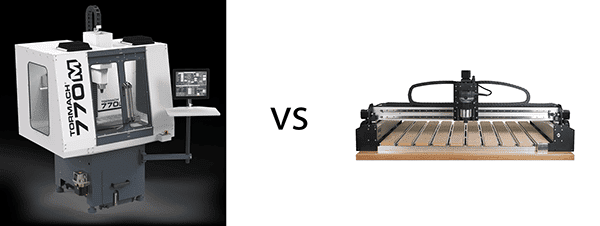

CNC Mill vs Router [How to choose the right one for you]

Introduction

One of the first decisions you'll have to make before acquiring a CNC Machine (or building a DIY CNC Machine) is which kind of CNC Machine do you want? This article focuses on comparing two of the most popular CNC Machines-the CNC Milling Machine (CNC Mill) and CNC Routers.

We will start out looking at key differences by which to choose a machine. Then we will summarize each machine's pros and cons and give you an idea of what you can make with it.

Material to Be Cut

There are pretty sharp differences in the types of materials that can be cut efficiently on a CNC Mill versus a CNC Router. That's because the spindles found on a CNC Mill have a much different rotational speed than those of a CNC Router.

CNC Routers typically have higher speed spindles or woodworking trim routers. They run at 20,000 rpm and up. Some can go a bit slower, but few go slow enough for really hard materials. Therefore we say that CNC Routers are best used to cut softer materials like wood, plastic, and perhaps soft metals (aluminum and brass). They can be the ideal wood cnc machines especially when equipped with CNC Router Bits that make for a better smoother cut in wood.

CNC Mills, OTOH, typically have much lower rpm capabilities. In fact, many cnc mills max out at 6000 rpm. That means they're better at cutting tougher materials like hard metals (like steel or even titanium). That's not to say they can't cut the soft materials, but they will do so much more slowly than a CNC Router, and the final finish may not be as good.

Rotational speed is one of the key differences that can matter a lot in defining what your machine can or cannot do.

Cutting area and Z-axis travel

In general, CNC Routers have a bigger work envelope, but their Z-axis doesn't travel very far. So they're great at making things sheet materials. For example, signs are rectangular and usually not very thick.

CNC Mills can have a lot more Z-axis movement, but their X and Y are smaller than the router. If you'll be making tall parts at all, you may prefer a CNC Milling machine.

Cost- CNC Router vs CNC Mill

The Shapeoko is a typical entry-level CNC Router while the Tormachs are the typical entry-level CNC Milling Machines. In general, CNC Routers are going to be cheaper than CNC Mills at a given level of capability. When we start talking about the very best CNC Routers, they cost more than the entry-level milling machine, but less than the very best CNC Mills.

The cost issue swings further in the CNC Router's favor when you consider the cost for precision measuring equipment (calipers, micrometers, and the like) and additional workholding like a milling vise. That's the difference between cnc machining and cnc woodworking. CNC machining is more expensive.

For a good introduction to what CNC Machines Cost, check out our linked article.

Accuracy and Rigidity

A CNC Milling Machine offers much greater Accuracy and Rigidity than a CNC Router. They weigh more (they're usually made of cast iron whereas routers are usually aluminum), and that weight is concentrated on a smaller work area.

For the most part this all works out due to the other characteristics of each cnc machine. You need more rigidity for harder materials like metal. You generally want tight tolerances (e.g. more accuracy) and high precision for those materials too.

With soft materials like wood you're generally not making precision mechanical parts, so it's okay if a little less accuracy is available.

Ease of Learning

The two machines are pretty similar in terms of ease of learning. Computer Numerical Control (CNC) is pretty standard technology for both routers and mills. But, and this is a big but, you will need additional skills to do the kinds of precision metal machining that a CNC Mill is capable of.

For example, just being able to take precision measurements of various kinds is a fair amount of learning that almost need not come up for CNC Routers.

Feeds and Speeds are more complicated and less forgiving with CNC Routers than CNC Mills.

You have to master CAD and CAM Software to a greater degree to succeed with precision machining metal parts than for most CNC Router projects.

Work Support

Work Support and Workholding differ between these two types of machines.

Both will involve clamping to the table. Better CNC Routers use T-Slots just like CNC Mills. Even better is a vacuum table.

CNC Milling Machine will often clamp in a vise while a CNC Router almost never does. You'll wind up spending a fair amount of additional money with a CNC Mill on workholding and fixturing tools.

CNC Router vs Mill: Which one first?

Think hard about what sorts of projects or products you want to tackle. Which machine better suits the needs of your projects? And does that machine fit your budget?

If you plan to build model steam engines, you need a machine that handles metal and is pretty accurate. Sounds like a CNC Mill.

OTOH, if you want to make furniture, you probably want a machine that's good with wood. That sounds like CNC Routing.

Ultimately, you may find that like me you want to wind up with both cnc machines in your shop. That being the case, I personally think CNC Routers are a little faster to learn and they're cheaper, so start there.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.