Tool Holder Types

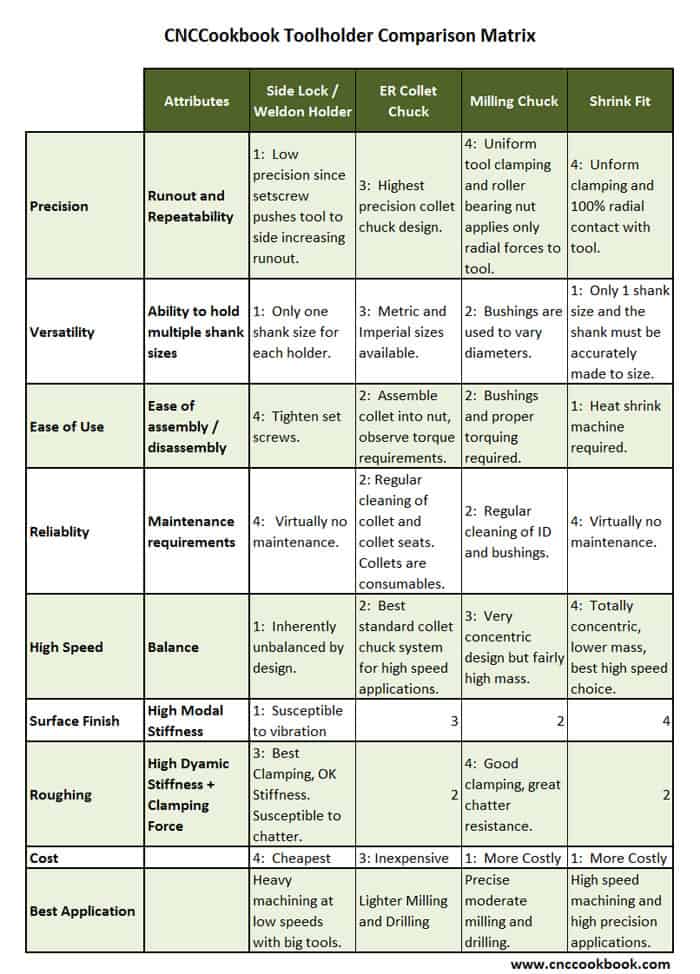

Over the years, we've written a lot of articles about tool holders for milling machines. They're an important topic and I frequently get questions about them. Recently, I found myself having to visit multiple CNCCookbook articles to answer a question and decided it was time to get all the information into one article along with refreshing the research and seeing what new information I could add. In addition, I wanted to make as much of the information tabular as possible to make it easy to refer to. Here's what I came up with:

For each tool holder type, there are multiple rows with scores from 1 to 4, where a higher score is better. 4 is the best score and 1 is the worst.

Let's go over each row and what it means.

Precision

To achieve precision, you'll need low runout and repeatability for the tool holder. The Weldon-style set screw holder has the lowest precision because set screws against a flat on the tool shank will push the tool off center and because you can't guarantee repeatability since a slight rotation of the cutting tools shank will change the exact point at which the setscrews engage.

Versatility

This is simply a measure of how many shank sizes a single tool holder of the type can accommodate. In theory, greater versatility means you'll need fewer tool holders.

Ease of Use

This is a measure of how easy it is to setup cutting tools in the tool holder or take them back out. Nothing could be easier than using a set screw holder-just stick a cutter in and tighten the set screws. The Shrink-Fit holder requires the use of a heat shrink machine to do anything. In the middle are tool holders that require proper assembly torque.

This is a good time to put in a plug for proper ER collet chuck torquing. For best performance, ER collet chucks require a lot more torque than most machinists realize. That torque goes to keeping the tool clamped so it won't pull out and to making the whole assembly rigid so it resists vibration and chatter.

When you hear a machinist talking about having an endmill slip in their ER collet chucks, you have to wonder two things:

- How clean was the chuck and cutter shank when they were tightened together? The slightest residue of oil or cutting fluid can rapidly reduce the collet chucks holding power.

- How much torque was used to tighten the collet nut?

Consider the following torque specs from Technik USA for ER Collet Chucks:

Collet

Nut Type

Collets I.D.

Collets I.D.

OVER 1/16″ (2mm)

UNDER 1/16″ (2mm)

ER 16

slotted

42 ft/lbs

30 ft/lbs

ER 16

hex

42 ft/lbs

30 ft/lbs

ER 20

slotted

59 ft/lbs

24 ft/lbs

ER 20

hex

59 ft/lbs

24 ft/lbs

ER 25

slotted

77 ft/lbs

77 ft/lbs

ER 25

mini nut

25 ft/lbs

25 ft/lbs

ER 32

slotted

100 ft/lbs

100 ft/lbs

ER 40

slotted

130 ft/lbs

130 ft/lbs

Are you torquing your ER32 collets to 100 ft/lbs? That’s a bunch more than a lot of folks expect going on feel alone.

Whether you use a torque wrench or not, and Technik as well as others make appropriate adapters, make sure you’ve at least got a nice wrench for your collet chucks. The single pin spanners are the worst for me when I have to apply a lot of torque. In addition, you’re going to need a way to solidly mount your collet chuck while you tighten the nut. Bench fixtures are the most helpful for this task.

Reliability

This is a measure of how much maintenance is needed to keep the tool holder performing to spec. Set screw holders are dead easy as are shrink-fit-no moving parts. Collet chucks and milling chucks need to be kept clean and torqued to proper specs.

High Speed

This row scores the suitability of different tool holders for high spindle speeds. "High" starts in the 8000-10,000 rpm range and the primary requirement is the ability to balance the tool holder well. Less mass in the tool holder will also help because the less mass that's spinning, the less vibration at a given level of balance.

Working well with high speed spindles is one of the biggest reasons to invest in fancier tool holders.

Surface Finish and Roughing

These two categories get into suitability for task. For surface finish, we need to keep the modal stiffness high to resist vibration. For roughing finish, we want high dynamic stiffness to resist chatter under varying loads, rpms, and frequencies, and we want strong clamping on the tool to resist the higher forces of roughing.

Cost

Cost is near and dear to everyone's pocketbook, and the costs vary quite a lot between these various tool holders

Best Application

Drumroll please, this is the one we've been waiting for: what's the best situation for each tool holder type?

This bears recapping:

- For your absolute highest MRR milling and drilling applications, consider a Side Lock or Weldon Shank-style tool holder. We're talking big indexable cutting tools for the most part, not solid endmills.

- For mid-sized milling and drilling, consider a Milling Chuck. This is your largest solid endmills and twist drills, say 3/4 to 1" and up. Also consider these when you have chatter problems on your big tooling using a Side Lock holder.

- For lighter milling and drilling, consider an ER collet chuck. Anything 3/4" or under makes sense.

- For high rpm applications, consider shrink fit tool holders.

Obviously there is some gray area of overlap in each of these cases, but this should serve as a good starting point for tool holder selection.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.