What's the best investment you've ever seen for a CNC Shop?

Imagine you could assemble a group of your peers to help you solve a problem. Further, imagine they aren't trying to compete with you and that they sincerely want to help. Your problem is where to spend scarce investment dollars to increase your shop's productivity so it will grow faster and be more profitable. After all, we're coming into the 4th quarter as I write this, and Q4 and Q1 are the biggest investment times of the year.

It turns out we can help you do exactly what I described. We asked our readers to tell us what the best investments to grow CNC shop productivity they had seen in the last 5 years. We've learned a lot of great things over the years from CNCCookbook surveys, but I was really excited to see the results on this one!

Read on to learn what we discovered!

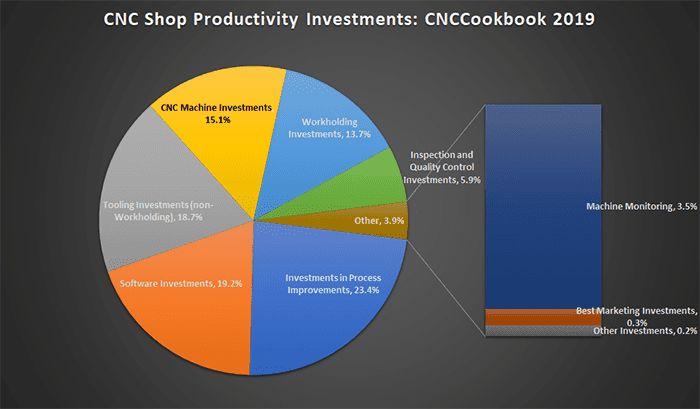

General Categories of Investment: The Best Investments Are Things You Can't Touch!

The two best investments are in Process Improvements and Software. Like I said, these are things you can't touch, at least not like you can touch a new facemill or CNC machine. Are you suprised that about 45 cents of each investment dollar should be put into these categories?

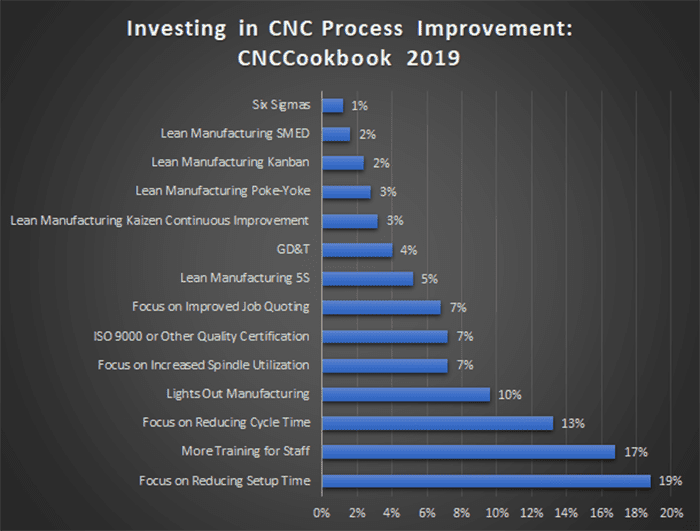

Process Improvement Drill Down: Reduce Your Setup Time!

Process Improvement should be 23 cents of every investment dollar, but which processes to improve?

Number on is to Focus on Reducing Setup Time. We've written a High Mix Low Volume guide that talks about that as well.

We live in a world where orders are much lower volume than they used to be. Everyone wants it just in time and not a minute before.

Once you've nailed setup time (and there are setup time-related investments in the other categories to look at too!), general training of more skills for your entire staff also pays great dividends.

Reducing Cycle Time and Lights Out Manufacturing are huge too.

After that, a lot of the traditional process investments don't seem to have been nearly as effective as claimed. I'm talking about all that black belt stuff like lean manufacturing and six sigmas. It's not that they can't bear fruit, but there are other investments that should be higher priority to nail first.

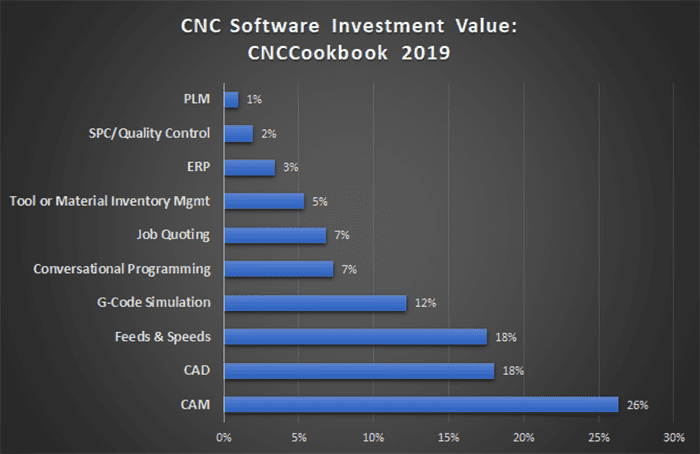

Software Investments: CAM, Feeds & Speeds, & CAD

Of course this is my favorite, given I run a CNC Software Company, LOL.

But this should come as no surprise. For decades the world's productivity improvements have been largely due to software. The move from manual to CNC is about getting machine tools to accept software in the form of part programs. Computers and automation are hugely powerful investments for any industry, and manufacturing is no different.

Here's the breakdown on which CNC Software makes sense:

The absolute number one first thing to get right is your CAM software. It's your CNC Software Productivity Lynch Pin.

After that, you're tied on CAD vs Feeds & Speeds Software (like our G-Wizard Calculator). If you aren't running any Feeds & Speeds software, start there first. You'll see an immediate black and white difference. Not just that, by using software, you are creating a process that you can optimize. If everyone is just running by the seat of their pants or with what has always worked, that's hard to optimize. I personally know of CNC Shops that made tens of millions just by getting very systematic about Feeds & Speeds.

You probably think I'm just saying all that because I happen to sell Feeds & Speeds software, but consider this. We asked CNC'ers at all experience levels what the hardest thing to learn in CNC was, and Feeds and Speeds came out as the hardest by a huge margin. This article gives the gory details of why.

So think of Feeds & Speeds software as helping you solve one of the hardest problems you face and you will see how such a small investment can make such a big difference. In fact, here's an article about what our customers tell us it has done for them.

CAM, Feeds & Speeds, and CAD account for 62% of your software investment. BTW, the packages mentioned most often in these categories are:

- Fusion360

- G-Wizard Calculator

- MasterCam

- SolidWorks

That "other" Feeds & Speeds software (LOL) was also mentioned, but way less than half as often as G-Wizard.

Next up is G-Code Simulation Software, like our G-Wizard Editor.

Why G-Code Simulation?

There are two reasons.

First, running g-code on your CNC Machine to find out if it works is expensive. You can "cut air" which takes forever (well, as long as it takes the program to run) and ties up the machine and an operator. You can also just let ‘er rip and run the risk of crashing, also expensive!

G-Code Simulation lets you test your program before you get it onto your machine. The goal for many shops is to be able to just load the program, set up the machine, and run, knowing the program will work correctly every time. That's a major improvement in Setup Time, BTW, which was the #1 process improvement to invest in. Consider that part of that investment is going towards G-Code Simulation.

Second is there are a ton of incredibly valuable things in g-code that CAM won't do. This is really cool stuff, and we have a whole article that describes a bunch of them.

Let me just give an example. With a little g-code programming, you can set up your program to deal with 1 part, 5 parts, 50 parts or whatever. This comes up all the time where you need to change the number of parts you're running, right?

Conversational Programming (The Second Bird)

Add G-Code Simulation to the mix and your total investment is 74%. But we have a few more to check into. If nothing else, you may have already covered the CAD, CAM, Feeds & Speeds, and G-Code Simulation Bases. Incremental improvements there will not be as effective as investments to bring new capabilities that never existed before.

Take Conversational Programming for one. The idea is to create g-code programs from simple Wizards asking questions. This is ideal for quick jobs and operations because it doesn't require you to fire up CADCAM, which will save you time.

Conversational isn't for every job. It's for those super-simple jobs that aren't worth spending time in CADCAM. Turning a simple bushing on a lathe. Drilling a few holes to make a rectangular bracket. Those are perfect for conversational, and they come up all the time.

BTW, I called Conversational the "Second Bird" because our G-Wizard Editor comes with a free Conversational Programming module free. So you're adding both G-Code Simulation and Conversational when you add G-Wizard Editor.

Job Quoting (Another Chance at a Second Bird)

Job Quoting is right up there with Conversational Software as a Productivity Enhancer. Here's what happens when your Job Quoting isn't up to par:

- You spend longer quoting jobs.

- You have to quote more jobs before you win one.

- You leave money on the table by quoting too low.

- You lose deals by quoting too high.

That's pretty important stuff, don't you agree?

Job Quoting is all about making the process of generating a quote systematic and reliable.

We believe the best way to do that is to use the same Feeds & Speeds engine you would use to program the part. So, we created G-Wizard Estimator to make that possible. It's the only Job Quoting software that does that. No other company in the Feeds & Speeds business is also in the quoting business.

But, it gets better.

Our Job Quoting Software, G-Wizard Estimator, is free to G-Wizard Calculator users while in Beta Test. Here's a screen shot of it:

Since it's free, it's another one of those two-birds-with-one-stone opportunities. Get G-Wizard Calculator and you have G-Wizard Estimator while it's in Beta Test.

The Rest of the Software Investments

If you've taken care of all the investments I've mentioned so far, you really are at a very progressive CNC Shop. Good for you guys!

By now we have accounted for 81% of the Software Investment Dollar. And there are 4 left to consider. In order of importance, they are:

- Tool & Material Inventory Management: Comes in at 5%

- ERP: 3%

- SPC/Quality Control Software: 2%

- PLM Software: 1%

Some of these packages score low because they're primarily of interest to fairly large firms. You reach a certain size where ERP is a must just to be able to juggle all the jobs running around your Shop Floor. PLM and Quality Control Software have more to do with the needs of your customers. If they require you to interact with a PLM (Product Life cycle Management) package, you'll have to deal with it.

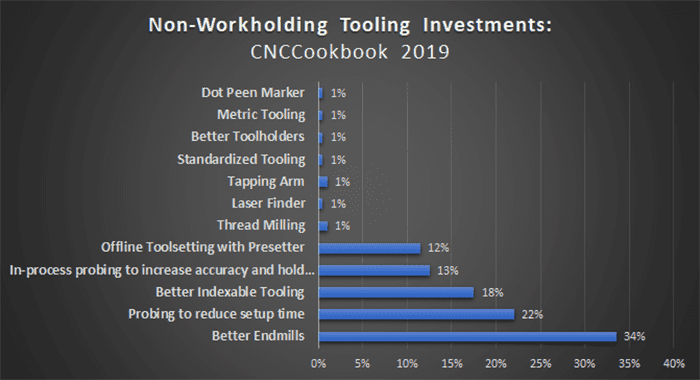

Tooling (Non-Workholding)

This category is about 19 cents of every investment dollar. Here's the breakdown:

Number one by far was to invest in a better grade of endmill. I have written about this before. Cutters are such a low percentage of the cost of any job, but they have the potential to increase performance by so much that it pays pretty quickly to use premium cutters.

Number two is probing to reduce setup time. For example, with a probe, you don't need to do any tramming. Drop your vise or fixture on the table. Run a probe routine to locate part zero and to sweep a surface. Use coordinate rotation g-codes to rotate the tool movement so the swept surface is parallel to the desired axis. The probe is almost done faster than I can explain it, and it is done WAY faster than the operate can do it manually. Big Savings!

Interestingly, using In-process probing to increase accuracy and hold tolerances is #4 at 13%, but if we add it to Setup Probing, the sum of it is 35%, which just beats investing in better endmills. CNC'ers, get yourself a probe ASAP and use it!

Number 3 is better indexable tooling.

And number 5 is the only other investment really worth messing with. It's going to Offline Toolsetting with a Tool Presetter. While you can put a toolsetting probe on the machine, offline tool presetting saves time, and that savings should be charged to setup time. You'll still want the toolsetter to be able to check tool wear on long jobs, but if you care about setup time and have the staff to deal with it, a tool presetter may be worthwhile.

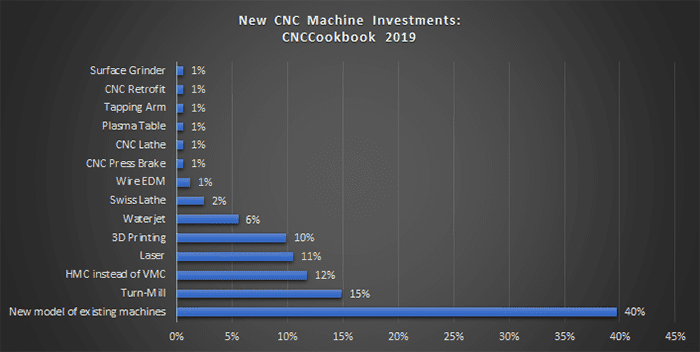

CNC Machine Investments

Who doesn't like a shiny new machine delivered to the shop?

Everyone!

But you're probably surprised to see it is #4 on the investment list and only 15 cents on the dollar. Perhaps that's because they don't improve overall productivity as much as the other investments. One new machine on a Shop Floor that already has 8 machines has limited potential to rock the bottom line.

But still, #4 ain't chopped liver. Let's drill down into the details:

I wanted to differentiate between just putting another machine on the floor and getting a whole new type of machine.

Nevertheless, getting a brand new version of something the shop already has is the winner by far.

Next up is adding a Turn-Mill machine. It's amazing what they can do productivity-wise. While they're not capable of heavy hogging, they often win on small parts that are primarily milled. They're bar-fed 4th axis machines, which gives a lot of flexibility.

Switching to a Horizontal Machining Center instead of a Vertical Machining Center also carries a number of advantages that account for the #3 position. Built in 4th axis, pallet changers, and just being generally more robust, higher horsepower, stronger taper, and so on, mean these machines can really make chips. Click that last link to read more about their advantages.

Number 4 is adding a laser cutter/marker/engraver. These machines don't take a lot of space, but they sure are handy to have around. Being handy to have around is probably also why 3D Printers took the next slot.

After that, we have Water Jets. They can really change the whole dynamic of a shop by cutting parts much closer to size before they even go on a milling machine.

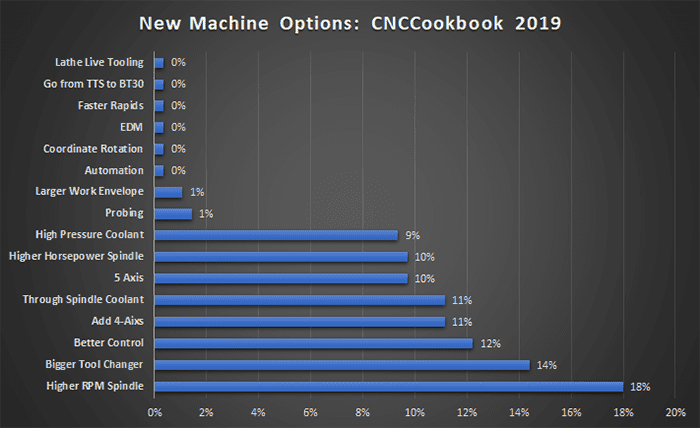

Which Options to Get on the New Machine?

These are the options that give the most bang for the buck if you're investing in a new machine:

Number one by far is more spindle rpm. For some materials, when you can't reach the optimal rpm your Feeds & Speeds software wants, every additional rpm goes straight to the bottom line.

Number two is a bigger tool changer. The more slots you have, the more you'll want it seems. Being able to keep more tools available does open a lot of possibilities that will make you more efficient. On machines with the largest capacity changers, you can even keep more than one of a particular tool and swap out when it wears or chips so the job can just keep running unattended.

A Better Control comes in at number three. Newer controls are faster, they have more memory, and if you get all the options can be more productive.

Fourth Axis and Through Spindle Coolant are tied for Numbers Four and Five.

Fifth Axis and High Pressure Coolant are tied for Six and Seven.

BTW, if you've ever wondered, get hold of G-Wizard Calculator and check out the impact of Through Spindle Coolant and High Pressure Coolant. I think you'd be surprised at how much faster Feeds & Speeds you can run, and if you're doing deep pockets or deep holes, they're even more valuable.

Everything else falls off pretty quickly. The rest were mostly write-ins from the "Other" category, so they may be artificially lower.

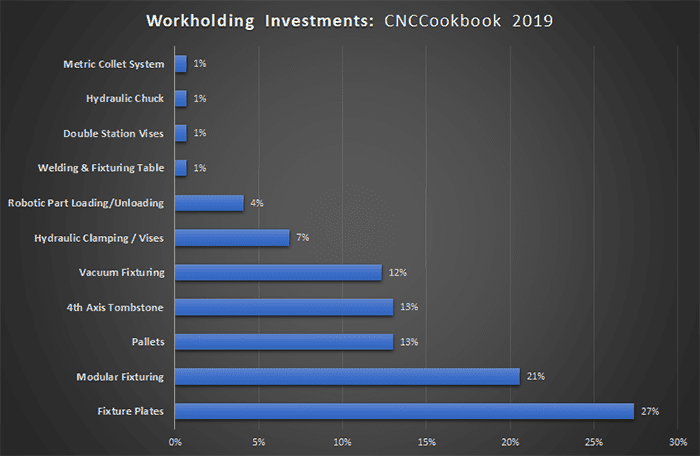

Workholding Investments

Personally, I would've bet that workholding would score higher than Number 5 overall, but there you are.

Here's the breakdown:

I'm not surprised that Fixture Plates and Modular Fixturing are the biggies here. They can save a lot of Setup Time when properly used, and we can see that's a very high priority for these investments. Pallets are another that's in the same vein.

A 4th Axis with Tombstone makes it possible to access more than just the top of a part. Depending on the part, it can really reduce the number of setups required. In addition, the total number of parts you can put on a good sized tombstone may be more than on your table's normal travel, which also helps productivity.

Vacuum Fixturing can solve workholding problems no other method can, and it does so with very low effort once you're all set up.

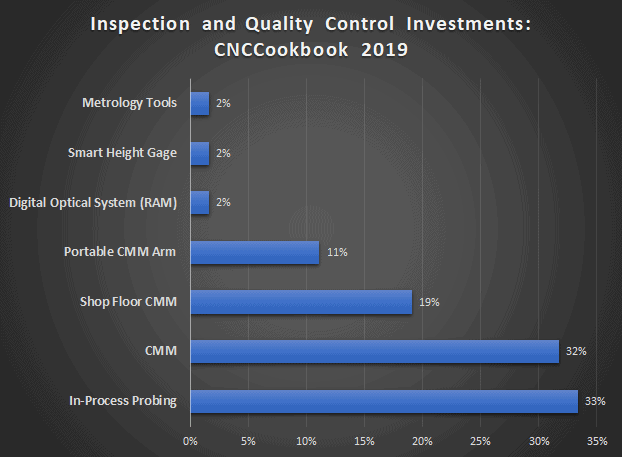

Inspection and Quality Control Investments

Almost the last, but certainly not the least, is Inspection and Quality Control. Many jobs are going to require inspection to verify that tolerances are being met.

Here's the best investments in this area:

Probing narrowly beats having a CMM (Coordinate Measuring Machine), and apparently, getting access to the CMM on the Shop Floor, and potentially as a portable CMM arm is also very helpful.

Nice to have's are Optical Vision Systems and Smart Height Gages. Metrology Tools was a write-in that basically says invest in the best specialty tools for whatever measuring job you have at hand.

Other Investments

The opportunity to write in Other Investments (things I didn't think of on the survey) and Marketing Investments didn't bear much fruit.There were a few one-offs mentioned, but no general consensus on anything.

How to Maximize Bang for Bucks

Is your CNC Shop constantly trying to improve and get ahead? If not, it should be. FWIW, investing in bad times is both the most difficult and also the most important. Most of your competition will choose not to invest in hard times. That means that if you do, you'll move ahead that much faster.

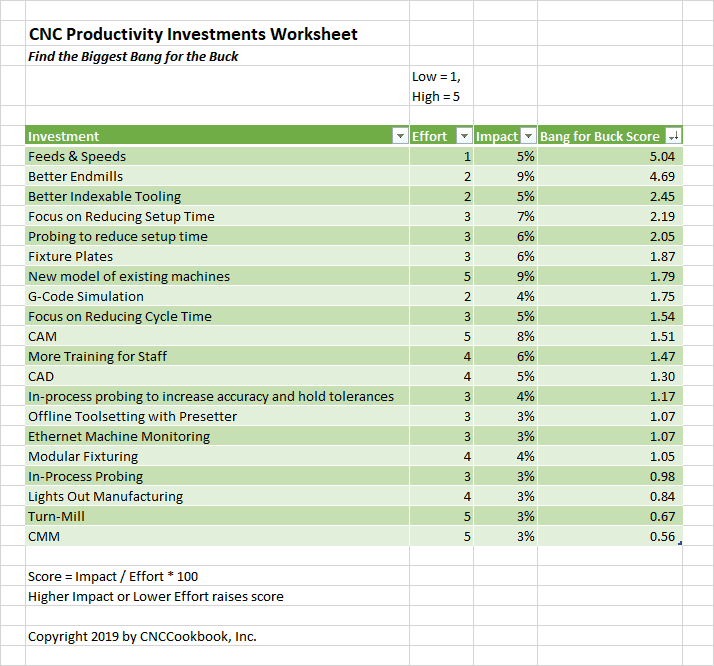

Just to take one last slice at this, if I combine the categories and nail down the top 20 investments, here is what you should look at:

Better Endmills

New model of existing machines

CAM

Focus on Reducing Setup Time

Probing to reduce setup time

More Training for Staff

Fixture Plates

CAD

Feeds & Speeds

Better Indexable Tooling

Focus on Reducing Cycle Time

Modular Fixturing

G-Code Simulation

In-process probing to increase accuracy and hold tolerances

Turn-Mill

Lights Out Manufacturing

Offline Toolsetting with Presetter

Ethernet

In-Process Probing

CMM

Think about what to do before end of year to lock in higher productivity for next year. To prioritize, let's take a "Bang for the Bucks" approach.

Here's a worksheet that'll help you get very organized about how to invest:

I've sorted our Top 20 Investments list by "Bang for Buck Score". That score is based on an Effort Score (1-5 where 1 is easy and 5 is hard in terms of cost, training, and effort). The Impact score is simply the numbers from our survey about how important our readers think each investment is.

The worksheet has my estimates on Effort. There's a ton of work and expense to get a new machine, for example. Upgrading your endmills is a lot less work, but you do have to do some evaluation to choose which endmills to go with. Grabbing a Feeds and Speeds Calculator is super easy, they're cheap and easy to learn, and they have an immediate impact.

Feel free to plug your own numbers in to see what will work for your shop. Just be honest. It's easier to start rating "Impact" more by how much you like the idea than how much it will really impact your productivity. Same with Effort-the things we'd like to do seem easier than things we don't want to deal with.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.