2 months by cncdivi

Are you tired of wasting valuable time searching for the right end mill in your workshop? A well-organized endmill storage system is key to a more efficient and productive workspace. In this blog post, we will explore various endmill storage solutions and share tips for maintenance that will not only help maximize your end mill’s performance but also extend their lifespan. Get ready to transform your workshop into a model of organization and efficiency with endmill storage!

Short Summary

- Assess storage needs to select the best end mill storage solution.

- Compare brands and web prices for cost-effective solutions that meet individual requirements.

- Implement strategies such as sorting by size, labeling systems, maintaining stock levels and proper care & maintenance of end mills for maximum efficiency in organization.

Understanding End Mill Storage Options

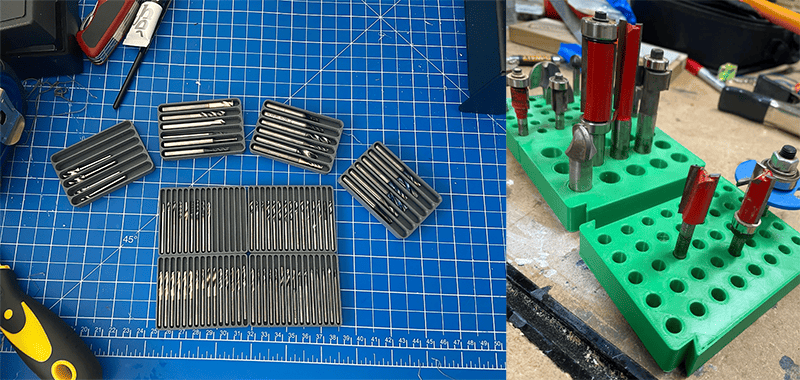

Haphazardly throwing end mills into drawers is not the best storage for them because they can rub up against either other and potentially chip. In addition, it’s pretty hard to see what you’ve got here without having to dig.

The market offers a wide range of end mill storage options, each with varying web prices, materials, and designs. Knowing which one suits your needs can be quite challenging. But fear not, because we are here to help you navigate through the world of end mill storage.

In this section, we will cover three popular storage options: drawers and compartments, stackable storage solutions, and cart-based storage systems. Stay with us as we dive deeper into each one of them.

Drawers and Compartments

Drawers and compartments are the classic solutions for end mill storage. They offer a convenient way to organize your end mills, making them easily identifiable and accessible when needed. These storage options also help reduce cubic space utilization, giving you more room for other tools or equipment in your workshop.

The market offers a variety of drawers and compartments designed to accommodate end mills of various diameters. To ensure the longevity of your end mills, it is important to keep them in clean and dust-free drawers or compartments. Proper labeling and numbering systems are also crucial for easy recognition and efficient organization.

Stackable Storage Solutions

If space is at a premium in your workshop, stackable storage solutions might be the answer you’re looking for. These storage options are designed to be placed one on top of the other, conserving valuable space. Stackable storage solutions are typically made from robust materials like steel and wood, and may feature modular designs, sub-dividable drawers, and label holders.

While stackable storage solutions offer significant space savings, there are some drawbacks to consider. Accessing end mills in stacked storage can be challenging if they are piled too high. Additionally, stackable storage solutions may be more expensive than other alternatives. Weigh the pros and cons before deciding if stackable storage is the best fit for your workshop.

Cart-based Storage Systems

For those who require mobility and flexibility in their end mill storage, cart-based storage systems are worth considering. These systems utilize carts with multiple compartments to store and transport end mills, making them easy to move around the workshop when needed. The added mobility and security provided by cart-based storage systems help prevent damage during transportation, increasing efficiency.

Despite their advantages, cart-based storage systems do have some downsides. They can be costly and require more space than other storage solutions. Maneuvering carts in confined areas can also be challenging. As with any storage option, it is important to weigh the benefits and drawbacks to determine if a cart-based system is the right fit for your workshop.

Choosing the Right End Mill Storage for Your Shop

ToolTray.org offers these tool trays which feature individual slots for tools and are available for Lista and Kennedy cabinets…

Now that we have explored the various end mill storage options, it is time to select the one that best suits your specific needs. The process of choosing the right end mill storage involves assessing your storage requirements, comparing brands and web prices, and customizing storage solutions to fit your workshop.

In the following subsections, we will provide guidance on each of these steps, inch by inch, to help you make an informed decision.

Assessing Your Storage Needs

Schaler bins in something like Lista cabinets is another common endmill storage method…

Before you can choose the ideal storage solution, it is crucial to evaluate your storage requirements based on the end mill inventory in your workshop. Consider the volume and type of products that must be stored, as well as the amount of space necessary for storage. This assessment will help you determine the most appropriate storage option for your needs.

Factors to consider include the size and type of end mills you need to store, the material they are made from, and the required finish for the tasks you perform. Once you have a clear understanding of your storage needs, you can move on to comparing brands and web prices.

Comparing Brands and Web Prices

When evaluating end mill storage options, it is essential to consider factors such as brand, material, size, capacity, durability, performance, and cost. By comparing different brands and their web price, you can find the most advantageous offers that cater to your specific requirements.

Keep in mind that there are potential drawbacks to online shopping, such as hidden costs and difficulty in returning items. To make the best decision, take your time to compare prices and features, read reviews, and gather customer feedback. This will help you find a storage solution that meets your needs and fits within your budget.

Customizing Storage Solutions

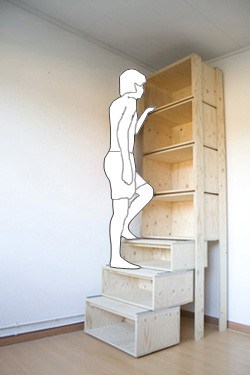

3D Printing offers the ultimate in customized endmill storage solutions…

Sometimes, off-the-shelf storage solutions may not perfectly fit your workshop’s specific requirements. In such cases, customizing your storage solutions can be a great way to optimize space and organization. Customized storage can involve selecting certain types of end mills to maximize tool life and reduce costs.

Examples of customizing storage solutions include utilizing drawers and compartments, implementing stackable storage solutions, and implementing cart-based storage systems. When customizing your storage solution, remember to evaluate your storage needs, compare brands and web prices, and follow best practices for end mill care and maintenance.

Organizing Your End Mills for Maximum Efficiency

Huot stackable end mill storage…

Now that you have chosen the ideal storage solution for your workshop, it’s time to focus on organizing your end mills for maximum efficiency. Proper organization will not only reduce setup time, but also enhance productivity.

In this section, we will delve into strategies such as sorting by size and type, labeling and numbering systems, and maintaining stock levels by monitoring quality, all to ensure an efficient sort of your inventory.

Sorting by Size and Type

Organizing end mills by size, including end mill diameter, and type is a practical approach to streamline your end mill inventory. This method enhances efficiency and structure in your workshop, resulting in reduced setup time and increased productivity.

Arrangement by size and type can be as simple as placing the largest end mills at the bottom and the smallest at the top. By implementing this sorting method, you will be able to locate the right end mill quickly and easily, making your workshop more efficient and organized.

Labeling and Numbering Systems

A well-organized labeling and number system is crucial for quick identification of end mills in your storage solution. There are various labeling and number systems available, such as barcodes, RFID tags, and manual labeling.

To preserve your labeling and numbering systems, regularly verify labels for accuracy, update them when required, and ensure that they are firmly attached. Add these simple steps to your routine to help you maintain an organized storage system, ultimately saving you time and effort in your workshop.

Maintaining Stock Levels

Maintaining adequate stock levels is essential for ensuring that there are enough end mills available for use, preventing any disruptions in production. Regular inventory checks and timely replenishment are crucial for keeping your stock levels optimal.

By staying on top of your stock levels, you can ensure that the correct tool is always accessible for the task at hand. This proactive approach will help prevent potential delays and contribute to a more efficient and productive workshop.

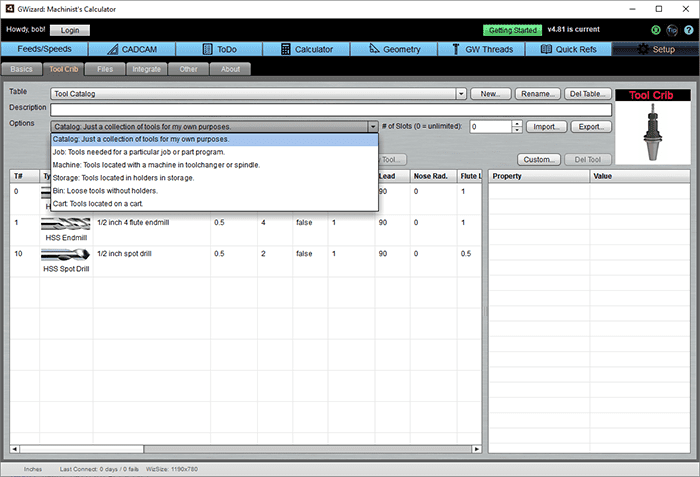

Tooling Inventory Software

G-Wizard Tool Crib is software to help you keep track of your tooling.

Tips for Proper End Mill Care and Maintenance

In addition to storage and organization, proper end mill care and maintenance are essential for ensuring their longevity and performance, including the shank.

In this section, we will share tips on cleaning and inspection, storage conditions, handling and transport, so you can keep your end mills in top-notch condition.

Cleaning and Inspection

Regular cleaning and inspection of end mills are vital to guarantee their performance and extend their lifespan. After each use, clean your end mill thoroughly to eliminate any debris or residue. Inspect them using a soft cloth and a magnifying glass, looking for signs of wear, damage, contamination, or lubricant buildup.

By adhering to a regular cleaning and inspection routine, you can detect potential issues before they become more serious and ensure that each tooth strikes the workpiece in the same spot, which is crucial for precise and consistent results.

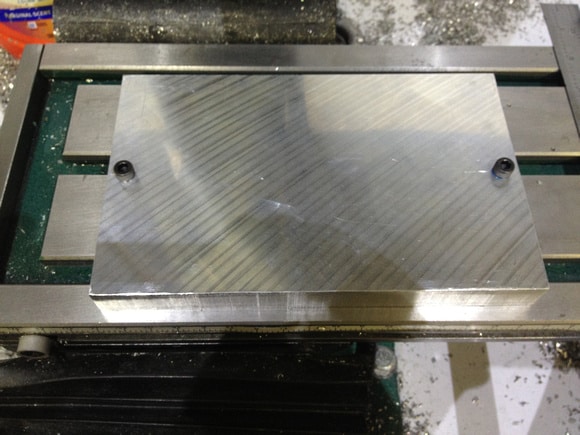

Storage Conditions

Proper storage conditions are necessary to prevent damage and corrosion of end mills. When safeguarding their edges, consider the material of the end mills and the environment in which they are stored. Keep your end mill storage clean and free of dust, and ensure that the storage area is dry to avoid moisture and oxidation.

By maintaining the right storage conditions, you can preserve the quality and performance of your end mills, ultimately contributing to the longevity of your tools and the efficiency of your workshop.

Handling and Transport

Proper handling and transport of end mills are crucial to avoid damage to the tool, which can negatively impact the quality of the workpiece and result in increased production costs. When transporting end mills, ensure they are securely packed in a suitable container.

Handling end mills with care and using appropriate tools for tool holding will help prevent accidents and damage to your tools. By following these handling and transport tips, you can ensure the safety and longevity of your end mills.

Summary

Throughout this blog post, we have explored various end mill storage solutions, discussed tips for organizing and maintaining end mills, and provided guidance to help you choose the right storage option for your workshop. By implementing these strategies and best practices, you can transform your workshop into a model of organization and efficiency.

Remember, a well-organized workshop is not only more productive, but also a safer and more enjoyable place to work. Invest in proper end mill storage and care, and you will reap the rewards in the form of increased efficiency, reduced downtime, and extended tool life. Happy organizing!

Frequently Asked Questions

What factors should I consider when choosing end mill storage solutions?

When selecting end mill storage solutions, it is important to consider the size of your collection, the amount of space you have available, and the features you need to keep your end mills organized.

Additionally, researching different brands and prices can help you find the best option for your budget.

How can I maintain proper stock levels of end mills?

Keeping accurate records of inventory, forecasting end mill needs based on past trends, and setting up a reorder system can help to ensure that stock levels of end mills are properly maintained.

By taking these steps, businesses can ensure that they have the right amount of end mills on hand at all times. This can help to reduce costs associated with overstocking or understocking, as well as minimize downtime due to lack of materials.

What is the importance of labeling and numbering systems in end mill storage?

Organizing end mills with labeling and numbering systems allows for efficient sorting and retrieval, minimizing the time spent looking for a particular tool. Labeling and numbering systems are essential for effective end mill storage, providing clarity and organization in a workshop setting. This way, users can access the necessary tools quickly without any hassle.

How should I clean and inspect my end mills?

To clean and inspect your end mills, it’s important to thoroughly wash them with mild soap and water after each use.

Next, use a soft cloth and a magnifying glass to check for signs of wear, damage, contamination, or lubricant buildup.

What are the ideal storage conditions for end mills?

For optimum performance and longevity of your end mills, make sure to keep them in a cool, dry, low-humidity environment away from dust and debris.

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Recently updated on February 20th, 2024 at 09:34 am

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

![Lathe Tool Storage [QCTP Holder Storage] Various metalworking tools and clamps organized on a workshop table, covered in metal shavings and debris, including a dedicated QCTP holder storage area.](https://www.cnccookbook.com/wp-content/uploads/2021/07/ToolHolder1-1.jpg)

![Machine Shop Quoting + Cost Estimation in 5 Simple Charts [ Survey Results ] Utilize survey results to estimate cost for machine shop quoting and drive market share.](https://www.cnccookbook.com/wp-content/uploads/2018/04/img_5ac7b224f27a5.png)

![Encrypted Personal Storage Vault [ daVinci Puzzle Cryptex ] An encrypted personal storage vault for a group of metal objects.](https://www.cnccookbook.com/wp-content/uploads/2020/06/img_5ee51eef0bafe.png)