Have you ever checked out Macro Programming for CNC?

For many CNC'ers, their first reaction is going to be that macro programming for cnc is all about hand coding CNC programs instead of using CAM Software. While that is one possible use, it's definitely not to the most common one.

What can Macro Programming for CNC do for you?

Let's forget fancy hand-coded g-code without CAM. If you're someone who does that, you probably already know macro programming. But for everyone else, everyone that normally uses CAM Software to create g-code programs, Macro Programming can give you a lot more power.

We've written a big article about it called, "37 Things Your CAM Won’t Do For You That GCode Programming Can". It's filled with great examples of what you can accomplish with macro programming.

Here are just some of the possibilities:

- Adjusting Feeds and Speeds: Suppose you call out your feeds and speeds as variables in the g-code programming. Put them all at the top where it's easy to access and modify them. You've just made it easy for the gang on the Shop Floor, the ones actually standing in front of machines who can tell what works and what doesn't, to fine tune feeds and speeds for much better performance. By modifying these variables instead of just using Feed Rate Override, their hand tuned inputs are captured for future runs. And, the guys in the programming office can take a look at the new values and see how much they should be tweaking future feeds and speeds to save the Shop Floor guys hand tuning. Before you know it, your shop has created a powerful learning cycle of continuous improvement.

- Deal With Material Variations: Say you make the same parts out of different materials. Perhaps you have standard and premium versions. Or maybe you want to take advantage of opportunities to buy different materials at lower prices that aren't always available. Again, using the right variables, you can set up your programs so that they track multiple feeds and speeds and more. Have the operator input a code for each material you support and the part program will automatically do the right thing.

- Working Around Processing Mistakes: Mistakes and scrap. They're a fact of life in a CNC shop. But, clever reworking can sometimes salvage what would've been scrapped. The trick is how to manage the rework? Macro Programming for CNC to the rescue! Say you mark each tool change in the program and add a function using macros that lets you skip forward to a later tool change. Maybe you only add these as needed for rework as problems develop. But, for example, if a tool breaks and isn't cutting on a pallet of parts, once you have this capability it sure comes in handy.

- Custom Drill Cycles: This is one of my favorites. Deep holes are hard. Even when you master the secret formula to keep from breaking bits right and left, you're still faced with how slow canned cycles can be. The solution is often to use a custom drill cycle. Rather than pecking the whole way down the hole with worst case parameters as many machine canned cycles force you to do, program each segment of the hole to go as fast as it can go. In fact, our G-Wizard Editor has a built in Conversational CNC Wizard that’s tailor made for producing such cycles.

- Entering Offset Data with G10 or System Variables: You don’t have to enter Tool and Work offset data by hand. It can be done in GCode using G10 or System Variables and it can be very helpful to do things this way. In fact, you can load up everything needed for your modular fixture right in the g-code so production is much less vulnerable to operator data entry mistakes.

I could go on with these examples for a long time-there are 32 more in that article I mentioned, and it barely scratches the surface.

Suffice to say-Macro Programming for CNC can be a real Power Tool for most any CNC'er.

How Do I Get Started With Macro Programming for CNC?

I thought you'd never ask!

Well, truthfully, I was betting you would ask once you saw what was possible. That's why I took the time to put together a Mini-Course on Macro Programming for CNC. It's part of our Big Free G-Code Programming Training, but you don't have to go through all of that to get started with Macro Programming for CNC.

This Mini-Course has the initial introductory chapter plus 5 chapters of drill-down on the various specific features and functions you'll want to use for your Macro Programming:

- Parameterized Programming

- Subprograms and Macros

- Conditions and Looping

- Modal Data

- Modal Macro Calls

Frankly, just the first 3 of those chapters is enough for you to do a lot. Even just the first chapter will teach you to use variables and arithmetic in your g-code to accomplish a lot.

The course will walk you step-by-step through macro programming in the Fanuc Macro B syntax. The vast majority of CNC controllers out there use that syntax, so your bases are covered.

Power Tool for CNC Macro Programmers?

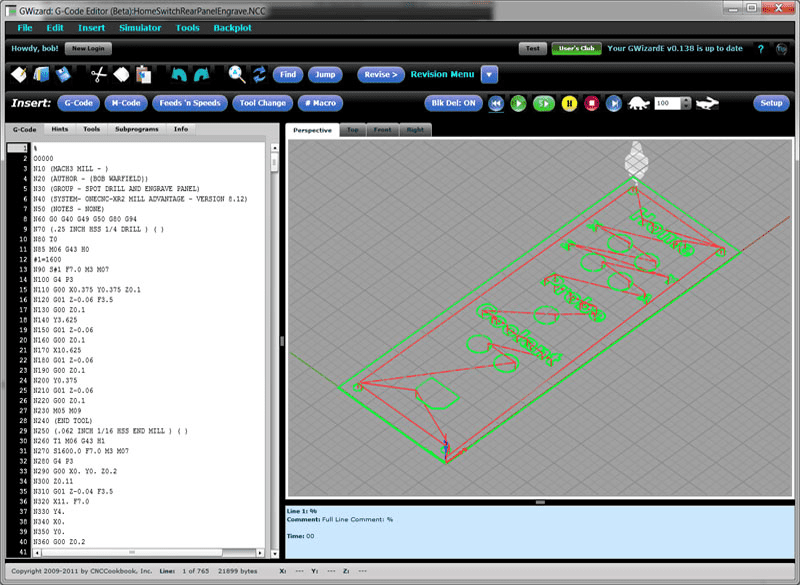

G-Wizard Editor is a powerful gcode simulator and debugger for CNC Macro Programming...

It gets even better. I know macro programming can seem a bit difficult sometimes, so how about a Power Tool to help you out with it?

I'm talking about a piece of software to help you understand what your macro programs do and to save you memorizing all the details. We call it G-Wizard Editor, and customers tell me it totally rocks for Macro Programming.

I'm not going to try to sell you on it here though. Get started on the Macro Programming Mini-Course. It is full of examples that show how you can use G-Wizard Editor to simplify your learning and to make your Macro Programming as easy as possible when you get ready to try it.

All the best software sells itself by making it easy to solve the real world programs its audience faces.

So, go for it. Up your CNC game tremendously and learn some Macro Programming. It's way easier than you think way more useful than you'd ever guess. Just click this link to get started:

Macro Programming for CNC Mini-Training

There are pro training courses with certification available too, but why not start here for free?

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.