2 months by cncdivi

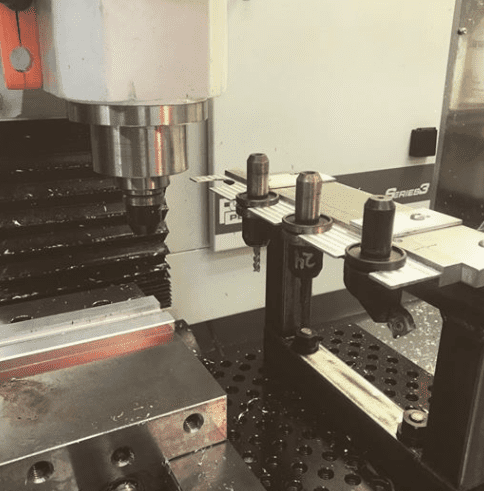

At CNCCookbook, our hands have been full with numerous successive projects, and we’ve been thoroughly enjoying it. The recent buzz is about the arrival of our all-new Tormach PCNC 1100 Mill, fully equipped with a Tool Changer, Full Enclosure, Spindle Speeder, and a host of other exciting features.

That also meant bidding farewell to our trusty Industrial Hobbies CNC Mill, which we converted to CNC, filled with epoxy granite, built a full flood enclosure, and made innumerable changes to over the course of the many years we’ve owned it. It was a great machine, but the Tormach is a better one in the end of the day. The work envelope is a touch smaller, but the spindle is much better and it is saving me the work of having to build a toolchanger.

We’ll have a lot more to say about the Tormach over time, but suffice to say I had been around them quite a lot over at the local Tormach dealer, Santa Cruz Electronics, and come to appreciate their capabilities. I get to work with a variety of machines around the Bay Area thanks to the generosity of a number of friends, but the machine in your own workshop will be the one you spend the most time on. Nice to be able to upgrade that. Tormach has taken to referring to their mills as “Prosumer,” and I think it’s a great term for their products. It’s been used in other areas like digital cameras, but it basic means good enough for professional use (albeit not at the highest possible levels) and priced at a value point that more dedicated hobbyists can afford. I’ve certainly talked to a lot of folks who have started very successful businesses manufacturing parts with the Tormach machines and they have no regrets whatsoever at having started there.

There’s still quite a lot of work to be done to get it all set up and accessories installed, but the difficult rigging part of the job is done. Here are a few photos of the move in:

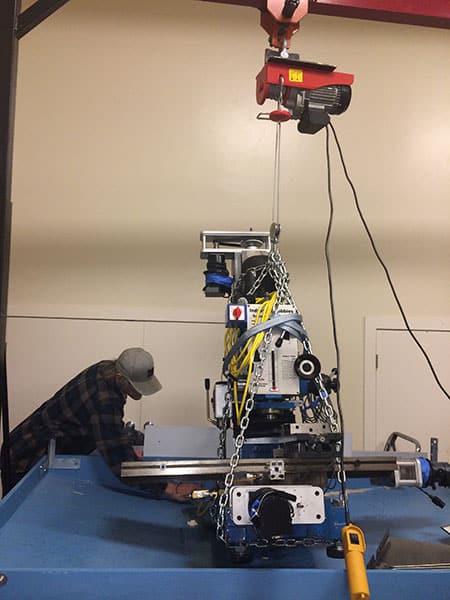

My brother and I first had to disassemble the IH Mill and get it ready to travel. Fortunately, my gantry crane made this pretty straightforward. The mill now resides with my brother so I’ll get to see it from time to time. He’s got some interesting plans for it that we’ll try to write about.

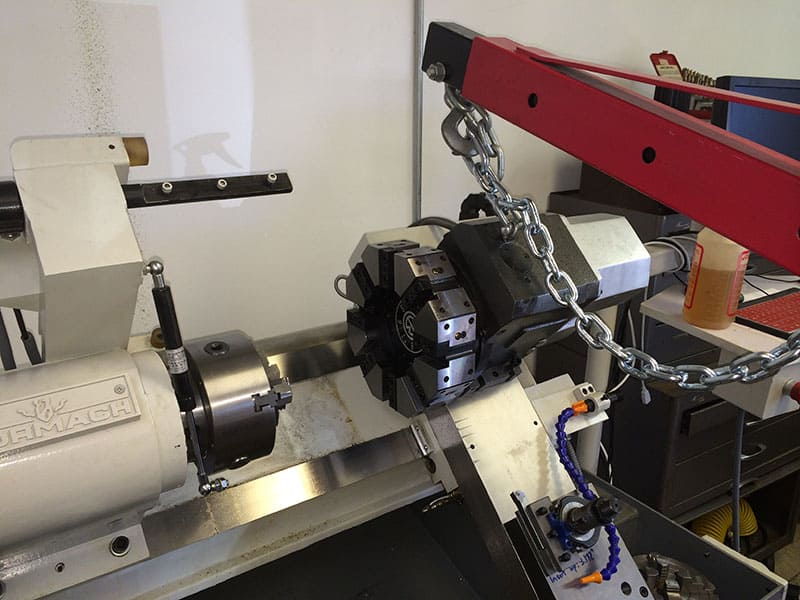

Unloading the Tormach from the Santa Cruz Electronics box truck. That’s John Bower (owner of SCE) barely visible in the truck. The Tormach and all of its accessories filled about 40% of the Box Truck. Quite a few treasures there!

Access was way too tight for the Box Truck, so we rented a forklift to take the mill up the hill. The forklift had some modest traction issues, but we got it done without too much drama. Forklifts are fairly cheap to rent and very handy things to have around!

And here’s the IH Mill, bolted to a pallet and ready to be trucked over to my brother’s workshop. Adios amigo, you’ve been a loyal old friend!

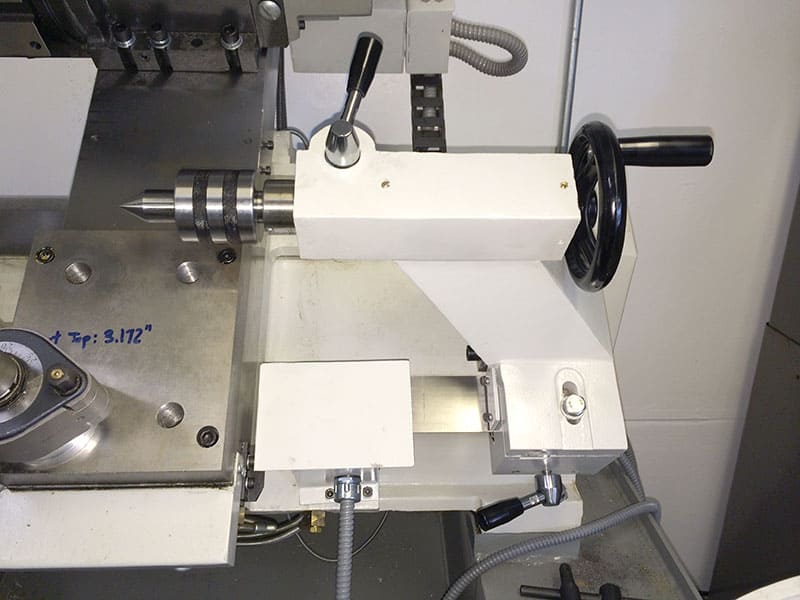

We’ll have more on the Tormach over time as we it set up. We’ve also got a Tormach Slant Bed Lathe that needs to be written about more too. The turret is all aligned and mostly tooled up. I have a couple more goodies to put on, then the enclosure and it’ll be fully operational, so I’ll try to write about all that too.

I’ve got a pretty good backlog of projects to tackle with the Tormach Twins and I’ve been using both Fusion 360 and OnShape to design the first one so I can get a good idea of how the two compare. I’ll write more about that soon, but so far they each have their strengths and weaknesses. Both are also very much capable of doing the job on these initial simple parts too. I am quite pleased with them.

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

![Tormach's New Machine [ 1500MX ] A new Tormach 1500MX CNC machine, primarily grey, with its protective enclosure partially open to show the interior.](https://www.cnccookbook.com/wp-content/uploads/2024/04/1500MX-Base-Machine_Windows_1500px-300px-150x150.webp)

Bob what was the ball park total price for the 1100 and the lathe.

Dave

Dave, I don’t want to be in the business of quoting their prices. Since I got both machines fully loaded, it wasn’t cheap. OTOH, the pair of nice CNC machines was substantially less than even a single brand new CNC from Haas or a similar supplier. Let’s say I’ve paid more for cars and probably had less fun for the money.

1100 mills aren’t bad machines but once you start upgrading the machine with a tool changer, pneumatic draw bar, stand, enclosure, and control (with all the upgrades, I was looking at 25K easy) you could have a haas mini mill for a little more money that is way more rigid, more HP, a powerful intuitive control with faster feed rates. I was seriously looking to purchase a tormach but after looking at the mini mill and using one, I am not so sure. I think if they were able to drop their price points significantly, they would be more appealing. On the other hand, their tormach CNC turning center is pretty slick!

Lee, the cheapest price I see on the Mini Mill is $34K. That’s a good $12-14K over what my machine invoices out at, plus, everything I buy after that for the machine will cost a lot more. A 4th axis, for example, is $2K. A CAT toolholder will be quite a bit more than TTS.

It’s all good, but now you’re tipping into the range of a full sized used Haas, at which point I’m asking you why not go for that instead of the little guy?

We all have our little budgetary limitations, LOL. Or in other words, it’s more than just a “little more” money.

The other thing is, the Haas control has some advantages over Path Pilot, but I don’t being more intuitive is one unless you just already know it well.

I agree, if we are talking the different between a new hass mini mill and a used VF series, I would choose the VF mill. I have seen used mini mills in the mid 20K range.

The prices aren’t a secret. Go to the Tormach website and load up the shopping cart. The website will even calculate your freight charges. The only thing they won’t tell you is the UPS shipping charge for the stuff that doesn’t get shipped with the mill.

why get rid of the IH cnc. I know they’ve changed hands a few times, but just curious as to what drove the change to the tormach. sure the tool changer is nice but when doing one offs not that handy.

Jerry, in a word: TIME.

To match the Tormach in capability the IH needed a new belt drive spindle and a tool changer. While I had plans on the drawing board for both, they were going to be a lot of hours and a long ways away.

Meanwhile, they’re plug and play for the Tormach. It’s the old story of building/converting versus buying. If what you want to do is play with the machines, by all means, build/convert. If, OTOH, you want to make other kinds of parts, buy. Knowing how many hours I’d already sunk into the IH, I knew getting it to parity with the Tormach was at least a couple years away. CNCCookbook just doesn’t leave me enough shop time.

Here’s another consideration. Just take the spindles of the two. I run mostly aluminum and TiAlN cutters. I can max out the rpms and therefore run about 3.5X the feedrate with the Tormach vs the IH. So I can finish a job in maybe 1/3 to 1/4 the time. Meanwhile, even if we don’t count any savings in toolchange time, I don’t have to watch the mill too closely with a toolchanger.

Again, it multiplies my time, which is one of my scarcest resources in the shop.

Awesome news Bob. My 1100 arrived last Saturday and I’ve been slowly moving it into place. At 1300 pounds the mill itself is a beast.

I’m pricing one out now for my garage workshop. Wife not happy but it should make money. Looking forward to reading your set up stuff and your final thoughts.

I visited tormach last and watched them getting the lathe with your name on it ready for shipment. I am considering the lathe but as a mill I have a Daewoo machining center my wife didn’t mind she worked a second job to help me get it. Can’t get her to tho.

Machining centers can get expensive to maintain and so I was wondering if you could report on what it takes to keep your machines running. I replaced a DNC board (Fanuc) in January and it wasn’t cheap.

I own a 770 and just upgraded to Tormachs new Path Pilot operating system.

Cost me $95.00 for new io board including shipping.

I am liking Path Pilot over mach3. Path Pilot is in beta but should be released some time in April.

Dave

Get article. Just to followon one of the other posts, did you look at the newer Charter Oak Turnkey Mills, they have greater work envelope and higher horsepower, than either the IH or the 1100. I am looking to get a mill and I am evaluating both Tormach and the Charter Oak turn key mill. Thanks

Chris, I’d be surprised if Charter Oak has a bigger work envelope than IH since it is just the current ownership of IH.

I liked my IH, but the spindle was very limiting. You also couldn’t really use the full work envelope. There were rigidity issues at the extremes. Unless you know for certain you’re going to do a lot of work that requires that bigger envelope, it would be hard for me not to choose the Tormach over a Charter Oak. The Customer Service is also quite a bit better with Tormach.

Typo on my part referencing HP or envelope between IH and Charter Oak, it was meant only to be the Tormach. On the Spindle, is the issue you mention related tool changing and lack of powered draw bar (belt drive and VFD preclude and fast change systems). Finally how bad was the rigidity issue at extreme travels and roughly what were the extents that you felt comfortable using the IH. Thanks again.

There were both rigidity and binding issues. I stayed away from the last 4-6″ of travel at the ends, so you’d lose 8-12″.

Biggest spindle issue is lack of rpm. You’ll need to plan to build a belt drive conversion immediately. The lack of tool changer and powered drawbar are also issues. I had built a powered drawbar for the IH from an impact wrench that worked well.

Bottom line is if you want to be making parts out of aluminum, brass, plastics, or any soft material, it is tough to justify the Charter Oak. I’d rather deal with creating fixtures to increase the work envelope on a Tormach than deal with all the upgrades needed for the IH/Charter Oak to perform similarly.

I do wish the Tormach had servos, but that’s about all it lacks in comparison.

Hi Bob,

Any more news on your PCNC 1100. Was interested to hear your thoughts now that you have had it for a while.

Anthony, I will have more to write about soon. In general, I really like the machine though. I don’t think you can do better in its price range.

Hi Gentlemen, I’ve owned the Tormach 1100 for a little over a year and I am really pleased with it’s performance as well as the quality for the money. My first CNC Mill was a CNC Masters Supra Mill, Bridgeport style, which was advertised as a turnkey mill. It was in fact easy to learn how to use, although the software that operated the machine wasn’t very robust and the machine was not ridged enough to run it at the speeds and feeds that G-Wizard calculated. At the time I was unaware of the Tormach machines until I watched U tube videos demonstrating the capabilities of their machine. I liked what I seen and purchased myself one. I’m retired so I have to watch my budget, so in order to cut down the cost, I manufactured the bar to hoist the machine onto it’s stand as well as I made a full enclosure (the Tormach enclosure is pretty expensive) using square and conduit tubing, some angle iron and visqueen plastic sheet. I also engineered and built my own arm assembly to mount the computer monitor on, which also includes a little table surface for the keyboard and jog control. I use the Royal Quick Change Tool System so I don’t need to use the drawbar every time I change a tool holder. I do not have professional experience, but for the money, I believe the 1100 is a great machine.

I can attest to the fact that the customer service at Tormach is awesome! My new 1100 arrived at the shop Friday. Of course I opened it immediately to start putting it together. I noticed a ding on the outside of the shipping crate and lo and behold the drip guard/limit switch cover was bent up and warped from the shippers rough handling, things happen… I sent the information to Tormach Friday, today they have solved the problem and the new part is on the way. It just doesn’t get any better than that.