This Definitive Guide will tell you about PCD, and gives all the tips, feeds and speeds, applications, and techniques needed to succeed with PCD tooling.

What is PCD / Polycrystalline Diamond?

PCD is the abbreviation for Polycrystalline Diamond. Depending on how you want to look at it, PCD is either a material cutting tools are made of or a coating. In the right applications, PCD can significantly reduce your tooling costs as well as your cycle times.

PCD is much harder and more resistant to abrasion the conventional carbide tooling. It consists of diamond particles (diamond grit) that is sintered with a metallic binder, and is one of the hardest and most abrasion resistant tooling materials available.

Like tungsten carbide, PCD is available in multiple quality grades. Better grades include coarser (larger) diamond grain and polished tips that reduce material buildup.

PCD Applications

Diamond reacts chemically with some metals including Iron, Cobalt, Nickel, Chromium, and Vandium. As such, machining steel and other alloys with these materials is out. The preferred harder alternative in these materials is CBN.

Materials suited to PCD Tooling include:

- Composites, especially abrasive composites like Carbon Fiber.

- Carbide alloys (e.g. cutting tools) and Tungsten

- Stone, concrete, asphalt, glass, ceramics, gem stones, and semiconductor materials.

- Machining of clean, graded hardwoods (avoid particle board and other wood products containing embedded grit).

- Non-ferrous metals such as aluminum, copper, and their alloys.

- Some soft but tough materials like rubber and resin.

An important consideration is that PCD is particularly brittle. Applications involving lots of vibration should be avoided.

PCD Tools & Cutters

A wide variety of PCD cutters are available.

PCD Diamond Drill Bits

PCD Drill Bits come in a variety of flavors:

- "Vein" style has PCD infused in the grain structure of the bit.

- Brazed has cutting edges brazed onto the bit much like the end mill pictured below

- PCD Tipped has a solid PCD tip such as this photo shows:

Sorry, but there's no text provided to rephrase. Please provide the text.

Note the dark-colored PCD tip...

PCD End Mills

The photo shows a typical end mill with PCD cutting edges brazed on. PCD is formed in large High Temperature-High Pressure presses as either a diamond wafer on carbide backing or forming a "vein" of PCD within carbide.

PCD Inserts

Given that PCD bonded to carbide for brazed tools is available, it should follow that PCD inserts are available for indexable cutting tools.

G-Wizard Speeds and Feeds for PCD Tooling on Composites

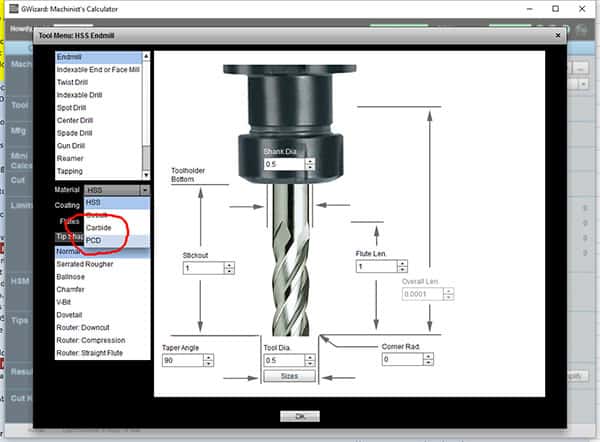

G-Wizard can calculate speeds and feeds for PCD End Mills and PCD drills.

PCD is a choice on the Tool Material menu of the pictorial popup:

PCD is a Tool Material choice on the pictorial popup…

The actual material removal rates may sometimes be less than conventional tooling, depending on the scenario, but the tool life is 10x – 50x longer. This makes PCD tooling a welcome addition. When you can find a combination where the MRR’s are better than conventional tooling and you’re also getting the tool life benefits, that’s where PCD tooling can really shine the brightest.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.