Mastering the use of spade drill bits is essential for any CNC Machinist. These versatile tools can save time and effort while providing clean, precise holes in various materials. Dive into the world of spade drill bits, and explore their design, usage, and maintenance techniques. Let's embark on a journey to enhance your drilling skills and make your projects more efficient and professional.

Short Summary

- Spade drill bits can drill precise holes in metals while offering a wide range of diameters.

- Consider material compatibility and whether carbide-tipped spades are necessary to select the right spade bit.

- Use proper techniques, chip removal processes, and maintenance tips to ensure successful results with spade drills.

- Twist drills & hole saws may be better suited to some materials.

Understanding Spade Drill Bits

Spade drill bits or spade drills are specially designed for drilling precise holes in metals. They are the ideal tools for drilling perpendicular holes. These handy tools have a flat cutting edge and a pointed tip that can create clean and precise holes.

Spade drills can be used in virtually any application where a traditional drill can be used to cut holes generally ranging from 1/2 to 4 inches in diameter. A series of basic, rigid holders is used with several insert sizes to provide this wide range of diameters. The alternative is to stock drills for every diameter, a costly proposition and one which results in a sizable tool inventory.

The common brazed type of carbide drill can also be successfully replaced by "off-the-shelf" spade drill holders fitted with standard, replaceable carbide inserts. When the insert edge wears out, it easily can be replaced on the machine, or, with indexable spade drills, the second edge simply is indexed into place. No regrinding is necessary, further reducing cost.

Special multidiameter brazed carbide drills can also be replaced economically with spade drill holders fitted with throw-away inserts. With spade drills, because only the insert cuts metal, the tool holder can be made from less expensive steel, providing another economic advantage to using them.

There is also a benefit to replacing indexable insert drills with spade drills. The primary advantage here is the ability of the standard spade drill to accept a wide range of different diameter inserts instead of the "one tool-one diameter" requirement of indexable insert drills.

Design Features

A spade drill bit is characterized by a flat surface with a sharp-edged center point and two lips and spurs to facilitate cutting and drilling through the material. The design of spade drill bits allows for fast and efficient drilling, making them a popular choice for metalworkers.

In addition to their design, spade drill bits can also be coated to enhance their performance and durability. Spade drill bits are often coated with two types of materials - titanium nitride and titanium aluminum nitride.

These coatings increase the durability of the drill bit, making it more effective for tougher drilling tasks. Titanium nitride coating is a robust coating that shields the spade from corrosion, while titanium aluminum nitride coating provides protection at even higher performance levels.

Diameter Range

Spade drill bits are generally available in metric sizes from 6mm to 36mm, as well as imperial sizes from 1/2′′ to 4′′ or more. This wide diameter range allows for the creation of various hole sizes, catering to the diverse needs of different projects.

Whether you're drilling small pilot holes or larger holes, spade drill bits have got you covered.

Spade Blade Holders

Spade Blade Holders come in a variety of styles:

- Straight Flute vs Helical Flute

- Different Overall Length will control the maximum drill depth

- Different Diameter Ranges

- Optional through-spindle coolant

Your shop will probably settle on a flute style and whether to invest in through-spindle coolant. After that, it primarily comes down to keeping an inventory of different spade blade holder overall length for various maximum drill depth and holders in each length for each diameter range. Most shops will buy spade drills on an as-needed basis.

Selecting the Right Spade Drill Inserts

The right spade drill insert for the job is crucial, as it impacts the quality of the drilled hole and the efficiency of the drilling process. When selecting a spade drill insert, consider the material you are drilling into and whether carbide-tipped spade bits are necessary.

Let's explore the factors that contribute to selecting the perfect spade bit for your project.

Diameter

Obviously, you will want a spade drill insert that is the right diameter for the holes you'll be making. Be sure your Spade Blade Holder can accommodate a diameter range that is compatible as well.

Carbide-Tipped Drill Inserts vs High Speed Steel

Carbide-tipped spade drill inserts are made from tungsten carbide, which is specifically designed to facilitate cutting through hard materials. These bits offer several advantages, including durability, improved precision, and faster cutting than traditional steel blades.

However, carbide-tipped spade bits come with their own set of drawbacks, such as a higher price tag and the need for more attention and upkeep. When using these bits, it's essential to employ the correct speed and pressure when drilling and to use lubrication to reduce friction and heat.

If your material allows, you can also use High Speed Steel (HSS) drill inserts. Also, if the spindle power requirements are too high with the carbide, you may find high speed steel spade drill inserts are a better match for your application. A High Speed Steel spade drill insert is often quite a bit cheaper than its carbide counterpart.

Proper Drilling Techniques with Spade Bits

Using proper drilling techniques with spade bits not only ensures the longevity of the bits, but also guarantees precise and clean holes.

Key factors to consider while drilling with spade bits are the drilling speed, chip removal, and preventing tear-out.

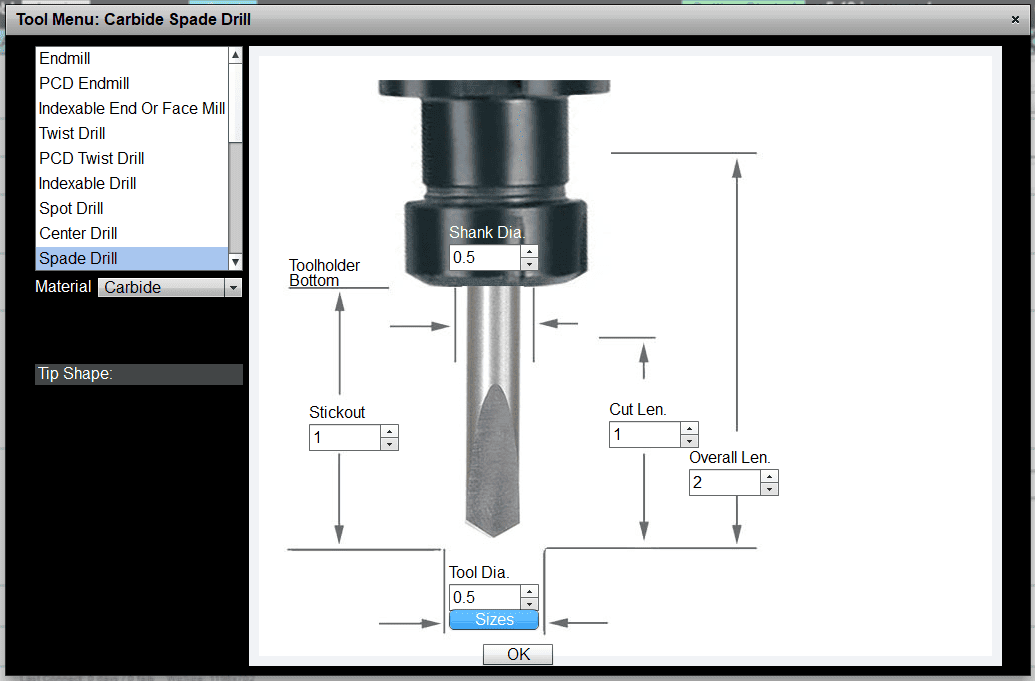

Spade Drill Speeds and Feeds Calculator

The significance of drilling speed when employing spade bits is to avoid overheating and blunting of the bit, and to create a neat hole.

Our G-Wizard Speeds and Feeds Calculator can compute proper Speeds and Feed Rates for Spade Drill Bits in a variety of materials.

[ Get G-Wizard Feeds and Speeds Calculator ]

Selecting a carbide spade drill in G-Wizard:

Chip Removal

Efficient chip removal is paramount when utilizing spade bits, as it enables a more rigid bit holder, guards against the bit becoming stuck, and aids in creating fast and smooth cuts. To ensure proper chip removal, it is essential to utilize the appropriate tools and methods, as well as take safety precautions to ensure the safe removal of chips without causing any damage.

Caring for Your Spade Drill Bits

Proper care and maintenance of your spade drill bits not only ensure their longevity but also help maintain their performance level. To keep your spade drill bits in top shape, focus on cleaning and lubrication, sharpening, and storage solutions.

Cleaning and lubrication are essential for spade drill bits. Make sure to clean the bit after each use and lubricate it with a light oil or grease. This will help prevent rust and corrosion.

Cleaning and Lubrication

Cleaning and lubrication are essential for preserving the performance and longevity of spade drill bits. Accumulation of dirt and debris can cause harm to the bit and impede its accuracy, while lubrication assists in reducing friction and heat buildup during use. The most effective techniques for cleaning spade drill bits involve using a brush or compressed air to remove any dirt and debris, followed by wiping away any remaining residue with a cloth.

When it comes to lubrication, light machine oil or a specialized lubricant specifically formulated for spade drill bits is recommended for optimal performance. Regular cleaning and lubrication not only keep your spade drill bits in excellent condition but also ensure that they are ready for use whenever needed.

Storage Solutions

Proper storage of drill bits is essential to guarantee that the bits remain in optimal condition and are ready for use when required. Bits should be kept in a dry, cool environment away from direct sunlight and humidity.

A rack or case designed specifically for spade drill bits can help ensure they do not come into contact with one another, preventing damage and keeping them organized. Investing in proper storage solutions will not only prolong the life of your spade drill bits but will also make it easier for you to find the right bit when needed.

Comparing Spade Drill Bits to Other Drilling Options

While spade drill bits are undeniably useful for drilling holes in metal, it's important to remember that they're not the only drilling option available. In fact, twist drills and hole saws may be better suited to your application.

Let's take a closer look at these two drilling options and how they compare to spade drill bits.

Twist Drills

Twist drills offer versatility and efficiency, as they can be used to drill holes in a variety of materials while requiring less power to drill the same depth and diameter of hole when compared to other types of drills. Available in straight shank, tapered shank, and spiral flute varieties, twist drills cater to different drilling requirements and materials.

When drilling with twist drills, it is essential to use the appropriate speed, guarantee effective chip removal, and avert tear-out, similar to using spade drill bits. However, their ability to handle harder materials makes them a more versatile option compared to spade drill bits.

Hole Saws

Hole saws are utilized to cut holes in wood, metal, and other materials, featuring circular saw blades with teeth on the edge. These tools offer the advantage of creating wider and more precise holes than spade bits. To use a hole saw, mark the center of the desired hole, affix the hole saw to a drill, adjust the drill speed, and carefully drill the hole.

Safety measures, such as wearing safety glasses and gloves, should be taken when utilizing hole saws to protect against potential flying debris. Although hole saws require more skill to use than spade drill bits, their ability to create clean, precise holes in a variety of materials makes them a valuable addition to your toolbox.

Summary

Mastering the use of spade drill bits is an essential skill for machinists. By understanding their design, selecting the right bit for the material, employing proper drilling techniques, and taking care of your spade drill bits, you can ensure precise and clean holes in your projects. With the right tools and techniques, you can tackle any drilling task with confidence and professionalism.

Frequently Asked Questions

What is a spade drill used for?

Spade drills are essential tools used for drilling holes in metal. Featuring a flat blade with a sharp-edged center point and two lips and spurs, these drill bits are designed to cut and bore through different kinds of metal with precision and accuracy.

Spade drill bits make creating clean, precise holes a breeze for any metalworking project.

What is the advantage of a spade drill is it really a drill?

A spade drill is not a traditional drill, but rather an efficient tool used for drilling large holes. It offers numerous advantages over standard drills such as increased cutting speed, accuracy, and surface finish.

Its replaceable inserts provide further cost and time savings, making it a great choice for any drilling project. Rather than keeping an inventory of one spade drill per hole size, you need only keep the inserts for each hole size which is much cheaper and more efficient.

Why use a spade bit instead of a drill bit?

Spade bits offer greater speed and efficiency when drilling large holes in metal, making them a great choice for many projects.

In addition, there is tremendous saving because spade bits just change inserts for each hole size whereas drill bits need to replace the whole drill bit to change hole sizes.

More Feeds and Speeds Calculators

-

G-Wizard Feeds and Speeds Calculator

-

Milling Speeds and Feeds Calculator

-

CNC Feed Rate Calculator

-

Chip Load Calculator

-

Simple Feeds and Speeds Calculator

-

Lathe Feeds and Speeds Calculator

-

Drill Feeds and Speeds Calculator

-

Tapping Feeds and Speeds Calculator

-

Master Feeds and Speeds Calculator List

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.