1 year by cncdivi

Trepanning Tool Toolgrinding

I prefer carbide inserted tools for most lathe work–they’re very convenient, cost effective if you shop carefully for inserts, and I have used them enough that I know how to get a good finish from them on my lathe. However, there are tasks where HSS tools are ideal. This page captures some of those I’ve come across over time. If you have a Tool Grinder, it’s worth learning to use it, and it isn’t hard.

Trepanning Tool Toolgrinding

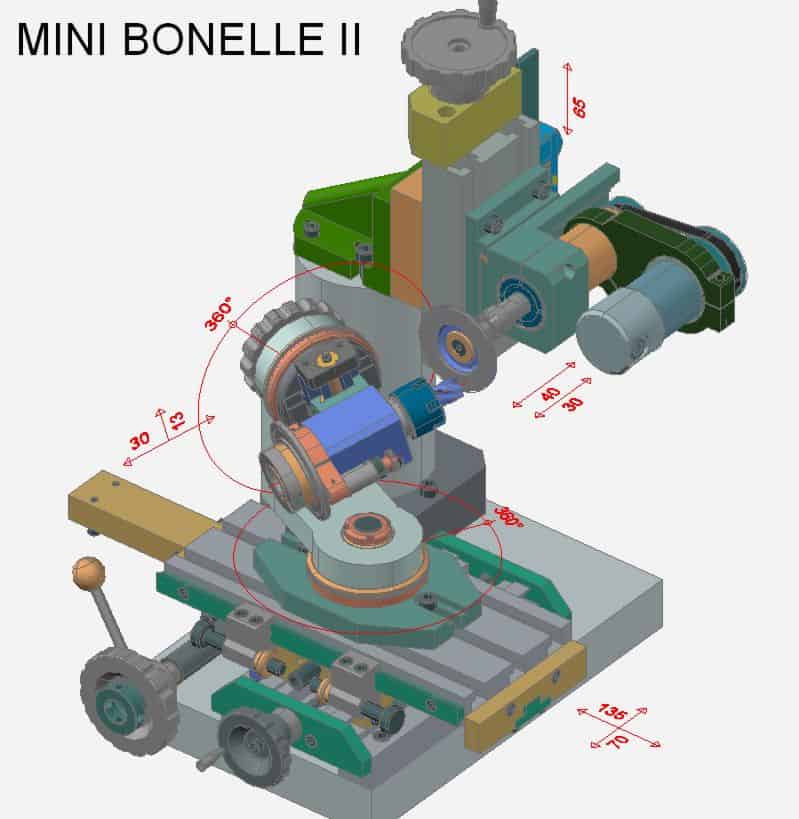

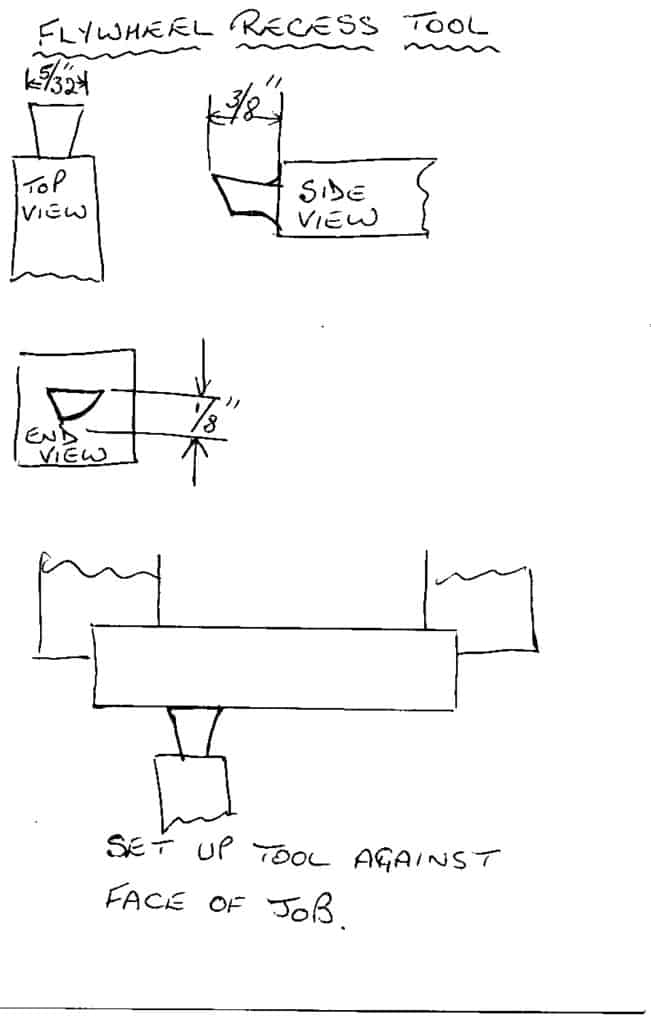

Trepanning is a useful operation that may be thought of as putting a groove in the face of a workpiece on the lathe. The groove may be narrow, a wide recess, or even all the way through to cut a disc out. Trepanning tools are available for mills and drill presses especially for the latter purpose. Here is a sequence Bobstandard published on HMEM showing how to trepan flywheels with a tool he has ground:

Here are a couple flywheels with trepanned recesses ground inside…

A look at the tool that did the work…

The tool in action…

General guidlines for grinding such a tool…

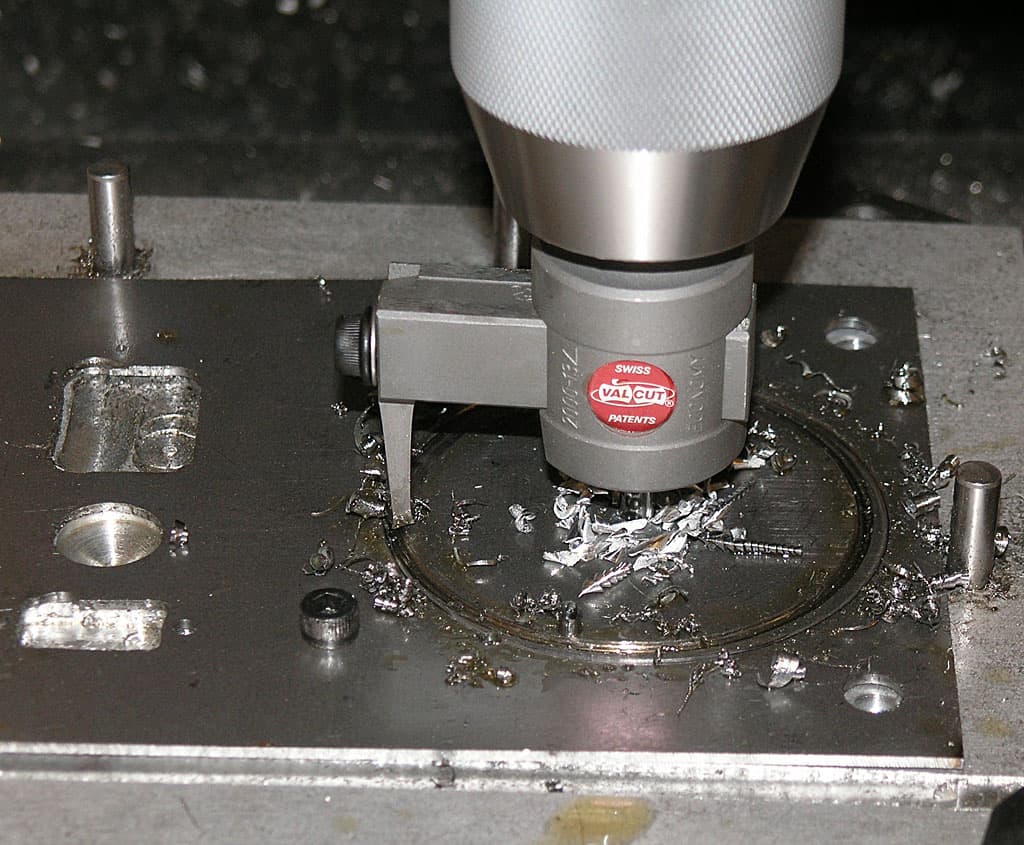

A commercially available treppaning tool for hole cutting: $29 apiece! You could grind this shape pretty easily too…

I’ve tried to grind my own trepanning tools for hole cutting on the mill with some success. I started with a dulled endmill and ground all but one flute off and tried to make that flute extend down as much as possible. I then installed the endmill in a boring head and went at it:

My trepanning tool ground from an endmill in action…

A commercially available trepanning tool of the type I show a cutter for above. It works a little better than the hand ground endmill, but not hugely better…

|

|

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Recently updated on March 22nd, 2023 at 04:30 pm

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

![Increase Tool Life, Reduce Tool Wear [ Easy Guide ] Improving Tool Life](https://www.cnccookbook.com/wp-content/uploads/2013/11/ToolLife.jpg)

![[Review] Tosa Tool's ER Tightening Fixture: Great CNC Shop Tool Tosa Tool TTS Compatible Tool Mount](https://www.cnccookbook.com/wp-content/uploads/2017/03/DSC00425.jpg)

![Lathe Tool Storage [QCTP Holder Storage] Various metalworking tools and clamps organized on a workshop table, covered in metal shavings and debris, including a dedicated QCTP holder storage area.](https://www.cnccookbook.com/wp-content/uploads/2021/07/ToolHolder1-1.jpg)