Introduction

When it comes to the world of machining, two machines stand out as the epitome of precision and efficiency: milling machines and lathes. These powerful tools have become indispensable in various industries, ranging from automotive and aerospace to manufacturing and jewelry making.

In this article, we will dive into the realm of milling machines versus lathes, exploring their unique capabilities, differences, and applications.

Brief overview of milling machines and lathes

Milling machines are robust devices designed to remove material from a workpiece through rotary cutters. They come in both vertical and horizontal configurations, boasting versatile cutting capabilities.

Vertical milling machines feature a spindle that moves vertically along the Z-axis, and horizontally across the X and Y axes, allowing for precise drilling or cutting operations. On the other hand, horizontal milling machines have a horizontally mounted spindle that facilitates cutting across the X-axis, while still retaining the ability to move in the X and Z axes.

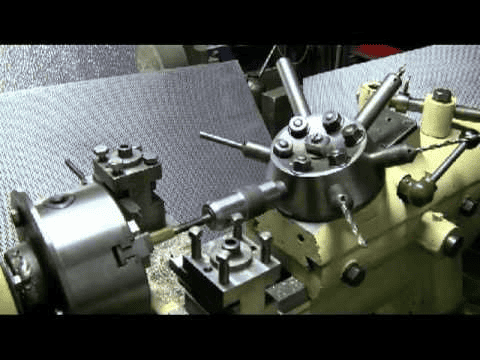

Lathes, on the other hand, specialize in rotational workpiece shaping. These ingenious contraptions rotate a workpiece while various cutting tools shape its exterior or create intricate internal features.

Engine lathes are commonly used for turning operations such as creating cylindrical shapes or facing an object's ends. Turret lathes take things up a notch by incorporating an automatic tool-changing mechanism that allows for complex operations without manual intervention.

Importance of these machines in various industries

The significance of both milling machines and lathes cannot be overstated when considering their widespread adoption across numerous industries. In manufacturing plants worldwide, these machines play pivotal roles in producing intricate components with exceptional precision.

In the automotive industry alone, milling machines and lathes contribute to every aspect of vehicle production – from engine parts to chassis components.

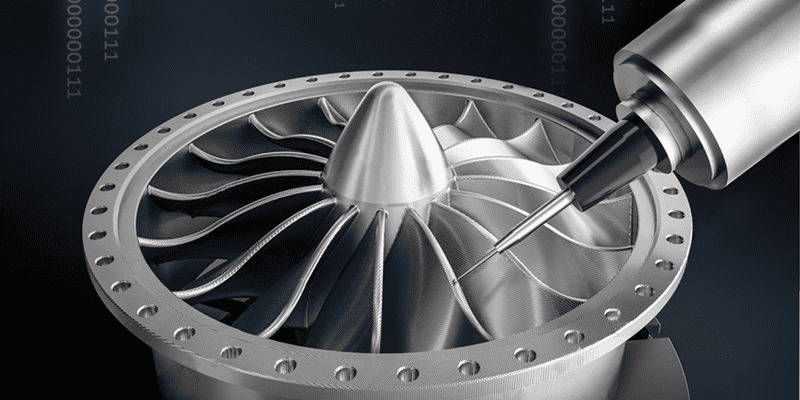

Similarly, aerospace manufacturers rely on these powerful tools to shape critical components like turbine blades or fuselage parts with utmost accuracy.

Aerospace milling image courtesy of Wayken...

Without milling machines and lathes, the complexity and precision demanded by these industries would be nearly impossible to achieve.

Moreover, milling machines and lathes find their place in the jewelry industry, where intricate designs are carved into precious metals like gold or silver. The ability of these machines to create complex patterns and intricate details is essential for producing stunning pieces of wearable art.

Milling machines and lathes form the backbone of modern machining operations across a wide range of industries. Understanding their capabilities, differences, and applications is crucial for anyone seeking to delve into the remarkable world of precision engineering.

Milling Machines

Definition and Basic Functionality

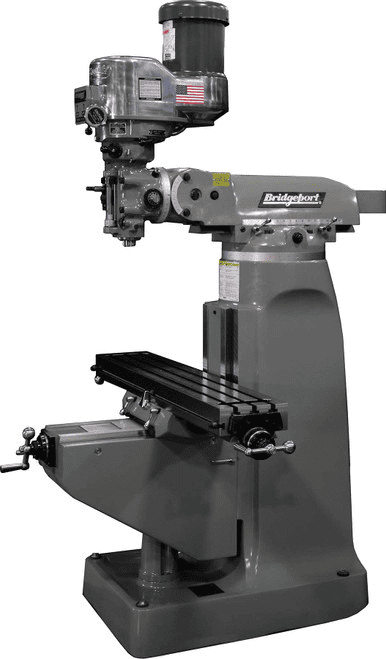

Typical Bridgeport Manual Milling Machine...

Milling machines are versatile power tools used in various industries to shape and cut solid materials. The basic functionality of a milling machine involves rotating a multi-point cutting tool against the workpiece, which is typically clamped or held in a vise.

This rotary motion of the cutting tool allows precise material removal, creating intricate shapes, holes, and contours. Compared to lathes, milling machines excel in their ability to remove material from different angles and directions.

Vertical Milling Machine: Exploring its Advantages and Applications

One popular type of milling machine is the vertical milling machine. As the name suggests, this machine's spindle axis is vertically oriented.

The vertical design offers several advantages, including easy visibility of the workpiece and easy access to workholding and machine setup. Vertical milling machines are widely used in manufacturing plants for tasks such as face milling, end milling, drilling holes precisely, slotting operations, and more.

In addition to their versatility in shaping complex parts accurately, vertical milling machines also allow operators to perform large-scale production runs efficiently due to their robust construction and high spindle speeds.

With the appropriate tooling setup and computer numerical control (CNC) capabilities added to modern models, vertical mills offer exceptional precision for prototyping or mass production projects across industries like aerospace engineering, automotive manufacturing, and even jewelry making.

Horizontal Milling Machine: Discussing its Unique Features and Uses

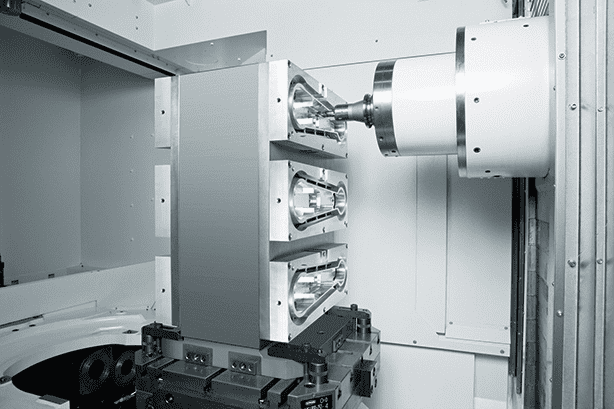

Typical horizontal milling machine...

Another essential type of milling machine is the horizontal mill. Unlike its vertically oriented counterpart discussed earlier, a horizontal milling machine has a horizontally oriented spindle axis parallel to the worktable surface. This design enables horizontal mills to perform tasks like heavy-duty face milling or milling things more efficiently compared to other types.

The unique feature that sets horizontal mills apart is their ability to create grooves, slots, and pockets at various angles by swiveling the worktable. This flexibility allows machinists to produce complex components with precision.

In addition, horizontal mills are especially good at clearing chips because the machine's orientation benefits from gravity.

Horizontal milling machines find widespread use in industries like shipbuilding, where large-scale metalwork requires contouring surfaces and creating deep cuts. Moreover, horizontal mills often incorporate additional features such as universal tables or rotary tables, expanding their capabilities even further.

These attachments enable the machining of circular or helical surfaces and facilitate intricate indexing operations for manufacturing gears or spirals. Milling machines offer immense versatility for shaping materials precisely.

Vertical milling machines provide excellent visibility and are more operator-friendly for a wide range of applications. On the other hand, horizontal mills excel in their ability to perform heavy-duty tasks and create complex contours efficiently.

The choice between these two types depends on specific machining requirements, material characteristics, and desired outcomes. When leveraged effectively, both milling machines can significantly enhance productivity across multiple industries by enabling precise material removal with remarkable efficiency.

Lathes

Definition and Primary Purpose

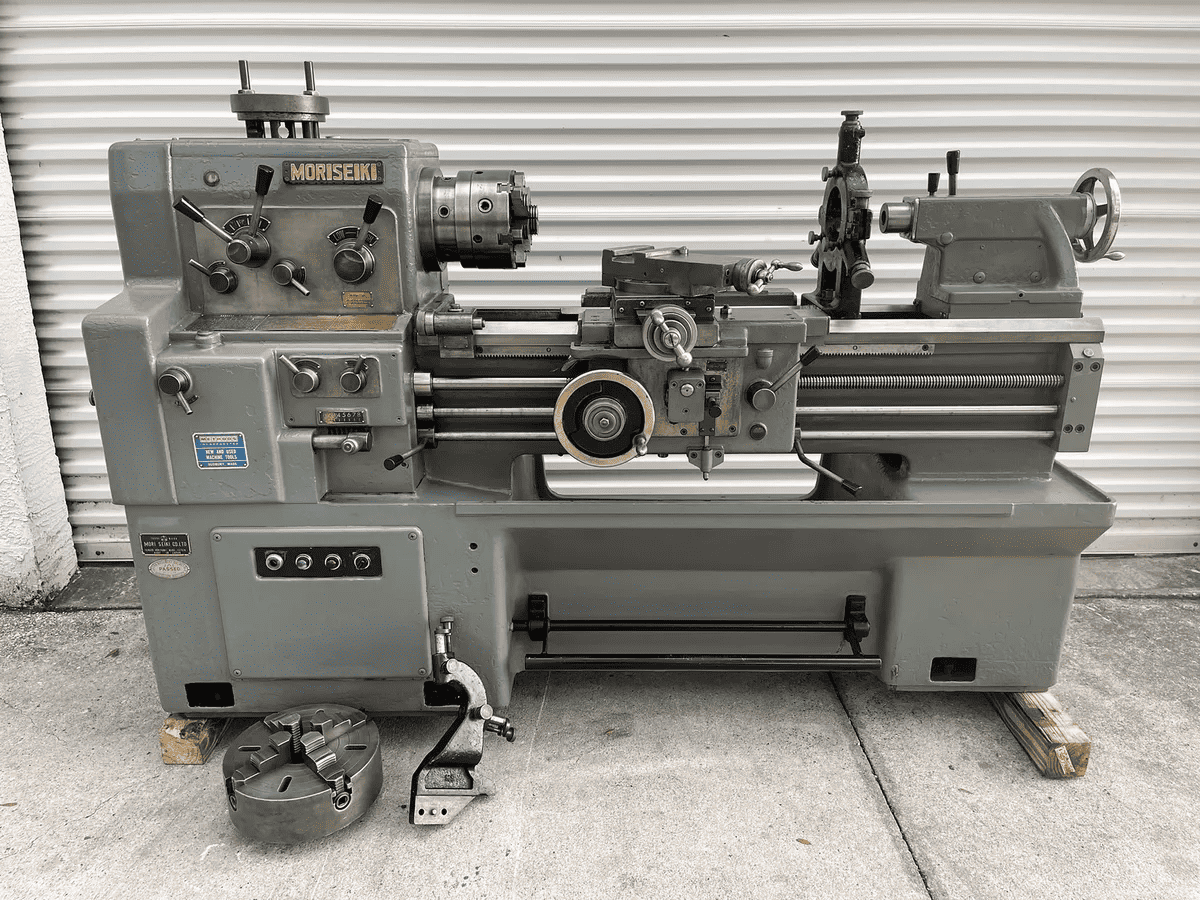

Lathes are fascinating machines that have been around for centuries, dating back to ancient civilizations. At their core, lathes are used for shaping workpieces by rotating them against a cutting tool.

This rotational movement allows for precise and controlled removal of material, resulting in various shapes being created. Lathes are commonly employed in metalworking, woodworking, and even pottery.

The primary purpose of a lathe is to turn cylindrical or symmetrical objects with accuracy and finesse. Turning refers to the process of removing excess material from the workpiece while it rotates on an axis.

This action produces smooth finishes with well-defined dimensions. Lathes enable craftsmen to create cylindrical components such as bolts, shafts, pulleys, and many other things we encounter daily.

Engine Lathe: Examining its Versatility in Turning Operations

Engine lathes, also known as center lathes or bench lathes, are the most common type of lathe found in workshops worldwide. These versatile machines can be manually operated or computer-controlled (CNC).

Engine lathes excel at performing a wide range of turning operations due to their robust design and flexibility. With an engine lathe by your side, you can effortlessly shape various materials like metals, plastics, and wood into intricate designs.

Whether you need to create threads on a bolt or simply turn down the diameter of a workpiece to precise specifications - engine lathes have got you covered! The ability to change speeds and feed rates ensures optimal control over cutting processes.

Turret Lathe: Highlighting its Automatic Tool-Changing Capabilities

Turret lathes represent an evolution in lathe technology by incorporating automated tool-changing mechanisms into their design. These machines boast a turret—a rotary tool holder—capable of holding multiple cutting tools simultaneously.

This feature allows for rapid tool changes during operations, enhancing productivity and reducing downtime. Turret lathes are particularly advantageous when dealing with complex workpieces that require different cutting tools for various machining operations.

By eliminating the need for manual tool changes, turret lathes save valuable time and effort. They are commonly used in high-volume manufacturing environments, where efficiency is paramount.

Lathes are invaluable machines in the realm of manufacturing and craftsmanship. Engine lathes provide versatility in turning operations, making them suitable for a wide range of applications.

On the other hand, turret lathes offer automatic tool-changing capabilities, streamlining production processes. Whether you're a seasoned professional or an aspiring hobbyist, understanding the capabilities and nuances of different lathe types will undoubtedly enhance your workmanship.

Differences between Milling Machines and Lathes

Primary function:

When it comes to their primary functions, milling machines and lathes are as different as night and day. Milling machines shine in their ability to remove material through the use of cutting tools.

They are designed to precisely shape and carve various materials by cutting away unwanted sections. With milling machines, you have the power to create intricate designs, sharp edges, and precise contours with ease.

On the other hand, lathes put rotational workpiece shaping at the forefront of their purpose. Instead of removing material like a milling machine, lathes excel in shaping workpieces by rotation.

Picture a cylindrical workpiece spinning on its axis while a cutting tool carefully shapes it into the desired form. Lathes offer unparalleled precision when it comes to creating symmetrical shapes or achieving smooth finishes on curved surfaces.

Cutting mechanisms:

Milling machines rely on multi-point cutting tools for their machining magic. End mills, face mills, and various other types of cutting tools take center stage here. These versatile tools consist of multiple blades or edges that actively chip away at the material as they rotate.

What makes milling machines truly remarkable is that they can accommodate different types of cutting techniques depending on the desired outcome. From traditional conventional cutting methods to more aggressive climb cutting techniques that minimize tool wear, milling machines provide an extensive range of possibilities.

In contrast, lathes utilize single-point cutting tools for their rotational workpiece shaping endeavors. These tools are primarily turning tools such as carbide inserts or high-speed steel cutters designed for precision machining operations.

Alongside turning operations like facing or taper turning where smooth surfaces and accurate dimensions are crucial, lathes also employ boring bars for enlarging existing holes or creating new ones with utmost accuracy. Now that we've explored these fundamental differences between milling machines and lathes, it becomes evident just how distinct their roles are in the machining world.

Milling machines boast versatility and precision when it comes to material removal, allowing for limitless creative possibilities. On the other hand, lathes excel in shaping workpieces by rotation, providing top-notch symmetrical designs and impeccable finished surfaces.

The cutting mechanisms further highlight these divergences: milling machines rock multi-point cutting tools for various cutting techniques, while lathes depend on single-point cutting tools tailored for turning operations. With such dissimilarities, both machines carve their niche in the realm of machining excellence.

Subtle Similarities between Milling Machines and Lathes

Common components shared by both machines:

When exploring the world of machining, it's intriguing to discover the subtle similarities between milling machines and lathes. These two heavyweights in the workshop share a few common components that contribute to their functionality and precision. Let's delve into these shared features and get a better understanding of how they work.

Spindles for holding the cutting tool or workpiece:

One essential component that both milling machines and lathes possess is the spindle. Think of it as the heart of these machines, responsible for holding either the cutting tool or the workpiece securely in place. In milling machines, the spindle typically houses various cutting tools like end mills, face mills, or even drills.

It provides rotational motion to these tools during operations. Similarly, lathes also rely on spindles to hold the workpiece with utmost stability.

The rotating spindle grips onto a chuck or collet that tightly clamps down on cylindrical or irregularly shaped objects. This ensures that as the lathe spins, precise turning operations can be performed with ease.

Feed mechanisms for controlled movement during operations:

Another crucial similarity between milling machines and lathes lies in their feed mechanisms. These mechanisms allow for controlled movement during machining processes, ensuring accuracy and repeatability. In milling machines, you'll find various feed mechanisms such as lead screws or power feeds.

These mechanisms enable precise linear movements along multiple axes (X, Y, Z). They allow machinists to maneuver cutting tools through complex paths with incredible precision.

Likewise, lathes feature similar feed mechanisms to facilitate smooth movements during turning operations. Whether it's longitudinal feeds (along the X-axis), cross feeds (along the Z-axis), or even compound feeds (combining both), these mechanisms aid in achieving desired dimensions and surface finishes.

While milling machines and lathes may seem distinct at first glance, they share significant similarities in terms of their key components. Both rely on spindles to hold either the cutting tools or the workpiece securely.

Additionally, they utilize feed mechanisms to ensure controlled movement during machining processes. Understanding these shared features helps us appreciate the underlying engineering principles and technical excellence that drive both these machines forward.

Advanced Features & Accessories for Milling Machines & Lathes

Milling Machine Add-ons

When it comes to milling machines, there is a myriad of advanced features and accessories that can enhance their functionality and versatility. One common add-on is the digital readout (DRO) system, which provides accurate measurements of tool positions, making it easier to achieve precise cuts.

Milling machine DRO kit...

Additionally, power feeds can be installed to automate the movement of the workpiece or cutting tool along the axes, saving time and effort. For more demanding applications, CNC (Computer Numerical Control) capabilities can be integrated into milling machines.

This allows for automated operations with complex cutting paths and facilitates the production of intricately designed components. Furthermore, coolant systems are essential for cooling down both the cutting tools and workpieces during high-speed machining, preventing overheating and maintaining dimensional accuracy.

Lathe Add-ons

When it comes to turning on a lathe, we've already seen the Turret add-on. But there are several other add-ons:

- Lathes benefit from DRO's just as mills do.

- Lathes can have workholding add-ons such as collet chucks and hydraulic or air-operated chucks.

FAQs

What is the difference between a mill turn and a lathe?

Mill-Turn is a Lathe with the ability to cut using tools that spin. In a lathe, the part spins and the tools are stationary. Mill-Turns have what's called Live tooling which lets you do both.

Which is better lathe or milling machine?

For cylindrical shapes, a lathe is better. They will achieve more precise cuts than a mill.

However, if your project requires straight cuts or drilled holes, a milling machine is probably better.

Is lathe the mother of all machines?

the lathe was very important to the industrial revolution. It has been called the Mother of Machine Tools because it was the first machine tool that led to the invention of other machine tools.

Conclusion

Both milling machines and lathes are indispensable in various industries that require precision machining operations. While milling machines excel in material removal through multi-point cutting tools and offer a wide range of add-ons like digital readouts or CNC capabilities, lathes are ideal for rotational workpiece shaping using single-point cutting tools.

Each machine has its unique advantages and applications. These advanced features and accessories not only improve the efficiency of milling machines but also enhance their accuracy and versatility.

Whether it's a digital readout system for precise measurements or CNC integration for automated operations, these add-ons take machining capabilities to new heights. Similarly, lathes benefit from accessories such as specialized chucks or quick-change tool posts that further enhance their performance.

By utilizing these advanced features and accessories while considering specific application requirements, manufacturers can unlock greater efficiency in their machining processes while achieving superior results. So embrace the possibilities offered by these remarkable machines to shape a future full of precision engineering marvels!

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.