The G-Wizard Estimator software we offer includes a Machine Hourly Rate Calculator. Numerous shops employ the concept of machine hourly rates to aid in job cost estimations and quotations. However, there's a lack of readily accessible information on how to effectively derive a suitable hourly rate to utilize.

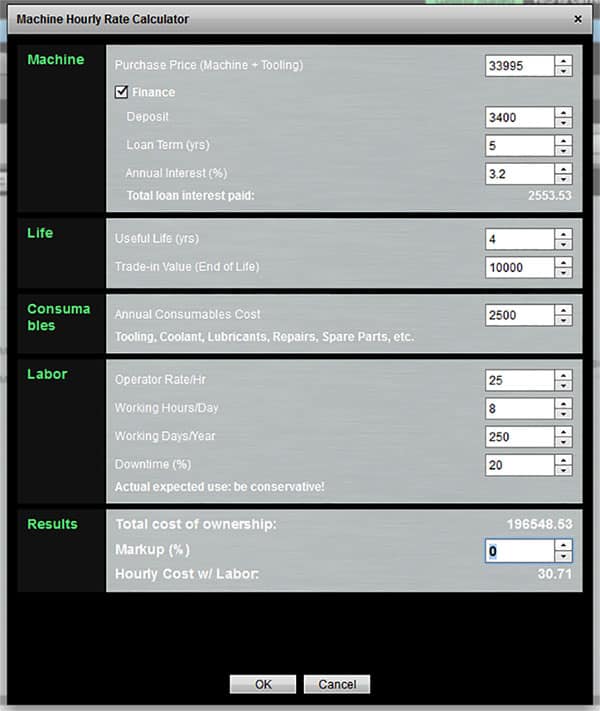

Here's what the CNC Machine Hourly Rate Calculator looks like:

CNC Machine Hourly Rate Calculator...

The basic strategy is to determine the machine's Total Cost of Ownership (TCO) over its useful life and then divide that by how many hours it will be used.

Here's a quick video demo of the hourly rate calculator:

Let's go over each piece of data that must be entered:

- Purchase Price: This is the cnc machine cost and its basic tooling. For example, a mill will probably need a vise and a few other pieces of basic tooling. Fixtures used for particular parts should not be included here.

- Finance: Check the box if you want to finance the machine.

- Depost: The amount you're putting down on the machine.

- Loan Term (yrs): How many years will you finance it for.

- Annual Interest (%): What interest rate is the financing?

- Total Loan Interest Paid: This just tells you how much loan interest will be added to the Total Cost of Ownership.

- Useful Life (yrs): How many years until you'll be ready to trade-in the machine?

- Trade-in Value: What will the value of the machine be when you're ready to trade it in. If you wonder, take a look at used machinery prices for similar machines.

- Annual Consumables Cost: This is the cost of tooling, lubricants, repairs, spare parts, and whatever else you'd like to include. Some shops want to bill all the cutters into the consumables cost while others want them as a separate line item by job since tool wear can vary quite a lot from job to job.

- Operator Rate/Hr: The hourly rate you'll need to pay this machine's operator.

- Working Hours/Day: How many hours a day will you run the machine? 8 is the default. If you have multiple shifts using the machine, it'll be more.

- Working Days/Year: Will you operate the machine every day or some subset?

- Downtime (%): Budget some percentage of time the machine will not be in use. Perhaps due to needing repairs, because work gets slow, or some other reason.

- Total Cost of Ownership: This factors in all of the above costs to give you a Total Cost of Ownership

- Markup (%): Some shops will want to apply a profit margin directly to the hourly rate of each machine. Others will keep it as a separate line item. You can do either by entering a value here or leaving it as 0%.

- Hourly Cost w/ Labor: This is the final number to come from the calculation.

The numbers in the example were for a Haas Mini Mill that I just took the information of their web site for.

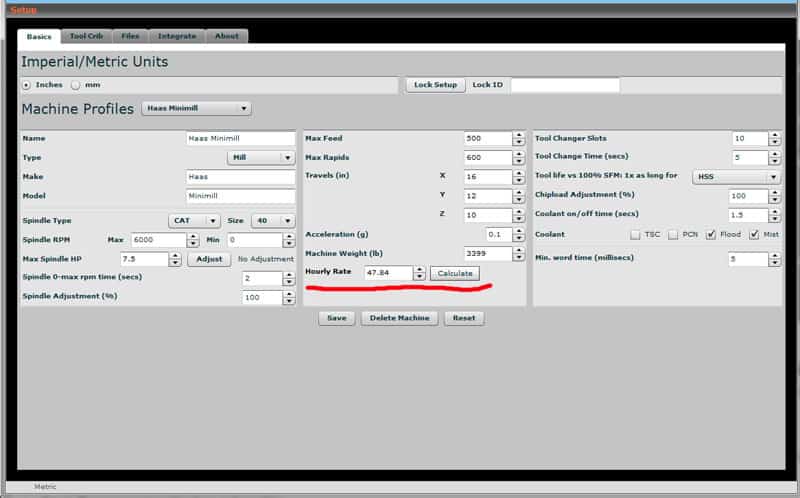

You can find the Machine Hourly Rate Calculator on the Machine Profile under the Setup Basics tab. Each machine has an Hourly Rate field. Next to the field is a Calculate button that brings up this calculator:

Press the "Calculate" button to figure out the machine's hourly rate...

How Can You Use Machine Hourly Rate When Estimating Jobs?

When you estimate your jobs, using a Machine Hourly Rate that's calculated based on each of the different machines needed to make the part will help ensure your job estimates are more accurate. What you need to do is combine the Hourly Rate on a per machine basis with your estimate of how many hours will actually be needed from each machine.

G-Wizard Estimator helps you build a simple spreadsheet to do this. It estimates how long each machine is in use via the CADCAM Wizards that are built into both G-Wizard Calculator and G-Wizard Estimator. Only the version in Estimator can do these estimates though.

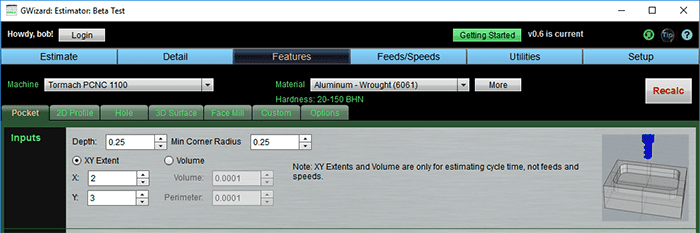

The CADCAM Wizards make it easy to do feature-based time estimates. Here's a screen shot of the CADCAM Wizards in GW Estimator showing just the inputs you'll need to make to get an estimate:

It's pretty straightforward and there are relatively few inputs needed:

- Machine

- Material

- Feature

- Feature Parameters

The Features are just the different types of operation you might perform-pocketing, 2d Profiling, boring holes, facing and so on. The goal is to be able to look over a print of the part you'd like to estimate and enter each feature quickly and easily. The CADCAM Wizards try to minimize the number of questions you have to answer to get a complete Feeds and Speeds recipe. The result looks like this:

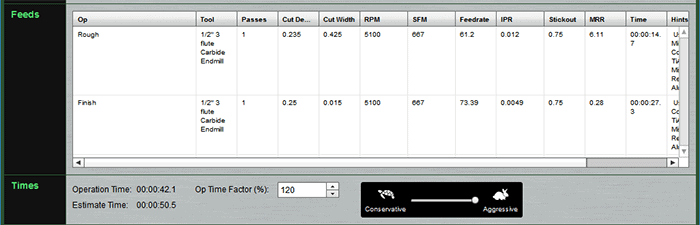

As you can see, CADCAM Wizards produce a pretty complete recipe that includes a tool selection, Cut Depth, Cut Width, Feeds and Speeds, and the time required for the roughing, finish, and total operation. There's even the ability to add a "Fudge Factor" to the total operation time.

Given a series of features, GW Estimator will multiply out the times by the Machine Hourly Cost based on which machine was selected and put all of that into a spreadsheet you can then use as the starting point for your job quote.

Here's an article and video that walk you through estimating a particular part:

[ Part Estimation Video ]

If you'd like to try G-Wizard Estimator, you can sign up for our Beta Test here:

G-Wizard Estimator is free during its Beta Test, but it does everything GW Calculator does for Feeds and Speeds so you'll need to have an active free trial or subscription to G-Wizard Calculator to use it. You can get your free trial here:

Improve My Feeds and Speeds For

More Feeds and Speeds Calculators

-

G-Wizard Feeds and Speeds Calculator

-

Milling Speeds and Feeds Calculator

-

CNC Feed Rate Calculator

-

Chip Load Calculator

-

Simple Feeds and Speeds Calculator

-

Lathe Feeds and Speeds Calculator

-

Drill Feeds and Speeds Calculator

-

Tapping Feeds and Speeds Calculator

-

Master Feeds and Speeds Calculator List

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.