There are literally thousands of CNC machines available in the world's markets, and they're aimed at a huge variety of different audiences. These audiences range from Hobbyists through large scale Aerospace Manufacturers that demand the very best CNC machines that technology can build. As such there is a huge range involved when talking about the cost of cnc.

Answering the question of How much does a cnc machine cost for yourself will require you to make some honest decisions about what your needs really are. You can have a lot of fun with a hobby-class DIY cnc machine, but they're not going to help you get ahead if you want to start a machining business or professional machine shop. Being more competitive means buying a more capable cnc machine.

Factors Affecting CNC Machine Cost

These are the broad factors that determine CNC Machine Cost.

CNC Machine Size

The size of the machine, typically measured as the cnc machine's work envelope (X, Y, and Z coordinate range), is a huge determiner of machine cost. CNC Machines range from tiny in size (small enough to fit on a tabletop) to gigantic (large enough you could drive a truck onto their work area).

Types of CNC Machines / Configuration (3, 4, or 5 axis cnc mills vs 2 axis or more lathe)

More axes make a machine more powerful, but they can also rapidly add complexity that drives up the cost of the CNC Machine. All other things being the same, CNC Lathes are often cheaper than CNC Mills simply because CNC Turning starts with fewer axes than CNC Milling Machines.

Power and Speed

A more powerful spindle or a spindle that can reach higher rpms can greatly enhance a cnc machine. High rapid motion speed can allow the machine to finish running a CNC Program faster. High speed in general adds a premium to any machine.

Machining Accuracy and Tolerances

The more accurate the cnc machine, the higher the cost.

Options

There are many options that add cost and complexity to cnc machines including:

- Automatic Tool Changer

- Tool and Part Probing

- Chip Conveyor, Chip Auger, or other Chip Management features

- Pallet Pool

- Bar Feeder

- Robotic Part Loader

- Through Spindle and High Pressure Coolant

- Vacuum Table with Vacuum pump

- Servo Motors vs Stepper Motors

Country of Origin

Was your machine made in Asia (China, Korea, Taiwan, or Japan), Europe, or the US?

How Much Does a CNC Machine Cost?

Given that background on what factors drive costs, let's break down CNC Machines into a set of Categories that you can use to put a ballpark around the cost of cnc machines.

Entry Level Desktop

CNC Routers - $150 to $500

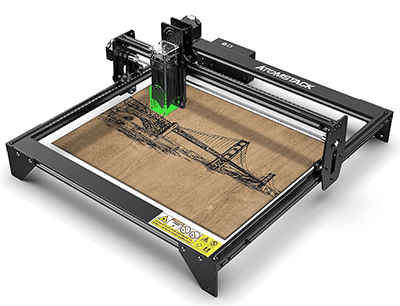

CNC Laser Engraving Modules and Machines - $300 to $500

3D Printers - $300 to $500

Honestly, the cheapest desktop CNC Routers are probably not worth it. I see so many letters from beginners who are utterly frustrated trying to make these underpowered machines achieve decent results.

On the other hand, I see a lot of folks who just love their 3D Printers and Laser Engravers in this price range, so consider those machines.

Hobby CNC Machines

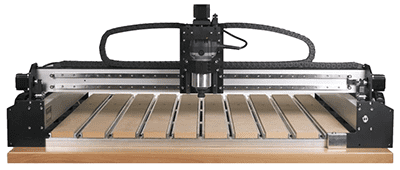

CNC Routers (Shapeoko CNC Router) - $1,000 to $3,000

CNC Laser Engraving Machines (K40 Class) - $500 to $3,000

Entry Level 2-Axis CNC Lathes (Taig and Sherline) - <$5K

Entry Level Plasma Table - $1,500 to $3,000

These machines are hobby-class, but they're pretty solid machines capable of doing a lot of good work. You can begin to consider building a business around some of these machines. The Shapeoko's are great sign making machines, for example.

Prosumer and Professional Prototyping

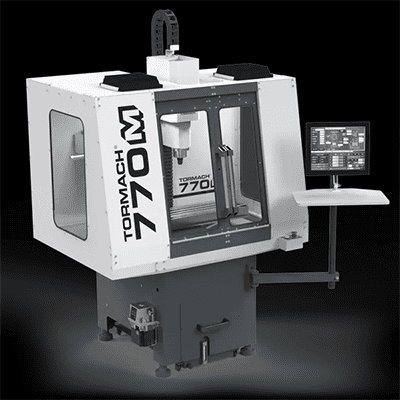

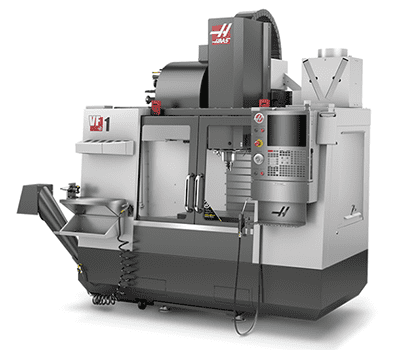

$5,000 to $50,000

This is the first level where you can hope to do serious professional work in metal. Any of the machine types are possible here, and they will all be quite capable. The lower end will be machines like the Tormach's, but this price envelope also covers machines like the Haas Toolroom Mill.

These machines are ideal for one-off and low quantity production, but they start to fall down the more volume you want to put through them.

Entry Level Machining Centers

$50,000 to $100,000

These machines are the entry level for production (i.e. quantity parts done at competitive prices). A cnc lathe will be quite a bit cheaper than the equivalent cnc mill in this price range.

Production Machining Centers

$100,000 to $500,000

These are mainstream to higher quality machines. Expect up to 4 axes on mills.

High End Machining Centers

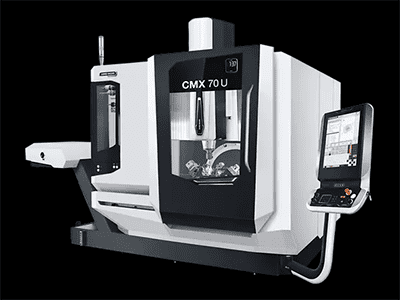

$500,000 and up

These price range machines are the very highest quality for aerospace and may be 5-axis or horizontal machining centers.

Other Costs To Budget For

Particularly for higher-end cnc machines, your costs don't end with the purchase of your new CNC Machine. Keep in mind you'll need budget for these additional costs.

Setting aside the cost of Shipping, Rigging, and Site Preparation, you should plan to budget as much as you paid for the CNC Machine to purchase all of the rest of the items necessary. Budget at least half as much, at any rate.

These costs will cover making your machine ready to begin cnc machining parts. After that, you will have ongoing costs to consider as well.

Shipping, Rigging, and Site Preparation

Having purchased your cnc machine, you must next deal with having it delivered to and installed in your machine shop.

Heavier machines will require a special crew to move them into place, a process known as "rigging." New machines will have particular requirements around what sort of electricity they require, and potentially also requirements for a clean supply of compressed air.

Particularly for a home shop you may need to purchase a phase converter or other power supply.

These can represent hidden costs to your cnc machine if you don't budget for them up front. Our article, Create a New Machine Checklist, can help you plan for the arrival and installation of your new CNC Machine.

Tooling and Consumables

Your cnc machine will require tooling and consumables before it can do anything. For example, you may need to purchase lubricants and coolants for the machine. You may need end mills, twist drills, or other cutting tools. Don't underestimate the cost to equip your machine which a comprehensive cutting tool assortment.

Work Holding Devices

Most cnc machines don't come with the complete set of work holding you may require. For example, you may need a milling vise or in the case of a cnc lathe a chuck.

Inspection and Measuring Tools

Inevitably you will need at least some basic inspection and measuring tools. The higher precision the work you do, the greater will be your need for these kinds of tools. Some of them may very well be needed just to set up your machine in the first place.

CNC Routers, Plasma Tables, and Laser Engravers are probably the least needy in terms of inspection and measurement. A CNC Lathe Machine or CNC Milling Machine will be more costly.

Check out our Complete Guide to Metrology to learn what the possibilities are.

CNC Software

The crown jewel of your support investment will be around your digital tooling needs. In other words, your initial suite of CNC Software.

At the very least you need CAD (Computer Aided Design) Software, CAM Software to generate your tool path, and some sort of Feeds and Speeds Calculator. The exception to this rule will be that CNC Lasers and Plasma Tables won't need the Feeds & Speeds Calculator.

The CNC Control System may or may not be included with your basic CNC, but it usually is.

Just as there are major differences between hobbyist cnc machines and professional machinist-grade cnc machining centers, you can find the same differences in CNC Software. Our Beginner's Guide to CADCAM Software will make sure you start off on the right foot.

Conclusion

By now you have have a pretty good idea about cnc machine cost. CNC Machine Cost can be all over the map, but once you understand how those costs break down and what drives them, CNC Machine Tools start to make more sense.

From the low-end hobby cnc machines through affordable cnc machines, and on into the more expensive cnc machines, you've got an idea of their price range and capabilities.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.