If you are unfamiliar with the process, you may not think of using a Vertical Machining Center (VMC) to machine wood. These devices are typically meant for working with metals and plastics, aren't they? While it's true that these materials are their most frequent applications, a VMC can actually be quite effective for machining wood. If your business involves the use of wood, a VMC could be an ideal solution for you. For example, Taylor Guitars, a leading guitar manufacturer, uses Haas VMC's for the creation of their guitar necks. Thanks to MMSOnline for bringing my attention to this fascinating video of Taylor Guitars in action with their VMC's:

See how Taylor uses Haas VMC's to make guitar necks...

With 21 VMC's in production and another 6 for their tooling area, they're not messing around either. Some of the sound bites that impressed me from the video:

- A VMC makes 8 necks in about 35 minutes of cycle time.

- One ballnosed endmill will last for 10 days making 100 necks/day during that time-so it's good for 1000 necks.

- The pocket tolerance is 0.003". They've got to hold that in wood (an organic material that isn't exactly stable) to create the pocket that the guitar neck is bolted into.

- They use vacuum fixturing to hold the necks down-nice workholding solution.

Precision inlay work and engraving is also found on custom guitars and is another great application for a VMC. Here's another video showing how Peavey uses a high speed air spindle to do this kind of thing:

Engraving the Peavey logo on a guitar with a high speed air spindle...

The Air Turbine Spindle used in this example offers some important advantages for the application:

- High rpm-the engraving is done on precious wood at 25,000 rpm at 2000 IPM of feedrate with a 0.003" depth of cut.

- The spindle is oil free-last thing you want is any kind of oil contamination on the precious wood.

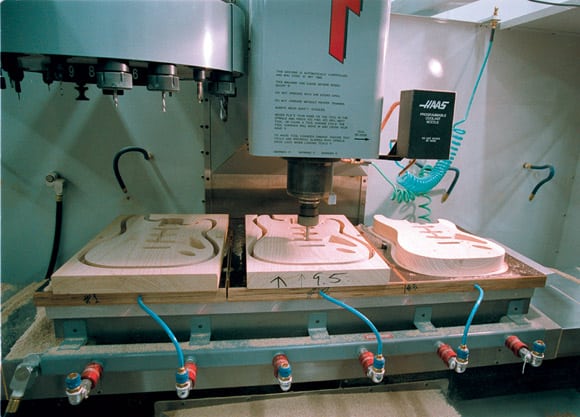

Or, how about Fender's custom guitar shop? There could hardly be a more iconic name in guitars, but they've definitely been successful applying VMC's to their work:

Making Fender electric guitar bodies on a Haas VMC. Note the vacuum fixtures!

I'll give kudos to the MMSOnline guys one more time and stay on the subject of machining wood on VMC's for guitars with their article about how Thorn Custom Guitars uses VMC's on wood. To say their guitars are gorgeous would be an understatement:

The Grantura, one of Thorn's premier custom guitars...

You may be wondering how the highest quality guitars can justify using a CNC machine instead of being 100% hand crafted. I loved the response of Fender's John Page to this question:

When John Page, co-founder and long-time head of the prestigious Fender Custom Shop, was asked how he could consider bringing a computer-controlled milling machine into a shop with a worldwide reputation for building custom, handmade guitars, he answered simply, “When was the last time you chewed down a tree?”

The retort by Page was not so much a snide remark as it was a realistic observation illustrating how power tools actually are a very vital element in the world of today's craftsmen. In order to keep final costs somewhat affordable, today’s luthier (guitar builder) is willing to leave the preliminary rough work to more economical, yet accurate, mechanical means.

What's Special About Machining Wood on a VMC?

There are some things to look out for if you're planning to machine wood on a VMC:

- Make sure the ballscrew and waycovers will provide adequate protection against the wood dust. There'll be no liquid coolant to keep the dust down and it'll go everywhere it can.

- Look for high speed spindle options. Life begins at 10,000 rpm with wood and more is better. Take a look at the CNC Router crowd to get an idea.

- Make sure you're set for higher feed rates. With those high spindle rpms, high feed rates are not far behind.

- To keep up, you may want to check into higher block per second processing options for your machine. It isn't just the high rpms and feedrates, if you plan to do flowing organic curves, these will often be simulated as thousands of short line segments. Your control will have to keep up with many blocks per second to keep that gcode flowing smoothly into motion. While we're on that subject, get plenty of RAM so you can keep large 3D profiling part programs in memory.

- If tolerances are going to be tight, look for climate control in your facility to help minimize shrinking and expansion in the wood you'll be machining. I wonder whether some RAMTIC-style in-process probing might not also be an answer to tolerances in a material like wood that won't sit still.

- You won't be using liquid coolant, but you can use a chip auger and you'll also want to make provision to vacuum out the machines from time to time to keep the dust under control.

- Wood, especially plywood and thin veneers, can splinter or tear out. Learn the best techniques for CNC machining plywood and similar materials to prevent splintering.

You might want to take a look at some Feeds and Speeds scenarios around wood in our G-Wizard Calculator to get an idea of where the sweet spots are for spindle rpm and feedrate. It even has a CNC Router setting and has the specialized kinds of cutters common in woodworking applications.

Why Not a CNC Router?

Many of you are certainly wondering by now why these shops choose to use VMC's over gantry-style CNC Routers?

Some of the reasons given were:

- Cost: For the level of precision, the VMC's were cheaper

- Floor Space: Most of the gantries are set up to take 4×8 sheets. These custom shops are doing smaller runs and they're not machining plywood sheets. The desire to include climate control to keep the wood stable also means shop floor square footage is at a premium. Smaller machine footprints help keep this cost under control.

- Precision: Inlay and similar kinds of work require precision that is very costly in a CNC Router.

- Dust Control: The full enclosure of a VMC really helps keep the dust down in the shop.

- Tool Changer: While they're certainly available for CNC Routers, they're standard on VMC's. Fender needs 21 tools for their application and keeps 20 in the changer and the 21st sits in a dedicated space on the table where the spindle can fetch it as needed.

Given a VMC, another difference will be a desire to use some of the specialized cutters made for CNC Routers. For example, a downcut endmill pushes the chips down rather than pulling them up. When you pull the chips up, it can split the wood. It's no problem to run the specialized cutters in a VMC once you know about them and their application. We have produced an article especially to help introduce them to you. VMC's can be perfectly capable wood cnc machines.

Conclusion

For the right type of work, a VMC can be exactly the right machine for wood. There are certainly going to be cases where the same is true of a CNC lathe. You just need to understand the special requirements of the medium and how to match those to the capabilities of the VMC.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.