2 months by cncdivi

In my younger years, I was deeply interested in model building, an interest I carried forward when I was much younger by constructing radio controlled planes. My main challenge was that I needed a lot of time to build a plane, compared to the relatively short duration it was airborne before a crash. Eventually, I reached a ratio of around 4 or 5 to 1. This meant that I could pilot the plane successfully for about 5 hours more than I had spent building it. Not all of this improvement resulted from enhanced flying skills; I also learned to build the planes far more rapidly over time. Observing the possibilities today, I can see how much times have changed—so much so that it tempts me to take up the hobby again. Well, almost.

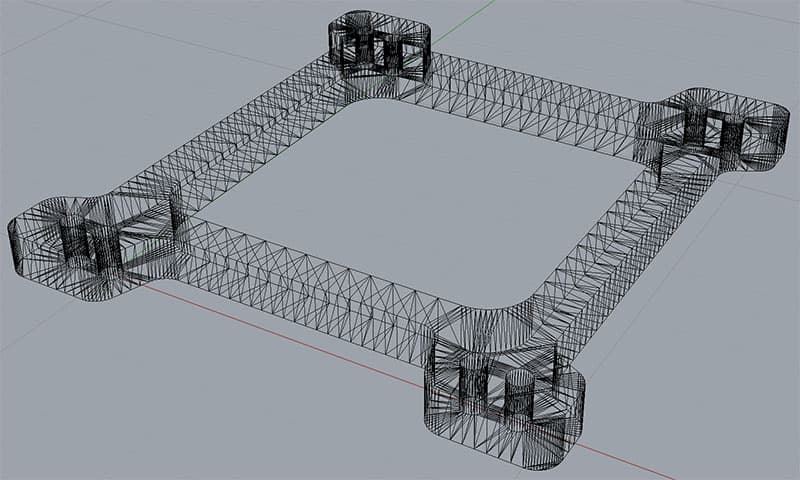

The advent of hobby class 3D printers has put a whole new tool into the hands of RC Modelers and Drone Builders that has some serious advantages over the old days of buying a balsa wood kit at the hobby shop. You’ve got an unprecedented ability to create one off models or to add 3D printed parts to an existing model to make it a better or more unique scale model. The details that go into making a scale model really beautiful were always scarce in those balsa kits. The best modelers had to fabricate all sorts of parts to add those details to their planes. A 3D Printer is an ideal tool for doing that. In addition to scale details, there’s a wealth of other parts that go into the plane–servo trays used to bolt your servos and RC electronics down, linkages to transmit power from a servo to a control surface or engine throttle, and so on.

Here’s a scrapbook showing some of the many amazing things talented modellers have accomplished for their RC Aircraft and Drone projects using 3D Printing:

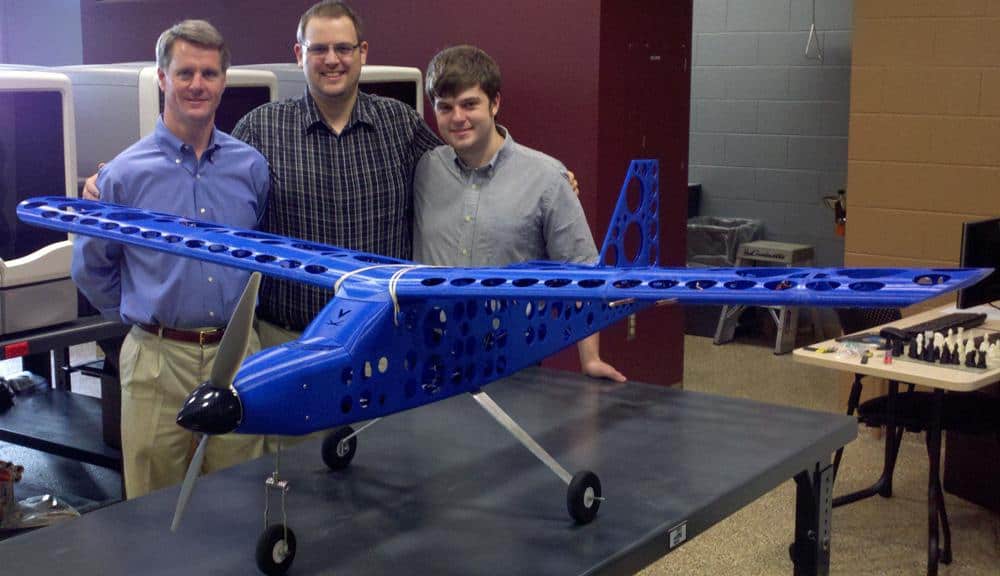

An R/C Trainer by the same University of Virginia team that did the 100 MPH drone below…

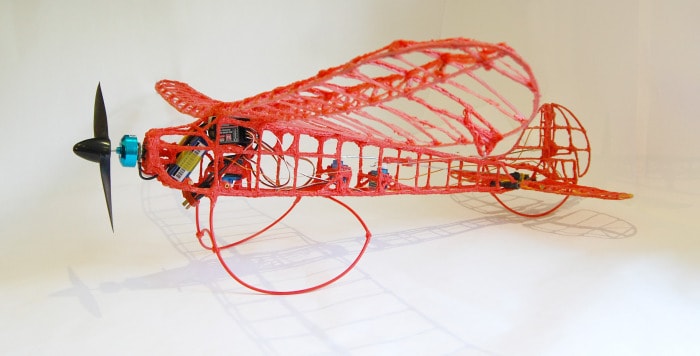

Old School flyer was made entirely with a 3DDoodler 3D Printing pen!

OpenSwift is an open source R/C Flying wing that combines 3D printing with conventional construction to produce a lighter model…

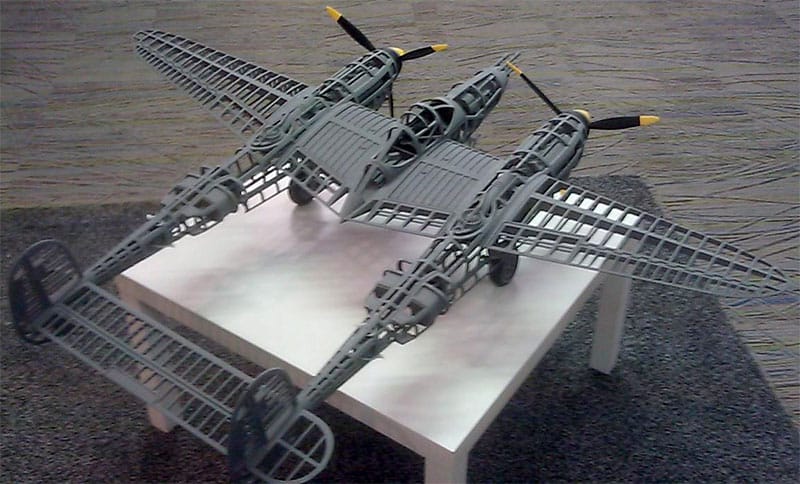

5 Foot Wingspan P-38 is a Monster…

There’s no end of parts like this 3D printed prop spinner needed to build a Scale R/C Plane…

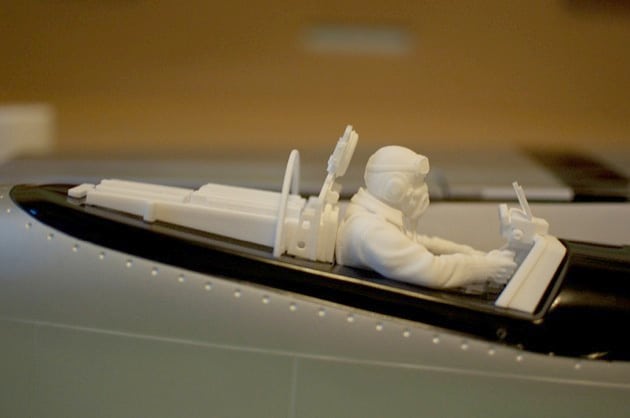

The detail on this 3D printed pilot is better than anything I ever saw come out of an R/C Kit. It was 3D printed by Shapeways on their high quality industrial 3D printers–just a reminder that you don’t even need to own a 3D printer to benefit…

[youtube width=”800″ height=”647″]http://www.youtube.com/watch?v=FwRD7UBGecg[/youtube]

A complete 100 MPH 3D Printed drone from the University of Virginia…

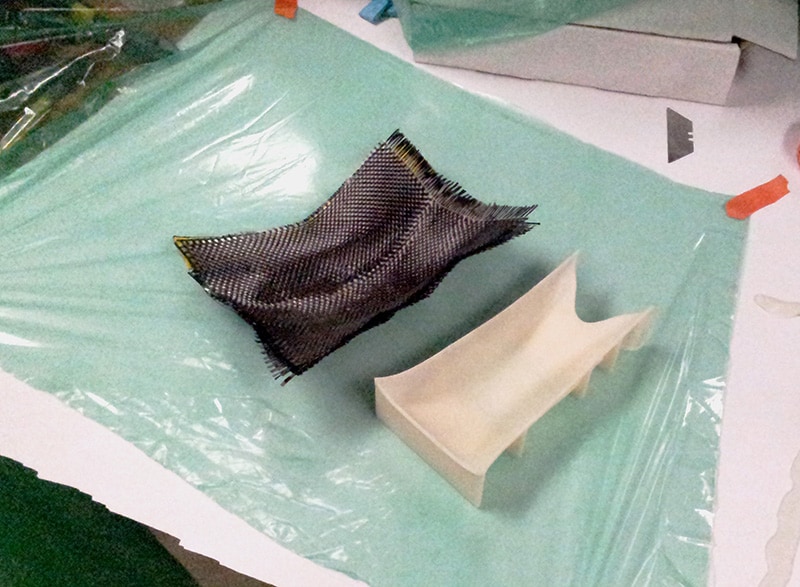

Want super-strong and light carbon fiber for your project? No problem. Use the 3D Printer to create the molds. Be sure to check out our CNCCookbook series on carbon fiber molding while you’re at it…

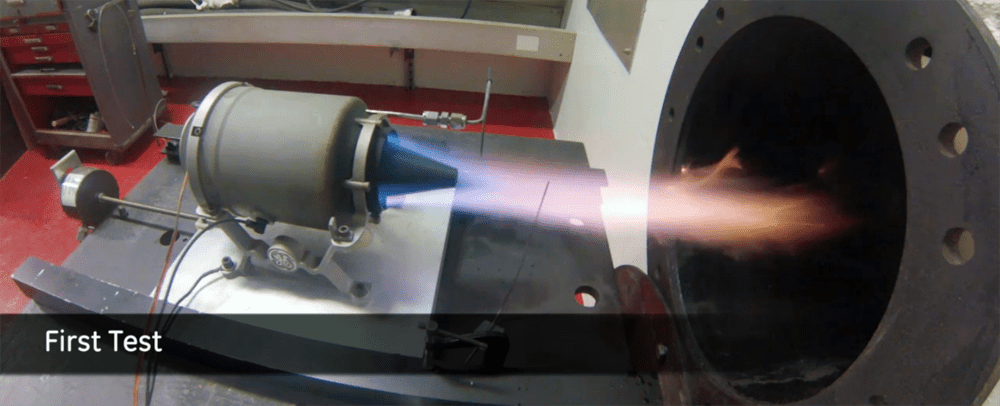

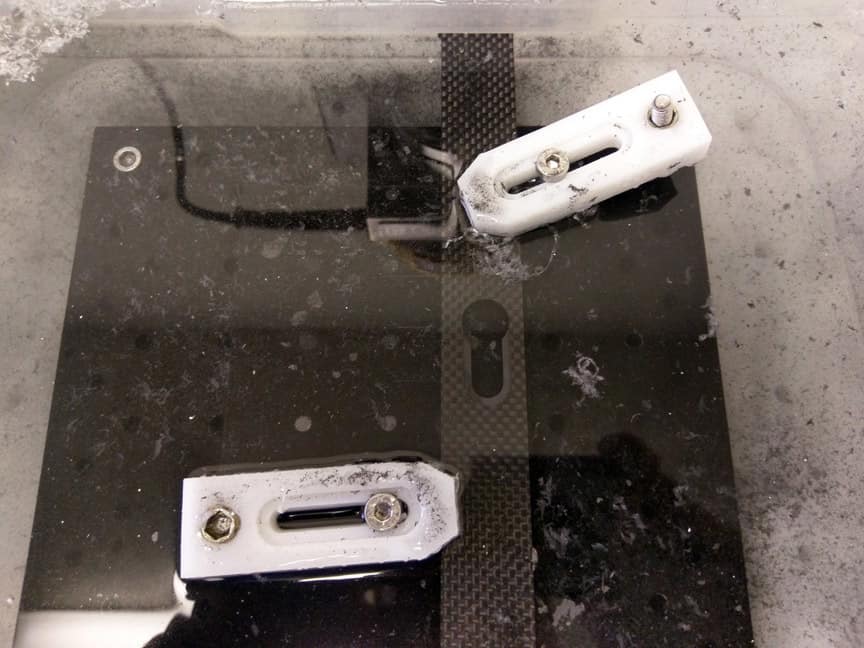

For the ultimate R/C project, how about 3D printing a real miniature turbojet engine? Visit MMSOnline for a great video about this GE project. Unfortunately, you’ll need Tony Stark’s Workshop Budget to be able to print one…

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

![G17, G18, and G19 G-Codes [Plane Selection] A 3D model of a cube with numbers on it, designed for G17 plane selection.](https://www.cnccookbook.com/wp-content/uploads/2024/03/img_65ef26e7eb4d3-150x150.png)

Well, although this is fascinating, I still enjoy the process of building balsa wood planes. Of course with superglues, I can build a plane a LOT faster than before. With a 3D printer, it’s not about building the model anymore. Its more about designing it on a computer.

I think the hybrid approach is interesting for details like the pilot and cockpit. That would just be too rude to create in balsa!

Song, these 3D printed aircraft aren’t any differently really than the balsa aircraft. You’re taking die cut balsa parts and assembling them. These would be 3D printed plastic parts that need assembly. You’re not doing your own die cutting, and if you wanted to design a custom airplane to be made out of balsa, you could do so using the same tools you’d use to 3D print. You could even cut out the balsa at home with a laser cutter. Again the difference is that for a lot less money than a laser cutter, you could be 3D printing those parts.

I’ve been toying with the idea of getting a 3D printer for a while now and these planes have really encouraged me to what is possible with this tech. There are so many times that myself or other club members have broken a part on various flying machines and haven’t been able to replace them easily or not at all that makes having a printer a ideal solution to solve a lot of frustration and heartbreak.

I am looking for a pair of spinners, flying articles, for my P-38 1/2 A scale control line model. These are 1 3/4 ” diameter and could be attached to an aluminum back plate if necessary.

No one has a correct shape spinner. I am going to compete at the Brodak contest in June.

If you could make the spinners as good as the P-38 model, it would be fantastic! I really need these spinners- can you help?

Thanks!

Len Bechtold

561 310-6125

Do the 3D printers simply take an STL file and printout the part?

Is it easy to upscale and down scale STL files?

What about print head resolution and the STL file?

Is there a variation of G Code for 3D Printers?

DesignCAD 3D Max ver 25 finally supports STL and OBJ files which I have been able to import and export from Blender, the Open Source and very powerful 3D Graphics program. I was about to abandon DesignCAD for its lack of STL support.

Most of what I want to do right now can be done with 2D CAD and basic G-Code but am working to keep up with he 3D formats.

Could you comment on CAD file formats and 3D surface resolution? I see that MeshCAM reads STL files.

Which CAD programs are the hobbyists using to generate their STL files?

I hope these are useful questions.

Thank You.

This is a great article. Thank you for taking the time to put this together. I look forward to reading more of your posts!

It took me 8 years to finish my Top Flite J3. My Top Flite DC3 was started 18 years ago. My P51 an T6 the same amount of time and they are not finished yet.

But in a week I printed my Stearman and now printing the Edge 540.

So yeah, I like building with balsa but I hit a little snag and the building stops.

I have not flown my printed planes yet but is much faster than before.