Have you ever wondered about the differences between reaming vs. boring in the machining world? These two processes may seem similar, but they have unique characteristics and applications that set them apart.

In this blog post, we’ll explore the distinctions between reaming vs boring, their advantages and limitations, and how they’re used in various industries. Strap in and get ready to dive into the fascinating world of metal cutting operations!

Short Summary

- Reaming and Boring are two distinct hole-making processes with different purposes, varying in the type of material removal and hole size.

- Reaming offers various advantages such as increased feeds/speeds, higher cutting speeds with lubrication & cost-effectiveness. While boring provides precise positional accuracy but a coarser surface finish.

- Adopting protective gear & following manufacturer guidelines are essential safety precautions to be taken when performing reaming or boring operations.

Understanding Reaming and Boring

Reaming and boring are two distinct hole-making processes that manufacturing companies employ to create or refine existing holes in a workpiece. Although they share some similarities, they serve different purposes and have unique characteristics. By understanding the nuances of these processes, you can make informed decisions when choosing the right method for your specific application.

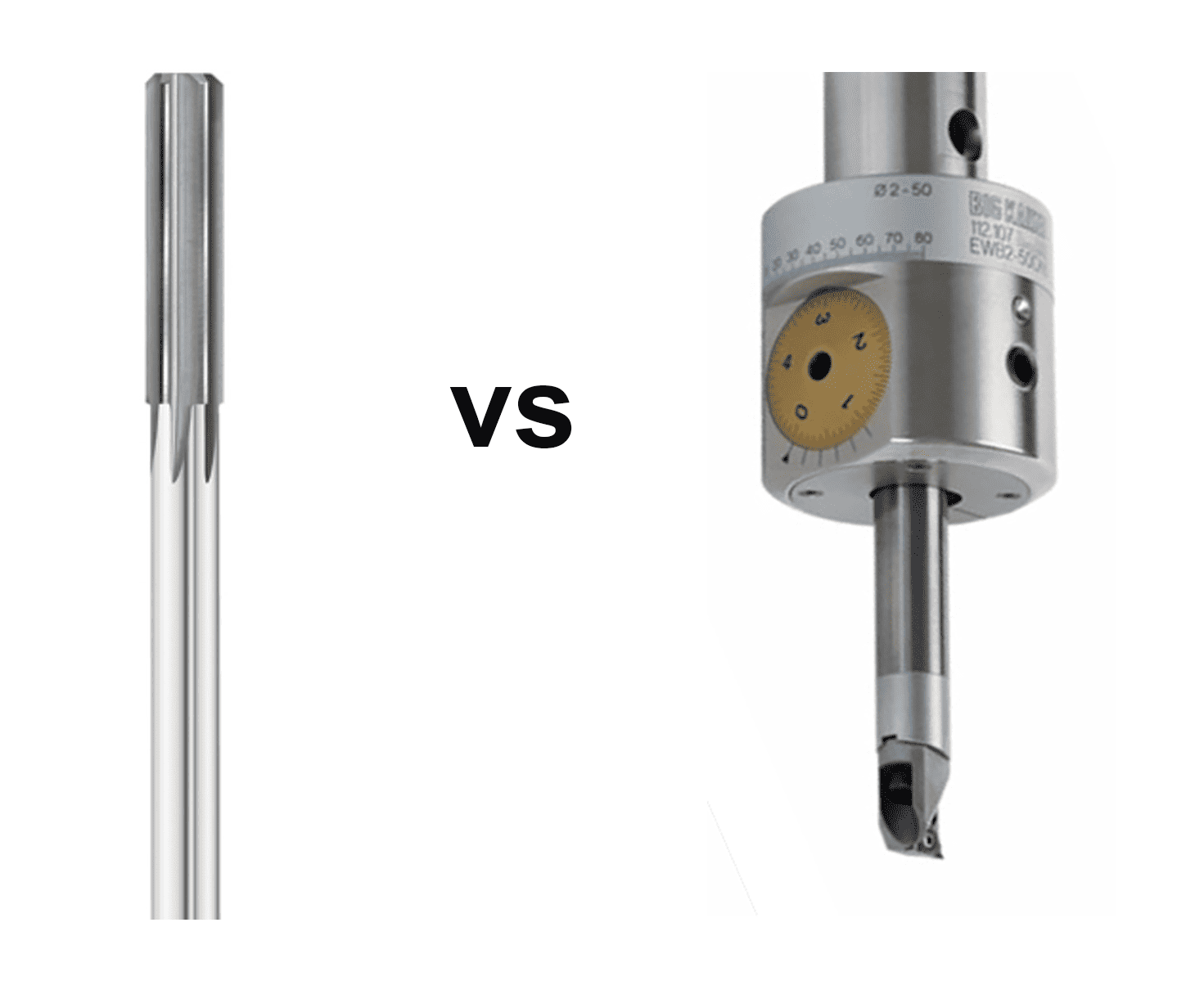

Reaming is a process that focuses on refining the interior walls of an existing hole, such as those created by a drill bit. It aims to generate even walls with a highly accurate and smooth surface finish using rotary cutting tools called reamers. On the other hand, boring is a metal-cutting operation. It enlarges an existing hole diameter using a single-point cutting tool or boring head. In both cases, the actual cutting tool is called a Boring Bar. Both processes involve material removal, but they differ in terms of the cutting tools used and the quality outcomes they produce.

Reaming Explained

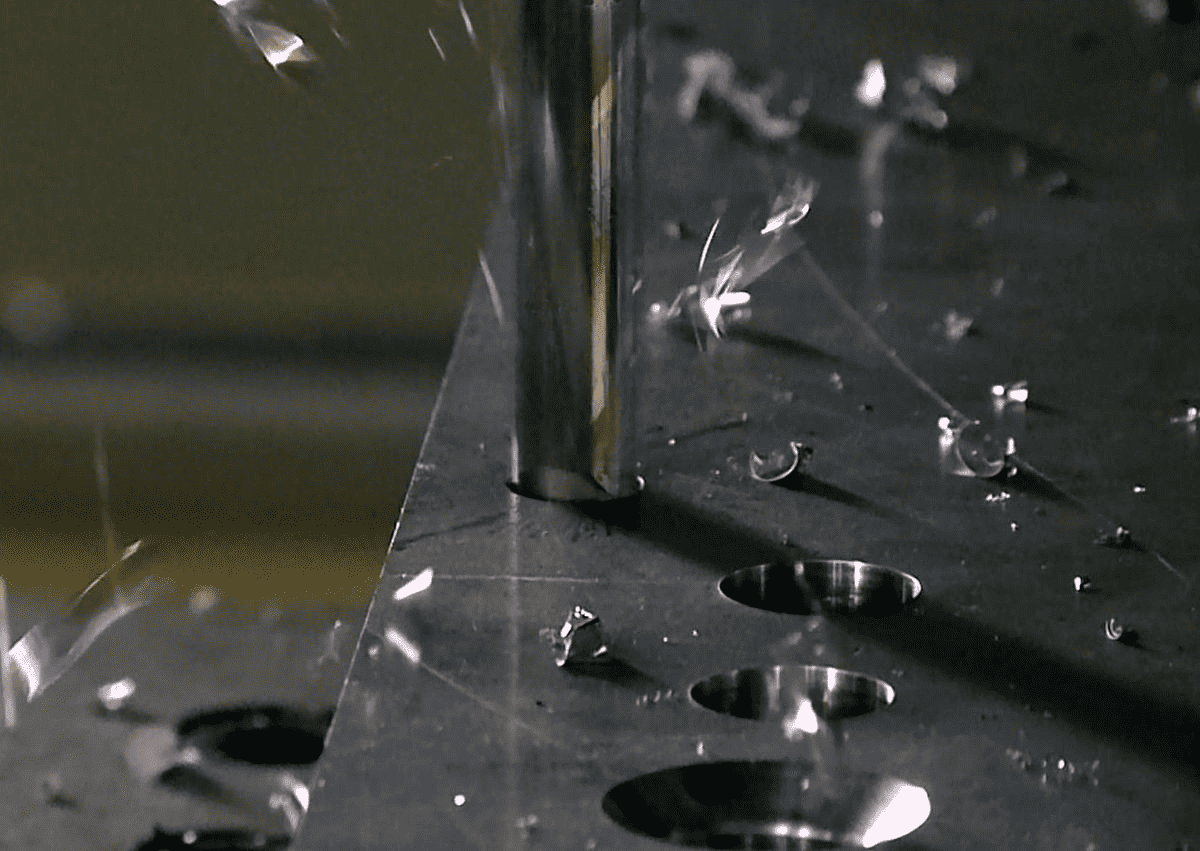

Reaming is a cutting process that utilizes a rotary cutting tool. It creates smooth interior walls in an existing hole of a workpiece. The primary objective of reaming is to refine and smooth out the inner surface of already drilled holes by removing any irregularities and improving the hole’s dimensional accuracy. Reamers, the cutting tools used in reaming, are multi-point cutting tools that evenly remove material from the hole’s interior walls, resulting in a high-quality surface finish.

Reaming is often performed after other machining operations, such as drilling or boring, to finish the inner surface of the hole. It is a versatile process that can be carried out using a milling machine or drill press, depending on the specific requirements of the application. The material removal rate of reamers is significantly lower than that of drill bits, making reaming more suitable for refining existing holes rather than creating new ones.

Boring Explained

Boring is a metal cutting process that involves the enlargement of an existing hole diameter. It is done using either a single-point cutting tool or a boring tool. Boring tools, also known as boring bars, are used to remove material from the existing hole to create a larger, more precise hole diameter. This process is typically employed to create holes that cannot be achieved with standard drilling methods, such as those with a high length-to-diameter ratio or a specific surface finish requirement.

Machines such as drilling, lathe, and milling machines can be used to perform tedious operations. They are helpful when performing repetitive tasks. The single-point cutting tool used in boring is less efficient as it takes more time for machining and a rough surface finish is acquired. However, the accuracy level of this tool is very high.

The boring hole process is a versatile technique that can be applied to various materials and applications, such as engine cylinders, hydraulic cylinders, and other components requiring precise hole enlargement.

Boring is programmed using the G85 and G86 g-codes.

Critical Differences Between Reaming and Boring

Reaming and boring, although similar in some aspects, have distinct differences that set them apart. These differences lie in their process variations, cutting tool characteristics, machinery requirements, and quality outcomes.

By understanding these key distinctions, you can make informed decisions when selecting the appropriate machining process for your specific application.

Process Variations

Reaming and boring both involve material removal, but they serve different purposes in the hole-making process. Reaming is used to create a smoother finish and more accurate hole size by refining the interior walls of an existing hole, often created by a drill bit. In contrast, boring is used for larger holes and can produce a larger hole size than reaming. Boring focuses on enlarging the existing hole, while reaming concentrates on refining the hole’s surface finish and dimensional accuracy.

Process-wise, boring and repetitive can be classified into different types. Boring includes line boring and back boring, whereas reaming consists of rose reaming, shell reaming, and straight reaming, which differ based on hole diameter and contour. Line boring involves supporting the boring bar at both ends, while back boring clamps the bar at one end. The choice of reaming type depends on the specific requirements of the application, such as the desired hole diameter and surface finish.

Cutting Tool Characteristics

The cutting tools used in reaming and boring operations are different in terms of design and function. Reaming employs a multi-point cutting tool called a reamer, which is used to refine and smooth the interior walls of an existing hole. Reamers have multiple cutting edges that evenly remove material from the hole’s interior walls, resulting in a high-quality surface finish.

On the other hand, boring utilizes a single-point cutting tool, also known as a boring head. This is used to enlarge an already existing hole. Boring tools have only one cutting edge that removes material from the existing hole to create a larger, more precise hole diameter. A single-point cutting tool is commonly used in boring. This typically results in lower material removal rate, longer machining time, and a rougher surface finish than other methods; however, it does offer high accuracy.

Machinery Requirements

The machinery requirements for reaming and boring operations also differ. Reaming can be performed using milling machines, lathes, drill presses, CNC machines, and reaming machines specifically designed for the reaming process. These machines usually have a spindle to hold the reamer, which rotates at approximately half the RPM of the drilling operation.

In contrast, boring operations require machines with a boring bar, such as milling machines, lathes, drill presses, CNC machines, and boring machines specifically designed for the boring process. These machines often have adjustable boring heads that allow precise control over the hole enlargement process, with the boring bar held stationary while the workpiece material is rotated against it during the boring operation.

Quality Outcomes

Reaming and boring operations differ in the quality outcomes they produce. Reaming yields a superior surface finish and accuracy compared to boring. This is due to the multi-point cutting tool used in reaming, which evenly removes material from the hole’s interior walls, resulting in a high-quality surface finish. Reaming merely follows the existing hole and is often performed after other machining operations, such as drilling or boring, to finish the inner surface of the hole.

Boring, on the other hand, offers precise positional accuracy, but it produces a coarser surface finish than reaming. This is because the single-point cutting tool used in boring removes material from the existing hole to create a larger, more precise hole diameter. An increase in the depth of cut and feed rate in boring will result in increased surface roughness and a decrease in surface quality.

Applications of Reaming and Boring

Reaming and boring have a variety of applications, which can be seen in the specific uses and industries where they are commonly employed. By understanding the unique capabilities of each process, you can determine which one is best suited for your specific needs.

Let’s explore the different reaming and boring applications to better understand their potential uses.

Reaming Applications

Reaming is typically utilized for the refinement of internal surfaces in metallic components, such as nuts, cylinders, and shafts. It is an essential process in the automotive industry, where it is employed to refine the inner surface of engine cylinders, providing a smoother and more accurate surface finish for better engine performance. Reaming is also used in the aerospace and defense industries, where precision and surface quality are of utmost importance.

In addition to its use in the automotive and aerospace industries, reaming is also employed in various other applications where a high degree of dimensional accuracy and surface finish is required. For example, reaming can achieve a smooth inner surface of a gear or a door lock slot. Its versatility and precision make it a valuable process in various industries that demand high-quality components.

Boring Applications

Boring is primarily used for enlarging holes in various materials, such as tunnels, engine cylinders, and steel or aluminum shafts. It is a widely used process in the construction industry, where it is employed to bore even tunnel openings in solid rock or sand. Boring is also used in the automotive industry to enlarge engine cylinders, providing a larger bore size for increased engine capacity and performance.

In addition to its applications in the construction and automotive industries, boring is also utilized in the manufacturing of steel or aluminum hollow shafts and rods, where it is employed to create precise and accurate bore sizes for various components. Boring’s versatility and ability to create large, precise holes make it an invaluable process in a wide range of industries and applications.

Advantages and Limitations

Both reaming and boring offer significant advantages in their respective applications, but they also come with certain limitations. By understanding the benefits and drawbacks of each process, you can make informed decisions when selecting the right machining process for your specific needs.

Let’s examine the advantages and limitations of reaming and boring operations.

Reaming Advantages and Limitations

Reaming offers various advantages, such as increased feeds and speeds, superior part quality, more holes with consistent quality, cost-effectiveness compared to boring, improved bore quality, and higher cutting speeds with lubrication. Reaming is faster, more cost-effective, and simpler to perform than boring due to the lower cost of tooling and equipment. Additionally, reaming tools and machines are known for their durability and long life, which can result in cost savings over time.

However, reaming has certain limitations, particularly in specific materials and applications. For example, reaming might not be the best choice for materials that are prone to chip or break during the cutting process, or for applications where a larger hole diameter is required. In such cases, boring might be a more suitable option.

Boring Advantages and Limitations

Boring provides several advantages, such as enlarging holes with a high length-to-diameter ratio, a simple and efficient process, durable machines, improved surface quality, and tighter tolerances. Boring is capable of creating larger and more precise hole diameters than reaming, making it suitable for a wide range of applications.

However, boring also has its drawbacks. It can lead to an extended machining time and a coarser surface finish compared to reaming. This is due to the use of a single-point cutting tool in boring, which removes material from the existing hole to create a larger, more precise hole diameter. In applications where a high-quality surface finish is required, reaming might be a more suitable option.

Summary

In conclusion, reaming and boring are two distinct machining processes that serve different purposes and have unique characteristics. While reaming focuses on refining the interior walls of an existing hole for a smoother surface finish, boring is used to enlarge holes with high precision. Both processes have their advantages and limitations, making them suitable for various applications and industries. By understanding the differences between reaming and boring, along with their specific uses, you can make informed decisions when selecting the appropriate machining process for your needs. Remember always to prioritize safety and follow proper guidelines to ensure a safe and successful operation.

Frequently Asked Questions

What is an advantage of a boring head over reaming a hole?

Boring heads are more versatile and forgiving than reaming when machining different hole sizes and when dealing with machine tools with a lot of runout at the spindle.

Why use a reamer instead of a drill bit?

Reamers are preferred to drill bits as they can create smooth walls in an existing hole, without removing too much material and leaving a precise size. They also create a smoother finish compared to hand reaming, which results in rougher edges.

What is the general rule for reaming?

When reaming, a general rule of thumb is to have 0.010" to 0.015" of material remaining for larger hold diameters and 0.003" to 0.005" for smaller hole diameters.

What are the key differences between the cutting tools used in reaming and boring?

Reaming uses a multi-point cutting tool called a reamer, whereas boring uses a single-point cutting tool or boring head, making them distinct in their application.

What are some common applications of reaming?

Reaming is commonly used to improve the accuracy and finish of cylindrical openings, holes, shafts, and nuts. It can also be employed to deburr and chamfer metal pieces.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.