Imagine the endless possibilities of creating intricate designs, carving intricate shapes, and fabricating your custom parts using your very own CNC machine. Whether you are an experienced engineer or a hobbyist looking to dive into the world of CNC, one crucial element remains the same for all: the GRBL software.

In this blog post, we’ll guide you through the ins and outs of GRBL, its role in CNC machines, setting up your CNC machine, and much more. Your journey to mastering CNC machines and GRBL starts here!

Short Summary

- GRBL is an open-source software that enables precise control of CNC machines.

- It offers superior motion control, accuracy, speed, and cost-effectiveness when used with Arduino boards.

- Alternatives to GRBL can be explored for specific needs and projects by understanding their advantages and limitations.

- GRBL is especially well-suited for DIY CNC Machines.

Here's a video showing how to use the GRBL Panel:

Understanding GRBL and Its Role in CNC Machines

GRBL is open-source software that translates G-codes into motor movements for precise control in CNC machines, ensuring accurate operation and flawless execution of your designs. The process starts with CAD software, which reads the design, and then CAM software converts it into G-codes. These G-codes are the lifeblood of your CNC machine, controlling everything from the laser module to the cutting and engraving processes.

While GRBL is a powerful tool, it does have its limitations, such as controlling a maximum of 3 axes and requiring specific Arduino pins for proper functioning. However, its compatibility with Arduino boards makes it a popular choice for many CNC enthusiasts. From milling to metal engraving, GRBL plays a crucial role in bringing your CNC projects to life.

The Importance of GRBL in CNC Operations

GRBL is an embedded, high-performance software designed for controlling the motion of machines that move, create, or both. Its compatibility with a range of CNC machines and superior motion control makes it a top choice for applications such as milling, laser cutting, and metal engraving.

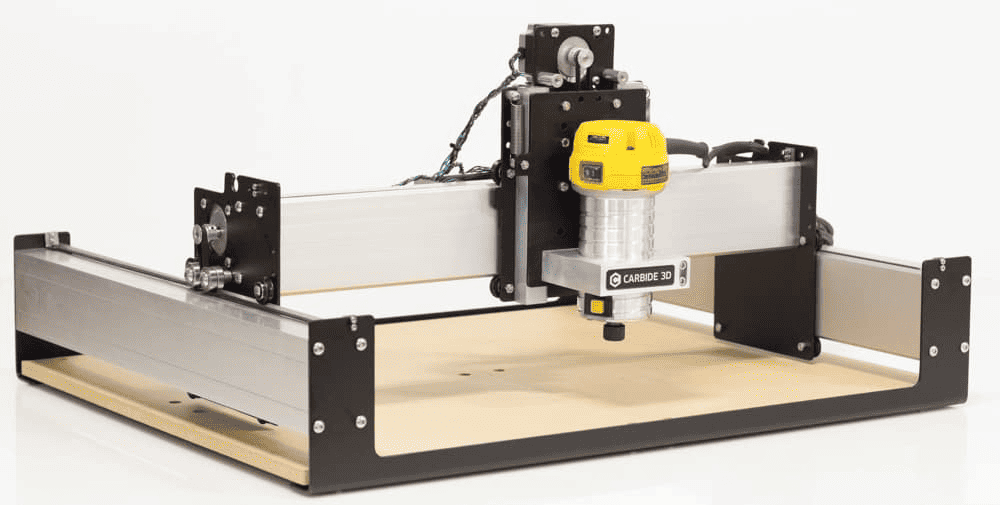

When selecting your first CNC machine compatible with GRBL, it is important to consider factors like the type of machine, worktop size, laser power, and control software. GRBL offers numerous advantages for motion control, including superior accuracy, rapid operation, and economical cost, making it an ideal choice for controlling CNC machines with Arduino Uno.

Compatibility with Arduino Boards

GRBL and Arduino boards, specifically ATmega328-based systems, go hand in hand, providing seamless integration for your CNC projects. GRBL interprets G-codes and communicates the necessary signals to Arduino, which subsequently manages the stepper motors of the CNC machine.

This close relationship between GRBL and Arduino ensures precise and efficient control of your CNC machine, ultimately giving life to your creative designs.

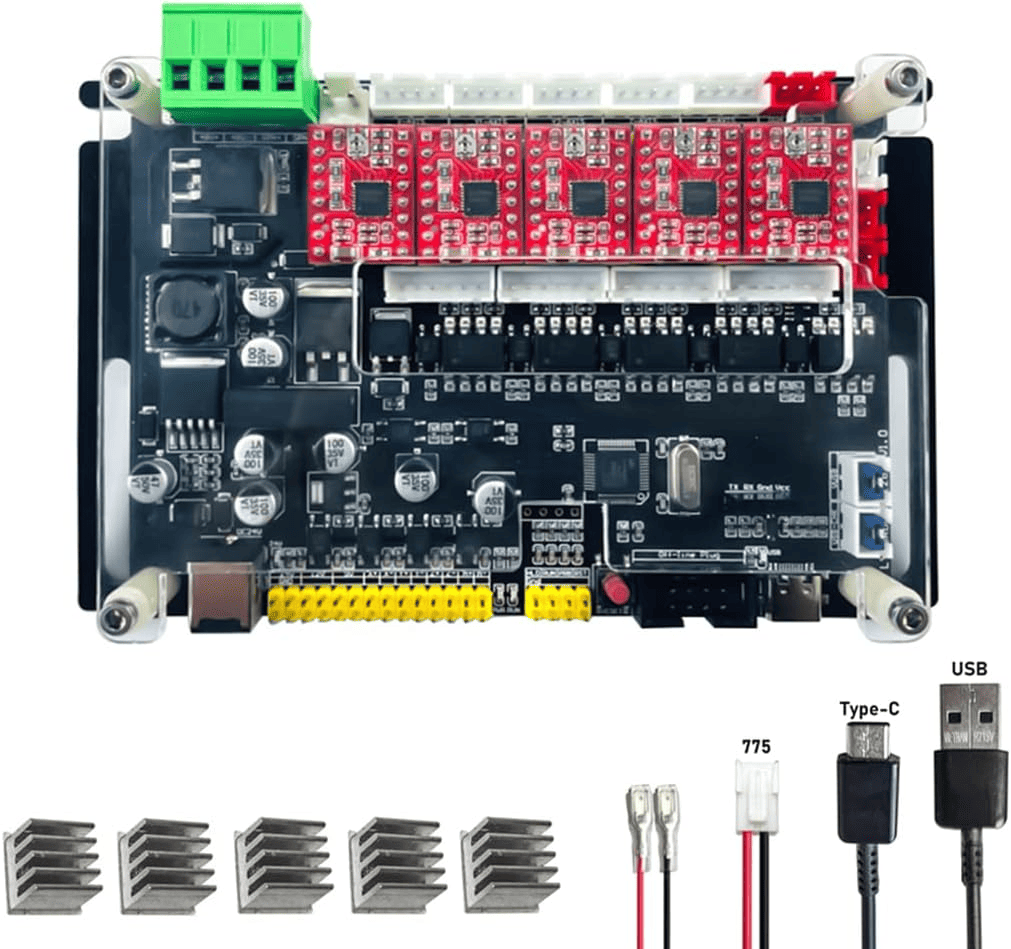

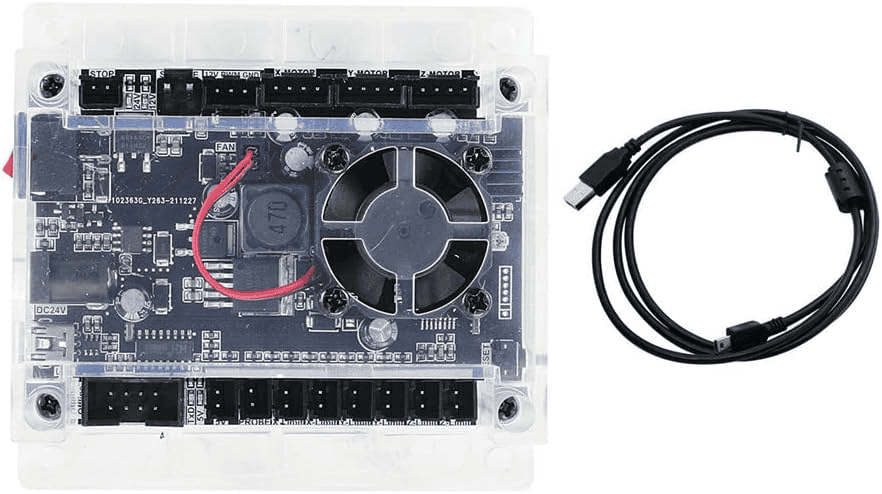

You can also purchase boards that are all set of with GRBL, eliminating the need to configure a blank Arduino board. Here is a typical 4-axis GRBL board available on Amazon:

GRBL Controller Board available on Amazon for about $59,,,

Setting Up Your CNC Machine with GRBL and Arduino

Setting up your CNC machine with GRBL and Arduino is a straightforward process that will have you up and running in no time. Once you’ve installed the GRBL firmware on your Arduino board, configuring the settings is crucial for achieving precise control of your CNC machine. From adjusting parameters such as steps per mm to setting the motor direction, the Arduino IDE serial monitor serves as your command center for fine-tuning your machine’s performance.

With your CNC machine set up and ready for action, it’s essential to test your configuration by executing a few simple commands in the Serial Monitor. This will ensure your machine is calibrated correctly and help you identify any issues that may need troubleshooting, such as soft limit alarms or unsupported G-codes.

Installing GRBL Firmware on Arduino

Before you can dive into the world of CNC machines, you’ll need to install firmware on your Arduino board. First, download and install the Arduino IDE tool. Then, download the latest release of GRBL from GitHub and extract the contents of the associated zip file.

Locate the ‘grbl’ folder in the Arduino library folder and navigate to ‘Sketch > Include Library > Add.ZIP Library’ in the Arduino IDE to load the GRBL library. With the GRBL library loaded, you can flash the firmware using the Arduino IDE by following the instructions provided.

Configuring GRBL Settings

Click the icon located in the top right corner of the Arduino IDE window. This will open the serial monitor and allow you to configure GRBL settings. To view the current settings of your Arduino system, type the command “$$” and press enter. The values displayed represent various parameters of your CNC machine, such as steps per mm and motor direction.

Adjusting these settings is as simple as entering the corresponding command with the desired value and pressing enter. It’s important to ensure that you’ve plugged into the correct port and set the baud rate to 115200 to guarantee seamless communication between your Arduino board and the Serial Monitor.

Choosing the Right Hardware for Your CNC Machine

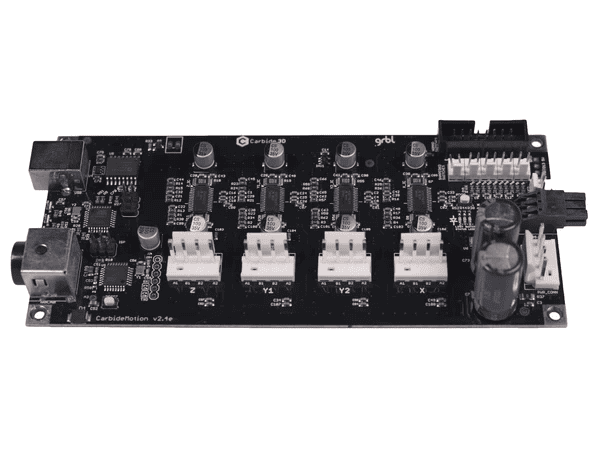

Shapeoko GRBL controller board...

The right hardware is essential for optimal performance and precision in your CNC machine. Stepper motors, motor drivers, and Arduino CNC shields are the key components that work together to bring your designs to life. Each component plays a crucial role in the overall operation of your CNC machine, and selecting the right hardware ensures your machine runs efficiently and accurately.

Understanding the role of each component and its compatibility with GRBL and Arduino boards is essential in building a CNC machine that meets your specific needs. From the power of the stepper motors to the features of the Arduino CNC shield, careful consideration of each component will help you create a CNC machine that is both reliable and precise.

Stepper Motors

Stepper motors are the driving force behind your CNC machine, generating motion through the control of electromagnetic fields that activate at different times, moving components in a predetermined sequence. These motors offer excellent performance with economical advantages for applications that require low speed, acceleration, and positioning accuracy.

Selecting the right stepper motor for your CNC machine is crucial for achieving the desired level of precision and control in your projects.

Stepper Motor Drivers

Stepper motor drivers are a vital component in CNC machines, converting low-level TTL signals from an Arduino into high-power signals for the stepper motor. These drivers provide precise electric pulses, allowing for the desired motion to be achieved.

Small-size stepper motors, such as NEMA 17, A4988 or TB6600, are recommended for DIY CNC machines. Stepper motor drivers can be selected accordingly. Choosing the right motor driver ensures your CNC machine operates smoothly and accurately.

Arduino CNC Shields

Arduino CNC shields enhance the functionality of Arduino boards for GRBL-based CNC machines, providing connectivity options for various components like stepper motor drivers, limit/homing switches, spindle/laser heads, cooling fans, and more. These shields enable your CNC machine to control multiple stepper motors and other components, ensuring optimal performance and precision in your projects.

Selecting the right Arduino CNC shield is essential for a seamless and efficient CNC experience.

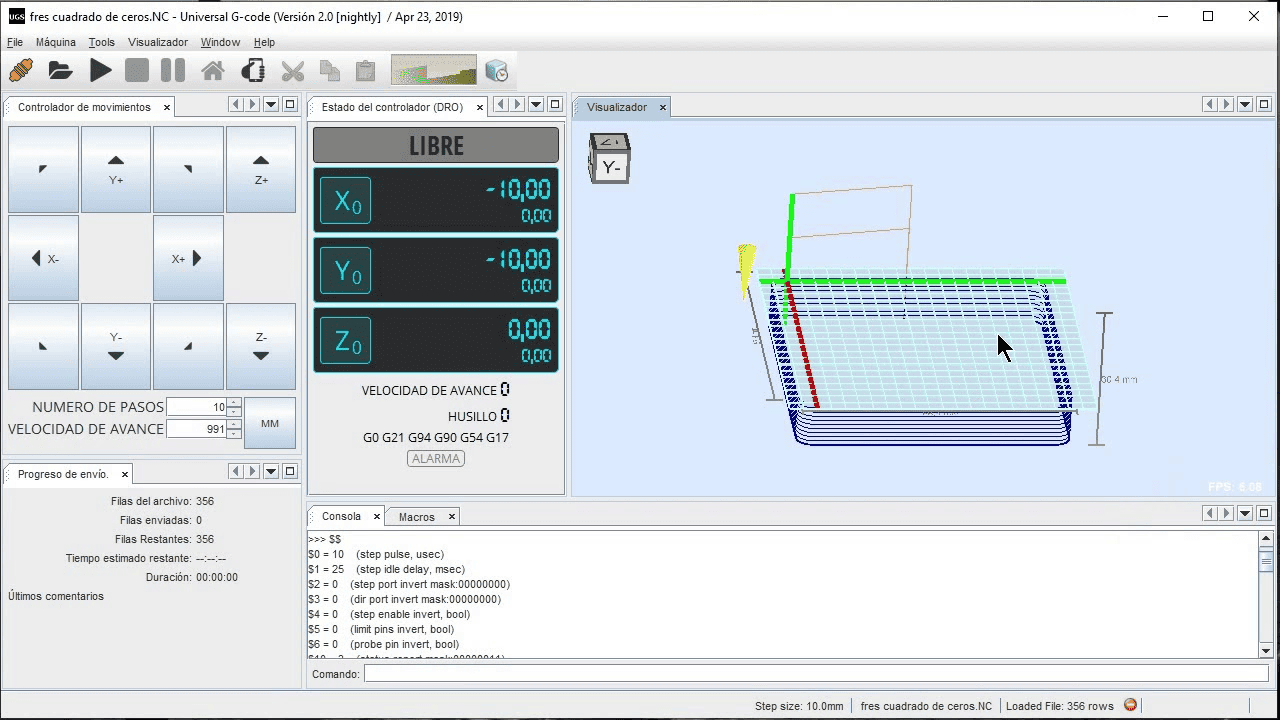

Using GRBL Controller Software

GRBL controller software, such as Universal G-code Sender (UGS), allows you to configure and control your CNC machine with ease and precision. This software provides a user-friendly interface for managing your CNC machine and adjusting the GRBL settings, ensuring optimal performance and accuracy in your projects.

From setting up your CNC machine to troubleshooting common GRBL issues, GRBL controller software is a valuable tool for any CNC enthusiast. Universal G-code Sender (UGS) is a popular choice for configuring and controlling CNC machines with GRBL. It offers advanced features like adjusting the steps/mm parameter and motor direction, making it an essential tool for fine-tuning your CNC machine’s performance.

With UGS, you can effortlessly manage your CNC machine and ensure it operates at its full potential.

Configuring and Controlling CNC Machine with UGS

GRBL controller board...

Setting up and controlling your CNC machine with Universal G-code Sender is a simple process. To adjust the steps/mm parameter, click the move “x+” button, measure the actual movement of the machine with a ruler, and enter the corresponding value in the “Actual movement” field. The UGS Setup Wizard will then calculate and suggest a new value for the steps/mm parameter.

To verify and adjust the direction of motor movement, select the direction of moving of the motors in the wizard and reverse it if required, or manually flip the connection of the motor on the Arduino CNC Shield. The default value for the steps/mm parameter in the UGS Setup Wizard is 250 steps/mm, and the recommended baud rate is 115200.

Troubleshooting Common GRBL Issues

Even with the right hardware and software, you may encounter some common GRBL issues that can affect the performance of your CNC machine. Troubleshooting these issues is essential for ensuring seamless CNC operation and maintaining the precision and accuracy of your projects.

From soft limit alarms to unsupported G-codes, addressing these problems will help you avoid potential pitfalls and keep your CNC machine running smoothly. By examining the GRBL settings, confirming hardware compatibility, and utilizing the appropriate GRBL controller software, you can effectively troubleshoot and resolve common GRBL issues.

With the right knowledge and tools at your disposal, you can confidently tackle any challenges that may arise during the operation of your CNC machine, including working with a CNC mill, and ensure optimal performance in your projects.

Soft Limit Alarms

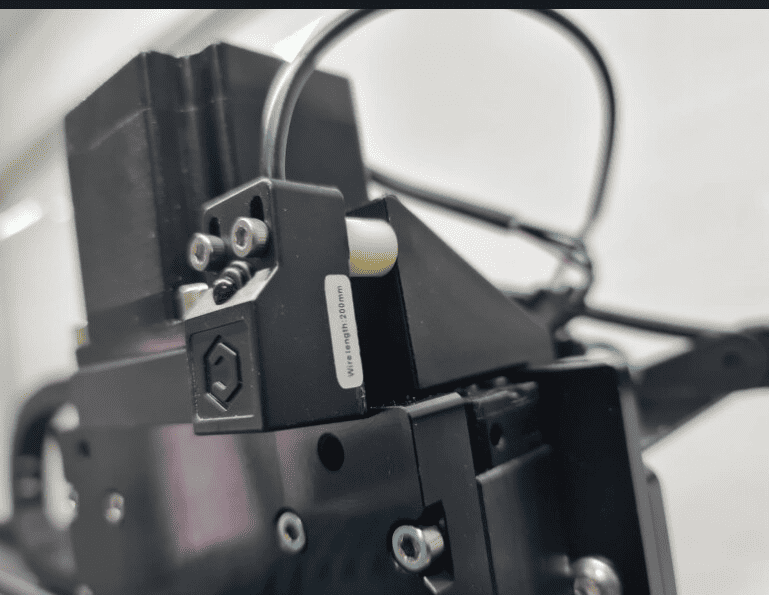

Shapeoko's Z-Axis soft limit alarm sensor...

Soft limit alarms are errors that arise when the CNC machine mistakenly interprets the position of the tool to be at the limiting value, despite it being within the operational area of the machine. These errors can be attributed to a range of causes, such as limit switches, mechanical issues, or configuration difficulties.

To resolve soft limit alarms, manually reset the machine to the origin by moving the router to the origin coordinates (0,0,0) and initiating a GRBL system restart. This will help you avoid potential damage to your machine and maintain the accuracy and precision of your projects.

Unsupported G-codes

Unsupported G-codes in GRBL can cause your CNC machine to function improperly, potentially resulting in unexpected pauses in the process. GRBL does not facilitate automatic tool-changing codes, which can cause issues during operation.

To troubleshoot an unsupported G-code error in GRBL, carefully examine the line of code that is causing the error and modify the code accordingly. By identifying and rectifying unsupported G-codes, you can ensure the smooth and efficient operation of your CNC machine.

Exploring Alternatives to GRBL

While GRBL is a versatile and reliable firmware for CNC machines, it’s essential to consider the advantages and limitations of each alternative before making a decision, as there may be more suitable options for certain applications. Some alternatives to GRBL include LinuxCNC, Marlin, and AccelStepper, each offering unique benefits and capabilities. By exploring these alternatives, you can expand your CNC toolkit and find the perfect solution for your specific needs and projects.

Understanding the advantages and limitations of each alternative to GRBL will help you make an informed decision when selecting the most suitable firmware for your CNC machine. From servo motor control to advanced features and capabilities, each alternative offers unique benefits that may align better with your specific needs and CNC projects. It’s important to weigh the pros and cons of each option to ensure optimal performance and precision in your CNC endeavors.

Advantages and Limitations of Each Alternative

Each alternative to GRBL has its own set of advantages and limitations. LinuxCNC is a powerful and versatile option with an extensive range of features and capabilities, but it may be more complex to use than GRBL and require more technical expertise to set up and configure.

bCNC offers a user-friendly experience compared to GRBL and features a graphical user interface with advanced capabilities, but it may not be suitable for all users due to these advanced features.

Universal G-code Sender is a free and open-source alternative that is user-friendly, but it may not possess all the features and capabilities of GRBL. By considering the advantages and limitations of each alternative, you can find the perfect match for your CNC machine and projects.

Summary

In conclusion, understanding the role of GRBL in CNC machines, setting up your CNC machine with Arduino, choosing the right hardware components, and using GRBL controller software are essential for optimal CNC operation. Troubleshooting common GRBL issues and exploring alternatives to GRBL can help you ensure seamless CNC operation and maintain the precision and accuracy of your projects. With this knowledge and the right tools at your disposal, you can confidently navigate the world of CNC machines and bring your creative designs to life.

Frequently Asked Questions

IS GRBL the same as G-Code?

No, GRBL is not the same as G-Code. G-Code is a set of commands for the CNC machine to follow and GRBL is an open-source software that translates the G-Code commands into motion control instructions for the CNC machine.

GRBL is used to interpret G-Code and generate motion control signals for the CNC machine.

What does GRBL stand for?

GRBL is an acronum for 'G-Code Reference Block Library', a popular open-source software for CNC machines.

This powerful tool offers support for real-time control of motion, by processing commands from different sources like G-Code files or direct serial communications.

It is designed to be easy to use and understand, with a simple user interface and a wide range of features. It can be usedto control a variety of machines, from 3D printers, to laser cutters and milling.

What is the function of GRBL?

GRBL is a free, open-source software that enables motion control on CNC machines using an Arduino. It translates G-Code commands into motion instructions and can be used in combination with Arduino Uno to execute commands and control machine movement.

It is a cost-effective way of controlling a CNC machine, making the setup much simpler and more intuitive.

Is GRBL good for CNC?

RBL has quickly become the go-to controller firmware for many CNC users, due to its feature set and ease of use. Its USB connection eliminates the need for a parallel port on your computer and it is able to handle three-dimensional G-Code commands.

With GRBL, hobbyists and professionals alike can access high-quality CNC control with minimal hassle. Thus, GRBL is an excellent choice for any CNC user.

How do I install GRBL firmware on my Arduino board?

Installing the GRBL firmware on an Arduino board is relatively straightforward. Begin by downloading and installing the Arduino IDE, followed by downloading the latest GRBL release from GitHub and extracting the contents of the associated zip filee.

Finally, upload the GRBL library into the Arduino IDE and flash the firmware as per the instructions included.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.