Daniel Herrington, CEO

Customer Spotlights are a regular CNCCookbook blog series where we tell our audience what the folks using our software are up to. This week we are spotlighting Voxel Innovations, which has developed a unique machining process called Pulsed Electrochemical Machining (PECM). For this spotlight I worked with Daniel Herrington, Voxel's CEO and Founder and Michael Bromley, their Lead Engineer.

Glad to have you for our Customer Spotlight series! I'd like to start out by asking you to tell us a little about your business?

Voxel is a start-up company focusing on a process called Pulsed Electrochemical Machining (PECM). Unlike other material removal processes which cut, abrade, or ablate metal, our PECM process dissolves the material and we do it without any tool wear. We take products from R&D or prototypes all the way to production with a focus on tight tolerance designs and hard-to-machine alloys in the medical, energy, and aerospace sectors.

Bevel and straight gears manufactured with PECM...

Bevel and straight gears manufactured with PECM...

How did you come up with the idea for your business?

A few years ago, I made a change in my career to focus on what I thought was an overlooked aspect to enabling new innovations – manufacturing. During some consulting work I was introduced to electrochemical machining and saw an opportunity to both bring this technology to a wider US market and to fundamentally improve the process. In general, tolerances get tighter, materials get harder, and features get smaller – all of which plays towards the strengths of PECM.

Tell us more about PECM-how does it work?

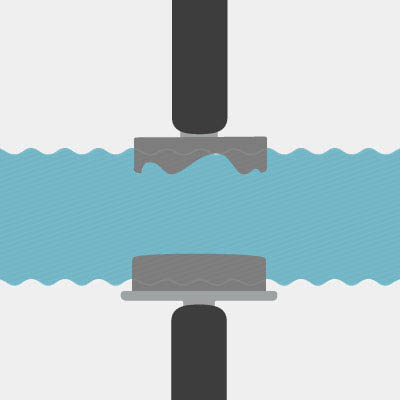

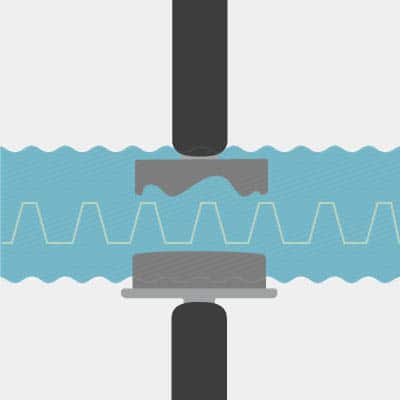

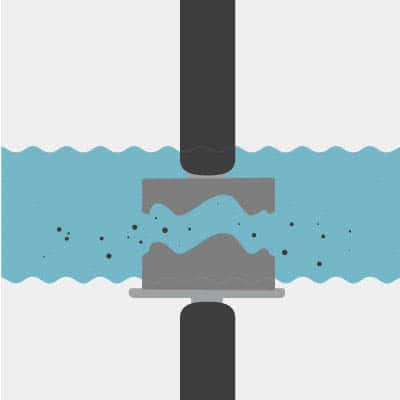

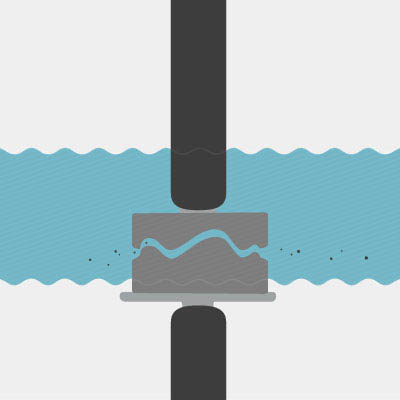

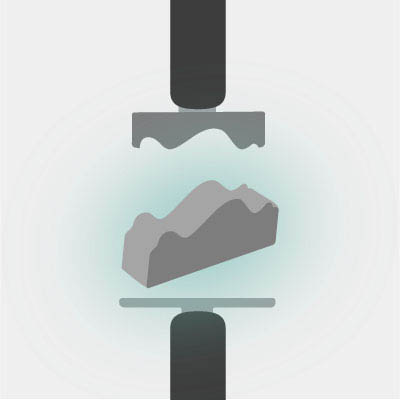

It's easiest to describe the process in pictures:

Step 1: Cathode and anode are set-up and electrolyte is pumped between the two parts.

Step 2: As the two pieces move together a pulsed DC current is applied.

Step 3: The flowing electrolyte removes heat and waste products from the gap.

Step 4: The anode workpiece is then machined into the complimentary shape of the cathode tool.

Step 5: The resulting piece has no thermal surface effects, high repeatability, and can be made from alloys that are otherwise impossible to machine conventionally.

Very cool! PECM sounds so much like EDM. What's the difference?

I would be happy to explain the differences. Electrical discharge machining (EDM) is a thermal removal process. A voltage is applied across the tool also known as the electrode and the piece to be manufactured which are both immersed in a dielectric liquid. A series of current discharges (discharges being the key part here) between the electrode and the workpiece erodes away the material through sparking.

Pulsed electrochemical machining (PECM) can be thought of as reverse electro plating or an accelerated corrosion process. Similarly to EDM a voltage is applied across a tool also known as the cathode and the workpiece to be machined. However, unlike EDM, the tool and workpiece are immersed in a conductive salt bath. A controlled pulsed waveform is then passed between the tool and the workpiece and the material is dissolved. PECM utilizes an electrochemical process to dissolve the material very near the tool or the cathode without causing any damage to the tool.

The biggest differences between EDM and PECM is that there is no tool wear in PECM and there is also no heat generated in the process. By eliminating tool wear PECM is well suited for high volume production as the tool does not need to be replaced on a regular basis. Also, the lack of heat in the process means that the material properties of the machined surface remain unchanged; as opposed to EDM where a heat affected zone exists similar to around a weld area.

Here's one of their PECM machines and the waste water treatment cell...

I can see why your customers would be interested in this new process!

How did you launch the business? How did you make people initially aware of it?

I had already spent a year or two of market research understanding the manufacturing challenges for medical, aerospace, and energy applications and knew the demand was there but at some point, Voxel had to validate our hypothesis. The business formally started in 2015 by designing and building our PECM machine from scratch which gave us a deep understanding of the process and the ability to create a product we could sell. Then the hard work began of finding customers primarily through my network, cold calls, and attending manufacturing conferences.

How did that launch go and what were some of the biggest challenges?

Our biggest challenge from the beginning is that our process is particularly well suited for markets that are hard to break in to (e.g. turbine engines and medical devices). To serve some of these markets, our customers want Voxel to have a long track record, quality certifications, and scale – all of which are impossible for a new business. It is a constant chicken vs. egg battle. However, when we can demonstrate what PECM is capable of, our customers are much more willing to work with us to meet those requirements. Also, we could use 48hrs in a day so if anyone has figured out how to do that, let me know!

How is the business doing today?

The business is growing and we are on pace for our first production contract sometime this year. We are also raising money to help accelerate our business growth to deal with the problems I mentioned above (scale, quality certs, etc). We also have a number of new technologies we are developing around the PECM process that we are very excited about! These improvements should create new opportunities and bring us more business in the next few years.

What are your plans for it going forward?

Voxel’s long-term focus is to create components in volume that no-one else can make and to help our customers design their products with PECM in mind. We are turning the art of PECM into a science and pushing the limits of what is possible with the technology. Our customers want a supplier that can create innovations and bring them to market quickly by acting as a partner, not just a supplier.

What were some of the biggest mistakes you made starting out and what would you do differently if you could start over?

The biggest mistake starting out has been time estimation – everything takes roughly 2-3x longer than you expect (we call it the factor of Pi). If I had known that at the beginning, I probably would have prioritized certain tasks over others. I hope we don’t lose our “time optimism” but it would be helpful if we were only off by 1.5x instead of 2-3x! Also, it is hard to underestimate how valuable the first few hires have been at Voxel and I wish I had hired them sooner.

VMC by Haas, Feeds and Speeds by G-Wizard Calculator

How did you become aware of CNCCookbook? Tell us what you think of CNCCookbook and our software?

My first hire, Michael Bromley, introduced me to CNCCookbook as the best-value CNC optimization software on the market.

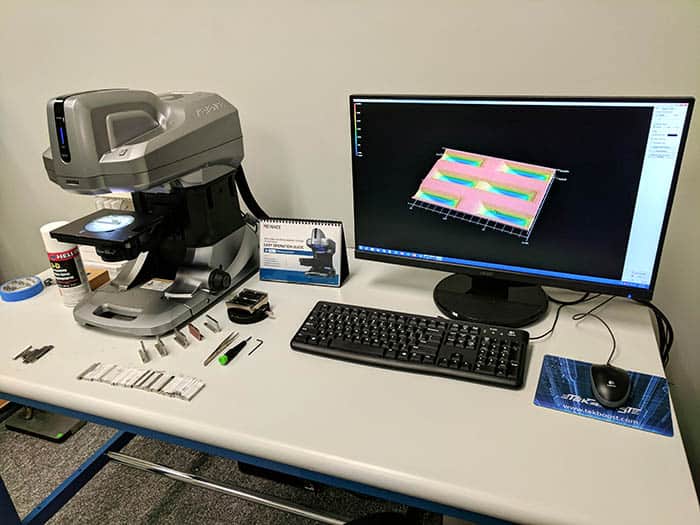

Michael Bromley: As we grew we decided to bring conventional machining methods in-house to accelerate the path from design to prototype. The PECM process requires jig/fixturing just like any other machining process and outsourcing it was consistently stretching our timelines. We decided to purchase a used Haas VF3 and at the same time GWizard Calculator to make the most of it.

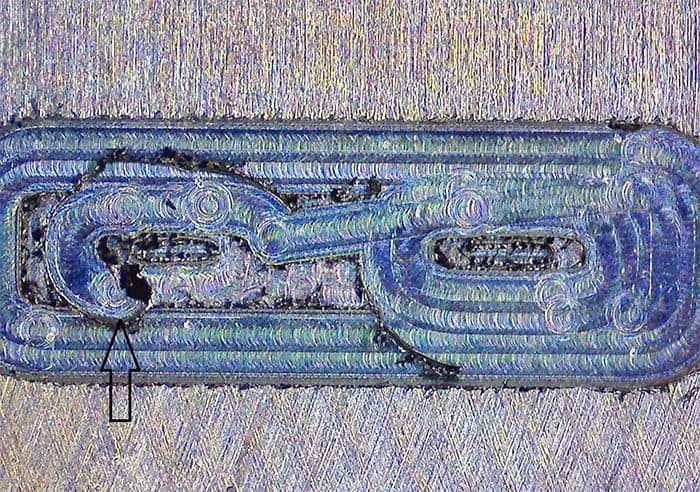

GWizard has already proved invaluable in a micromachining scenario; we needed to cut some tooling for our process using a 0.01” ball end mill in stainless steel. Utilizing the manufacturers recommended feeds and speeds consistently resulted in broken end mills and wasted time. After a handful of attempts we went with GWizards feeds/speeds recommendation and it worked the first time! When evaluating the previous settings GWizard warned of tool rubbing due to moving too slowly which correlated well with our observations under a microscope.

Machining features this small and accurate requires serious metrology!

Here's a picture that I thought you may find interesting. It is an image under our microscope when we were diagnosing the micromachining issues. The cutter there was a 0.01” 4 flute carbide square end mill. You can visibly see the rubbing and the pushing of material as opposed to cutting. That is when we turned to GWizard which actually recommended much faster feed rates than we had been using.

Here's an actual photo Voxel took of the rubbing effect when your feedrates are too slow.

Anything else you want our readers to know about your business or story?

We are constantly looking for smart people with a passion for manufacturing, feel free to contact us through our website if you are interested in learning more about the opportunities at Voxel.

Thanks guys! I learned a lot. It's not every day you get introduced to a whole new machining process.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.