The goal of any fixture clamp is to hold your workpiece in the fixture, and to help you make more parts in a shorter time.

Step Clamps

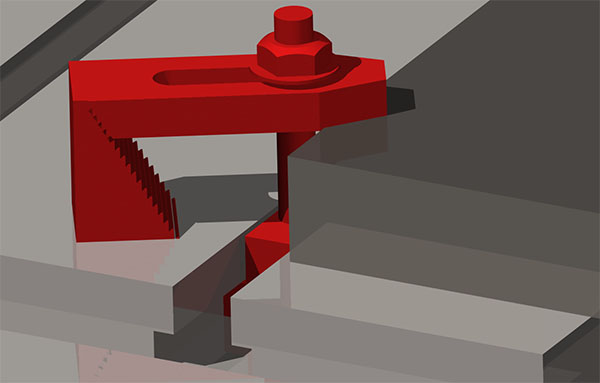

The most common type of fixture clamps are called step clamps because they have little steps machined on them. They’re commonly used with T-Slots, although you can also use bolt them into a Tooling Plate. Here are some typical Step Clamps:

Step Clamp holding down plate, step block supporting end of clamp, and bolt goes through T-Slot Nut…

A typical Step Clamp Set with black oxide finish…

Pictured is a typical Step Clamp Set. It can be handy to stock up on a an extra set so you’ve got more clamping parts to work with. By stacking the Step Blocks and using longer bolts, you can clamp workpieces that are quite tall.

When using step clamps, keep the bolt close to the workpiece rather than the step block. Also, it can be helpful to angle the fixture clamps down on the part by raising it up a step or two from level. You may also want to put a shim of soft material between the clamp and the workpiece if you want to avoid marring the workpiece. Soda can makes a great shim for this purpose if you slice out some strips with your snips.

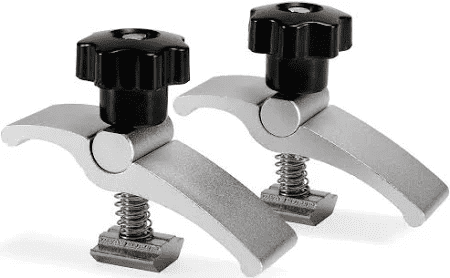

Hold-Down Clamps

These are similar to step clamps, but they're more often seen on CNC Routers. The models shown are equipped with hand wheels. They're very convenient but can't produce as much holding force as the more normal screw-type fasteners.

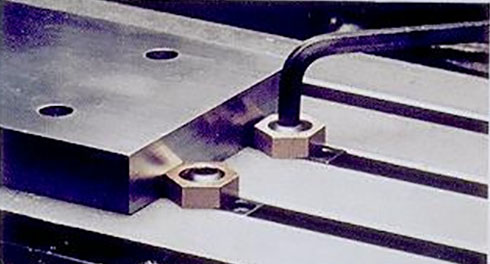

Toe Clamps

Step Clamps grip the top of the workpiece, which is sometimes inconvenient because you might need to machine the area being gripped. Toe Clamps grip the side of the workpiece to give you full access to the top of the workpiece. They are low profile and less likely to get in the way of your cutters. There are a wide variety of different styles available:

This toe clamp moves the clamp down a ramp when tightened to press against the workpiece…

These Mitee Bite Edge Clamps have an eccentric bolt head that forces the hex against the workpiece as you tighten it…

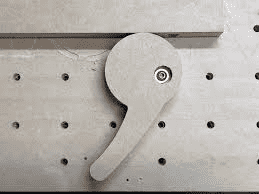

Cam Clamps

Cam Clamps are mostly seen on CNC Routers and other woodworking applications.

Toggle Clamps

Quick-release toggle clamps can be ideal in fixtures built for a particular part. They're typically used on purpose-built fixtures in industrial applications.

Double Sided Tape, Glue, Wax, and Low Melting Point Alloys

Some workpieces can be very difficult to hold because they’re too thin or because they're shaped so there’s just no way to clamp on. Some solutions for these situations are in the form of Double Sided Tape, Glue, Wax, and Low Melting Point Alloys.

The Glue needs to be something that will release when needed. For example, Super Glue releases at a particular temperature just like LocTite. The fumes from it are toxic, so take care to release with plenty of ventilation. Double-sided tape can work great, especially for really thin materials.

Wax and Low Melting Point Alloys (typically Bismuth alloys) can be used to embed the workpiece and create grippable area. When the machining is done, one can melt the wax or alloy away and save for reuse.

Fixture Plate

A Fixture Plate can make working with fixture clamps much easier.

Clamping Force

What is Clamping Force?

Clamping Force is the amount of force applied to the workpiece when a clamp is closed. You want the clamping force to be high enough to resist external machining forces.

How to Measure Clamping Force

Here is a simplified version:

Image courtesy of Carr-Lane...

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.