Introduction

This piece is a component of our CNC Beginners Cookbook series.

Workholding is the generic term for any device or method used to firmly hold your workpiece while machining it. While CNC Routers are technically milling machines, and they share some similarities in workholding, they're basically a whole new ballgame. To understand CNC Mill vs Router more deeply, check out our article.

Spoilboard

A spoilboard is a disposable work surface mounted atop the router's permanent table. The spoilboard is typically MDF and protects the router table from damage as well as being an expendable surface that can participate in workholding.

From time to time a spoilboard will need to be surfaced. That means using a spoilboard cutter to clean up any gouges or cuts and make the board flat and parallel to X and Y axis travel.

Screw into Spoilboard

This is a very common method and involves screwing into the spoilboard to hold the work. It's cheap and cheerful, but it does leave holes in the workpiece and can be slow. For tasks like this, grab an electric impact driver, air ratchet or similar tool to help drive the screws faster (as well as removing them faster). Another disadvantage aside from it being slow to bolt things down is that hitting one of the screws with a cutter will often break the cutter. If it's travelling at feeds and speeds intended for wood or other soft materials, it's going way too fast when it unexpectedly hits hard metal.

Polymer Nails into Spoilboard

This interesting idea is courtesy of James Irmiger of TechShop SOMA and Instructables. The idea is to use polymer (plastic) nails to secure the workpiece to the spoilboard:

Using Polymer Nails to secure the workpiece to the spoilboard...

According to James, the process is a little bit fussy and requires adjustment of air pressure and can be sensitive to overly hard wood. But, when once it is dialed in, it works great. Removing the workpiece just requires a little tap with a mallet to break the nails-they're strong at resisting pullout but shear off easily. With a nail gun, this technique can be a lot faster than screwing into the spoilboard.

Double Sided Tape and Glue Fixturing

Small parts that don't expect high cutting forces can do well with double sided tape and various kinds of glue.

One popular method is to use painter's tape and super glue.

Here's what you do:

- Scuff the pieces and clean as best you can. For metal, I clean with acetone, isopropyl alcohol, or brake cleaner.

- Apply the painter's tape. That's the blue stuff painter's use to mask parts.

- Apply super glue to the tape.

- Lay the part down carefully onto the tape. Try to make sure any air escapes.

- Clamp it briefly or put a weight on it.

Your part should now be adhered to your bed and it will be held pretty solidly.

How do you get the parts loose?

Pry up with screwdriver, putty knife, or razor blade. You can also soak it in acetone, which will dissolve the superglue. Lastly, heat will break it loose. Be very careful with heat:

Danger: Super glue, or cyanoacrylite, releases toxic cyanide gas when heated!

You may need to sand or fly cut the superglue off in the worst case, but it usually doesn't come to that.

Clamps and T-Slots/T-Track

On CNC Routers, T-Slots are typically created using T-Track, which are metal T-Slots designed to be attached to your MDF spoilboards.

Rockler T-Track bolted down to top of MDF with CNC Clamps...

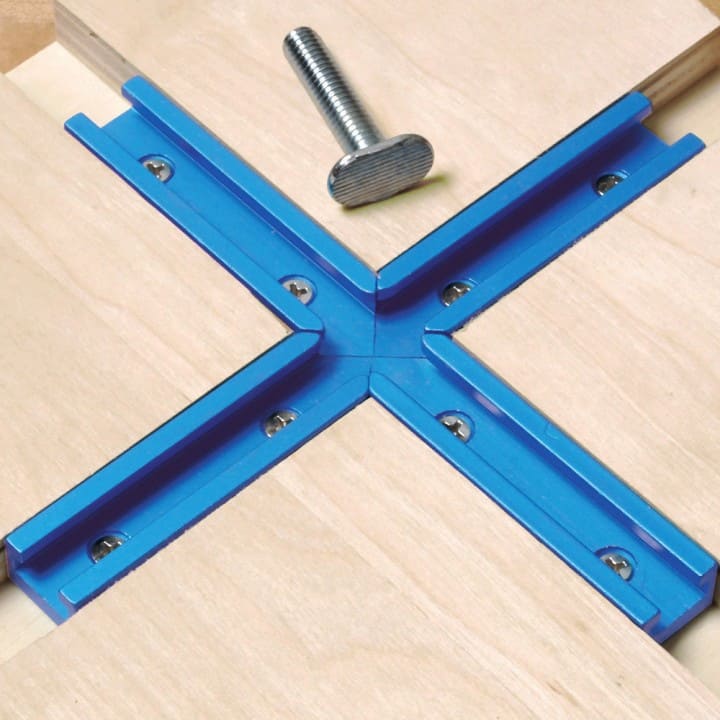

Rockler T-Track Intersection Kit in a recessed slot with a typical bolt used with the track. Rockler has a wide variety of parts and kits for T-Tracking...

There are a wide variety of different T-Track systems and accessories for them available if you search the web. T-Tracks can be very versatile, but like bolting through to the spoilboard, you must take care the router doesn't hit a bolt or T-Track in the middle of the job.

Tab Supports: Workholding Via CAM Software

What if your CAM software could solve some major workholding problems for you, wouldn't that be neat?

Turns out some CAM software can help out with workholding quite a lot by automatically creating tabs. Here's a video of MeshCAM's facility for creating tab supports to help machine a part that has to be machined on 2 sides and is awkward to hold otherwise:

Using MeshCAM to add tab supports so you can machine a part on 2 sides...

We offer MeshCAM at CNCCookbook because it's one of the easiest to use CAM packages there is.

Vacuum Tables

Vacuum Tables are often the best solution for the flat sheet work often being done on CNC Routers. We've got an entire article dedicated to CNC Router Vacuum Tables, so click through to check it out:

Related Article: CNC Router Bits

Learn about the specialty CNC Router Bits that make life easier for CNC Router owners.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.