2 months by cncdivi

Let’s delve into a topic that cnc machinists relish discussing:

Should CNC Machinists Learn Manual Machining First?

I’ll go on record as saying I learned it first and based on that experience I think it is very beneficial but not a requirement. I say that because learning manual first limits the number of new concepts a beginner has to master. Jumping directly into CNC, particularly if we’re talking about every aspect from CAM to chips, is a much bigger commitment. OTOH, many feel it is a requirement every CNC machinist should fulfill.

I’ve prepared a survey so we can quantify everyone’s opinions about the matter and maybe see what the consensus is among machinists on this topic. Let us know your thoughts on the matter:

There’s only a few questions and it won’t take but a minute. Once you’re done, you’ll be able to see how other’s voted.

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

![Profitable CNC Business Ideas to Make Money [Read this first!] A startled brown dog swimming in a pool with a caption that reads "that moment when you realize you shouldn't have quit your job.](https://www.cnccookbook.com/wp-content/uploads/2017/09/img_59bab6eb4d6a3.png)

That’s a tough one… What you learn on a manual machine rarely works on a CNC lathe. Take cut-off for instance. Cutting off a piece in a manual lathe is “troublesome” then do it on a CNC lathe and it’s done in seconds. Try to do it in seconds on a manual lathe and… well.. broken tool. CNC Lathes make things EXACT, where as manual machining is done by “FEEL”. 2 different animals. I personally learned on a Manual lathe, then when I went CNC I was called a wuss for going so slow, and in turn wearing tools faster than going fast. Tricky!

I left a long comment in your survey, but in a nut shell the more you know the bigger your set of assets. Assets are of value to you as a person and to your employer if you are working for somebody.

I started in machining before CNC was the rage. I have only been using CNC milling for a couple of years now and feel that my manual experience helps me to figure how to set up my CAM operations best.

Dave

My first cuts in metal were on CNC. While I’m no pro, I think I do pretty well. That said, I’ve learned a lot from old grizzled machinists since then.

My first chips were made on CNC. As a production programmer, my main interests are not so much best practice, it’s haul ace and try every new trick in the book as they come.

As such I think there is a certain level of pride that comes with cranking handles that I just don’t get out of any CNC. I’ve really come to have a passion for the trade and call me crazy, but I do believe manual machines are just plain fun.

Love the website and Gwizard, keep it up Bob!

Matt

I essentially learned CNC first (for any kind of non-hobby work anyway.) I’m an electrical and embedded software engineer by original training. For me, CNC was about repeatability and removing the human factor. I can make perfect parts every time with a much lower skill level on CNC equipment. If something didn’t work correctly, I can reliably change a single variable at a time until I get what want. When I’m working with manual equipment I find that’s much harder to achieve.

I tell anyone that asks that they should learn CNC first if they can. As long as you have enough common sense to not break stuff as you are learning, I think you are more likely to make good parts faster this way.

I believe that G-Wizard was an absolute game changer in this area. Instead of having to count on decades of experience and “feel” I can get a pretty good cut out of the box every time.

I have been a machinist for 50 years. I also firmly believe that engineers should be required to complete a minimum 2 year apprenticeship to avoid designing crap that is impossible to make. You only imagine some of the crap I have dealt with from young engineers in 50 years. Many think if it can be drawn it can be machined.

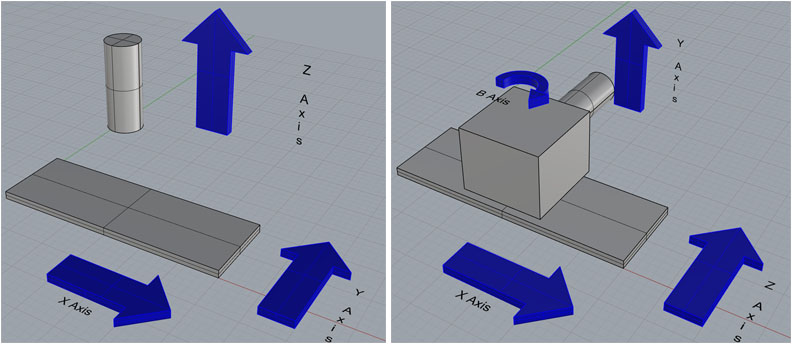

A Machinist should know the mechanics of any machine that he is working on and at the same time should know the commands to control these mechanics.

I am of the opinion that a machinist should first learn manual machine before stepping on to CNC machine and agree with Dave – Experience on manual machine helps to understand the machine setting.

I think a good machinist needs to know both but I don’t think manual machining needs to be first. Your point that manual machines limit new concepts is a good one. However, I don’t believe CNC completely supplant manual machines. The manual lathe / mill is just another tool alongside the Machining / Turning Centers. The more tools you know how to use the better.

While I agree prior manual machining experience would be greatly beneficial, the other side of that coin is lack of access to the machinery required to obtain it. I can’t justify taking my business through the expense and time necessary for such a path when it seems more direct to wade through the learning curve of a CNC approach. Ultimately, CNC is what I’ll be using, so that’s the wagon I need to jump on.

Coming from an old-school career in pen & ink drafting, I see a lack of knowledge and protocol in an applicant with a fresh CAD degree from whatever trade school it came from. I can hardly fault them for learning the current tools, though, nor can I insist they understand manual techniques.

Now I make musical instruments, and CNC is a natural evolution for the craft. I didn’t come from a machinist background, but this is the most expedient tool for the job. So be it. I’ll learn it, use it, and not bemoan the fact I wasn’t part of the previous evolution.

I think that the current tech program I am learning machining from has it spot on, learn both at the same time! My first chips were made with a hack saw, then on a manual mill, next is manual lathe, and in between we are being taught gcode on simulators. Soon we’ll be making parts in the machining centers. Being able to compare manual versus CNC shows more than one solution to produce a part.