Keeping your employees trained up yields a strong return on investment, including boosts in productivity, safety, recruiting and competitiveness. Here's a quick look at why small manufacturers should invest in employee training.

We’re pleased to offer this guest posting from our friends at Xometry for some great tips on how small shops can get a foot in the door at large organizations. Some good ideas to get your business faster this year! Learn more about how Xometry can help CNC shops find more work and get paid faster. Here at CNCCookbook we specialize in knowledge. We've been writing articles that bring CNC'ers knowledge that ups their productivity for years. This article will walk you through why it's beneficial for Manufacturing Employees to get as much knowledge as they can. At the conclusion below, I'll turn you on to the best Free Training Resources CNCCookbook can give you today.

Should Your Manufacturing Employees Get More Training?

You didn't provide any text for the rephrase. Please provide the text and I'll be more than happy to help you out.

“Since most small manufacturing owners wear many hats, they have limited time to plot out comprehensive workforce learning and development strategies tied to business objectives,” says Jeannine Kunz, vice president of Tooling U-SME. “Although they realize people need access to continual learning opportunities, it is difficult to allocate the time, resources and funds needed to invest in training. Unfortunately, in the end most owners don’t act, as other more time sensitive projects take priority.”

76% of respondents believe their employee training programs are not sufficient to meet ongoing needs.

Tooling U-SME’s Readiness Assessment Insights Report,

Yet employee training and certification are worthy of a higher position on your punch list. Notes Kunz: “Organizations that have a strong learning foundation in place significantly outperform their peers in quality, productivity, customer satisfaction, and market share.”

When your manufacturing workforce is properly trained, your company is better positioned to take advantage of technological and productivity improvements, and reduce turnover and improve your recruitment prospects. Here, then, is a quick look at the four benefits of highly-trained manufacturing employees.

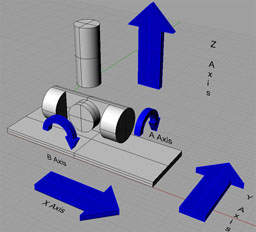

1. Leverage Technological Innovation and Advancement

“As operations become increasingly advanced, employee development programs are becoming critical to manufacturing success,” Kunz says. “Manufacturers can buy all the new equipment/tools and source all the materials they want, but it’s the people they put in place to program, maintain and operate that make the difference in the effective use of the technology. That is why continual learning and development is such an integral part of a company’s overall strategic plan.

2. Improve Productivity

Better-trained employees work more efficiently and make fewer mistakes. This reduces waste and do-overs, which has the additional value of stoking customer trust, satisfaction and loyalty. To quantify training’s impact in this area, multiply your labor cost by your estimated productivity improvement.

3. Reduce Turnover and Improve Recruitment

“Employee retention is a significant issue for companies and building a culture of learning is a big step towards improving turnover,” Kunz adds. It’s also a key factor in recruiting and retaining younger employees. Multiple surveys show that professional or career growth and development opportunities are especially important to younger members of the workforce. Mentioning continuing education and training opportunities in want-ads and recruitment marketing is a smart move.

4. Enhance Safety

It’s also vital to keep employees trained on general health and safety to avoid fines and lawsuits. OSHA offers free compliance assistance for small- and medium-sized businesses to help you identify where you need additional programming. You can also get no-fee insights from your state’s On-Site Consultation Program.

Training is Worth the Investment

Should you pay for training? Most experts say yes. Successfully trained team members produce results that benefit the entire company, and Kunz adds: “When you consider the process of recruiting and replacing an employee can actually cost more than the employee's annual salary, the return on investment can be quite substantial over time.”

“When successfully organized, workforce training can yield good returns for talent as well as the small manufacturer. Employees inspired by their training become loyal, they innovate and contribute to the strategic goals of the business,” Kunz concludes. “On the flip side, satisfied employers are more apt to invest in their career growth, because their upskilled staff are more productive and efficient.”

Used with permission

CNCCookbook's Free CNC Training Resources

For a complete guide to all our learning resources, we have a page dedicated to our Free CNC Training.

Here is the short list of the very best resources we offer:

Free Feeds and Speeds Master Class: Weekly email course will take you from Beginner to Expert.

CNC Feeds and Speeds Cookbook: Get the best Material Removal Rates, Tool Life, and Surface Finish. Plus specific guides for cutters and material types.

More Feeds and Speeds:

Quick Video Course in Feeds and Speeds: 2 videos-theory + practice.

G-Wizard Machinist's Calculator: Fast, Easy, Reliable Feeds and Speeds.

CNCCookbook's G-Code Course: Use an Interactive Learning Tool and online courseware to learn g-code or polish your skills.

More G-Code Programming:

G-Wizard G-Code Editor: Editor, backplotter, and g-code simulator: a radically easier way to deal with GCode.

G-Code Quick Reference Guide: G-Code quick references for mills, routers, and lathes.

What is a CNC Programmer? Learn all about the job and what professionals do.

Complete Guide to Metrology and Measurement

All about Machinist's Measuring Tools, what they can do, and how to use them.

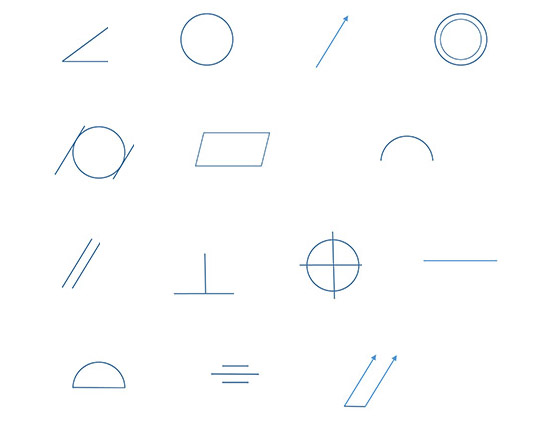

Geometric Dimensioning and Tolerancing (GD&T) Tutorial

How to understand and use GD&T.

- GD&T Symbols Quick Reference

- Free GD&T Calculator

Lean Manufacturing Principles Tutorial

Lean Manufacturing is a powerful tool for improving productivity in Manufacturing (actually for many other business areas too).

We've published a series of articles that taken together provide a Free Lean Manufacturing Mini-Course to help shops understand what Lean Manufacturing is, what it can do for them, and how to go about implementing it.

Calculators and Reference Charts

**Need a quick, specialized calculation for CNC? Perhaps a reference table?

Tired of searching through Machinery's Handbook?

**

This is the right place, click on through!

Definitive Guide to Lights Out Manufacturing

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.