Key Takeaways

- A Dial Indicator measures how far up the plunger moves while the Dial Test Indicator measures how far the tip of a needle moves when deflected sideways.

- Dial Indicators and Dial Test Indicators are available in a variety of accuracies and styles. The DTI’s are typically available with finer accuracy. I have both a half thousandth (0.0005″) and tenths (0.0001″) Interapid DTI’s. The most common accuracy for a Dial Indicator is 0.001″.

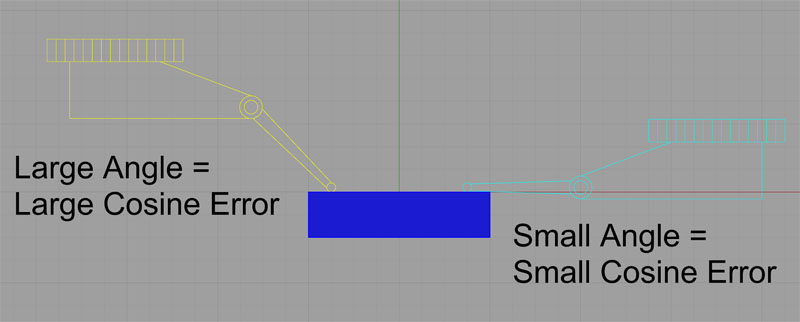

- Given that DTI’s work by deflecting the needle through an angle, they are subject to something called “Cosine Error”. To minimize the error, use the DTI with it’s arm as close to the center of travel as possible.

- It’s often convenient to use a Dial Test Indicator with a magnetic base. The magnetic base will secure the indicator where it’s needed and a fine adjustment lets you zero the indicator. Noga makes some of the best Dial Indicator Stands.

Dial Test Indicators & Dial Indicators (DTI, Dial Gauge, Digital Dial Indicator, Digital Dial Gauge)

Dial Indicators are also known as Dial Gauges.

First, what's the difference between a Dial Indicator and a Dial Test Indicator?

It's pretty simple. The Dial Indicator has a plunger and reads how far the plunger is raised by the surface below. The Dial Test Indicator has an arm that sweeps an angle. It measures how far the arm is pushed sideways. Both are handy, but you'll tend to use a Dial Test Indicator more often.

These photos should make the differences clear:

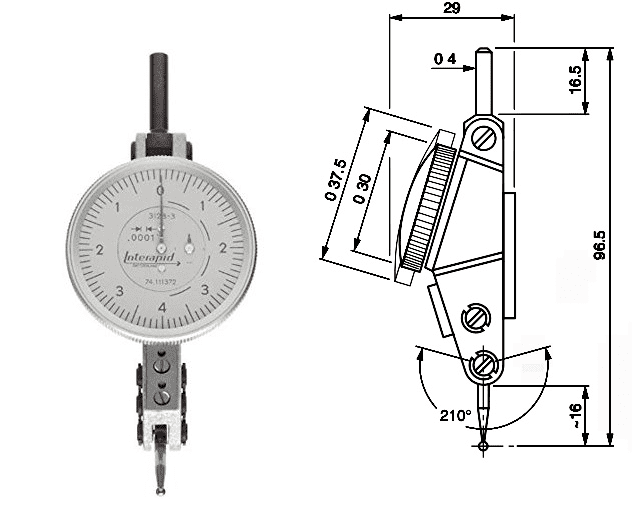

Interapid Dial Test Indicator, Tenths Accuracy (0.0001")...

Once again, a Dial Indicator measures how far up the plunger moves while the Dial Test Indicator measures how far the tip of a needle moves when deflected sideways.

Dial Test Indicators usually have a Balanced Dial, meaning they can read comparative distances if the needle is deflected in either direction. Dial Indicators will have Continuous Dials, meaning they read the total displacement of the plunger. The Continuous Dial may also have a smaller sub-dial that measures how many full revolutions about the Continuous Dial have been made.

Why use the Dial Test Indicator more often?

Largely because these instruments are typically used to measure relative motion, not absolutes. For example, to ensure a vise jaw is square with the travel of the machine, you would sweep the arm of a Dial Test Indicator over the jaw while moving in the direction of travel. The DTI (Dial Test Indicator) will read how far off square the vise jaw is on its Balanced Dial. When it doesn't move (or doesn't move more than is acceptable for your application), you will have verified it is square and you can lock down the vise.

There are also operations where the Dial Indicator is handy. For example, you might determine the zero point on your machine's Z-axis by putting a Dial Indicator in the spindle and jogging down Z until the indicator is zeroed on its Continuous Dial.

Dial Indicators are often mounted using a lug on the back. Dial Test Indicators typically mount via either a dovetail or a small shank that can go into a collet or chuck.

A common specification for Dial Indicators is their Stem Diameter. A typical stem diameter is 0.375".

Interapid: The Best Dial Test Indicators

I've tried a bunch of Dial Test Indicators from Starrett, Interapid and others, and I have to say, the Interapid's are my favorite. They're Swiss-made, and a tenths indicator will set you back $245, but they're darned well worth it. For a beginner, I'd get the half-thou version and purchase a tenths indicator later. A half-thou Interapid DTI costs a little less at $184.69 and they're a little less sensitive so adjustments are less fiddly.

They have a balanced dial and some special features that help minimize cosine errors. They're just extremely well made.

Digital Dial Indicators

Mitutoyo Digital Dial Indicator. About $162.31 on Amazon...

Dial Indicators are available with Digital Readouts too, but most prefer the analog dial. As mentioned, they're often used for making relative measurements, and it's harder to see relative motion with a digital readout than an analog dial. Digital Dial Indicators are also called Electronic Indicators. An advantage they have is they're typically better at measuring small linear distances.

By definition, Electronic Indicators all have Continuous Dials. Other than the electronic readout, Electronic Indicators are pretty similar to Dial Indicators. Same stem diameter, and so on.

Dial Indicator Stand

It's often convenient to use a Dial Test Indicator with a magnetic base. The stand will secure the indicator where it's needed and a fine adjustment lets you zero the indicator.

Here's a Noga Magnetic Indicator Stand, one of the best:

Noga Magnetic Indicator Stand (about $84.95 on Amazon)...

Dial Indicator and Dial Test Indicator Accuracy

Dial Indicators and Dial Test Indicators are available in a variety of accuracies and styles. The DTI's are typically available with finer accuracy. I have both a half thousandth (0.0005") and tenths (0.0001") Interapid DTI's. The most common accuracy for a Dial Indicator is 0.001".

Cosine Error

Given that DTI's work by deflecting the needle through an angle, they are subject to something called "Cosine Error". To minimize the error, use the DTI with it's arm as close to the center of travel as possible:

Check out our article for more on Cosine Error.

Dial Indicator Do's and Don'ts

- Do ensure you always protect the spindle by keeping it clean

- Do ensure the indicator hand is able to move freely. It must be able to move to its fullest extent as well as to the zero end of the scale in one fluid movement. Make sure the stem diameter is small enough that it isn't grating against your workpiece or workholding.

- Do ensure you use your indicator correctly by securely affixing it to the holding device or magnetic base.

- Do use your dial indicator often to prevent the spindle from sticking. Even testing it periodically throughout a month will ensure the spindle continues to move freely, especially if stored correctly.

- Do ensure you keep your dial indicators stored away correctly in a dry place and try to keep them covered to minimize dust and moisture getting into the dial.

- Do clean the dial with warm soapy water and try to keep the dial clean and dry at all times.

- Do ensure you carry out regular testing of the indicators.

- Do keep the reference surface clean.

- Don’t use an indicator that has been hit with something heavy or dropped. If this happens then you should try it to ensure it still does its job correctly

- Don’t over-tighten contact points or adapters. This can cause a distortion in the measurements or cause the spindle to bind or the mechanism to stick.

- Don’t forget to look at ways to achieve a better outcome, such as considering accessories to make your indicator more efficient. These kinds of accessories include right-angle attachments or lifting levers

- Don’t lock your indicator into position without first setting it to gage tension correctly

- Don’t treat indicators with sudden or harsh movements or blows, as this can affect the delicate balance

Conclusion

This guide has been part of our Free Metrology Course:

CNCCookbook Free Metrology & Machinist's Tools Course

Frequently Asked Questions (FAQs)

What is the dial indicator used for?

One use for a dial indicator is to indicate the run-out (or misalignment between the workpiece's axis and the axis of rotation of the spindle) of the workpiece. The ultimate aim is to reduce it to a suitably small range using small chuck jaw adjustments. For example, on a 4-jaw chuck.

What is the working principle of dial indicator?

The working principle of a dial indicator is that it transforms mechanical displacement into rotation motion which is amplified and displayed on a graduated dial.

What are the two types of dial indicators?

The two types are the dial indicator and the dial test indicator.

A dial indicator measures how far up the plunger moves while the Dial Test Indicator measures how far the tip of a needle moves when deflected sideways.

Where would a dial test indicator be used?

The two tool are used for different applications.

A Test Indicator is used for layout work on surface plates or aiding in part setup during the machining process. A dial indicator is used for comparative measurements with gages and fixtures.

What's the difference between a balanced dial and a continuous dial?

A balanced dial reads both clockwise and counterclockwise. They're most commonly found on Dial Test Indicators.

A continuous dial can read either clockwise or counterclockwise, but not both. They're most commonly found on Dial Indicators and may include a small dial that counts how many rotations around the full continuous dial the needle has made.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.