CNC Programmers write the instructions that cause CNC machines to manufacture parts. The CNC Machines use different dialects of a programming language called "G-Code".

They use several types of CNC software to write the instructions including:

- CAD Software: Used to create designs and blueprints of the part. CAD stands for "Computer Aided Design".

- CAM Software: Used to generate CNC Machine instructions (g-codes) from a CAD drawing. CAM stands for "Computer Aided Manufacturing."

- G-Code Editing and Simulation Software: Software used to test, simulate, optimize, and otherwise edit g-codes.

There are many more types of CNC Software, but those are the most common.

CNC Programmers use their software to create, test, and revise CNC machine programs (also called Part Programs).

What skills do CNC Programmers need?

In addition to proficiency with the software they'll be using, CNC Programmers need the following skills:

- Ability to read and understand drawings and blueprints. This includes the ability to understand the dimensioning and tolerance information on the print.

- Solid understanding of the different machines they're programming for and what they're capable of.

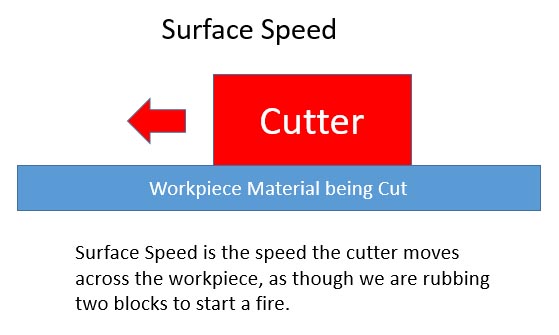

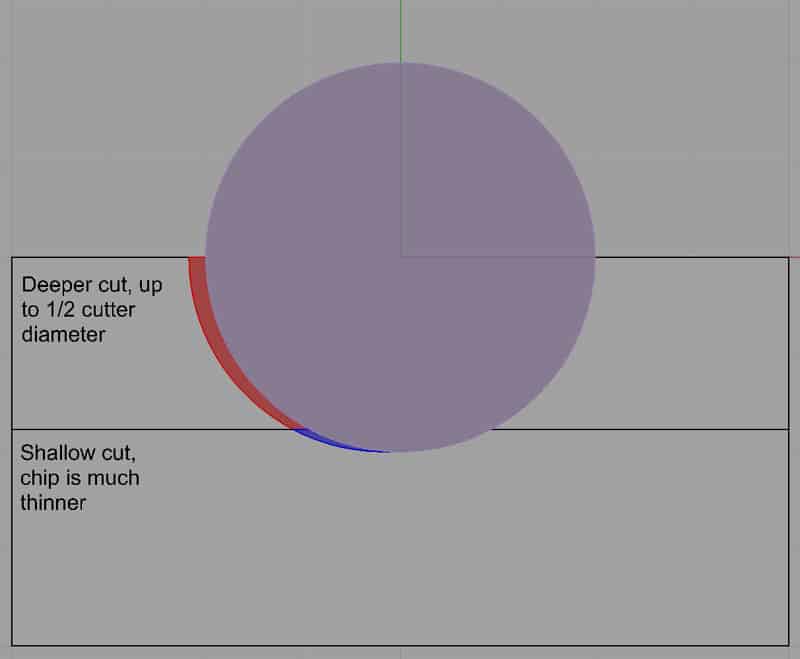

- Understanding of the different tooling (cutters) used by the machines as well as the Feeds and Speeds the cutters are capable of for various materials.

- Understanding of workholding and fixturing to be used to hold the parts during machining.

- Ability to coordinate with the Purchasing Manager to help manage the inveotires of raw materials.

- People who are detail oriented and have good math and technical skills make the best CNC Programmers.

Typically, CNC Programmers work for Production Managers, which is the next position up the ladder for those who seek to advance.

Other Resources

- How to Hire for your CNC Machinist Jobs

- 50 Interview Question Ideas for CNC Jobs

- 15 Best Web Sites for CNC Job Search

- CNC Skills Survey: Which Skills Give You the Advantage?

CNC Programmer FAQ

What is a CNC Programmer?

CNC Programmers write the instructions that cause CNC machines to manufacture parts. The CNC Machines use different dialects of a programming language called "G-Code".

What kinds of CNC Software do CNC Programmers work with?

They use several types of CNC software to write the instructions including:

- CAD Software: Used to create designs and blueprints of the part.

- CAM Software: Used to generate CNC Machine instructions (g-codes) from a CAD drawing.

- G-Code Editing and Simulation Software: Software used to test, simulate, optimize, and otherwise edit g-codes.

There are many more types of CNC Software, but those are the most common.

How are CNC Programmers Trained and Credentialed

There are several ways to become a CNC Programmer, and it can be done with nothing more than a high school degree. First, you could take some classroom training and finish that with an apprenticeship in a shop. Second, you could obtain a certificate or associate's degree in CNC operation and programming. You could also get a Bachelor's degree in machine tool technology, industrial automation engineering, or industrial engineering, all of which should include at least some training in CNC Programming.

Once you have the basics, your work experience will be the most important determiner of the jobs you're eligible for. Certification is voluntary, and not required by most employers, but it is looked on favorably.

The National Institute for Metalworking Skills, Inc (NIMS) offers several certifications to candidates who can pass written and practical examps.

How much do CNC Programmers make?

The median wage for CNC Programmers was $53,190 in 2018 according to the Bureau of Labor Statistics. Their average hourly rate is $22.76. The top programmers can make as much as $80,000.

{"@context": "https://schema.org","@type": "FAQPage","mainEntity": [ {"@type": "Question","name": "What is a CNC Programmer?","acceptedAnswer": {"@type": "Answer","text": "CNC Programmers write the instructions that cause CNC machines to manufacture parts. The CNC Machines use different dialects of a programming language called “G-Code“." }}, {"@type": "Question","name": "What kinds of CNC Software do CNC Programmers work with?","acceptedAnswer": {"@type": "Answer","text": "They use several types of CNC software to write the instructions including: CAD Software: Used to create designs and blueprints of the part. CAM Software: Used to generate CNC Machine instructions (g-codes) from a CAD drawing. G-Code Editing and Simulation Software: Software used to test, simulate, optimize, and otherwise edit g-codes. There are many more types of CNC Software, but those are the most common." }}, {"@type": "Question","name": "How are CNC Programmers Trained and Credentialed?","acceptedAnswer": {"@type": "Answer","text": "There are several ways to become a CNC Programmer, and it can be done with nothing more than a high school degree. First, you could take some classroom training and finish that with an apprenticeship in a shop. Second, you could obtain a certificate or associate’s degree in CNC operation and programming. You could also get a Bachelor’s degree in machine tool technology, industrial automation engineering, or industrial engineering, all of which should include at least some training in CNC Programming. Once you have the basics, your work experience will be the most important determiner of the jobs you’re eligible for. Certification is voluntary, and not required by most employers, but it is looked on favorably. The National Institute for Metalworking Skills, Inc (NIMS) offers several certifications to candidates who can pass written and practical examps." }}, {"@type": "Question","name": "How much do CNC Programmers make?","acceptedAnswer": {"@type": "Answer","text": "The median wage for CNC Programmers was $53,190 in 2018 according to the Bureau of Labor Statistics. Their average hourly rate is $22.76. The top programmers can make as much as $80,000." }}]}