Great news! This page offers two Free Online Speeds and Feeds Calculators.

You can use both Hss Feeds And Speeds with simple shop formulas and a full-featured calculator (free for a limited time) that is the industry leader, used daily by top manufacturers worldwide.

They know what they're doing and wouldn't waste time or money if the software didn't work.

Why use the simple free calculator when you can get our full-featured G-Wizard Feeds and Speeds Calculator free for 30 days?

It takes just 37 seconds to download and start using G-Wizard. It costs nothing, and you?ll get great feeds and speeds for 30 days. After that, you can always return to our free online calculator.

Why not use the high-performance model while it?s free?

Click on the Version of G-Wizard Best Suited to Your Needs:

Or, use our simple online cutting feeds and speeds calculator below:

Hss Milling Cutter Speeds And Feeds

Spindle Speed Calculator

Tool Diameter

inches

Surface Speed / Cutting Speed:

SFM (see table below for SFM values).

To learn what is SFM and how to go from SFM to RPM, click this link.

Spindle Speed:

RPM

Spindle RPM Formula = (12 * SurfaceSpeed) / (PI * CutterDiameter)

Feed Rate Calculator

Feed/Tooth (Chipload):

IPT (inches / tooth)

Number of Flutes (Teeth):

Feed Rate:

IPM (inches / minute)

Feed Rate Formula = Chipload * NumberFlutes * RPM

Milling Surface Speeds for HSS End Mills

Material

Surface Speed (SFM)

Aluminum - Wrought (6061)

250

Brass

200

Cast Iron - Ductile

90

Cast Iron - Gray

100

Copper Alloy - Wrought

120

Magnesium Alloy

250

Stainless Steel

30

Steel - Mild

110

Steel - Hard Alloy

60

Steel - Tool

60

Wood - Hardwood (For more wood see linked article)

500

Need a Material Not Listed? We Can Help!

Drilling Surface Speeds for HSS Twist Drills

Material

Surface Speed (SFM)

Aluminum - Wrought (6061)

250

Brass

200

Cast Iron - Ductile

80

Cast Iron - Gray

120

Copper Alloy - Wrought

70

Magnesium Alloy

250

Stainless Steel

30

Steel - Mild

110

Steel - Hard Alloy

60

Steel - Tool

60

Need a Material Not Listed? We Can Help!

Milling Chiploads for HSS End Mills

Material

Chipload (IPT)

Aluminum - Wrought (6061)

0.005 - 0.010

Brass

0.005 - 0.010

Cast Iron - Ductile

0.004 - 0.008

Cast Iron - Gray

0.002 - 0.006

Copper Alloy - Wrought

0.004 - 0.008

Magnesium Alloy

0.005 - 0.010

Stainless Steel

0.002 - 0.006

Steel - Mild

0.002 - 0.010

Steel - Hard Alloy

0.002 - 0.006

Steel - Tool

0.002 - 0.006

Note: Chipload should be adjusted for tool diameter. Smaller tools tolerate much lower chip loads! You can look this up in the manufacturer's catalog, or we can help.

CNC Feeds and Speeds Chart Wood

Not Sure the Correct Value for Your Cutter? We Can Help!

Hang on: You Deserve Better!

Software that makes anyone a better CNC'er... Even beginners:

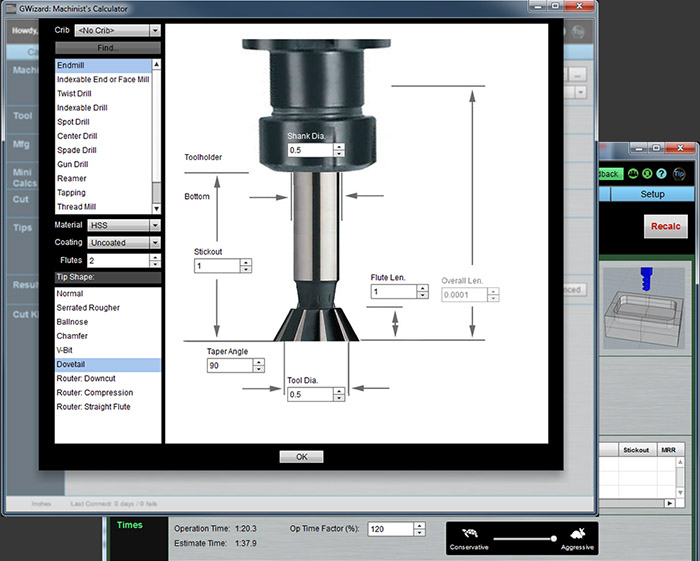

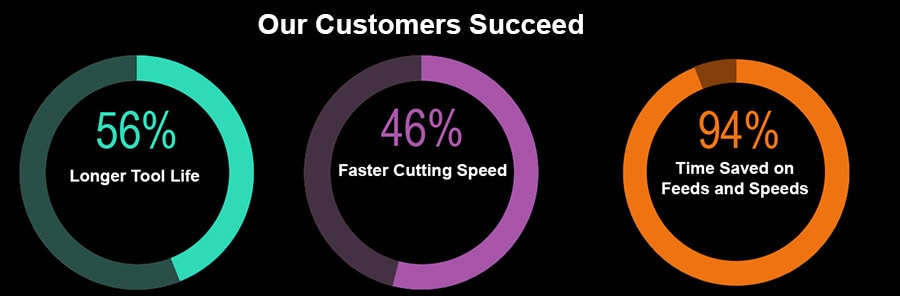

Better Tool Life, Surface Finish, and MRR with G-Wizard

It took years, we analyzed data from over 250 tooling catalogs,

we built a powerful cutting physics engine

with advanced algorithms that consider

almost 60 different variables, and we

worked with over 50,000 CNC'ers

like yourself to make sure you'd

have the Best Feeds and Speeds.

Improve My Feeds and Speeds For

More Feeds and Speeds Calculators

-

G-Wizard Feeds and Speeds Calculator

-

Milling Speeds and Feeds Calculator

-

Chip Load Calculator

-

Simple Feeds and Speeds Calculator

-

Lathe Feeds and Speeds Calculator

-

Drill Feeds and Speeds Calculator

-

Tapping Feeds and Speeds Calculator

-

Next Feeds and Speeds Calculator

-

Prev Feeds and Speeds Calculator

-

Master Feeds and Speeds Calculator List

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.