1 month by cncdivi

Winning the High Mix Low Volume Manufacturing Game [ HMLV ]

My CNC Chef video on Optimizing for HMLV…

High Mix Low Volume is the norm for manufacturing these days. At first, it seems hard to do it profitably, but once you understand the game you can win.

What is High Mix Low Volume (HMLV)?

If you’re not in the Job Shop business, you may have visions of assembly line manufacturing of thousands to hundreds of thousands or even millions of parts. Each minute step along the road to making the part is individually tweaked and optimized. Saving a few cents here and there adds up to big money over so many parts.

That type of production work is High Volume Low Mix–a Job Shop is going to make huge quantities of very few parts over the course of a year. Much of that business has gone offshore, leaving High Mix Low Volume work. That’s the work of producing small batches of parts, and to keep a shop busy, a lot of these orders (that’s the “High Mix” part) get done over the course of a year.

To win the game of HMLV, you can’t focus on optimizing individual parts too much. You’ll be done with the job before you’ve had time. Instead, you need to focus on changes that deliver savings on every job.

Let’s define it a little closer. Datron says Low Volume is any job for under 1000 parts.

But, if we look at the statistics, we see the average batch size is more like 95 parts.

How do we succeed in a world where we have to get it right with just 95 parts?

What’s Different About HMLV?

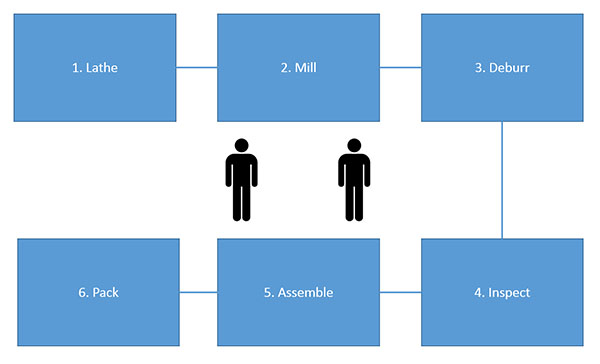

Let’s start by analyzing what’s different in the mindset of these two different styles.

High Volume Low Mix is all about optimizing production for a particular part. But, High Mix Low Volume is the art of performing optimizations that will improve all jobs, not just specific jobs.

That’s a very important distinction, so let me say it again:

Focus on changes that improve all jobs, not just specific jobs.

The other thing is that HMLV has a much smaller margin for error. If you’re only making 95 parts, you can’t scrap many. HMLV has to be right the first time.

Once you’ve wrapped your mind around how differently this game works, you can figure out how to win!

Using REAL to Optimize for HMLV

In the video I describe a framework I call “REAL” to help optimize for HMLV. It works like this:

- (R)educe Cycle Times

- (E)liminate Uncertainty and Surprisees

- (A)utomate and Standardize Routines

- (L)oading and Setup Optimization

Those four areas, if improved, will benefit virtually every job and pay off very quickly.

Check out the video to learn more about how to win the HMLV game.

Reduce Cycle Time by Optimizing Feeds & Speeds: An HMLV Boost Across All Jobs

HMLV is all about finding investments that will optimize ALL jobs, not just a few. One of the easiest investments you can make in that area is better Feeds and Speeds. The right Feeds and Speeds software can often make an immediate improvement across all your jobs.

Why?

Because it automates a set of Best Practices for Feeds and Speeds. It makes Feeds and Speeds systematic and repeatable. And, because a good Feeds and Speeds solution is not job-specific. You’ll see the benefits of improvement across all your jobs.

How much improvement?

We surveyed G-Wizard customers and here’s what they told us:

Frankly, I was shocked at these results. But, then I thought about the many conversations I’ve had with folks and I was a lot less shocked. G-Wizard considers over 60 variables, and it uses Machine Learning (AI) techniques to optimize your Cut Depth and Width for the best possible results.

Get the G-Wizard Calculator Free Trial today and see how much it can improve your Feeds and Speeds.

Get my G-Wizard Calculator Free Trial

More Ways to Reduce Cycle Time for All Jobs

Better Tooling is another. By spending a little more on your tooling you can improve cycle times across the board.

When considering tooling costs, keep this in mind–your consumable tooling typically accounts for 5% of job cost. The biggest cost by far is hourly wages and hourly cost of the machine. If you double tooling cost to 10%, you made the job 5% more expensive. So all that fancy new tooling has to do is save more than 5% on time and it will pay for itself. Suddenly, that fancy tooling looks a lot more affordable!

Likewise, if your CAM doesn’t offer the latest toolpaths, or you’re not using it to its full potential, now is the time to up your game.

Offline Tool Setting can also improve your cycle times because it doesn’t you don’t have to stop the spindles to do it.

Lastly, if you’re contemplating any new machinery, look for things that will improve any job. Machines with faster rapids, faster toolchanges, and more acceleration can speed jobs up. Features like higher spindle rpms, through spindle coolant, and high pressure coolant can all make a difference. BTW, you can use G-Wizard Calculator to model many of these differences and see what the savings might be on a job.

Being able to put more tools on the machine as well as being able to change tooling while the machine continues making chips both benefit all jobs.

If you’re not already, look into fourth axis with tombstones so you can cut more sides with fewer setups.

How to Eliminate Uncertainty and Surprises

Remember we talked about getting HMLV work right the first time? Well, eliminating uncertainty and surprises sure can help that. If nothing else, stable processes are much easier to optimize.

Here’s a good list to start with.

Make sure your g-code runs the first time you put it on the machine so you’re not wasting valuable spindle time cutting air. That means using a simulator on every job, like our G-Wizard Editor. See our article on how you can eliminate errors in g-code with simulators.

Make your workpiece and fixture locations repeatable with fixture plates.

Figure out how you can cut to tolerance without test cuts. It may require better tooling, different programming, different feeds and speeds, or in-process probing to automate test cut adjustments

Make Tool Wear predictable so you can pre-plan tool changes instead of being surprised when a tool breaks.

Standardize your tool setups. Maybe the first 10 slots in the toolchanger are the same for every job.

Get consistent materials and standardize material per-cut sizes and grades

Inspect and Identify problems earlier

Plan for emergencies: keep a couple of pallets set up with vises so you can rework and do one-offs as needed

Automating Routines

Automating routines that every job needs to go through is obviously going to bear fruit.

Probes enable a lot of automation for setup, tool handling, adjusting cuts, and in-process inspection.

Standardizing routines can be almost as valuable. A well-documented standard routine is not only done faster and with fewer errors, but it’s perfect for further optimization.

Fixtures offer huge opportunity for standardization once you realize the goal is to create general purpose fixtures that are not part-specific. How is that possible? Think about standardized Material Sizes as a starting point. You can whip up a plate fixture to hold different standard material sizes and reuse it across many jobs.

Think about standardizing repeat jobs. Are you set up so you can just leave fixtures for repeat jobs setup on pallets so you can pick up where you left off?

Think about standardizing chip and coolant management so they are handled while the machine runs. Can your operators check coolant, clean and top off, while chips are being made? Are your chip augers and conveyors set to run automatically as needed? What other preventative maintenance can they do?

Loading and Setup Optimization

The last part of getting REAL for HMLV jobs is Part Loading and Setup Optimization.

Your first job is to invest in pallets so parts are unloaded and loaded while the machine is making chips on the next batch.

Once that’s done Standardize, Organize, and Optimize the work:

Use checklists and standard fixtures. Follow 5S to organize, make things visual, and eliminate clutter. Stop searching for tools needed for setup and keep everything right with the machine.

Got that all working great? Go from hand tools to power tools, air or electric for part loading and unloading. Provide help handling heavy pallets. There’s a lot to be gained from optimizing this area and it will benefit every single job.

Conclusion

Once you get the central tenet of HMLV–don’t waste time on optimizations unless they benefit every part–you’ll see opportunities you can move ahead with. Soon you’ll be much more competitive and much more profitable.

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Recently updated on March 13th, 2024 at 12:16 pm

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.