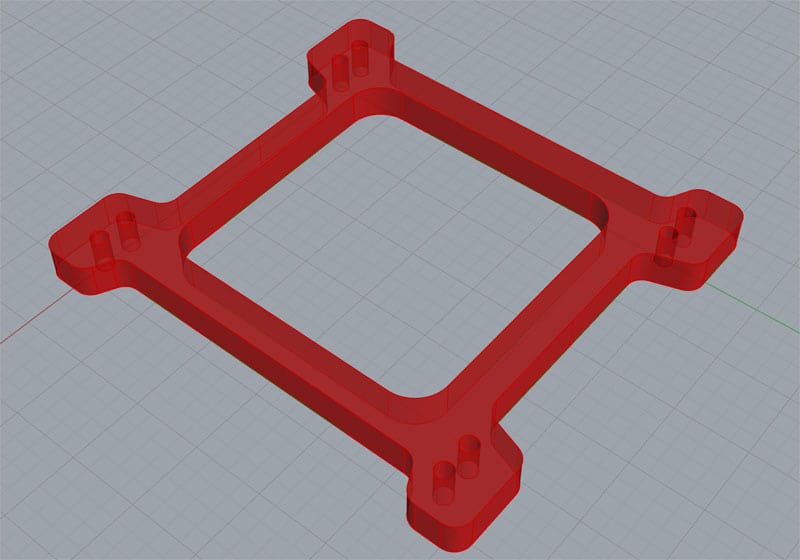

In addition, I recommend you try to draw at least 3 or 4 of the same parts in each package you're evaluating. That can help make the comparisons more Apples-to-Apples. Pick something simple to start with. Here's the first part I ever drew in a CAD package:

It's hard to tell, but it's a backplate for a lathe chuck. It's just complicated enough to be a real example, but there aren't so many different features on the drawing that it takes forever to learn how to do. An even simpler part would be this 4-barrel carburetor spacer plate:

That one comes from my article "Secrets of Going From CAD, Image, DXF, or STL to GCode for CNC and 3D Printing".

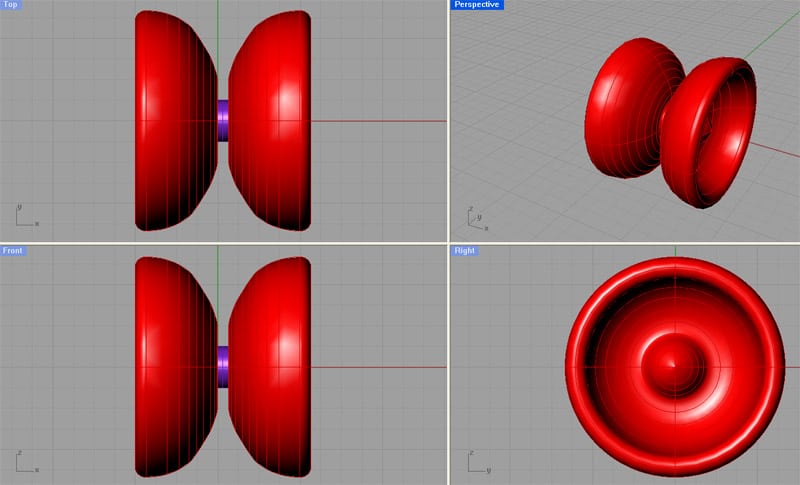

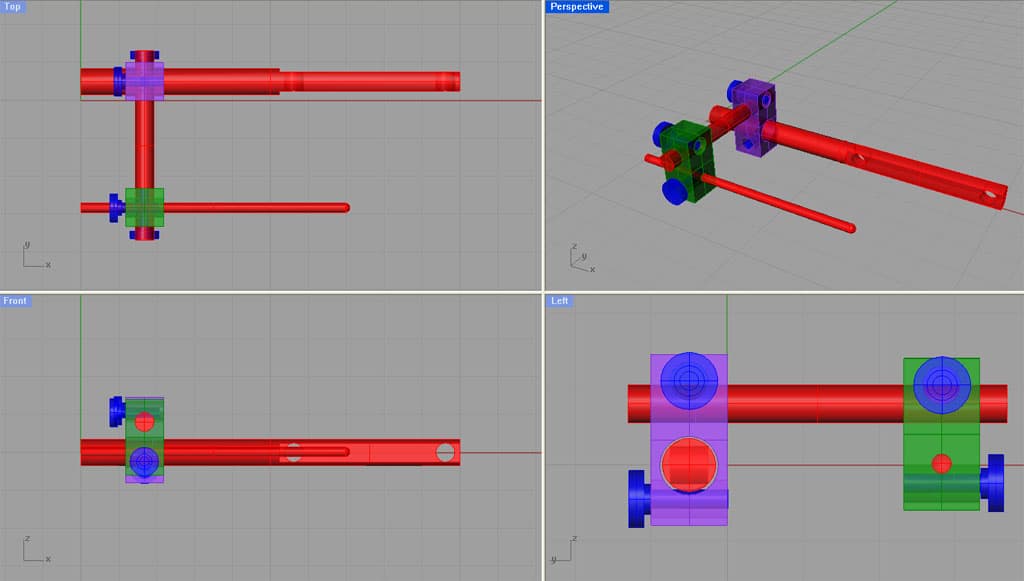

You should also draw something that requires multiple components. This is what the CAD world calls an "Assembly", and it's something you'll wind up doing a lot. Here are some simple assemblies I've drawn:

YoYo's can be awesome CNC projects!

More into tooling? Here's a vise stop I made that's been a great help around the shop...

If you can draw all of those in each CAD package you're evaluating (or similar things you want to draw), you've done your homework.

You have to spend the time to know which package is for you!

There is no one best CAD package for everyone. They are often quite different from one another. What makes sense to me may be total nonsense and very hard to learn for you. Therefore, plan to try several and spend a couple of weeks with each. Draw the same 3 or 4 parts in each package. By the time you have gone through your shortlist, one package will hugely stand out from the others: that's your best choice.

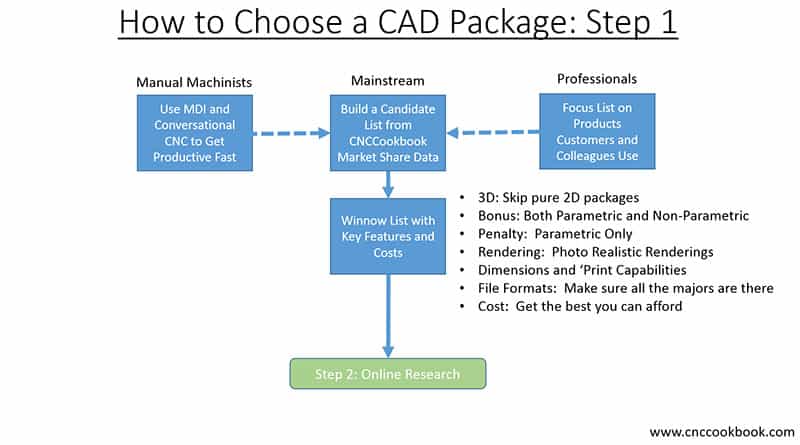

Here's a pictorial guide if you want a detailed and deep process for choosing your CAD software:

Step 1: Build Your Candidate List...

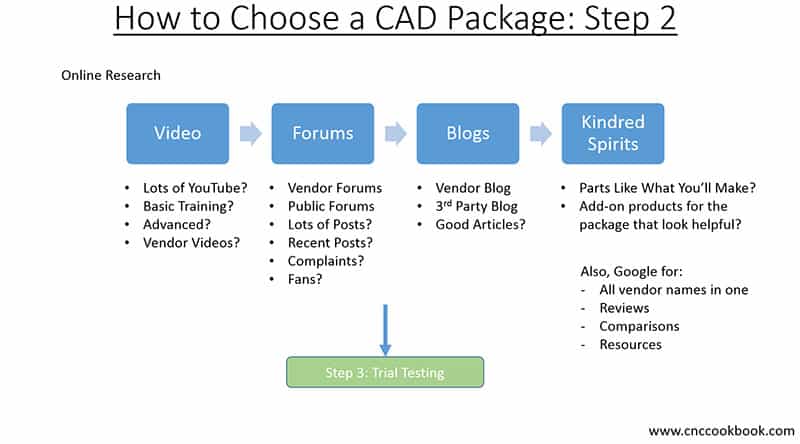

Step 2: Do your online research...

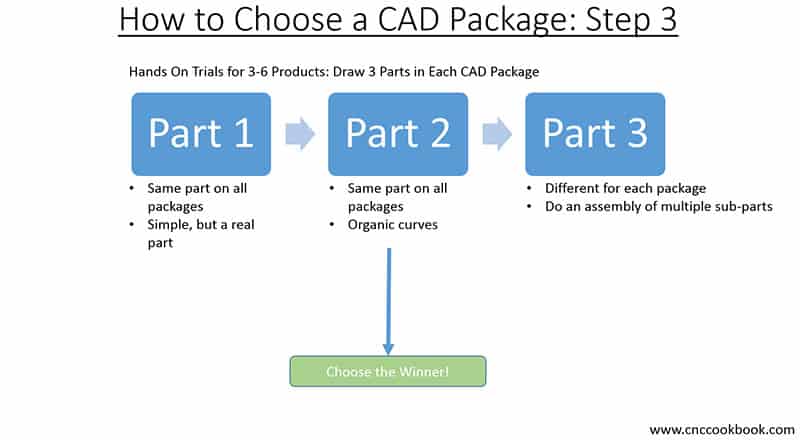

Step 3: Hands-on Testing. Draw 3 parts in each CAD package to see which one is best for you...

Now ask yourself, "Which one was the easiest to learn?" And also, "Which one feels more natural so that I'd like to keep right on using it?"

In all likelihood, one of the packages will stand out from the others. Your choice will probably not be the same as your buddy's choice or the choice of the gang in the online Machinist's Board talking about CAD. That's fine. We all have different styles. The important thing is to choose the software that's best for you!

CAM Software for Beginners and Hobbyists

Having gotten your CAD software chosen and more or less under control, the next step is CAM software. Recall that the role of CAM is to take in the CAD model and generate g-code from it that your CNC machine can run. CAM software is largely about creating toolpaths that guide cutting bits through the material to produce the desired shape.

Every beginner hears that bit about the role of CAM software and they get the wrong impression about 90% of CAM programs. They think they're just going to load the CAD into the CAM package, push a button, and out comes their g-code ready to go. What a disappointment it is to learn that things are a LOT harder than that! At least they're harder in most cases, I will mention an exception shortly.

In reality, using a CAM package means understanding what toolpaths it can create, and then matching those toolpaths to the various features on the finished part to cut each feature. Our article Complete Guide to CAM Toolpaths walks you through all that and includes examples.

BTW, for 3D Printing, their equivalent of CAM is "Slicing" software, and it really is a lot simpler than CAM. I guess that's one reason a lot of folks recommend beginners start with 3D printing. But here's the thing:

If you're open to choosing the right simplified CAM software instead of insisting on the all-time most powerful CAM, you can greatly reduce your learning curve.

Ask yourself, "Do you want to greatly extend your learning curve in a quest for ultimate power or do you want to get started making parts now?"

The answer will determine the best solutions for you.

The Beginner's Secret Weapon: World's Easiest CAM Software

If you're open to accept a less powerful CAM program for a little while, you can get started making parts almost immediately. And, you'll come as close to the ideal of "Push a button and automatically convert a CAD model to G-Code" as is possible.

The less powerful CAM program you want in this case is MeshCAM. When I discovered how easy it is to get results with MeshCAM, I went straight to the developers and begged them to let me be a MeshCAM dealer. I wanted to be able to share this incredible find with others, especially beginners. Personally, I think every beginner should start with MeshCAM and graduate to something more powerful when you're ready. It will get you making real parts faster than anything else out there.

But what do you give up?

MeshCAM makes some compromises in order to make things simple. These compromises have the following consequences:

- MeshCAM's G-Code programs are not the optimal production-speed programs other CAM can produce. BTW, they're not horrendously slow either, they're just not going to be in the top 10-20% of the speed demons. For many hobby machinists, this doesn't matter at all. But, if you're trying to run a CNC Business, you won't be able to afford manufacturing inefficiency for very long.

- MeshCAM's G-Code programs may be longer than other CAM software. This is part of the whole efficiency thing, but looked at in a slightly different way. Unless your CNC Machine is old and has very little memory, this just isn't going to matter to you at all.

- You may give up some precision. A lot of beginners get wrapped up in precision too early. Give a competitive person a number they can measure and suddenly they have to beat it. For most CNC Work, MeshCAM will be fine. If you need to have accuracy to the last thousandth, let alone the last ten thousandth of an inch, MeshCAM doesn't give you enough control to accomplish that easily. For most beginners and hobbyists, this won't matter at all.

On the other hand, there are literally TONs of concepts and skills you won't need with MeshCAM:

- You don't need to understand when and how to use a zillion different toolpath types. Our Toolpath overview page literally has many different types listed, and the better CAM packages can do them all. The trouble is, that's a lot to learn just to understand when to use each one let alone how to set each one up. MeshCAM limits that to just a few and helps you determine which ones to use.

- Telling the CAM where on the CAD drawing to put the toolpath. This is a complex and often frustrating process for beginners to master. Establishing coordinate systems, origins, and designating different features to your CAM software is a hassle. Yes, it gives you ultimate control over what happens, but there's no middle ground for beginners. With MeshCAM, it takes the CAD drawing as a hole and figures out how to deal with it. You answer a bare minimum of questions to get it going.

- Tool Libraries, Style Sheets, and more. Fancy CAM has fancy power user features. In many cases, they make you use them whether or not you need them. MeshCAM has thrown away most of this in the interests of simplicity. That means you get g-code for simple jobs done a LOT faster.

MeshCAM has a free trial, so I seriously recommend you give it a try before you even look at the competition.

I Need the POWER!

Yeah, I get it. All the guys over on the Machinist's Board have gotten you all wound up about how awesome the Acme Terminator Super Whiz Bang CAM software is. They learned it, they say it was easy, so why can't you learn it too?

Of course the answer is you CAN learn it. It's just a question of how long it will take. So let's borrow as many pages as we can from our CAD evaluation. Look for:

- Community. Keep a special eye out for video

- Market Share & Lots of YouTube Videos: I'll give you the list below. Watch a ton of those videos and see which ones are easier to follow. That may be because that CAM software is easier to follow!

- Affordability: You don't need a $10,000 CAM package. You don't even need a $1000 package in all likelihood.

- Plan to try 2 or 3 packages. Spend up to 2 weeks on each.

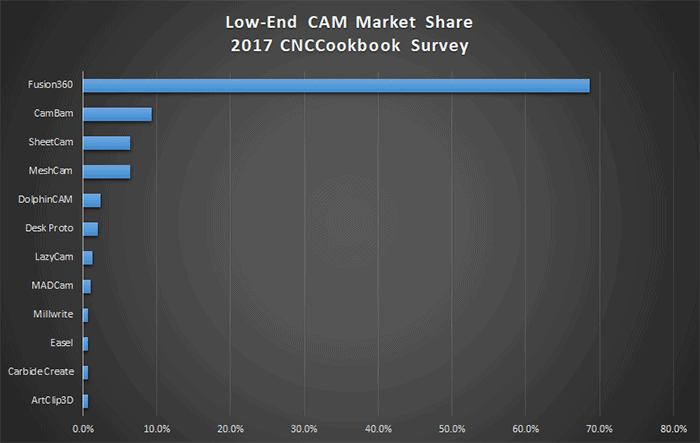

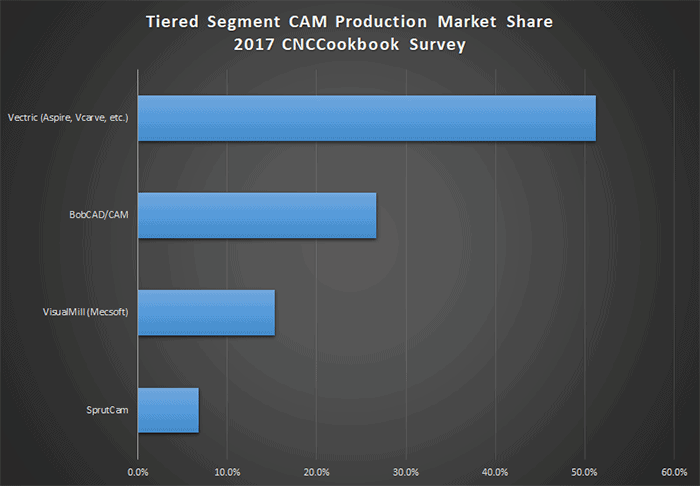

Okay, let's have a look at market share for these products. These charts are from our 2017 CAM Survey.

You could do worse than to take the top 5 off this chart as your starting point. I want to include what's called the "Tiered" products too. These are offered at multiple price ranges:

Cut to the chase with Bob's Short List of CAM Packages

Let me cut to the chase. I've looked at most of this software in great detail. I talk to LOTs of folks, and have done lots of these surveys. My takeaway is you want to consider the following:

- MeshCAM: Just because it really is the easiest CAM Software by a wide margin.

- CamBam: Cheap and cheerful. This is what you get if you take conventional CAM, greatly simplify it, and leave out a lot of Power User Features. Think of it as a Mustang among Corvettes and Porsches. Not the ultimate but a pretty sweet ride. My only issue with it is I wonder whether it sits too close to MeshCAM without the simplicity and too far from the other two without the power. I kinda think it is, but that doesn't mean you shouldn't spend time with it and make up your own mind.

- Vectric/Aspire: This software is hugely popular with the CNC Router crowd because it does so many cool things for making fancy signs and artistic designs. I like it a whole lot, and if I wanted to do a bunch of artsy stuff, I would choose it over Fusion 360 for sure.

- Fusion 360: This is the current fave at the low end. If nothing else it marries a pretty high-powered CAM Package (HSM Works) with pretty good CAD at an incredibly low price. What's not to like? Well, let me be honest. I use Fusion 360 more than any other CAM, but I hate how buggy it is and I think it's User Interface is the worst of any of the software I talk about here. It's a fairly nasty uphill slog to become proficient, and if you don't use it constantly, you will backslide and have to relearn things that should be obvious. But, once you are proficient, you will rock with it. Except when the bugs are biting.

Here are the stats on YouTube videos available for each:

In fairness to MeshCam, it's so simple I can't imagine what you would make over 2500 videos about. But you can clearly see that Fusion 360 and Vectric Aspire have a ton of videos available for you to learn from.

Personally, I recommend you evaluate all four software packages. Get the free trials. But get them one at a time. And be sure to do the MeshCAM trial first. That way you'll see how easy it can be. With that in mind, what you're evaluating with the others is whether you think you can get proficient fast enough to be satisfied skipping MeshCAM and going to something else that's more powerful. If you can, great! But if you can't, no worries. MeshCAM has your back until you have enough experience to want to try something else again.

What about 4th Axis Support?

I'm going to throw one more topic into your thought process for choosing CAM software. That is the question of whether your CAM needs to support 4th Axis Work or not.

4th Axis may be called for strictly for efficiency's sake. It allows you to rotate your part to give access to more sides without having to rotate the part by hand. So, it allows an increased level of automation. But, that shouldn't matter to a Beginner.

What may matter is that certain kinds of projects require a 4th axis or you simply can't do them at all. A good example is laying down inlay or designs on round workpieces. Custom pool cues, chess sets, and furniture legs are all good examples.

For more on 4th axis cnc routers, check our article which gives a number of examples. If expect to do this kind of work, you'll have to allocate more budget as it is often an extra-cost item for CAM software to support 4th axis work.

Feeds and Speeds Calculators

You've got CAD and CAM covered, you are ready to make parts, right?

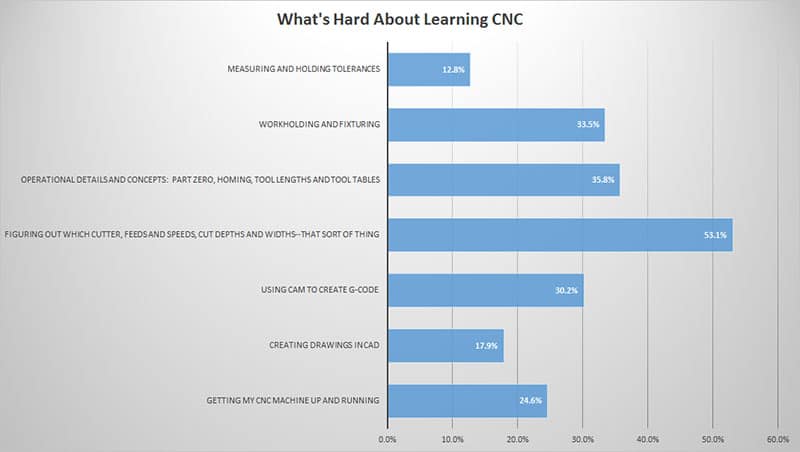

Hang on there! Friends don't let friends make parts with CAM software feeds and speeds. Simply put, CAM software does a lousy job of it, something our survey respondents have told us year after year. Plus, when we surveyed folks and asked them what was hard to learn about CNC, guess what they said?

Ouch!

Feeds and Speeds are by far the hardest thing to learn. Much harder than CAD or CAM. That's why you need a good Feeds and Speeds Calculator. And boy have I got one for you.

The World's First Feeds and Speeds Calculator Built for Beginners and Hobbyists

I won't lie-our G-Wizard Feeds and Speeds Calculator is AWESOME for professional CNC'ers. That's why thousands of the world's best manufacturers use it.

But, at the same time, I have talked to literally thousands of CNC Beginners and helped them through all the common problems. And every time I discovered a case where lots of people were hitting the same problem, I tried to build the solution into G-Wizard Calculator. I wanted it to help beginners to help themselves before they got into trouble. That process continues to this day.

Here are just some of the things G-Wizard does especially for Beginners:

- It is set up to deal with the limitations of lightweight CNC machines. It will adjust your Feeds and Speeds to what your machine can handle.

- It is the world's first Feeds and Speeds Calculator that deals with the special needs of CNC Routers. Many beginners start with that type of machine, and if you are using a CNC Router, there really is no better Calculator for you to choose.

- It gives you lots of written Tips that professionals take for granted but beginners don't get to learn unless they're lucky enough to be mentored by professional CNC'ers.

- It has a powerful "Cheat Sheet" that lets you tailor your cuts as you wish. Do you want to go faster? Slower? Get better finish? Longer tool life? The Cheat Sheet is built in and will tailor Feeds and Speeds for your goals.

- Giant Materials Database. But especially, lots of the softer materials Beginners and CNC Routers often cut. Wood and Plastics are called out in detail.

- Comprehensive Cutters. G-Wizard has more different kinds of cutters than any other Feeds and Speeds Calculator including the special cutters needed for CNC Routers. Experienced Professionals can find a way to get feeds and speeds for weird tooling, but Beginners need to have it spelled out easily.

- Getting Started Tours and Glossary. We offer the best training in the business with guided tour videos, worked examples, and even a built-in glossary of terminology. This is all stuff many had to dig out bit by bit that G-Wizard gives you in easy to consume tidbits.

To learn more about exactly why G-Wizard is perfect for beginners and hobbyists, visit our G-Wizard page for Beginners & Hobbyists:

[ Tell Me More About G-Wizard for Beginners & Hobbyists ]

Secret Tip #1: Skip CAD for Now

Hey guess what?

You may be able to skip learning CAD for now!

How?

Simple: use one of the many Free DXF File download sites and download premade CAD files. We've even got one (I linked to it).

The downside is you're limited to the designs they have available. But you can learn a lot about how to use your CNC machine by downloading some simple artwork and making some fun signs or other projects.

Secret Tip #2: How Manual Machinists Can Sidestep CAD CAM Software

You've got pretty much the whole story of how a Beginner can get their CNC Software act together on the cheap and have the best solution for their needs. Just one or two more things I need to cover.

If you're an accomplished Manual Machinist, this section is for you. If not, go ahead and skip it.

Manual Machinists can make parts without needing CAD or CAM software. You know that if you're a Manual Machinist. But here's the thing-you can do the same only even better on a CNC Machine!

That's right, you can leverage your skills to be making parts right away. Yes, you will want to learn CAD/CAM too, but for now, you can be at least as productive as you are on a manual machine with a minimal learning curve.

MDI Makes Your CNC a Manual Machine With Power Feeds and DRO's

The first thing to realize is you can run your CNC a lot like a manual machine using something called "MDI". It stands for "Manual Data Input." Basically, you type in a simple command and the machine executes it immediately. Those commands are g-code, but all you need is a simple subset consisting of just 10 g-codes. We give you everything you need to master it in our G-Code Course. Go ahead and check it out. You can be making chips on a CNC in a matter of hours.

A Manual Machinist who understand MDI can basically treat a CNC Machine as a manual machine that has DRO's and Power Feed on every axis. You'll quickly see it's even better though. For example, the "DRO's" are tied into the power feeds and you can set them to stop feeding at a precise coordinate. Also, you can move in any direction, not just X or Y. So you can cut diagonals. Plus, circles and arcs are easy-no need to set up a Rotab. It's pretty sweet once you understand how easy it is to make chips this way.

Conversational Programming Takes You A Step Further Than MDI

Ever hear of "Conversational Programming?"

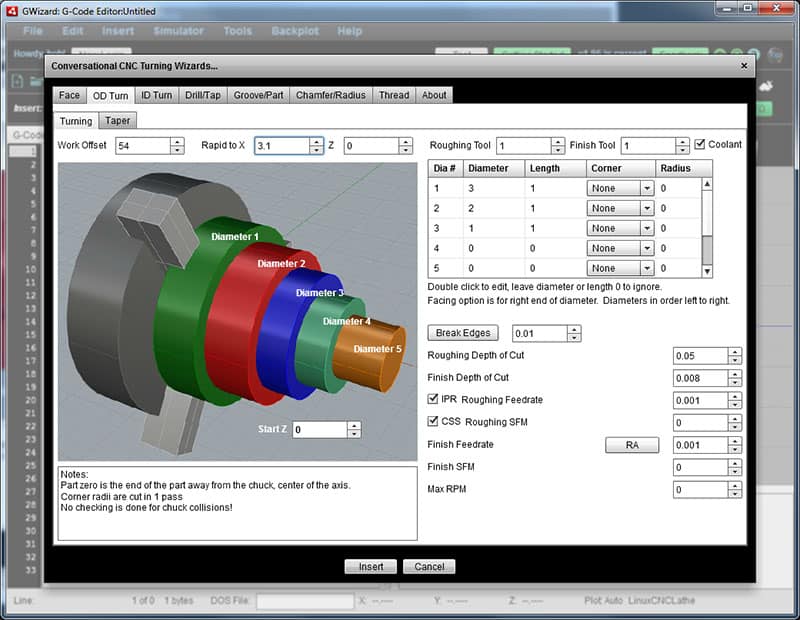

It's the next step past MDI. With Conversational Programming Software, you answer questions in a simple Wizard and it spits out g-code you can then run. The questions are simple and things any manual machinist could easily answer. For example. Suppose you're want to turn a bunch of OD's on a CNC Lathe. Here's the Conversational Programming Wizard for it:

You can create a g-code program to cut a bunch of OD's on a part really fast with Conversational Programming. Learn more about it here.

CNC Control Software for Beginners

I want to talk briefly about Control Software, because it's not all created equal. Some of it is powerful but hard to use, some is not so powerful but still not that easy to use, and some fits a nice balance.

I want to give special mention to Tormach's PathPilot. I think it is one of the best in terms of providing both power and ease of use. It even incorporates Conversational Programming.

As far as Control Software on Professional Class machines, Fanuc is the most common but Haas is easier to use and a little more powerful. But, if you're used to the Control Software on Hobby-Class machines, get ready for a learning curve on on Professional Class Machines. I've talked to experienced users of Control Software like PathPilot and Mach 3 and they say it took them 2-4 weeks to get comfortable with their Pro Control Software.

If you're building your own machine or using one of the lighter-weight CNC Routers, you'll run into Control Software like Mach 3 and GRBL. The bigger CNC Router makers have spent time making their Control Software intuitive for beginners, so view that as a definite reason to look at machines like the Shapeoko.

OTOH, no-name Chinese machines often have very poorly documented Control Software, so watch out.

Mach 3 was the defacto standard for many years for DIY machines, but it's gotten long in the tooth and is fairly buggy. I'd be looking at newer alternatives like LinuxCNC (PathPilot is built on LinuxCNC) or Centroid's Acorn Control.

Smokin' Special Offers on CAD CAM Software!

Hey you stuck with us through a very thorough but long article-I appreciate it! I know this stuff is important, that's why I work so hard to put these articles together. But I'd like to reward you with a Smokin' Deal.

How about a copy of MeshCAM and a 1 year license for our G-Wizard Feeds and Speeds Calculator?

If you buy MeshCAM from the developers, it's normally $250. And, if you buy the 1 year G-Wizard Calculator from us, it's normally $79. Together, they'd wind up costing you a total of $329. I can let you have them both together for $259 so you save $70. Put another way, I am giving you GW Calculator for just $9 instead of $79.

Whoa! You don't see those kinds of software offers every day, but this one will get you started making parts fast.

If you're interested, you can purchase the deal just by clicking here:

BTW, if you're worried about GW Calculator only being 1 year, don't. At the end of the year, when it expires, every single feature keeps working. The only thing that changes is there will be a spindle power limit of 2 horsepower. That's all many hobbyists need, and you've got that for life. If you want more, the 3-year subscription has a 5 Horsepower limit after it expires. C'mon, if you have a machine with more than 5 HP that's a very serious machine. Meanwhile, hobbyists get lifetime use for a lot less.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.