Having founded 4 Silicon Valley startups and participated in success and failure at 3 others, I've learned a little bit about making a business successful. I write another blog called Smoothspan that specifically discusses business strategy for entrepreneurs, but I like to do a post here every now and again when I have something to say that is particularly suited to the CNC, machining, and manufacturing world. I know a lot of you out there either have your own businesses or have considered starting a business, so I want to pass along whatever I can.

Every business needs a difference in order to stand out, get noticed, and attract customers. If you don't know what's different about your business or idea for a business, it's time to get busy creating a difference. We do a lot of things differently here at CNCCookbook. Some of the most obvious differences have to do with our approach to marketing, our approach to pricing, and what we try to do differently with our software.

With marketing, we try to avoid overt hard sell tactics, or what I would view as spam. We send email, but mostly it is a digest of the articles from this blog. The closest we get to a hard sell is to send an email letting people know we're running a sale.

We also give away a ton of information that has nothing whatsoever to do with our software. We believe that all things CNC, manufacturing, and machining are interesting and that the job of our marketing is to attract a community of individuals who agree with that proposition.

If we build our software right, some of you will also decide to be customers. But we're very patient about that. We get folks buying the product more than a year after trying it, and that's fine with us. A lot happens in a year and it may take that long before you develop the need for it. Given that we get over a million visitors a year to the site, I'd say this strategy is working well.

Our approach to pricing is different than most of the CNC software world. We don't believe in a big up-front fee. We analyze the market, decide who the competitors are, look at their prices, and then charge a fraction of that as a subscription.

Eventually, we'll make more money, but we have to keep you happy enough to keep subscribing for years. If you're a hobbyist with a hobby-class machine, you can quit subscribing and keep using the software with a horsepower limit that matches your machine's capabilities. And you will have paid less than the competition's up-front one-size-fits-all pricing.

Then, there is the software. We do a lot of things differently there. This is the Internet Age, and we believe in leveraging the connection to add value to the software. We believe in providing our customers with as many ways as possible to connect back with us and get help or make suggestions.

We believe in leveraging the Wisdom of Crowds, and we have now had over 15,000 machinists use the software and help us shape our thinking about what works and what our audience wants. We believe in innovative User Interface, and we have pioneered a number of capabilities you just can't get anywhere else such as our Cut Optimizer for G-Wizard Calculator or the Hints and G-Code Wizards in G-Wizard Editor.

There's a lot more to it than that, and I don't want to monopolize this post talking about CNCCookbook, but you get the idea of what we're all about.

In this day and age of Global Hyper Competition, you've got to figure out how your business can be different. Just doing the same as the other guy, but doing it a little bit better or a little bit cheaper is hard to impossible. It's hard because it doesn't last.

The other guy sees what you're doing, and pretty soon they have made their product that little bit better or that little bit cheaper. This becomes a race to the bottom, and the winner is a loser because they had to work so hard for the privilege of earning a wage that has little profit left. To prosper, you need to get out of that rat race and off the radar screens of the competition. You need to figure out how your business can be different.

There are a lot of ways to be different, but most of all, being different means you're serving a need that almost nobody else serves in the way you do. If you run a job shop, get some machines that are different.

Perhaps they have a larger capacity than all the other shops in your area. Perhaps they can do some certain kind of job much faster and better than the machines the other shops are using, so you can focus on that kind of work. Maybe your specialty is micro-machining and nobody else has your expertise.

I have talked to shops that are using very unique and innovative ways to lower their cost structure far below what the competition has. I wish I could say more, but of course they wouldn't want me to lest it destroy their unique advantage.

Frankly, it's harder to be different as a job shop, but it is still very possible and worth thinking about. Where you have the most flexibility to be different is making your own products. The best way to know that your products are different is to be able to tell a compelling story. A story that is unlike what your competition has to say. A story about how you discovered some special need and built the very best product to fill that need.

Recently, we got a new customer, a company called Midwest Mountain Engineering. They have a story like this and they build a special product as a result. Their story begins a bit sadly:

They say “Necessity is the mother of all invention” and this is true in this case. My riding buddy developed a severe case of Psoriatic Arthritis affecting his hands and feet. He eventually gained control of his condition with self administered injections but for a while, it was looking like his riding days were over.

But it ends on a strong note:

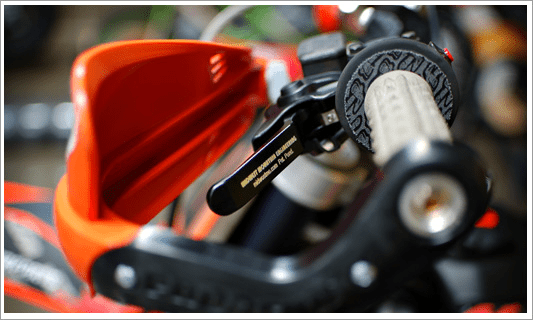

We began discussing ways to reduce clutch forces. Jerry had purchased the smaller diameter master cylinder for his old KTM 200 and I had put the Raptor lever sold by MSR on my YZ250 years ago. We got to thinking that there must be a mechanical way to do the same thing for a hydraulic clutch that the Raptor did for a cable clutch. We handmade several prototypes to take to a local trail ride and found some Double-A riders to try them out. They worked well enough that one guy who squeezed the lever questioned whether it was connected to the clutch!

To make the long story short, their special dirt bike levers make it possible for folks like their buddy to ride again. But they're not just for folks who have trouble pulling the normal levers. A whole legion of riders are getting to enjoy the softer touch of MWE's custom levers.

Now there are a lot of companies making motorsports parts, but when I read that story, I knew I had come across something different.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.