Are you curious about how computer numerical control (CNC) machines are transforming the manufacturing landscape? You're in the right place! In this comprehensive guide, we'll give you an in-depth look at the diverse world of CNC machine types, from milling to plasma cutting, and the various axes of operation. Get ready to embark on a fascinating journey into the intricacies of CNC technology.

Short Summary

-

CNC machines are precision tools used for shaping workpieces and producing parts with a high accuracy rate.

-

Different types of CNC machines offer varying levels of performance, complexity, cost, and maintenance requirements depending on the application.

-

Advantages include increased productivity and accuracy. Consider limitations such as specialized programming, tooling & maintenance when choosing the right machine for your needs.

Understanding CNC Machines

CNC machines have revolutionized the manufacturing industry, offering increased productivity, precision, and versatility. From creating simple components to complex parts, CNC machines have become indispensable in various sectors, including automotive, aerospace, and medical fields.

There are several types of CNC machines, such as milling machines, lathe machines, drilling machines, grinding machines, plasma cutting machines, laser cutting machines, waterjet cutting machines, electrical discharge machines (EDM), router machines, press brake machines, and punch machines, each tailored to specific applications and materials.

Let's dive deeper into each type and understand its unique capabilities.

CNC Milling Machines

A CNC Milling Machine...

A CNC milling machine is a powerful tool that uses cutting tools to remove material from a workpiece and shape it to the designated specifications. Designing a part on computer-aided design (CAD) software is the first step of the CNC milling process. This design is then converted into a format suitable for CNC machines. The machine interprets the coded instructions and puts them into action, directing every move the machine makes to replicate the CAD design in the specified material with precision. CNC milling machines are ideal for generating gears, drilling workpiece boreholes, and creating slots. CNC Milling Machines can machine hard metals, while CNC routers are more suitable for working with softer materials like wood, plastic, and soft metals.

End mills, reamers, face mills, taps, and drills are some of the commonly used cutting tools in CNC milling machines. CNC mills come in various configurations, with options ranging from basic 2-axis machines to more complex 5-axis or even 6-axis systems. The CNC Supra Vertical Knee Mill, for example, is a Bridgeport-type CNC knee mill with useful features, available in two table sizes, and suitable for production work, product development, rapid prototyping, engraving, and teaching applications.

CNC milling machines are versatile tools that can perform tasks such as tapping, drilling, turning, face milling, and shoulder milling.

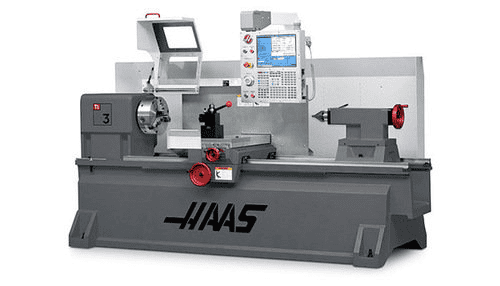

CNC Lathe Machines

Toolroom CNC Lathe...

A CNC lathe machine can produce an end product with a high precision rate. It does that by spinning the workpiece at a high speed while a stationary cutting tool is applied to attain the desired shape. CNC lathe machines are utilized for their capacity to generate external and internal characteristics on the workpiece through executing various operations, such as turning, drilling, boring, etc. They are widely used across many manufacturing industries for the production of items such as capstan and turret.

CNC lathes are most suitable for producing cylindrical, conical, or flat shapes, in contrast to CNC mills, which are able to work on any shape. CNC lathe machines are typically capable of performing tasks such as cutting, sanding, facing, drilling, and turning. They usually feature two axes: the Z-axis, which governs the movement of the cutting tool along the length of the workpiece, and the X-axis, which controls the movement of the cutting tool perpendicular to the chuck.

CNC Drilling Machines

CNC drilling machines are highly precise and adaptable devices that utilize CNC technology to fabricate holes with tolerances as tight as 0.001mm in a variety of materials. Creating holes in all sorts of materials is convenient with these tools. They can be used for screws, secondary assembly, as well as for visual purposes.

However, CNC drilling machines lack the ability to create deep or large holes and necessitate the use of specific-sized drill bits for different diameters. Materials can be processed at a much greater rate in comparison to manual drilling approaches. CNC drills have evolved so they are now equipped with intelligent tool swapping and positioning technologies to increase their efficiency. This offers significant advantages in production lines.

CNC drilling machines are a valuable asset in the manufacturing industry, offering speed, precision, and versatility in creating holes in various materials using a CNC drilling machine.

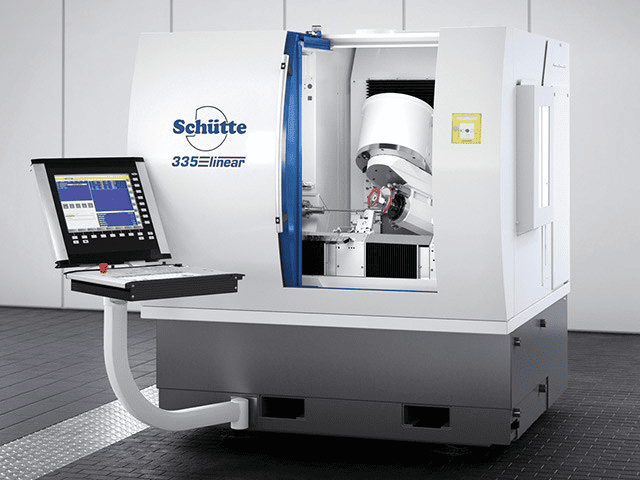

CNC Grinding Machines

CNC Grinding Machine...

CNC grinding machines are devices that utilize a rotating wheel to grind metal for an exact and precise finish. These machines are used to produce cylindrical objects and other functional items, such as engine parts. CNC grinding machines are available in a range of styles. These include surface grinders, roll grinders, and cylindrical grinders.

The product is initially created with a coarse surface using a CNC mill or lathe, then transferred to the CNC grinder for grinding operation to acquire the ultimate finish. A variety of abrasives are employed for grinding, including plated or vitrified CBN, Diamond grinding wheels, Aluminum Oxide, and Ceramic Blend Grinding. Wheels, among many others.

CNC grinding machines, including the CNC grinding machine, offer increased precision and the capacity to manufacture complex components with fewer setups.

CNC Plasma Cutting Machines

CNC Plasma Cutting Machine...

CNC plasma cutting machines cut through electrically conductive materials using high-powered plasma produced by a plasma torch. The CNC plasma cutting machine operates by propelling a gas or compressed air through a nozzle at high speeds and then introducing an electric arc to the gas, thereby creating a plasma that is capable of cutting through metal.

Plasma cutters are widely used in fabrication shops, automotive repair and restoration, construction, and salvage operations. They provide an efficient way of cutting metal into precise shapes and sizes. Artists and designers use them to create signage, sculptures, and decorative panels for interior projects. Additionally, these materials can also be used in creative and innovative ways.

CNC plasma cutting machines come in various price ranges, depending on the model and features, but an entry-level CNC plasma cutting machine typically starts at approximately $5,000.

CNC Laser Cutting Machines

A CNC Laser Cutting Machine...

CNC laser cutting machines use highly focused lasers to cut through strong materials with greater precision and better surface quality than CNC plasma cutters. They are typically employed for cutting plastic, paper, fabric, metals, and hardwood, making them versatile and highly efficient machines.

CNC laser cutting machines utilize a powerful beam of highly focused laser to cut through materials, whereas CNC plasma cutters employ plasma (ionized gas). CNC laser cutting machines are beneficial for engineering purposes, where the accurate cutting of components for machines is essential. Additionally, laser cutters are used to cut structural and piping materials as well as flat sheet metal.

The cost of acquiring a laser cutting machine can range from $5000 to $300,000, depending on the model and features.

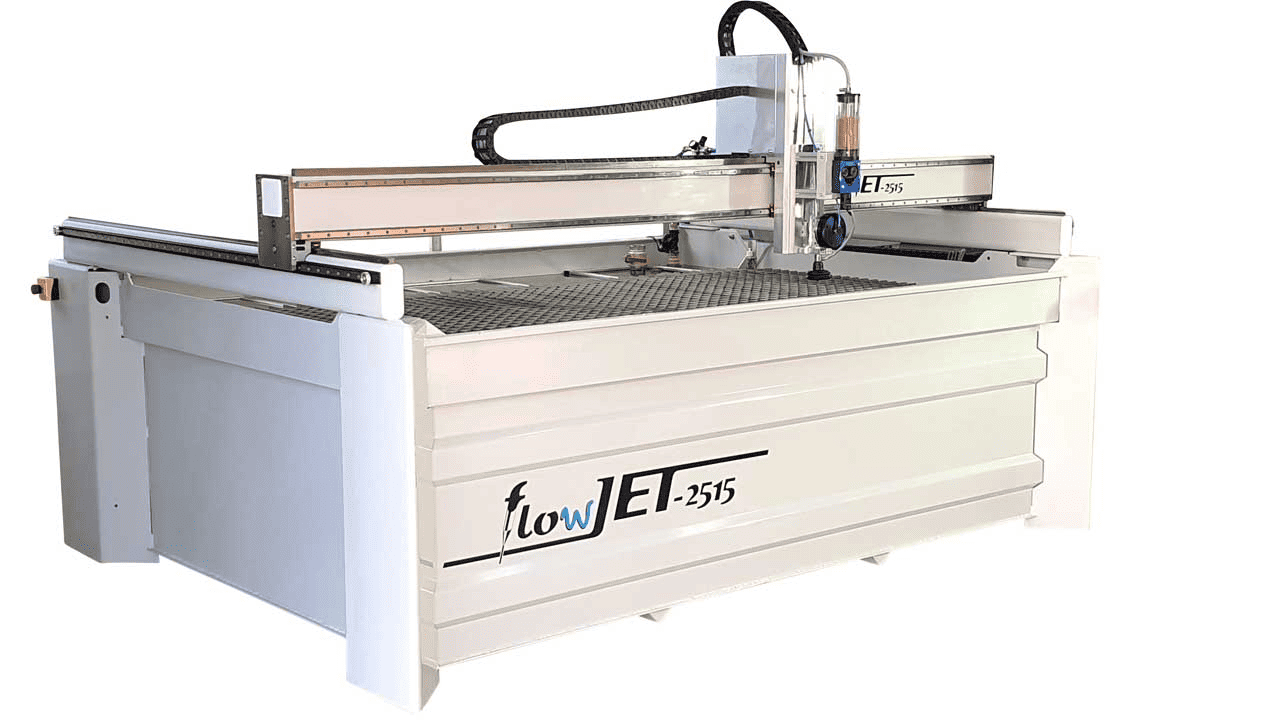

CNC Waterjet Cutting Machines

CNC Waterjet Cutting Machine...

CNC waterjet cutters are cutting machines that use high-pressure water jets. These water jets can be used to cut materials like plastic and aluminum. They are suitable for materials that are sensitive to temperature and could melt at high temperatures, such as plastic and aluminum. Waterjets are widely used in glassworking. They can create magnificent decorative pieces, like kitchen splashbacks, stained glass, shower screens and floor inlays.

The benefits of utilizing a CNC waterjet cutting machine include the ability to cut through materials that are sensitive to heat and may melt at high temperatures. However, they are slower than CNC plasma cutters and CNC laser cutters. The cost of CNC waterjet cutters ranges from $50,000 to $200,000.

CNC Electrical Discharge Machines (EDM)

CNC Electrical Discharge Machines (EDM)...

CNC electrical discharge machines (EDM) are specialized CNC machines that shape materials through electric sparks. The materials are situated between the upper and lower electrodes, and the computer then determines the amount of electrical discharge the electrodes generate.

Wire EDM is widely used in the production of molds and dies. It is particularly suitable for extrusion dies and blanking punches. EDM is a great technology which can be used for producing prototypes as well as for total production runs. It is particularly effective when it comes to creating metal components and tools. The automotive, aerospace, and electronics sectors regularly employ EDM for their components.

A new EDM cutting machine can cost a minimum of $15,000. Prices vary depending on the model and features.

CNC Router Machines

CNC Router Machine...

CNC router machines use computer numerical control to shape materials like wood, steel, composites, aluminum, foam, and plastic. They are primarily utilized for working with softer materials and are less precise than CNC milling machines. CNC routers are widely used for machining solid surfaces. They can be programmed to create intricate shapes and designs in any material.

CNC routers are capable of producing intricate shapes and are used in a variety of applications, such as doors, spinning wheel rims, electronic guitars, and dental crowns. The utilization of a CNC router can provide a reduction in wastage, an increase in productivity and accuracy, as well as an expedited production rate.

A high-quality CNC router can be acquired for an amount less than $2,000.

CNC Press Brake Machines

CNC Press Brake Machine...

CNC press brake machines are computer-controlled devices that utilize press and die to apply the necessary pressure to form the workpiece into the desired shape. They are well-suited for large-scale industries, such as automotive, aerospace, construction, and metal fabrication. CNC press brake machines are capable of producing bends of remarkable precision.

These machines are available in both manual and automated versions, with manual machines requiring an operator to manually load and unload the material, while automated machines are designed to operate independently. CNC press brake machines offer a versatile solution for bending sheet metal into complex shapes and reducing production time.

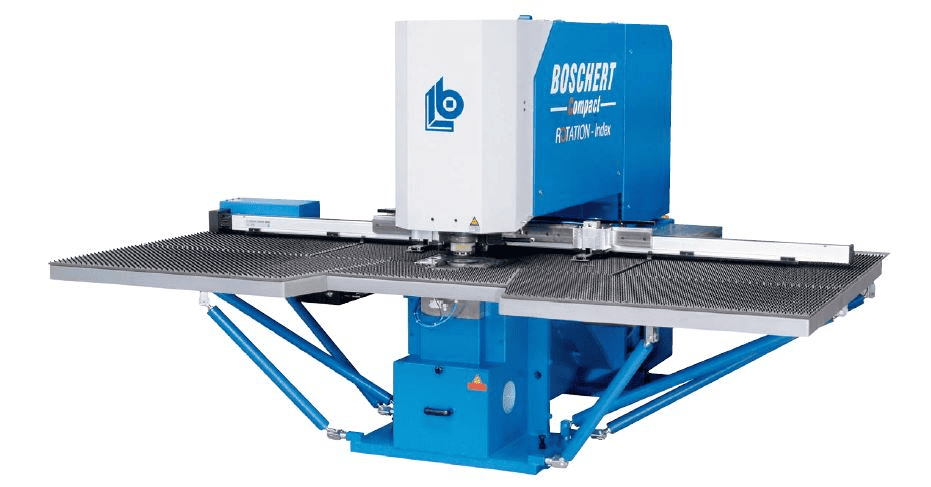

CNC Punch Machines

CNC Punch Machine...

CNC punch machines are electromechanical devices that utilize computer programming inputs to move tools and generate patterns. They can be either a single head and tool rail or a multi-tool tower and are utilized to punch holes and shapes in sheet metal. CNC punch machines are used to generate holes in sheet metal for a variety of industries, including automotive, aerospace, and medical.

The capability to replicate a design as many times as possible after the design has been established is the primary benefit of CNC punching. CNC punch machines can be found in both manual and automated varieties, with manual machines necessitating an operator to manually load and unload the material, while automated machines are designed to operate independently.

Other CNC Machines

Multiaxis CNC Machining

Multiaxis machining is a type of CNC machining that uses multiple axes of movement to create intricate geometries and maintain precise tolerances. CNC machines are available in various configurations, from basic 2-axis to more complex systems with up to 6 axes of operation. Each type of CNC machine offers unique capabilities, making them suitable for a wide range of applications.

In the following sections, we'll explore the different types of multi-axis CNC machines and their specific uses.

2-Axis CNC Machines

A 2-axis CNC machine is a basic type of CNC machine that can move along two axes, usually the X and Y axes. It is typically used for turning cylindrical parts, with the two axes of movement being the X-axis, which is the vertical axis, and the Y-axis, which is the horizontal axis.

2-axis CNC machines are ideal for simple applications and are often used in small-scale manufacturing, prototyping, and hobbyist projects. While limited in their capabilities compared to more advanced CNC machines, 2-axis machines still offer increased precision and control compared to traditional manual machining methods.

3-Axis CNC Machines

A 3-axis CNC machine is a type of CNC machine that is capable of operating on three axes simultaneously, typically the X, Y, and Z axes. These machines are widely used in the manufacturing industry and can produce basic parts in 2.5 dimensions.

3-axis CNC machines offer increased precision and versatility compared to 2-axis machines, making them suitable for a wider range of applications. They can be used for milling, drilling, and cutting operations, and are commonly found in industries such as aerospace, automotive, and medical device manufacturing.

4-Axis CNC Machines

A 4-axis CNC machine operates on the X, Y, and Z axes, as well as an additional axis of rotation, generally around the X-axis, referred to as the A-axis. This additional axis allows the machine to create more complex geometries and shapes, making 4-axis CNC machines more versatile than their 3-axis counterparts.

The benefits of utilizing a 4-axis CNC machine include enhanced precision, augmented productivity, and the capability to manufacture complex components with fewer setups. However, the drawbacks of utilizing a 4-axis CNC machine include increased costs, heightened complexity, and the requirement for specialized programming.

5-Axis CNC Machines

A 5-axis CNC machine is a machine that is capable of executing movements in five distinct axes simultaneously, thereby enabling the tool to access all sides of a part without requiring additional turning or setup. This type of machine is commonly utilized in industries that require intricate shapes and features, such as the aerospace and medical sectors.

The advantages of 5-axis CNC machines include higher precision, enhanced surface finish, and the capacity to create intricate shapes. On the other hand, the drawbacks of 5-axis CNC machines include their high cost, programming complexity, and specialized tooling requirement.

6-Axis CNC Machines

A 6-axis CNC machine is a more sophisticated variation of 3, 4, or 5-axis machines, offering the ability to rotate both the workbed and the cutting tool. This type of machine is commonly utilized in industries that require intricate shapes and features, such as automotive, aerospace, and medical device manufacturing.

6-axis CNC machines provide increased flexibility and accuracy compared to 3, 4, or 5-axis machines. They are capable of producing intricate shapes and features with greater accuracy and speed. However, 6-axis CNC machines are more expensive than 3, 4, or 5-axis machines and necessitate more intricate programming.

Additionally, they require more space and are more challenging to maintain.

Choosing the Right CNC Machine

Selecting the right CNC machine for your needs depends on various factors, such as the intended purpose, available space, level of automation, accuracy, budget, and maintenance costs. It's also crucial to consider the material and features of the workpiece, production volume, and tool material. By evaluating these factors, you can make an informed decision about which CNC machine is the best fit for your specific application.

Bear in mind that each type of CNC machine has its unique capabilities and limitations, making it more suitable for certain industries and applications. For example, CNC milling machines are ideal for hard metals, while CNC routers are more suitable for softer materials. Consider the specific requirements of your project and the capabilities of the CNC machines available to make the best choice for your needs.

Advantages and Limitations of CNC Machines

CNC machines offer numerous advantages, including increased productivity, accuracy, and reduced risk of human error in production operations. These machines can efficiently produce complex parts and components with tight tolerances, making them indispensable in various industries. CNC machines also offer a high degree of automation, allowing for faster production times and reduced labor costs.

However, CNC machines also have their limitations. CNC machines' capabilities are dependent on the control and drive systems. If these systems are outdated or lack features, the machine could be limited in its ability. Devices that are older and cost less likely will not be able to do tasks very efficiently. It's similar to how an old computer can't handle difficult tasks as efficiently or quickly as a newer one.

Additionally, CNC machines require specialized programming, tooling, and maintenance, which can be time-consuming and costly.

Real-World Applications of CNC Machines

CNC machines are used in a wide range of industries and applications, showcasing their versatility and efficiency. In the dental industry, for example, CNC machines are used to manufacture dental crowns and implants with precision and accuracy. In the armaments industry, CNC machines are employed to fabricate weaponry and equipment, showcasing their ability to handle complex and precise manufacturing tasks.

Other real-world applications of CNC machines include the production of doors, spinning wheel rims, electronic guitars, and even intricate sculptures. With their ability to produce practically any item from the appropriate quantity of any material, CNC machines have become indispensable tools in various industries, including automotive, aerospace, and medical device manufacturing.

Summary

In conclusion, CNC machines have revolutionized the manufacturing landscape, offering increased productivity, precision, and versatility. With various types of CNC machines available, such as milling machines, lathe machines, drilling machines, grinding machines, plasma cutting machines, laser cutting machines, waterjet cutting machines, electrical discharge machines (EDM), router machines, press brake machines, and punch machines, these highly efficient machines cater to diverse applications and materials. By understanding the capabilities and limitations of each type of CNC machine, you can make informed decisions and choose the right machine for your specific needs, paving the way for innovation and success in your projects.

Frequently Asked Questions

What are the 5 common types of CNC machines?

CNC machines are used in precision machining and have five common types: milling machines, lathes, grinders, laser cutters, and EDM (electrical discharge machining) machines. Each type serves a unique purpose in fabricating metal and plastic components, enabling a wide range of intricate and complex designs to be created.

With their high-precision, versatility, and efficiency, CNC machines are an essential tool for advanced industrial production.

What is the most common CNC machine type?

The most common type of CNC machine is the 3-axis CNC. This type of machine has three axes of movement, namely the X, Y, and Z-axis, and is able to machine parts in 2.5 dimensions.

This makes it a popular choice for many production purposes.

What are the names of CNC machines?

CNC machines come in a variety of shapes and sizes, with different names such as milling machines, lathes, routers, grinders, and plasma cutters.

Each type of CNC machine is designed to perform specific tasks depending on its type and the material it's working with.

What is the difference between a CNC mill and a CNC lathe?

CNC mills use a rotating cutting tool to shape material, while CNC lathes rotate the material and utilize a stationary cutting tool for shaping.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.