11 months by cncdivi

|

We’ve all seen photos of unbelievably spectacular garages filled with exotic cars. Some of them are more like museums or theme parks than garages. Jay Leno and Ralph Lauren both have amazing facilities of this kind. But let’s say that in addition to having the time and wealth to do nearly anything you want, you’re also the type to get grease under his fingernails. You know, the Tony Stark type. |

Table of Contents

|

|

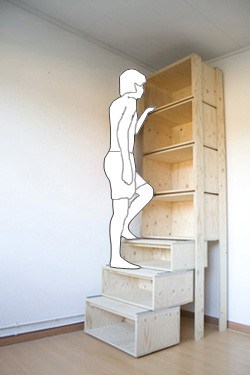

Part 1: The SpaceLet’s start with the space you’ll build the workshop in. Whether it’s in a building that’s part of your estate compound or a short drive away (Jay Leno uses aircraft hangars), you’ll want to ensure there is lots of space available. |

|

Part 2: CADCAM and Computer FacilitiesThe first stage of turning imagination into reality is the Design Office. Check this one out for the Ultimate Workshop.

|

|

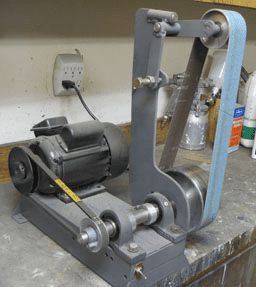

Part 3: Cutting Rough Stock, Fabrication, and WeldingCutting the rough stock is the first stop on the road to machining. Fabrication and Welding are separate paths all their own. |

|

Part 4: MachiningCome on, you know this is the part you’ve really been waiting for–what kind of lathes and mills would be hiding in a workshop like this? |

|

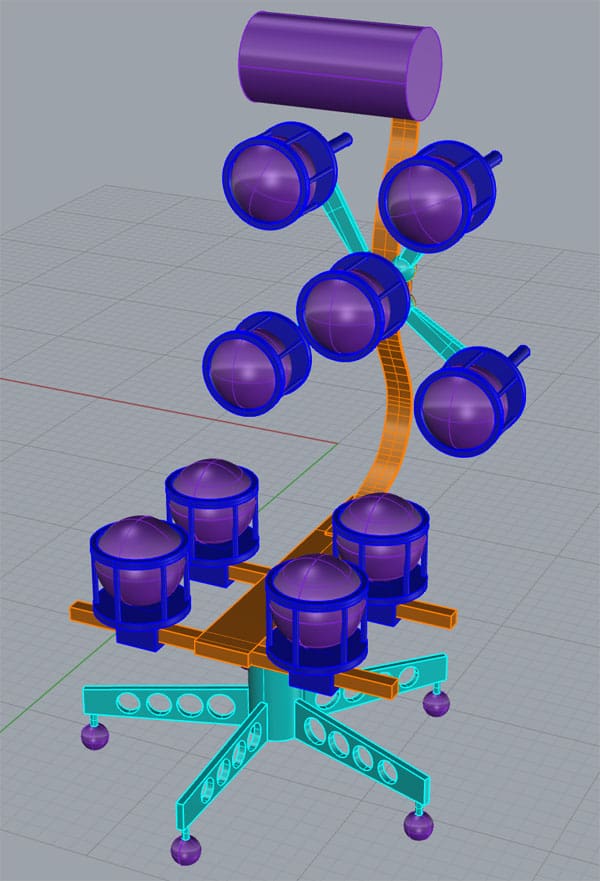

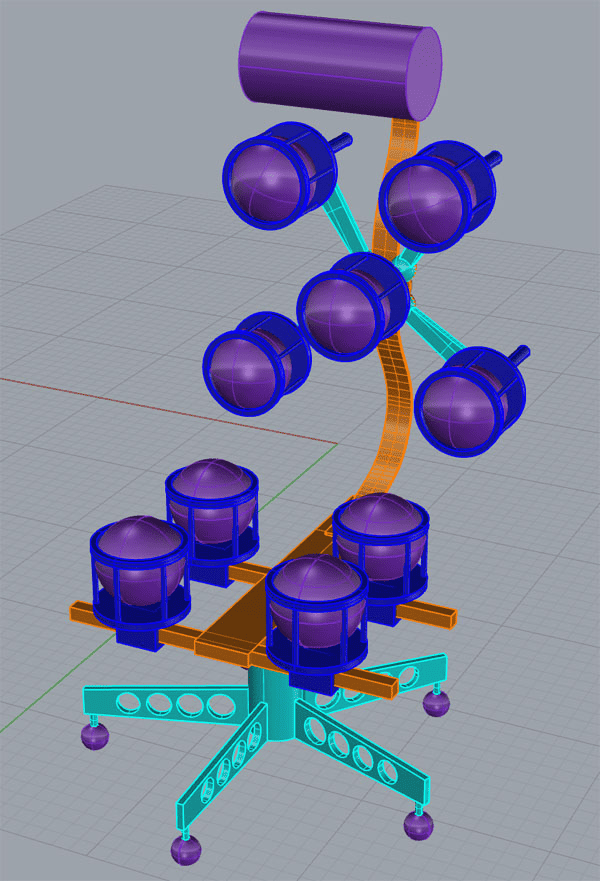

Part 5: 3D PrintingWhat’s next after Machining, why 3D Printing, of course! |

|

Part 6: Metrology and Reverse EngineeringIf we can measure it, we can machine it. |

|

|

|

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.