This is the fifth installment in our Ultimate Workshop Series inspired by Tony Stark.

In this installment, we'll be taking a look at what sort of 3D Printers a workshop like this might include. There are a number of different 3D Printing technologies available, and no one process is suitable for all parts, so we'll take a look at two different categories: plastic and metal printers.

Why Do We Need a 3D Printer?

Aside from the cool factor (which is undeniable), why would a workshop like this even need a 3D printer, let alone two?

There are two strong answers to that question.

First, recall that this shop is all about doing one-offs as quickly as possible. When an inspiration arises, the objective is to realize it as a finished part as quickly as possible. Depending on the part, 3D printing can be ideal for that purpose, especially where plastics are concerned. Imagine trying to make a bicyclist's helmet like the ones pictured to the right. First thing is they use multiple plastic colors. Second is that their design is intricate. The process of making a set of injection molds for such a product would be extremely time consuming, yet the Stratasys 3D Printer we've choosen for plastics can produce these in full color in just a few hours. In addition, there is very little of the complex and time-consuming CAM process required with 3D printing. The equivalent is something called "Slicer" software, and it is generally pretty straightforward to go from design to ready to print. Score a big advantage to 3D printing when making very small quantities of these kinds of parts. That goes a long way to explaining their popularity in product prototyping situations.

Second, it is possible to make parts with additive manufacturing processes that simply cannot be made at all through subtractive machining. Imagine our would-be workshop owner deciding to make a helmet like the ones pictured out of titanium instead of plastic. That seems a little more fitting for Iron Man, after all. We'll assume a padded liner keeps the titanium from doing more harm than good. We could simply use one of the 5-Axis mills from our prior installment to create such a helmet, no big deal. But let's also suppose that in order to keep the helmet light, it's designer wants each of those sections to be hollow.

Whoa, hang on there!

With a subtractive process like milling, there's no way to machine the material out of the center of each piece. Suddenly we have to imagine some sort of two part assembly that splits open so we can machine out the innards. That's not going to be nearly as strong and it sure isn't going to be easy. But, a 3D Printer capabable of printing Titanium can make short work of a project like that. Hollow components? No worries. And that's exactly why GE is using them to make the fuel injection nozzles for some of their latest jet engines.

Having established why a shop like this needs 3D printing, let's take a look at some of the potential machines that might be at home there.

Plastic Printers

For plastics, we've chosen the Stratasys Objet500 Connex printer. It's capable of beautiful 3D prints in full color due to its unique PolyJet Technology. The rainbow hued bicycle helmets pictured above were done with this printer's technology. This technology is similar to inkjet printing, but it jets drops of curable liquid photopolymer onto the build tray. UV light then cures the tiny droplets. The printer is also capable of jetting a removable gel-like support material to take care of overhangs that would otherwise sag. The support material is easily removed either by hand or with water.

The real fun begins with the ability to jet multiple materials or colors at once. The Objet500 can include up to 14 different materials in a single job. Using multiple colors of the same material, they're able to produce color palettes with many different colors in a single part. Imagine multiple colors for the following base materials:

- Rigid Opaque Materials: Digital ABS, High Temperature Plastics and more

- Simulated Polypropylene for snap fit, flexible closures, and hinges.

- Rubber-like Materials for creating non-slip or soft surfaces

- Transparent Material that mimics transparent thermoplastics

All told there are over 100 different materials available for this printer.

The accuracy and finish are good too. Layer thickness can be as little as 16 microns (0.0006").

This printer is cutting edge as it was just announced in January, 2014.

Stratasys Objet500 Connex printer...

Even the rubber-like materials can be done in multiple colors on this machine...

Metal Printers

Remember our Titanium Helmet with hollow load-bearing struts? Now we need to look at what sort of 3D printers can do that sort of work. The world of 3D Metal Printing is much more rarified than plastics. There are fewer processes, fewer players, and just plain fewer such machines that even exist in the world.

With that said, one of the companies that has the most experience manufacturing 3D Metal Printers is German company EOS. These are the machines that GE will be using to manufacture the afore-mentioned Jet Engine parts, and they're also the machines used by Solid Concepts to create the world's first "real" metal 3D printed gun:

The world's first 3D Printed Metal Gun...

For that project, every component of the gun was made via 3D printing except for the springs. That goes right down to the rifling grooves in side the barrel. Not only did the gun function perfectly, but it was found to be accurate as well. 3D printing is capable of a great many things, especially when talking about very high end machines like these. The EOS M270 Direct Metal Laser Sintering machine used to create this M1911 gun project cost somewhere in the neighborhood of $500,000 to $1 million-not exactly the sort of thing to be found in very many shops.

Each of these machines has a fiber laser of between 200W and 400W power. In addition, provision must be made to do the printing in an inert atmosphere, such as argon, and to manage the powdered metals that are used to print with. Dust is a real problem, and powdered metal dust is potential a fire and explosion hazard. One of the main ingredients of firecrackers is powdered aluminum. These machines have the proper management for all that built right in, but it is this sort of thing that drives the cost up.

Like most 3D printers, these EOS machines take an STL file and run it through their own Slicer software to produce the file needed by the machine to do the job.

The EOS M 280 Direct Metal Laser Sintering 3D Printer...

Build volumes for a machine like this are not huge: 9.85 x 9.85 x 12.8 in. The minimum layer thickness is 0.0008" and it has a mode that can also do 0.0016" layers. Tolerances on parts are in the 0.002-0.005" range.

The machine can handle a wide variety of metal powders including aluminum, cobalt chrome (popular for medical devices), tool steel, aerospace nickel alloys, stainless steels, and of course, the titanium required for our bicycle helmet's frame. They even make machines for the jewelry industry that work with precious metal powders.

Pretty cool machine. Insanely expensive. Probably only to be seen in high end Service Bureaus, aerospace manufacturers (GE), and perhaps in the occasional Tony Stark-inspired workshop. For those of you that don't have Tony Stark's budget, you can contract with one of the aforementioned Service Bureaus to have your parts 3D printed in metal. Even this isn't cheap, but it is a fascinating process. Perhaps make a few in plastic first until you're sure, and then get the final prototype done in Titanium, Stainless, or Solid Green Unobtanium, as suits your fancy.

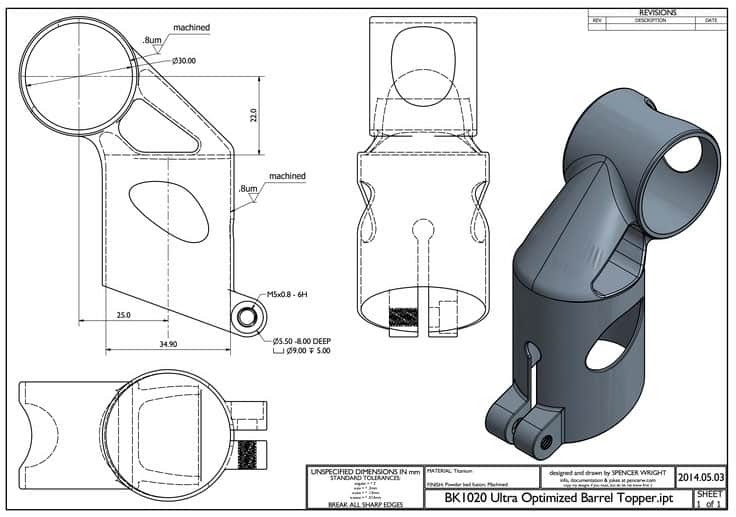

For those interested in the Service Bureau approach, I recommend checking out Spencer Wright's ongoing blog about his fancy Titanium Seatmast Topper, which he's been researching for potential 3D printing in Titanium.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.