Latest news: We just added a slick new Hardness Conversion Calculator to our G-Wizard software.

Jump To:

Hardness Conversion Chart & Calculator

Rockwell Hardness

Brinell Hardness

Vickers Hardness

Article on Work Hardening / Strain Hardening

Definition of Hardness

Hardness signifies how effectively a solid material can resist permanent deformation when subjected to a compressive force. It's contingent on a wide range of factors including the robustness of intermolecular bonds, ductility, elastic rigidity, plasticity, strain, strength, toughness, amongst many others.

Hardness Tests: Measuring Hardness

There are three ways hardness is typicall measured:

Scratch Hardness

Scratch Hardness testing is based on the idea that harder materials will scratch softer materials.

Indentation Hardness

A typical hardness tester...

Indentation hardness measures the resistance of a sample to deformation due to a constant compression load from a sharp object. After the material under test is subjected to a specially loaded and dimensioned indenter, the dimensions of the indentation left behind in the test subject determine the hardness.

This is the most common method of hardness testing used for CNC and machining purposes, and the Rockwell, Vickers, Shore, and Brinell Hardness scales are all based on Indentation Hardness.

Rebound Hardness

In Rebound Hardness measurements, the height of the "bounce" of a dimaond tipped hammer dropped from a fixed height onto the test material determines its hardness.

Rockwell Hardness Test (HR)

In the Rockwell Hardness Test (whose values are referred to with the abbreviation "HR"), a diamond cone or steel ball indenter is used. The indenter is forced into the test material under a minor load, usually 10 kgf. When equilibrium is reached (i.e. no further indentation at that load is happening), a datum position is established. An additional major load is applied, which increases penetration. Removing the major load results in a minor recovery of the material in most cases. The difference between the indentation after that minor recovery and the datum established by the minor load may be used to calculate the Rockwell hardness number.

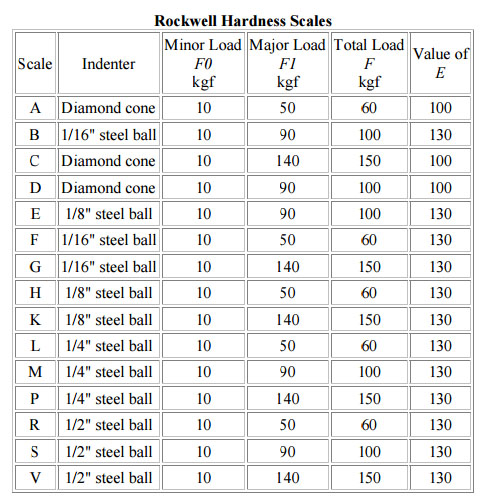

The various Rockwell Hardness Scales differ in the nature of the indenter as well as the Major Load:

Testing parameters for the various Rockwell Hardness Scales...

The Rockwell Hardness Test is conveient to automate, but it suffers from many arbitrary scales and possible effects from the specimen support anvil. The Vickers and Brinell methods don't suffer from this effect.

Brinell Hardness Test (BHN)

The Brinell Hardness Test consists of indenting the test material with a 10mm diameter hardened steel or tungsten ball subjected to a load of 3000 kg. For softer materials, there are alternate scales using a 1500 kg or 500 kg load to avoid excessive indentation.

The full load is applied for 10 to 15 seconds for iron or steel and at least 30 seconds for other materials. The diameter of the indentation left is measured by a low powered microscope. The Brinell Hardness Number may be calculated from the diameter of that indentation. The average of two measurements taken at right angles is used for the diameter to ensure accuracy.

Compared to the other test methods, the Brinell ball makes the deepest and widest indentation, so the test results average hardness over a wider area. This can result in more accurate results when there are multiple grain structures and other irregularities in material uniformity.

Vickers Hardness Test (HV)

The Vickers Hardness Test uses a diamond indenter in the form of a right pyramid with a square base and an angle of 136 degress between opposite faces. The indenter is subjected to a load of 1 to 100 kgf. the full load is applied for 10 to 15 seconds. The two diagonals left in the surface of the material are measured using a microscope and their average is taken. From this, the area of the sloping surface of the indentation is calculated, and from that the Vickers Hardness may be determined.

Surprisingly, different loading settings give practically identical hardness numbers on uniform material, which is much better than the arbitrary changing of scale with the other hardness testing methods. The advantages of the Vickers hardness test are that extremely accurate readings can be taken, and just one type of indenter is used for all types of metals and surface treatments. The disadvantage is that the machines that take the reading are large floor-standing units (not benchtop), and they're more expensive than Brinell or Rockwell machines.

Other Hardness Scales

The Rockwell, Brinell, and Vickers are the most common hardness scales, but there are many others:

- Shore Scleroscope

- Knoop

- Leeb (HLD): Leeb is a rebound hardness test that was developed in 1975 to provide a portable hardness test for metals.

- Janka Hardness: Janka is used exclusively for wood, but it can be very helpful when CNC'ing wood.

G-Wizard Hardness Conversion Charts & Calculator

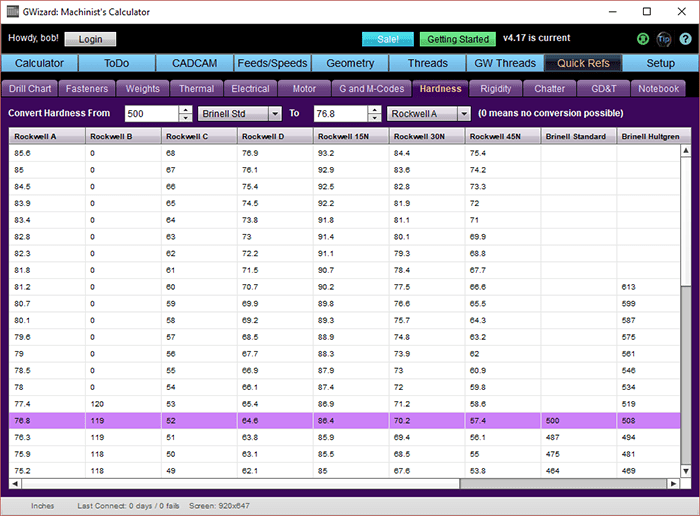

Our G-Wizard Calculator software includes a hardness conversion calculator because it has a full set of hardness conversion charts and a calculator built right in on the "Quick Refs" tab:

Hardness conversion calculator for Rockwell, Brinell, Vickers, Shore Scleroscope, and Tensile Strength...

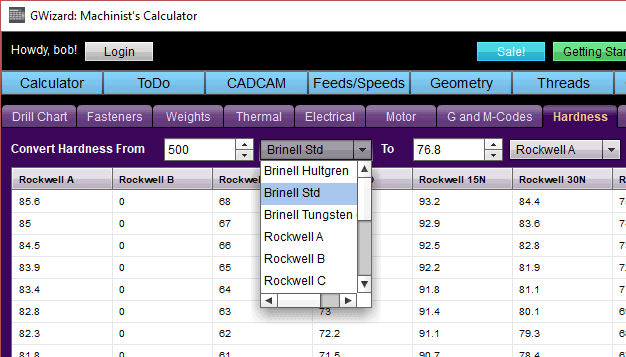

The Hardness Conversion Calculator is particularly handy. Enter a from value, select the from units, enter the "to" units, and G-Wizard will give you a value (if there is one) in the new hardness units. Here's a closeup of the unit selector:

Here's something else-you can get lifetime access to all the reference calculators and materials except the Feeds and Speeds Calculator just by signing up for a Free Trial of G-Wizard. That's right, it is completely free to access all that just by signing up for a free trial and you'll also get all the upgrades and customer service for life! Plus, buy the $79 version and you get up to 1 HP on the Feeds and Speeds too for life.

So what's the catch? Why does anyone ever pay more than $79?

Many hobbyists don't pay more than $79, BTW. The catch is a spindle power limit. When you buy the 1 year G-Wizard for $79, you get 1 year of unlimited spindle power for Feeds and Speeds. When that expires, you get a spindle power limit of 1 HP. That limit is based on however many years you subscribe for. You can increase it any time you like by renewing the subscription. Or, if you don't like subscriptions, you can also by the product outright. And we never charge for updates or customer service.

So go ahead, give G-Wizard a free trial. You'll be surprised at all the time it saves you on things like Tap Drill Sizes, not to mention the longer tool life, better surface finish, and shorter cycle times you'll get from better Feeds and Speeds.

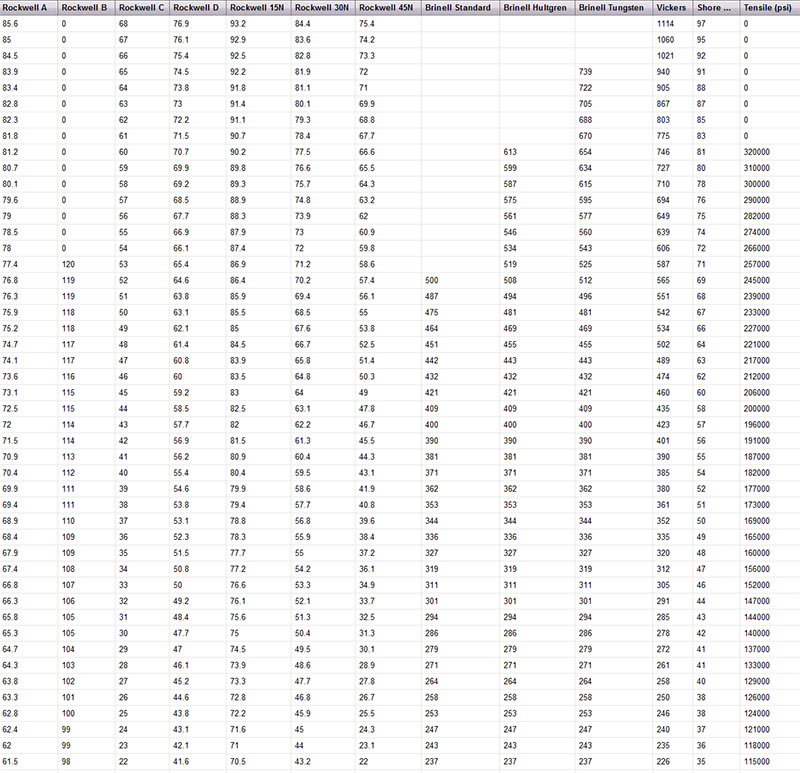

Hardness Conversion Charts and Tables

Rockwell A

Rockwell B

Rockwell C

Rockwell D

Rockwell 15-N

Rockwell 30-N

Rockwell 45-N

Brinell Std

Brinell Hultgren

Brinell Tungsten

Vickers

Shore Sclero-Scope

Approx Tensile Strength (psi)

85.6

68

76.9

93.2

84.4

75.4

1114

97

85

67

76.1

92.9

83.6

74.2

1060

95

84.5

66

75.4

92.5

82.8

73.3

1021

92

83.9

65

74.5

92.2

81.9

72

739

940

91

83.4

64

73.8

91.8

81.1

71

722

905

88

82.8

63

73

91.4

80.1

69.9

705

867

87

82.3

62

72.2

91.1

79.3

68.8

688

803

85

81.8

61

71.5

90.7

78.4

67.7

670

775

83

81.2

60

70.7

90.2

77.5

66.6

613

654

746

81

320000

80.7

59

69.9

89.8

76.6

65.5

599

634

727

80

310000

80.1

58

69.2

89.3

75.7

64.3

587

615

710

78

300000

79.6

57

68.5

88.9

74.8

63.2

575

595

694

76

290000

79

56

67.7

88.3

73.9

62

561

577

649

75

282000

78.5

55

66.9

87.9

73

60.9

546

560

639

74

274000

78

54

66.1

87.4

72

59.8

534

543

606

72

266000

77.4

120

53

65.4

86.9

71.2

58.6

519

525

587

71

257000

76.8

119

52

64.6

86.4

70.2

57.4

500

508

512

565

69

245000

76.3

119

51

63.8

85.9

69.4

56.1

487

494

496

551

68

239000

75.9

118

50

63.1

85.5

68.5

55

475

481

481

542

67

233000

75.2

118

49

62.1

85

67.6

53.8

464

469

469

534

66

227000

74.7

117

48

61.4

84.5

66.7

52.5

451

455

455

502

64

221000

74.1

117

47

60.8

83.9

65.8

51.4

442

443

443

489

63

217000

73.6

116

46

60

83.5

64.8

50.3

432

432

432

474

62

212000

73.1

115

45

59.2

83

64

49

421

421

421

460

60

206000

72.5

115

44

58.5

82.5

63.1

47.8

409

409

409

435

58

200000

72

114

43

57.7

82

62.2

46.7

400

400

400

423

57

196000

71.5

114

42

56.9

81.5

61.3

45.5

390

390

390

401

56

191000

70.9

113

41

56.2

80.9

60.4

44.3

381

381

381

390

55

187000

70.4

112

40

55.4

80.4

59.5

43.1

371

371

371

385

54

182000

69.9

111

39

54.6

79.9

58.6

41.9

362

362

362

380

52

177000

69.4

111

38

53.8

79.4

57.7

40.8

353

353

353

361

51

173000

68.9

110

37

53.1

78.8

56.8

39.6

344

344

344

352

50

169000

68.4

109

36

52.3

78.3

55.9

38.4

336

336

336

335

49

165000

67.9

109

35

51.5

77.7

55

37.2

327

327

327

320

48

160000

67.4

108

34

50.8

77.2

54.2

36.1

319

319

319

312

47

156000

66.8

107

33

50

76.6

53.3

34.9

311

311

311

305

46

152000

66.3

106

32

49.2

76.1

52.1

33.7

301

301

301

291

44

147000

65.8

105

31

48.4

75.6

51.3

32.5

294

294

294

285

43

144000

65.3

105

30

47.7

75

50.4

31.3

286

286

286

278

42

140000

64.7

104

29

47

74.5

49.5

30.1

279

279

279

272

41

137000

64.3

103

28

46.1

73.9

48.6

28.9

271

271

271

261

41

133000

63.8

102

27

45.2

73.3

47.7

27.8

264

264

264

258

40

129000

63.3

101

26

44.6

72.8

46.8

26.7

258

258

258

250

38

126000

62.8

100

25

43.8

72.2

45.9

25.5

253

253

253

246

38

124000

62.4

99

24

43.1

71.6

45

24.3

247

247

247

240

37

121000

62

99

23

42.1

71

44

23.1

243

243

243

235

36

118000

61.5

98

22

41.6

70.5

43.2

22

237

237

237

226

35

115000

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.