Downcut and other special router cutters.

In our last example we saw how to limit feeds and speeds so smaller parts wouldn't pop off our vacuum table if the feeds and speeds are too aggressive. In this example we'll take a look at how to set up G-Wizard for Downcut, V-Bits, and other special CNC Router Bit geometries.

.Downcut end mills use a helix that pushes down into the material instead of pulling up out of it. This is great for reducing splintering, chipping, and pullout at the top of the cut. There are also Compression Cutters that change helixes at the ends so they're pulling into the material both at the top and the bottom to keep either side from splintering.

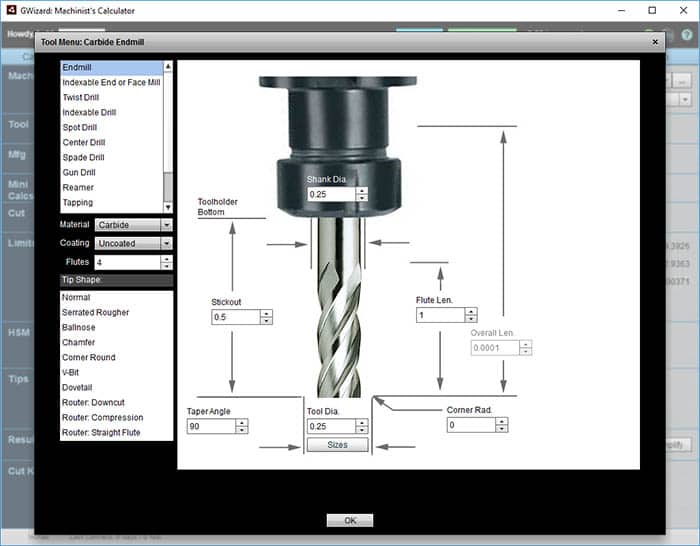

G-Wizard Calculator handles all these and more. It sees them as alternate Geometries for basic endmills. So, to select them, either click the "..." button to the right of the Tool Selection dropdown or the "Geometry" button. You'll get a comprehensive tool selection popup that looks like this:

Look at all the different endmill geometries in the lower left menu...

You can see all the different endmill geometries in the lower left menu. Towards that bottom are three CNC Router-specific choices:

- Downcut: What we're looking for to reduce chipping on the top surface.

- Compression: Reduces chipping on top and bottom surfaces.

- Straight Flute: People usually buy these because they are cheaper, but they're lower performance too.

Once you choose an alternate geometry, you're reminded it is in effect because the title of the Geometry button changes to show your geometry. In this case, it now says, "Router: Downcut" as the button's label.

That G-Wizard sure is a potent Feed and Speed Calculator Wood!

Examples Home Page:

Beginner's Examples:

Example 1: Quick wood cutting with a Shapeoko

Example 2: Fine Tune Your Cuts with Tortoise and Hare Slider

Example 3: Avoid Tool Deflection with Cut Optimizer

Example 4: The Easiest Feeds and Speeds Ever: CADCAM Wizards

Experienced CNC'ers Examples:

Example 1: How much faster can I go with High Pressure Through Spindle Coolant?

Example 2: Playing "What-If" to optimize MRR's

Example 3: Optimizing Cut Width and Cut Depth for Higher MRR's and Better Tool Life

Example 4: Mastering High Speed Machining

CNC Router Examples:

Example 1: Figure out proper Feeds and Speeds to cut walnut plaques.

Example 2: Feeds and Speeds that won't pop small parts off our vacuum table.

Example 3: Downcut and other special router cutters.

Note: Many of the early Beginner's Examples use a small Shapeoko CNC Router too.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.