Welcome to the world of CNC programming Languages List! Whether you're experienced or new, mastering the languages that drive CNC machines is key to precision manufacturing.

Our guide delves into G Code for geometric moves and M Code for machine functions, essential for CNC programming.

Unlock CNC Programming: The Complete Guide to G Code and M Code

CNC machines rely on G Code and M Code, foundational programming languages. G Code controls movement, while M Code manages machine functions.

Understanding these languages is vital for effective communication with your machine, enabling you to translate digital designs into physical parts with accuracy.

G Code governs movements and speeds, while M Code handles machine functions like tool changes and coolant flow.

These languages are universal across machines, providing consistency and flexibility in programming.

Mastering CNC programming allows for precise, efficient, and creative manufacturing, empowering you to bring intricate designs to life.

How is G-Code and M-Code Created?

Generally, there are 3 ways to create G-Code and M-Code:

- A CAM Program can produce it from a CAD model.

- A Conversational CNC Program can produce it from a simple Wizard-style UI.

- A CNC Programmer can hand write G-Code and M-Code to create a custom CNC program.

G-Code and M-Code Come in Multiple Dialects

It's a mistake to speak of g-code and m-code as though they are complete cnc programming languages on their own. G-Code and M-Code come in various distinct dialects such as RS-274 (NIST standard gcode), Fanuc (the most common commercial dialect), LinuxCNC, Mach 3, GRBL, and many more.

While they are quite similar, you need to be sure you're familiar with the particular dialect your CNC machine uses to be a successful programmer.

What About CNC Programming Languages Other Than G-Code and M-Code?

There are several proprietary dialects. Here is a CNC Programming Languages List:

- GCode and MCode

- Mazatrol

- Heidenhain

- Datron and Mach 3 can augment g-code with a BASIC-like language.

- Shopbot

Generally, these proprietary languages are meant to be easier or more powerful than standard g-code and m-code. However, they lose out by not being a part of the massive ecosystem of products that support g-code and m-code.

Introduction to CNC Programming and Its Importance in Machine Operations

CNC programming is essential for transforming ideas into tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine.

G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow.

Efficient CNC programming enhances productivity, safety, and cost-effectiveness in manufacturing.

As technology advances, the demand for skilled CNC professionals continues to grow, highlighting the importance of continuous learning and adaptability.

List of Basic G Codes: The Building Blocks of CNC Programming

Basic G Codes are fundamental instructions for CNC machines, directing movements, speeds, and operations.

Mastering these codes is essential for effective communication with your machine, enabling you to execute precise machining operations.

The repetition of "CNC" emphasizes the central role of these codes in programming.

Understanding Basic G Codes lays the foundation for efficient CNC programming and enables you to create complex components with accuracy.

Here is a list of the 12 most important G-Codes:

- G00 - Rapid Positioning

- G01 - Linear Interpolation

- G02 - Circular Interpolation Clockwise

- G03 - Circular Interpolation Counterclockwise

- G04 - Dwell

- G17 - Select XY Plane

- G20 - Programming in Inches

- G21 - Programming in Millimeters

- G28 - Return to Home Position

- G90 - Absolute Positioning

- G91 - Incremental Positioning

- G92 - Set Current Position to Coordinates

For more information on these g-codes, including examples and tutorials on their use, visit our G-Code Reference List.

The Essential Role of M Codes in CNC Machine Functionality

M Codes control essential machine functions, enhancing efficiency and safety in CNC operations.

These codes automate processes like spindle activation and coolant flow, ensuring precise and consistent results.

Mastering M Codes is crucial for orchestrating mechanical movements and optimizing machine functionality.

List of Basic M Codes

Here's a list of the most commonly used m-codes:

- M03: Spindle ON, clockwise

- M05: Spindle Stop

- M08: Flood Coolant ON

- M09: Flood Coolant OFF

- M06: Tool Change

- M30: End of Program. Rewind and Reset Modes.

For more information on these m-codes, including examples and tutorials on their use, visit our M-Code Reference List.

Differences Between G Code and M Code in CNC Programming

G Code governs tool movements, while M Code controls machine functions, ensuring seamless CNC operations.

Understanding the distinction between these codes is essential for effective CNC programming.

G Codes dictate motion and cutting paths, while M Codes manage auxiliary functions, optimizing machine performance.

Step-by-Step CNC Programming with G Code

CNC programming with G Code involves setting up the machine, defining tool paths, and scripting precise commands.

Each line of G Code directs machine movements, ensuring accurate and efficient machining operations.

Mastering step-by-step CNC programming enables you to translate digital designs into physical parts with precision and creativity.

Tools to Assist With CNC Programming with G Code

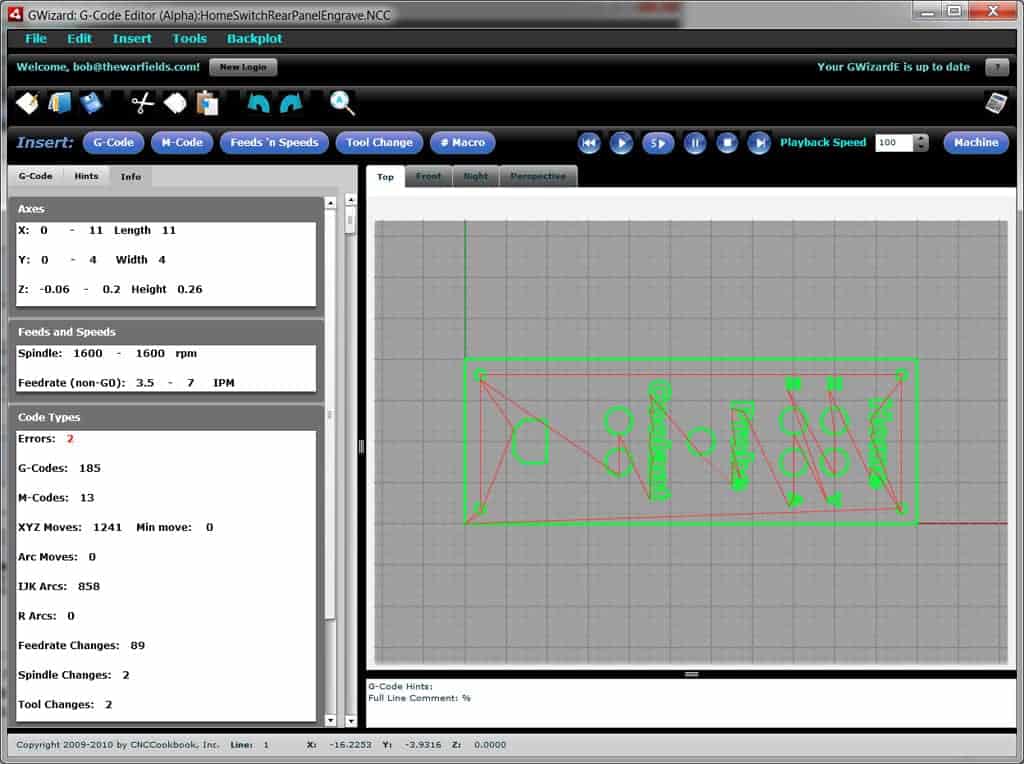

The most important tool to have is a G-Code Editor with Simulator when programming directly in G-Code.

A typical program would be our G-Wizard Editor:

If you haven't already, you should try our free 30-day trial of G-Wizard Editor:

Summary: Enhancing Efficiency with CNC Programming Techniques

CNC programming techniques, including G Code and M Code, are essential for optimizing efficiency in machining operations.

Mastering these techniques empowers machinists to execute precise and efficient machining operations, translating digital designs into physical parts with accuracy.

Continuous learning and practice are key to mastering CNC programming and achieving excellence in machining.

Conclusion

Mastering CNC programming is essential for precision manufacturing. Understanding G Code and M Code enables machinists to communicate effectively with CNC machines, translating digital designs into physical parts with accuracy and efficiency. Continuous learning and practice are essential for honing skills and achieving excellence in CNC machining.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.